About metalworking

Electrode coating

Covered electrode is a consumable arc welding electrode that has a coating on the surface that is adhesively bonded to the metal of the electrode.

Electrode coating is a mixture of substances applied to the electrode to enhance ionization, protect against harmful environmental influences and metallurgically treat the metal of the weld pool.

The following materials (components) are introduced into the electrode coating: ionizing, gas-forming, slag-forming, alloying, deoxidizing, binding and molding.

Ionizing or stabilizing components are introduced to ensure stable arc burning. They contain elements with low ionization potential, such as potassium, calcium, which are found in chalk, feldspar and granite, as well as sodium, etc.

Gas-forming components are introduced to create gas protection for the arc zone and weld pool. These include organic substances: starch, food flour, dextrin, etc., as well as inorganic substances: usually carbonates (marble CaCO3, magnesite MgCO3), etc. Gas protection is formed as a result of the dissociation of organic substances at temperatures above 200 ° C and the dissociation of carbonates at a temperature of about 900°C. The dissociation process occurs near the end of the electrode. With the usual composition of electrode coatings, for every gram of metal of the electrode rod, 90-120 cm3 of protective gas is released, consisting of carbon dioxide CO2, carbon monoxide CO, hydrogen H2 and oxygen O2. This ensures fairly reliable displacement of air from the welding zone and entry of a very small amount of nitrogen into the weld metal (not more than 0.02-0.03%).

Slag-forming components are introduced to form liquid slag. Ores and minerals are used as slag-forming materials: ilmenite, rutile, feldspar, silica, granite, marble, fluorspar, etc. The composition of slag-forming materials includes oxides CaO, MgO, MnO, FeO, Al2O3, SiO2, TiO2, Na2O, fluorspar CaF2 etc. The ferroalloys present in the coating bind oxygen, which is released when heated by the slag-forming oxides included in the coating. Liquid slag, covering the molten metal of the electrode drops and the weld pool, chemically interacting with the molten metal, deoxidizes the weld metal and binds oxides into fusible compounds. At the same time, the weld metal is alloyed with elements contained in the slag. Liquid slag passes (absorbs) gases released during chemical reactions in the liquid metal and forms the surface of the weld.

Alloying components are intended to give the weld metal increased mechanical properties, heat resistance, wear resistance, corrosion resistance and other properties. Alloying elements include chromium, manganese, titanium, vanadium, molybdenum, nickel, tungsten and other elements. Alloying elements are introduced into the coating in the form of ferroalloys and pure metals.

Deoxidizing components are introduced to deoxidize (reduce) part of the molten metal in the form of oxides. These include elements that have a greater affinity for oxygen and other elements than iron (when welding steels), the oxides of which must be removed from the weld metal. Most deoxidizers are introduced into the electrode coating in the form of ferroalloys.

Binding components are used to bind the powder components of the coating into a homogeneous viscous mass, which will be firmly held on the electrode rod during crimping and form a durable coating after drying and calcination. Aqueous solutions of sodium (Na2O SiO2) or potassium (K2O SiO2) liquid glass are most often used as binders.

Molding components are substances that give the coating mass better plastic properties: bentonite, kaolin, dextrin, mica, etc.

Some materials in the coating perform several functions, for example: marble is both a stabilizing, slag-forming and gas-protective component, and ferroalloys are alloying and deoxidizing components.

Electrode coating has a significant impact on the entire welding process. Therefore, the following requirements are imposed on the coating: ensuring stable arc burning; obtaining weld metal with the required chemical composition and properties; calm, uniform melting of the electrode rod and coating; good formation of the seam and the absence of pores, slag inclusions, etc.; easy separation of slag from the weld surface after cooling; good technological properties of the coating mass, which do not complicate the electrode manufacturing process; satisfactory sanitary and hygienic working conditions during the manufacture of electrodes and welding. The composition of the coating also determines such important technological characteristics of the electrodes as: the type and polarity of the welding current, the possibility of welding in various spatial positions or in a certain way (welding with support, inclined electrode, etc.). The composition of the electrode coating and the properties of the resulting slags also determine the amount of current recommended for welding. To obtain quality welds, the electrode coating must be held on the metal rod and be continuous until the end of the electrode's use (cinder) to provide the necessary protection for the welding area. Therefore, the heating of the metal rod, determined by the value of the welding current, by the end of the electrode melting should not be more than 500°C, and with coatings containing organic substances, no more than 250°C.

