It would seem that there is something complicated in the pipes? Connect and twist... But, if you are not a plumber or an engineer with a specialized education, then questions will definitely arise for answers to which you will have to go wherever you look. And most likely the first thing they look at is the Internet)

We have previously talked about the diameters of metal pipes in this material. Today we will try to clarify the threaded connections of pipes for various purposes. We tried not to clutter the article with definitions. The basic terminology is contained in GOST 11708-82, which everyone can familiarize themselves with.

American inch thread, section sizes

Unified inch threads of the UN standard (UNC, UNF and UNEF) are widespread in America and Canada, where the inch measurement system is used. Here this standard is the main one for bolts, screws, nuts and many other fasteners used in mechanical engineering. Their production is regulated and controlled by ASME and ANSI organizations.

American thread has the same profile with an apex angle of

60°

as the metric ISO standard, but its main parameters are expressed not in millimeters, but in inches.

Depending on the frequency of turns, it can also be large (main) UNC, small UNF and superfine UNEF. The number of turns per inch is called pitch TPI, while in the metric the pitch refers to the distance between adjacent vertices of the helix P (mm).

These parameters are related by the ratio: P = 1″/ TPI (remember that 1″ = 25.4 mm).

Legend

The thread designation indicates its outer diameter - D

, followed by a pitch -

TPI

(threads per inch) and its type -

UNC

or

UNF

.

For diameters less than 1/4″

The size is indicated by an integer from

0 to 12

, which appears after the

#

or

No

.

Each number corresponds to a specific external D, the exact value of which can be found in the reference table. For all other diameters above 1/4″ this value is expressed in inches.

American thread with coarse pitch - UNC

| Thread size | Threads per inch | D - outer diameter | Dp - average diameter | Di - internal diameter | Thread pitch, mm | |

