What is metric thread

Thin metric threads are more susceptible to galling. They require long gears and are less suitable for high speed assembly. Thin threads can penetrate hard materials more easily, require less torque, and have little tendency to loosen. They are also stronger than coarse thread and allow for finer adjustments due to their smaller pitch. Coarse threads have a larger pitch and are easier to use than fine thread fasteners, and are designed for most applications.

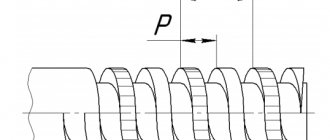

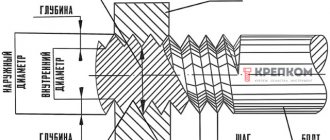

Metric threads consist of symmetrical V-shaped threads. In the plane of the thread axis, the V flanges have an angle of 60° to each other. The thread depth is 0.614 × pitch.

The thread angle is the angle formed by the intersection of the two sides of the threaded groove. Depth is the distance between the comb and the root of the thread, measured perpendicular to the axis. Lead angle is the angle of the thread's helix based on the lead distance. A single starting thread has a lead-out distance equal to its pitch, and in turn has a relatively small lead-out angle. Multi-start threads have a longer lead-out distance and therefore a larger lead-out angle.

Features of metric thread

Screw threads serve three primary functions in mechanical systems:

- provide clamping force;

- restrict or control movement;

- transmit power.

Geometrically, a screw thread is a spiral inclined plane. A spiral is a curve defined by the movement of a point with uniform angular and linear velocity around an axis. The distance a point moves linearly (parallel to the axis) in one revolution is called the pitch.

The term "internal thread" refers to a thread cut into the side wall of an existing hole. Male threads are rolled into the outer cylindrical surface of a fastener or stud. The size most commonly associated with screw threads is the nominal diameter. For example, a bolt and nut may be described as having a diameter of M12 x 1.75. The first value is the diameter, and the second is the thread pitch. But neither the external thread of the bolt nor the internal thread of the nut are exactly 500mm in diameter. In reality, the diameter of the bolt is slightly smaller and the diameter of the nut is slightly larger. But it is easier to specify components using a single size designation, since the bolt and nut are mating components.

Metric thread specifications always begin with a thread series designation (such as M or MJ), followed by the nominal diameter of the fastener and the thread pitch in millimeters, separated by an "x". There are several series of metric threads used for special applications. The standard is the M series. The MJ series is one of the most common specialty application threads.

The M series metric fastening thread is a general thread profile. The MJ series designates an external thread that has an increased root radius, thereby having higher fatigue strength (by reducing stress concentrations), but requires a truncated flange height of the internal MJ thread to prevent interference with the external root of the MJ thread. External M threads are compatible with both internal M and internal MJ threads.

Unless otherwise noted, screw threads are considered right-handed. This means that the direction of rotation of the thread's spiral clockwise will cause it to move along its axis. Left-handed threads move forward when rotated counterclockwise.

Left hand threads are often used in situations where rotational loads would cause right hand threads to become loose during service. A common example is a bicycle. Bicycle pedals are attached to the crank using screw threads. One side of the bike uses right-hand threads and the other uses left-hand threads. This prevents the pedals and crank from coming loose and falling off during use. Left-hand thread must be specified in the product specification. This is achieved by adding "LH" to the end of the specification description.

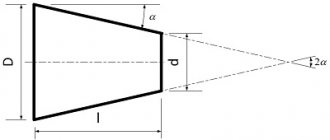

Tapered pipe threads

drawing of pipe tapered threads

Tapered pipe thread GOST 6211-81 (1st standard size)

Parameter Unit: Inch

Fits a rounded 55° straight pipe thread profile. See the top part (I) of the 3D image "drawing of pipe tapered threads".

Symbol

International: R

Japan: PT

UK: BSPT

The letter R and the nominal diameter Dy are indicated. The designation R means external thread, Rc internal, Rp internal cylindrical. By analogy with cylindrical pipe threads, LH is used for left-hand threads.