The physical properties of the slag formed by the coating include melting point, solidification temperature range, heat capacity, thermal conductivity, heat content, viscosity, gas permeability, density, surface tension, thermal expansion (linear and volumetric). All electrode coatings must ensure that, when melting, the density of the slag is lower than the density of the liquid metal to ensure the floating of the slag from the weld pool. The temperature range of slag solidification must be below the crystallization temperature of the weld pool metal to allow the passage of gases released from the weld pool. Slags have the best welding qualities if their melting point is 1100-1200°C. Depending on the change in slag viscosity with temperature, “long” and “short” slags are distinguished. “Long” slags, in which the transition from the liquid to the solid state is extended over a significant temperature interval, ceteris paribus, is worse at ensuring the formation of a weld. For “short” slags, the viscosity of the molten slag increases quickly with decreasing temperature and the crystallized slag prevents the drainage of the weld metal, which is still in a liquid state, when welding in various spatial positions. “Short” slags produce electrodes with a basic coating. The viscosity of the slag is important. The less viscous the slag, the greater its mobility, and therefore physical and chemical activity, the faster chemical reactions and physical processes of dissolution of oxides, sulfides, etc. occur in it. Acidic slags are usually very viscous and long, and the viscosity increases with increased acidity.

Hardened slag should have little adhesion to the metal; the linear expansion coefficients of slag and metal should be different for easier separation of slag from the weld.

Chemical properties include the ability of slag to deoxidize the weld metal, bind oxides into low-melting compounds and alloy the weld metal.

The welding-technological properties of electrodes include easy arc initiation, stable arc burning at optimal conditions for a given diameter and brand, the ability to weld on direct and alternating currents, and suitability for welding in various spatial positions. In addition, the coating should melt evenly, without excessive spattering, pieces falling off and the formation of a peak that prevents normal melting of the electrode. The slag formed during welding should provide a favorable smooth shape of the weld and be easily removed after cooling.

Types of electrode coatings.

GOST9466-75 “Coated metal electrodes for manual arc welding of steels and surfacing. Classification, dimensions and general technical requirements" divides electrodes into the following types: A - with acid coating; B - with main coating; C - with cellulose coating; R - with rutile coating; P - with other types of coating. With a mixed type coating, the corresponding double designation is used. If the coating contains iron powder in an amount of more than 20%, the letter Z is added to the designation of the type of coating.

For electrodes with an acid coating (A), the slag-forming base consists of iron (hematite - Fe2O3) and manganese (MnO2) ores and silica (SiO2). Gas protection of the molten metal is carried out by organic components that burn during the melting of the electrode. Ferromanganese is introduced into the coating as deoxidizing agents. The resulting acidic slags do not contain CaO and do not purify the metal from sulfur and phosphorus. The deposited metal contains a lot of dissolved oxygen (up to 0.12%), hydrogen (up to 15 cm3 per 100 g of metal) and non-metallic inclusions. As a result, the seams have reduced resistance to hot cracking and reduced impact strength. Electrodes are unsuitable for welding steels alloyed with silicon and other elements, since they are intensively oxidized. When welding mild low-carbon steels with a high silicon content, pores may form. When welding, a lot of toxic dust containing manganese and silicon oxides is released and increased spatter occurs. The advantages of these electrodes are: stable arc burning on direct and alternating currents; possibility of welding in various spatial positions; absence of pores in the presence of scale or rust on the welded surfaces, as well as in case of accidental lengthening of the arc; fairly high melting speed and high penetration capacity. Electrodes of the MEZ-04 and SM-5 brands are typical for this type of coating. Currently, acid-coated electrodes are produced in small volumes. These electrodes are used for welding non-critical metal structures.