| inches | mm | millimeters | ||||

| #1 | 1,85 | 64 | 1,85 | 1,6 | 1,42 | 0,40 |

| #2 | 2,18 | 56 | 2,18 | 1,89 | 1,69 | 0,45 |

| #3 | 2,51 | 48 | 2,51 | 2,17 | 1,94 | 0,53 |

| #4 | 2,84 | 40 | 2,84 | 2,43 | 2,16 | 0,64 |

| #5 | 3,17 | 40 | 3,18 | 2,76 | 2,49 | 0,64 |

| #6 | 3,50 | 32 | 3,51 | 2,99 | 2,65 | 0,79 |

| #8 | 4,16 | 32 | 4,17 | 3,65 | 3,31 | 0,79 |

| #10 | 4,83 | 24 | 4,83 | 4,14 | 3,68 | 1,06 |

| #12 | 5,49 | 24 | 5,49 | 4,8 | 4,34 | 1,06 |

| 1/4 | 6,35 | 20 | 6,35 | 5,52 | 4,98 | 1,27 |

| 5/16 | 7,94 | 18 | 7,94 | 7,02 | 6,41 | 1,41 |

| 3/8 | 9,53 | 16 | 9,53 | 8,49 | 7,81 | 1,59 |

| 7/16 | 11,1 | 14 | 11,11 | 9,93 | 9,15 | 1,81 |

| 1/2 | 12,7 | 13 | 12,70 | 11,43 | 10,58 | 1,95 |

| 9/16 | 14,3 | 12 | 14,29 | 12,91 | 12,00 | 2,12 |

| 5/8 | 15,9 | 11 | 15,88 | 14,38 | 13,38 | 2,31 |

| 3/4 | 19,1 | 10 | 19,05 | 17,40 | 16,30 | 2,54 |

| 7/8 | 22,2 | 9 | 22,23 | 20,39 | 19,17 | 2,82 |

| 1 | 25,4 | 8 | 25,40 | 23,34 | 21,96 | 3,18 |

| 1 1/8 | 28,6 | 7 | 28,58 | 26,22 | 24,65 | 3,63 |

| 1 1/4 | 31,8 | 7 | 31,75 | 29,39 | 27,82 | 3,63 |

| 1 3/8 | 34,9 | 6 | 36,93 | 32,17 | 30,34 | 4,23 |

| 1 1/2 | 38,1 | 5 | 38,10 | 35,35 | 33,52 | 4,23 |

| 1 3/4 | 44,4 | 5 | 44,45 | 41,15 | 38,95 | 5,08 |

| 2 | 50,8 | 4 1/2 | 50,80 | 47,13 | 44,69 | 5,64 |

| 2 1/4 | 57,1 | 4 1/2 | 57,15 | 53,48 | 51,04 | 5,64 |

| 2 1/2 | 63,5 | 4 | 63,50 | 59,38 | 56,63 | 6,35 |

| 2 3/4 | 69,9 | 4 | 69,85 | 65,73 | 62,98 | 6,35 |

| 3 | 76,2 | 4 | 76,20 | 72,08 | 69,33 | 6,35 |

| 3 1/4 | 82,5 | 4 | 82,55 | 78,43 | 75,68 | 6,35 |

| 3 1/2 | 88,9 | 4 | 88,9 | 84,78 | 75,68 | 6,35 |

| 3 3/4 | 95,2 | 4 | 95,25 | 91,13 | 88,38 | 6,35 |

| 4 | 101,6 | 4 | 101,60 | 97,48 | 94,73 | 6,35 |

American fine pitch thread - UNF

| Thread size | Threads per inch | D - outer diameter | Dp - average diameter | Di - internal diameter | Thread pitch | |

| inches | mm | millimeters | ||||

| #0 | 1,52 | 80 | 1,52 | 1,32 | 1,18 | 0,32 |

| #1 | 1,85 | 72 | 1,85 | 1,63 | 1,47 | 0,35 |

| #2 | 2,18 | 64 | 2,18 | 1,93 | 1,76 | 0,40 |

| #3 | 2,51 | 56 | 2,51 | 2,22 | 2,02 | 0,45 |

| #4 | 2,84 | 48 | 2,84 | 2,50 | 2,27 | 0,53 |

| #5 | 3,17 | 44 | 3,18 | 2,80 | 2,55 | 0,58 |

| #6 | 3,51 | 40 | 3,51 | 3,09 | 2,82 | 0,63 |

| #8 | 4,17 | 36 | 4,17 | 3,71 | 3,4 | 0,71 |

| #10 | 4,83 | 32 | 4,83 | 4,31 | 3,88 | 0,79 |

| #12 | 5,49 | 28 | 5,49 | 4,90 | 4,40 | 0,91 |

| 1/4 | 6,35 | 28 | 6,35 | 5,76 | 5,37 | 0,91 |

| 5/16 | 7,94 | 24 | 7,94 | 7,25 | 6,79 | 1,06 |

| 3/8 | 9,53 | 24 | 9,53 | 8,84 | 8,38 | 1,06 |

| 7/16 | 11,1 | 20 | 11,11 | 10,29 | 9,74 | 1,27 |

| 1/2 | 12,7 | 20 | 12,70 | 11,87 | 11,33 | 1,27 |

| 9/16 | 14,3 | 18 | 14,29 | 13,37 | 12,76 | 1,41 |

| 5/8 | 15,9 | 18 | 15,88 | 14,96 | 14,35 | 1,41 |

| 3/4 | 19,1 | 16 | 19,05 | 18,02 | 17,33 | 1,59 |

| 7/8 | 22,2 | 14 | 22,23 | 21,05 | 20,26 | 1,81 |

| 1 | 25,4 | 12 | 25,40 | 24,03 | 23,11 | 2,12 |

| 1 1/8 | 28,6 | 12 | 28,58 | 27,20 | 26,28 | 2,12 |

| 1 1/4 | 31,8 | 12 | 31,75 | 30,38 | 29,46 | 2,12 |

| 1 3/8 | 34,9 | 12 | 34,93 | 33,55 | 32,63 | 2,12 |

| 1 1/2 | 38,1 | 12 | 38,10 | 36,73 | 35,81 | 2,12 |

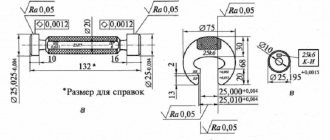

Tool design

The UNF/UNC tap is a screw with flutes and corresponding sharpening of the front, back and other corners. The main elements of the tool are the cutting (taking) and calibrating parts, grooves for removing chips. The cutting part is made of high-speed steel or hard alloy. A suitable shank is available for manual use or installation in a chuck.

The advantage of the tool is the simplicity and manufacturability of the design, as well as high cutting accuracy and the ability to work due to self-feeding. The difficulty is the need to apply large cutting forces and friction forces, and difficulties in removing chips.

Depending on the design, UNF/UNC taps are divided into:

- manual or metalworking;

- machine-manual;

- machine;

- nuts and others.

Inch thread - table, sizes, types

Fastening with threads has been known since antiquity. Scientists are still finding remains of parts that look like modern screws and nuts. But carving became most widespread during the industrial revolution of the 18th century.

Initially, the spread of detachable threaded connections was hampered by the lack of standardization, which made it impossible to ensure the interchangeability of products. The talented English engineer Charles Whitworth solved this problem. He developed a unified system of sizes and designations, using the English inch for this.