Examples:

R1 ½ - external pipe thread, nominal diameter Dy = 1 ½ inches.

R1 ½ LH - external pipe thread conical, nominal diameter Dy = 1 ½ inches, left.

Conical inch thread GOST 6111 - 52 (2nd standard size)

Parameter Unit: Inch

Produced on surfaces with a taper of 1:16

Has a profile angle of 60°. See the bottom part (II) of the 3D image "drawing of pipe tapered threads". It is used in pipelines (fuel, water, air) of machines and machines with relatively low pressure. The use of this type of connection assumes tightness and locking of the thread without additional special means (linen threads, yarn with red lead).

Symbol

The first letter is K, then GOST.

Example:K ½ GOST 6111 - 52

It stands for: inch conical thread with an outer and inner diameter in the main plane approximately equal to the outer and inner Ø of a cylindrical pipe thread G ½

Table of main parameters of tapered inch threads

| Thread size designation (d, inches) | Number of threads per 1″ n | Thread pitch S, mm | Thread length, mm | Outer thread diameter in the main plane d, mm | |

| Working l1 | From the end of the pipe to the main plane l2 | ||||

| 1/16 | 27 | 0,941 | 6,5 | 4,064 | 7,895 |

| 1/8 | 27 | 0,941 | 7,0 | 4,572 | 10,272 |

| 1/4 | 18 | 1,411 | 9,5 | 5,080 | 13,572 |

| 3/8 | 18 | 1,411 | 10,5 | 6,096 | 17,055 |

| 1/2 | 14 | 1,814 | 13,5 | 8,128 | 21 793 |

| 3/4 | 14 | 1,814 | 14,0 | 8,611 | 26,568 |

| 1 | 11 1/2 | 2,209 | 17,5 | 10,160 | 33,228 |

| 1 1/4 | 11 1/2 | 2,209 | 18,0 | 10,668 | 41,985 |

| 1 1/2 | 11 1/2 | 2,209 | 18,5 | 10,668 | 48,054 |

| 2 | 11 1/2 | 2,209 | 19,0 | 11,074 | 60,092 |

Basic GOSTs

All hardware and fasteners with screw threads according to the metric measurement system are manufactured in accordance with state and international standards and regulations. Therefore, they may differ in class, size and some other parameters, but they must comply with the permitted requirements and permissible values. Otherwise, the products cannot be certified and used in the production sector. In addition, official sales of such products are prohibited.

Fasteners with metric screw threads are regulated by several regulatory documents:

- GOST 8724, which specifies the permissible values of diameter and pitch;

- GOST 24705 2004 contains information on the main dimensions of metric threads;

- GOST 9150 includes the necessary information about the metric thread profile;

- GOST 16093 prescribes tolerances and designations for products.

Metric threads are also regulated by the international standard ISO 261-98. Russian GOST 8724-2002 completely repeats its text in Russian. True, it contains additions that are characteristic of the needs of the Russian economy.

Geometric dimensions

The performance characteristics depend on the parameters listed above. All three diameters determine which hole needs to be made with a drill when working with a tap. From the pitch and stroke - how firmly the screwing will occur, the more turns, and the more often they are, the better. This kind of work is more delicate, so it is virtually impossible to do it at home, only with special equipment.

The strength of the connection depends on how deep the grooves are. There are limitations here too. If the bolt is made in miniature, then there should not be too much of a difference between the recesses and ridges, as this increases fragility.

The profile angle determines how well the front of the tap will penetrate the material. It’s not so easy to start rotations, and besides, to do it quite smoothly, without distortions. The softer the material (for example, copper or aluminum), the better the screwing. The proportionality of the two elements that come into interaction is very important.