For electrodes with a rutile type of coating (R), the slag-forming base consists of: rutile concentrate containing up to 45% rutile (TiO2); aluminosilicates - mica (K2O 3Al2O3 6SiO2 2H2O), feldspar (K2O Al2O3 6SiO2), kaolin (Al2O3 2SiO2 2H2O), etc.; carbonates - marble (CaCO3) and magnesite (MgCO3). Gas protection of the molten metal is provided by the introduction of organic compounds (up to 5%), as well as by the decomposition of carbonates. The deposited metal is deoxidized and alloyed with ferromanganese (up to 10-15%). Since the oxidizing ability of rutile coating is less than that of acidic coating, the amount of manganese in it is lower and its hygienic characteristics are much better than that of acidic coating. The content of manganese oxides in aerosol during welding is 3-5 times less than that of acid aerosol. In terms of the quality of the deposited metal, the electrodes occupy an intermediate position between electrodes with acidic and basic coatings. The electrodes have high welding technological properties: they provide excellent weld formation with a smooth transition to the base metal, low spatter, easy slag separation, stable arc burning at direct and alternating currents, welding in all spatial positions. The weld metal has little tendency to form pores when the arc length fluctuates or when welding on an oxidized and contaminated surface. The deposited metal corresponds in chemical composition to semi-quiet or calm steel. Electrodes with this type of coating include electrodes of the ANO-4, OZS-12, etc. brands. To increase the deposition rate, iron powder is often introduced into coatings of this type. When the iron content in the coating is up to 35% by weight of the coating (in electrodes of the ANO-5, OZS-6, etc. brands), the electrodes can be welded in various spatial positions. Electrodes containing 50-65% iron powder in the coating (for example, electrodes of the ANO-1, OZS-3, etc. brands) are intended for high-performance welding of long-length seams of products with a thickness of 10-20 mm. By diluting the weld pool metal with low-carbon iron powder, you can significantly increase the resistance of the weld metal to the formation of crystallization cracks. Electrodes with a rutile coating are used for welding metal structures and pipelines made of carbon and low-alloy steels with a tensile strength of up to 490 MPa.

Electrodes with the main type of coating (B) have a slag-forming coating base consisting of carbonates (marble, chalk, magnesite) and calcium fluorides (for example, fluorspar - CaF2). Gas protection of the molten metal is provided by carbon dioxide and carbon monoxide formed during the dissociation of calcium carbonate during the heating and melting of the coating. The coating may contain ferromanganese, ferrosilicon, ferrotitanium and ferroaluminum as deoxidizing agents. Coatings of this type are weakly oxidized, and therefore allow the molten metal to be alloyed with elements with a high affinity for oxygen. Alloying is carried out with manganese and silicon during their transition from ferromanganese and ferrosilicon into the weld pool, which gives the joint high strength. In addition, metal powders can be introduced into the coating for alloying. The presence in the coating of a large number of calcium compounds, which bind sulfur and phosphorus well and release them into slag, ensures high purity of the deposited metal with a low content of sulfur and phosphorus. Fluorspar decomposes at high temperatures to release atomic fluorine, which binds hydrogen into a stable, metal-insoluble HF molecule. As a result, the deposited metal contains a small amount of hydrogen (4-10 cm3 per 100 g of deposited metal). The use of active deoxidizers (titanium, aluminum and silicon) in the coating ensures a low oxygen content in the weld metal (less than 0.05%). Therefore, the deposited metal is little prone to aging, is resistant to the formation of crystallization cracks and has increased plastic properties at low temperatures. The welding and technological properties of electrodes with the main type of coating are lower than those of electrodes with another type of coating. The formation of a large number of negative fluorine ions during coating melting leads to a decrease in the conductivity of the arc discharge and a decrease in the stability of the arc. Therefore, welding with electrodes with the main type of coating is carried out using direct current of reverse polarity. For welding with alternating current, it is necessary to use electrodes with an additional content of ionizing elements in the coating, for example potassium (in electrodes of the SM-11 and UP-1/55 brands), or the use of electrodes with a special two-layer coating (for example, electrodes of the ANO-D brand). The presence of moisture, oil, scale or rust on the welded edges, the presence of moisture in the coating, as well as an increase in the arc length lead to the formation of pores in the weld metal. Before welding, it is necessary to calcinate the electrodes at a temperature of 350-400 °C for one hour. To obtain high-quality seams, it is necessary to strictly comply with the requirements for product preparation and maintain the technological regime of the welding process. Electrodes with the main type of coating are intended for welding critical structures made of carbon, low-alloy and alloy steels. Electrodes with a basic coating are sometimes called calcium fluoride coated electrodes.

Electrodes with a cellulose coating type (C) contain a lot (up to 50%) of organic components (cellulose, grass meal, etc.) to form a large amount of gases. Rutile, carbonates, aluminosilicates, etc. are most often used as slag-forming agents. Sometimes asbestos is added - CaO3MgO4SiO2. Ferromanganese is added to deoxidize the deposited metal. When welding, a conical bushing from the unmelted coating is formed at the end of the electrode, which contributes to the formation of a directed flow of gases, which ensures the displacement of liquid metal from under the arc and deeper penetration of the base metal. These electrodes (grades VSC-4A, etc.) are used for welding the root layer of the seam of fixed pipeline joints using the top-down method of support at high speeds, reaching 25 m/h. They provide a good back side of the seam, so there is no need to weld the seam from the inside. To perform filling and facing seams when welding critical structures made of low-alloy steels in all spatial positions, for example, electrodes of the VSC-60 brand are intended.

Electrodes with a mixed type of coating include electrodes with a rutile-basic (rutile carbonate or carbonate-rutile) type of coating (RB), electrodes with an acid-rutile type of coating (AR), with a rutile-cellulose type of coating (RC), etc. Electrodes The acid-cellulose type of coating includes electrodes of the OMA-2 brand, intended for welding thin-sheet structures (1-3 mm thick) made of carbon and low-alloy steels with direct and alternating current. Electrodes with acid-rutile (ilmenite) type of coating include electrodes of the brands OMM-5, ANO-6, ANO-6M, ANO-17, etc. They contain ilmenite (FeO TiO2) in the coating and are intended for welding structures made of carbon steels in all spatial positions with direct and alternating current. Electrodes with rutile-basic coatings emerged as a result of attempts to combine the advantages of rutile and basic coatings. They are designed for welding equipment made of carbon and low-alloy steels with a tensile strength of up to 490 MPa, when increased requirements for ductility and impact toughness are imposed on the weld metal. Electrodes with a rutile-based coating include electrodes of the MR-3, ANO-30, OZS-28, etc. brands.

In addition to the above types of coatings, there are special electrode coatings: hydrophobic, for welding and surfacing of non-ferrous metals and their alloys, etc. Hydrophobic coatings are intended for welding work in particularly humid conditions: at high atmospheric humidity, under water, etc. They contain up to 10% of special hydrophobic polymers are added, which, during the polymerization process, fill the pores between the coating particles and block the paths of moisture penetration into the inner layers of the coating. For lying and inclined welding, special electrodes are used, for example, electrodes of the NE-1, NE-5, OZS-17N, etc. brands. In this case, elongated electrodes (up to two meters) and with a diameter of up to 8 mm are often used. The coating of these electrodes usually has an increased thickness.

The specific composition of the coating and rod in a given electrode is determined by the brand of the electrode. Brand designations often contain the initial letters of the organization in which the electrodes were developed and a serial number.

Classification and symbols of electrodes.