Metric Thread Size Chart

ISO Metric Thread Chart:

| Metric ISO Profile | External thread | |||||

| Threads | Main diameter | Step diameter | Small diameter | |||

| Step size | Maximum | Minimum | Maximum | Minimum | Maximum | Minimum |

| M 2 x 0.4 | 1.981 | 1.886 | 1.721 | 1.654 | 1.548 | 1.408 |

| M 2.2 x 0.45 | 2.18 | 2.08 | 1.888 | 1.817 | 1.693 | 1.54 |

| M 3 x 0.5 | 2.98 | 2.874 | 2.655 | 2.58 | 2.439 | 2.272 |

| M 8 x 1.25 | 7.972 | 7.76 | 7.16 | 7.042 | 6.619 | 6.272 |

| M 12 x 1.75 | 11.97 | 11.7 | 10.83 | 10.68 | 10.072 | 9.601 |

| M 16 x 2 | 15.96 | 15.68 | 14.66 | 14.5 | 13.797 | 13.271 |

| M 20 x 2.5 | 19.96 | 19.62 | 18.33 | 18.16 | 17.252 | 16.624 |

| M 24 x 3 | 23.95 | 23.58 | 22 | 21.8 | 20.704 | 19.955 |

| M 30 x 3.5 | 29.95 | 29.52 | 27.67 | 27.46 | 26.158 | 25.306 |

| M 36 x 4 | 35.94 | 35.47 | 33.34 | 33.12 | 31.61 | 30.654 |

| M 48 x 5 | 47.93 | 47.4 | 44.68 | 44.43 | 42.516 | 41.351 |

| M 60 x 5.5 | 59.93 | 59.37 | 56.35 | 56.09 | 53.971 | 52.7 |

| M 80 x 6 | 79.92 | 79.32 | 76.02 | 75.74 | 73.425 | 72.047 |

| M 100 x 6 | 99.92 | 99.32 | 96.02 | 95.72 | 93.425 | 92.027 |

ISO Metric Thread Table 2:

| Metric ISO Profile | Internal thread | |||||

| Threads | Small diameter | Step diameter | Main diameter | |||

| Step size | Maximum | Minimum | Maximum | Minimum | Maximum | Minimum |

| M 2 x 0.4 | 1.679 | 1.567 | 1.83 | 1.74 | 2.148 | 2 |

| M 2.2 x 0.45 | 1.838 | 1.713 | 2.003 | 1.908 | 2.36 | 2.2 |

| M 3 x 0.5 | 2.599 | 2.459 | 2.775 | 2.308 | 3.172 | 3 |

| M 8 x 1.25 | 6.912 | 6.647 | 7.348 | 7.188 | 8.34 | 8 |

| M 12 x 1.75 | 10.441 | 10.106 | 11.063 | 10.863 | 12.453 | 12 |

| M 20 x 2.5 | 17.744 | 17.294 | 18.6 | 18.376 | 20.585 | 20 |

| M 30 x 3.5 | 26.771 | 26.211 | 28.007 | 27.727 | 30.785 | 30 |

| M 60 x 5.5 | 54.796 | 54.046 | 56.783 | 56.428 | 61.149 | 60 |

| M 80 x 6 | 74.305 | 73.505 | 76.478 | 76.103 | 81.241 | 80 |

| M 100 x 6 | 94.305 | 93.505 | 96.503 | 96.103 | 101.27 | 100 |

Scope of application

They are used everywhere - in the automotive industry, machine tool industry, in the manufacture of household appliances and in everyday life. The peculiarity of the technology is that it has firmly entered our lives because of its convenience, and has also captured all areas of production, since structures can be produced both large and miniature. The simplest examples are a nut and a bolt. In the first case, an internal thread was made using a tap, and in the second, an external thread was made using a die.

Nuts and screws of different materials are used everywhere. From the smallest fastenings, for example, when screwing the lid of a mobile phone, to the huge nuts that hold the wheels of heavy-duty vehicles.