Electrodes intended for manual arc welding are classified in standards according to the following characteristics: the metal for which they are intended for welding; thickness and type of coating; mechanical properties of the weld metal, etc. According to GOST 9466-75, electrodes for welding and surfacing of steels, depending on their purpose, are divided into classes: for welding carbon and low-alloy structural steels with σw < 600 MPa - U (symbol); for welding alloyed structural steels with σв > 600 MPa - L; for welding heat-resistant steels - T; for welding high-alloy steels with special properties - B; for surfacing surface layers with special properties - H. This standard regulates the dimensions of electrodes, thickness and types of coatings, symbols, general technical requirements, acceptance rules and test methods.

Classification of files

There are different types of files. These devices are divided according to several factors:

- type of notches;

- the form of the device for working with workpieces;

- purpose.

Each of the groups presented should be discussed in more detail.

In the understanding of people not involved in metalworking, a device designed for grinding metal workpieces is a tool consisting of a working rectangular part, which is connected to a handle. There are notches on the metal rectangle. They remove part of the metal when transferring forces. However, there are different forms of the working part.

The file cannot be made of soft materials. The steel used for them must be harder than the surfaces being processed.

File notches play a direct role when working with different materials. To apply them to the working surface of the tool, several technological operations are used - turning, milling, notching, drawing, cutting.

Types of file notches:

- Single - designed for working with soft materials: alloys of non-ferrous metals, wood and plastic.

- Double - represent additional and main notches. The additional one is adjacent to the main one at an angle. This design allows you to work with hard materials. This is due to the fact that two notches remove a layer of material while crushing the emerging chips.

Tools are classified by tooth size. This indicator depends on how many notches are present on the working part. The fewer there are, the larger the tooth is made. There are 5 tooth size numbers:

- Numbers 0, 1 - used for rough processing of metal surfaces. The teeth are the largest, allowing you to quickly remove a lot of material in a short period of time. The disadvantage of such devices is low processing accuracy.

- Sizes 2.3 - used when you need to clear a layer down to 0.06 mm.

- Sizes 4, 5 - used for finishing parts. A small layer of material is removed, which allows for precise operations and bringing the workpiece to the required dimensions.

It is advisable to have all the numbers in order to gradually process the work surface.

According to their intended purpose, the following types of files are distinguished:

- General purpose hand tools. Used in plumbing work. Double notch. The size of the teeth is selected depending on the required quality of processing.

- Special purpose devices. They are used in metalworking factories. With their help, defects remaining after processing workpieces by machines are corrected. Withstands long-term active use.

- Needle files are the most common group, which consists of 11 subgroups of models of different shapes. They have number five notches and are small in size. Needle files are used for precise processing of parts.

- Rasps are long-length models with large teeth. Used for rough metal processing.

You need to choose a device based on its size, shape, and size of teeth.

Metal files are classified depending on their shape. The following types of instruments exist:

- Flat - the classic form of devices for processing metal surfaces.

- Triangular - they are used to bore grooves, grooves, and holes.

- Square - used when working with holes of complex shape.

- Semicircular tools - they are used to bore large diameter holes.

- Round - used for boring oval round holes of different diameters.

- Diamond-shaped - process the teeth of parts, gears, and equipment.

Rules for working with a file

The tool looks absolutely safe, but there are several rules that should be followed:

- do not allow the handle to touch the part - the handle may come off, and this will lead to injury,

- do not put your fingers under the file - you can cut yourself on the sharp edges of the part,

- Do not blow off or shake off the shavings with your hands - they dig into the skin. It is better to remove with a brush or rag.

These simple rules will help you finish your work faster and stay healthy.

File technique

There are four types of file movement direction: cross stroke, longitudinal stroke, cross (oblique) stroke and circular stroke. Cross filing

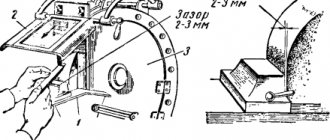

- Clamp the workpiece in a vice so that the edge of the metal is as close as possible to the jaws of the vice.

- Place the file on the edge in a diagonal direction and push the file handle with one hand and guide the tool with the other.

- When filing lightly, hold the nose of the file with your thumb and forefinger; For more intense and faster work, hold it with your entire brush.

- Apply pressure only when moving forward (working stroke), then lift the file to return to the next pass.

- Work with smooth, even movements; Avoid shaking the file or hitting the edge of the workpiece.

Longitudinal filing

- After fixing the workpiece as shown in the picture above, grasp the flat file with both hands at a distance of a few centimeters. Hold the file perpendicular to the workpiece and parallel to the surface being cut.

- Pull the file towards you in an even, smooth motion from the far end of the workpiece.

- Move the file slightly between passes so that you always work with a clean section of the blade. If the notch is clogged, stop and clean it with a special brush.

Filing internal corners

- Clamp the workpiece in a vice in a position that allows you to work comfortably with both hands. Place one edge of the triangular file on one side of the inner corner.

- Push the file forward, aiming it “out of the corner.” Use smooth forward movements, each time returning the tool to its original position.

- Process the sides of the corner one at a time. Do not “crash” into the corner so as not to distort its shape. Make sure that the edge of the file is perpendicular to the edge you are filing.

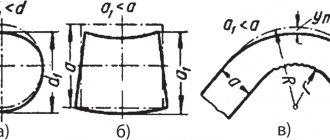

Filing a curved edge

- Clamp the workpiece in a vise so that the curved edge is vertical, and file it with the rounded edge of a semicircular file. Hold the nose of the file with your thumb and forefinger, thumb on top.

- Saw as you move forward, turning the blade clockwise half a turn as you move forward.

- Rotate the workpiece in the vise as often as necessary to ensure even, smooth passes. Important: files must be clean to be effective. After every few strokes of the file, tap the handle on the workbench to remove any metal filings, and if the cut becomes clogged, thoroughly clean it with a file cleaning brush.

Special types

Sometimes the master faces tasks that are difficult to perform with a conventional tool. In this case, he has to think about buying special types of files that will help him perform operations with metal more efficiently and quickly.

Rasp

Along with metalworking tools, you can grind metal products and other materials using rasps, which have their own notch. Their surface contains fairly large teeth, made in the form of a pyramid, and behind them there are special grooves. The notches are located on the rasp in the form of rows at right angles to the axis. Using rasps, you can grind soft materials - duralumin and aluminum.

For the manufacture of this tool, steel grades U7A and U10A are used. They have a hardness level corresponding to 35−40 HRC. Rasps reach a length of 25−35 cm. Manufacturers offer four types of rasps: round and semicircular, as well as pointed flat and blunt flat. They are used mainly in the manufacture of tin products, as well as in medicine.

Files

Among all manufactured types of tools for processing products, they are the smallest

They are used to perform work where it is important to ensure high processing accuracy. This type of tool is made from steel grades U12 and U12A with a hardness of 54−60 HRC

If we consider needle files according to their cross-sectional shape, they can be divided into the following groups:

- groove and hacksaw;

- diamond shaped;

- oval;

- round and semicircular;

- triangular;

- square;

- flat.

There is no need for a home craftsman to purchase all of the above types of files. He can easily cope with all the tasks that arise in everyday life, having in his arsenal a flat, triangular and round file. It wouldn’t hurt to additionally purchase a set of needle files and a few rasps. This entire set of tools will help you quickly solve any problem related to metal grinding.

Sharpening methods

The file can be returned to its working shape using chemical, mechanical, sandblasting and electrochemical methods. Each tool sharpening option requires a special approach and is used for specific purposes.

Chemical:

One of the simplest and most effective methods for sharpening a file. Etching in chemical solutions allows you to completely restore the working surface of an old, dull instrument covered with rust.

Before treating a file with a chemical liquid, its surface is prepared:

- All dirt is removed with a metal brush.