Geographically, the method is used all over the world. In Russia there are GOSTs, our markings are measured in mm. Abroad, inch measurements are used. We offer a table showing how millimeters and inches relate:

| Diameter in inches | External section in mm | Internal section in mm |

| 0,25 | 6,35 | 4,724 |

| 0,375 | 9,525 | 7,492 |

| 0,5 | 12,7 | 9,989 |

| 0,75 | 19,05 | 15,798 |

| 1 | 25,4 | 21,334 |

| 1,125 | 28,575 | 23,929 |

| 1,025 | 31,75 | 27,104 |

| 1,375 | 34,925 | 29,504 |

| 1,5 | 38,1 | 32,679 |

Tolerance fields

For a number of production cycles, maximum compliance of the parts being connected is important. Such values are called exact. It leads to:

- increased tightness - no extra gaps;

- strength;

- no vibration.

Manufacturing takes place exclusively on metalworking machines, which are based on a remote control. Here the operator is not responsible for the process, but only enters the design developed using a computer-aided design program into the computer. Tools grind teeth with high precision up to 0.001 mm.

The second standard accuracy size for metric threads is medium. It is the norm and is used most often. It is this category that includes the fasteners that are supplied to the shelves of hardware stores. Manufacturing is machine-made, but with the use of manual installation and fastening of the part, drill direction, etc.

Third class is rough. This includes cuts that are made by craftsmen at home. Often do not have three-layer processing, in many cases the ends of the turns are broken or ready to crumble.

Designation rules

The marking contains several parameters. Each of them finds a letter or number display. If there is no such set at the end of the product (die and tap, ready-made metal fasteners), then it is probably a fake. What is indicated:

- The tolerance level, that is, the accuracy of compliance with the declared dimensions.

- Type. For metric - the letter M. For other options, other markings, for example for cylindrical - G.

- Inner diameter. The step is not indicated, since according to the standards, all structures have a similar move if they have the same cross-section.

There is also a designation for the make-up length. She may be:

- N – average.

- S – small.

- L – large.

All of the above is indicated both on the drawing during the design and manufacture of products, and already at the time of production - the engraving method is usually used. It is the most durable, and when trying to save money, paint is used.

Measuring the internal diameter of a thread

The internal thread is measured using calipers. The tool is installed on a template part using a thread gauge, and then compared with the original internal diameter of the threaded connection. To obtain accurate values, the caliper must be positioned at an angle to the axis being measured.

You can also use cylindrical thread gauges to measure the internal diameter of a thread. This is because the inner diameter has a smooth surface and is ideal for the shape of the tips used in these instruments. The results obtained are checked using plug gauges.

Measuring the average diameter of a thread

To measure the average diameter of a thread, you must use a thread micrometer complete with different tips (one with a cone, the other with a cutout). The measurement limit is usually indicated on the measuring instruments themselves. Thus, the marking M 3–5 means that the kit allows you to measure threads in increments of 3; 3.5; 4; 4.5 and 5 mm.

Inserts for thread micrometer

A micrometer is used to measure the average thread diameter. Replaceable tool tips are inserted into the screw hole and allow for the most accurate measurements.

If averaged values are sufficient as a result, calipers can be used instead of a micrometer. By design, it consists of ball tips, the dimensions of which must match the type and pitch of the threaded connection. To find out the average diameter, the tips of the calipers must be aligned with the thread gauge. Then the procedure is repeated with the sides of the part. Threaded clamps are used to evaluate measurement results. And the accuracy of the diameter is checked by comparing the resulting thread with the template.

To control the average diameter of a thread consisting of a maximum of two turns, use the two-wire method. The measurement is carried out as follows: wires, the diameter of which coincides with one of the tabular units, are placed on the opposite protrusions and recesses of the thread. In this case, the distance between the ends of the wires shows the average diameter of the part. For each accuracy class, separate wires are created that comply with GOST 2475-88. When deriving final numbers, possible errors are taken into account, because the two-delay method does not allow achieving accurate values.

Another method for measuring the average thread diameter is to use a microscope. The device is applied to the side of the workpiece profile, and the eyepieces are pointed at the profile image on each side to determine its size. The values obtained as a result of measurements are added and divided by the number of sides. The resulting arithmetic mean is the average diameter of the threaded connection.