- If there is rust, the instrument is treated with a special solution.

- Then the cutting part of the tool is degreased. To do this, you can use any dishwashing detergent or washing powder.

- The file, cleaned of grease deposits, is washed under running water. After this, it must be dipped in acetone to wash away any remaining oil deposits.

After such procedures, the rod with the teeth of the file will become completely clean and prepared for the etching process. For restoration, a special solution is used, the component composition of which has the following ratio:

- 86% – water;

- 8% – nitric acid;

- 6% – sulfuric acid.

The file is dipped into this mixture for ten minutes. The chemical solution allows you to increase the height of the teeth on the cutting surface without changing the thickness of the tool.

After the specified time, a check is performed on the work area. A file that is not sharpened well enough can be re-etched. The restored instrument is washed with soda solution.

Electrochemical:

This method of sharpening a file also requires preliminary cleaning of its cutting surface from dirt and grease deposits. After this, the instrument is immersed in an acid mixture:

- 80% – water;

- 11% – sulfuric acid;

- 9% – nitric acid.

In this case, a low voltage direct current is passed through. Aluminum plates are used as cathodes, the area of which must correspond to or slightly exceed the surface area of the file - the anode.

READ What is a caliper used for?

Mechanical:

This option for restoring a file involves replacing old notches with new teeth. The working part of the tool is pre-fired.

Heat treatment is performed in a special oven at a temperature of 760 – 820 degrees. After this, the old notch is removed on a milling machine and the surface is completely sanded.

New tooth cutting can be done manually using a chisel. Factories use special sawing equipment to produce the ribbed surface of the tool.

The final stage of mechanical restoration of a file is hardening. For this, a solution consisting of 50 liters of water, 2 kilograms of table salt and 1 liter of hydrochloric acid is used. After this, the tool is cleaned, washed in water with a small amount of lime to protect against corrosion and dried.

Sandblasting:

For this method of file restoration, fine-grained sand is used. It is directed towards the cutting part of the tool at a slight angle. Sharpening is carried out from the shank side. Sand is passed under a pressure of 5 kgf/cm. sq. through a nozzle measuring 5 to 7 centimeters.

Sandblasting restoration method

The speed of sandblasting depends on the degree of flooding of the teeth and the grade of steel from which the file is made. The sand is directed towards the tool at a right angle. Initially, the main notches are sharpened, and then the surface of the auxiliary teeth is restored.

Features of using the tool

Working with a file does not require special knowledge and skills, however, do not forget about attentiveness and caution. An incorrect movement can ruin the workpiece; if you gape, you can get hurt.

To make work convenient and safe, the workpiece must be clamped in a vice or secured with several clamps on a workbench.

With your right hand, take a file or rasp by the handle, and place your left hand on the edge of the work surface. They make reciprocating movements from themselves - towards themselves. In this case, the left hand presses lightly on the instrument. A good result is obtained by moving not perpendicular to the grain of the wood, but slightly at an angle.

The quality of work is constantly monitored; for this it is necessary to periodically sweep away the chips with a long-haired brush. Towards the completion of the work, the pressure on the tool is reduced. At the same time, you don’t need to try to get an ideal surface right away; most likely, in order to completely remove roughness, you will have to work with sandpaper.

Knowing how to use a file is a useful skill in all respects. This is not difficult to learn, you just need a little practice. Diligence and hard work will help you master this simple instrument, which will certainly come in handy more than once in life. It is only worth noting that you need to choose a quality tool, otherwise simple work can turn into real hard labor.

Using files

Different shapes need to be used for certain parts. The classic flat model is used when you need to sand smooth surfaces. Triangular machines process grooves and grooves. Work is performed at an angle. Square - holes of different shapes. The bumps are ground into semicircular shapes and the grooves are leveled.

Metal files are considered a universal tool that is used for processing parts of various shapes. The variety of shapes, sizes of devices, and tooth sizes allows you to expand their scope of application.