This is how inch thread was born. And all sizes are listed in the table according to GOST.

Options

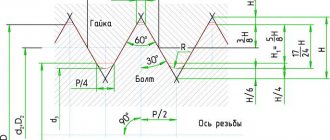

An inch thread is a detachable connection of a triangular profile, the angle of the vertices of which is 55 degrees. Its unit of measurement is inches. It is worth noting right away that in Russia the use of inch threads when designing new products is prohibited.

Its use is permitted only in the case of the manufacture of spare parts of equipment for which inch threads have already been manufactured.

In addition, it is allowed to use this thread as a pipe connection and in the manufacture of sealing hydraulic elements.

Inch, like any other, is characterized by the following basic parameters:

- Outer diameter is the distance between the tops of the threads located on opposite sides of the thread. The larger the value of this parameter, the greater the axial load the thread can withstand. The other side of the coin is the deterioration of tightness associated with the accumulation of errors during thread cutting.

- Nominal (average) diameter is a circle inscribed in the thread profile, the diameter of which depends on the pitch, and occupies an intermediate position between the internal and external diameters. This parameter is difficult to measure under normal conditions, and there is a reference table for threads to determine it.

- Internal diameter is the diameter of a circle inscribed along the recesses of the thread profile.

- Pitch is the distance between adjacent ridges of a threaded connection. This parameter is measured in the number of threads per inch. The pitch size characterizes the value and distribution of stress between the turns of inch threads. Designers in their practice increase the pitch when subjecting the thread to large mechanical loads. If requirements are imposed on the thread to maintain tightness, then the pitch is reduced.

- The angle of rise of the turns is the angle between the sides of the profile of the turns. Initially, its value for all types of inch threads was 55 degrees. But now, inch threads with a profile angle of 60 degrees are becoming more and more common.

Correspondence of two notation systems

Metric and inch threads have a relatively small number of differences. Let's take the following signs as an example:

- Shape of the threaded flange profile.

- The procedure for determining the diameter and pitch of the coils.

Various units of measurement are used to indicate the main parameters. When considering a pipe inch in millimeters, it should be taken into account that the indicator is not standard, it is 3.324 cm. Therefore, inch threads in millimeters with a non-standard designation ¾ in terms of the metric designation is 25 mm. The translation is carried out quite often, since the diametrical size is important when choosing fittings and other elements. A table of inch and metric threads can be found in special reference books.

Differences between inch and metric threads

It is worth considering the fact that not many versions of metric and inch coils are compatible. That is why, in most cases, translation is performed to determine the diametrical size of the product on which the connecting surface is cut.

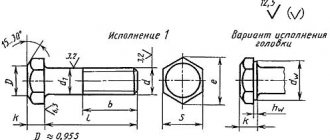

Inch thread table. Classification

An inch thread is a thread, all parameters of which are expressed in inches, the thread pitch is in fractions of an inch (inch = 2.54 cm). For inch pipe threads, the size in inches characterizes the clearance in the pipe, and the outer diameter of the pipe itself is slightly larger.

Inch threads are used in threaded connections and screw drives. Inch threads come in the following types:

- Inch cylindrical – UTS (Unified Thread Standard). This type of carving is widespread in the USA and Canada. The apex angle of this thread is 60 degrees. Depending on the step, it is divided into: UNC (Unified Coarse); UNF (Unified Fine); UNEF (Unified Extra Fine); 8UN; UNS (Unified Special). The most widely used thread is UNC. This thread conforms to ANSI 1 standard.

- British standard inch thread - BSW. Fine pitch threads are called BSF (British Standard Fine). The apex angle of this thread is 55 degrees.

- Inch tapered NPT or cylindrical NPS. Meets ANSI/ASME 20.1. This thread is used for pipe connections. Has an apex angle of 60 degrees. In Russia, such threads correspond to GOST 6111-52.

Most often in Russia recently you can find fasteners with inch UNC threads (unified coarse thread).

Such fasteners are often found on equipment imported into our country (lawn mowers, trimmers, generators, cultivators, American-made cars, etc.) from the USA, China and some other countries.

When working with inch fasteners, you must remember that the sizes of the keys for inch fasteners are different from the keys for metric fasteners.

The main dimensions of inch UNC fasteners are given in the table of inch threads

Standard size Outer diameter, inches Outer diameter, mm Drilling diameter, mm mm Number of turns per inch Pitch, mm

| N 1 – 64 UNC | 0,073 | 1,854 | 1,50 | 64 | 0,397 |

| N 2 – 56 UNC | 0,086 | 2,184 | 1,80 | 56 | 0,453 |

| N 3 – 48 UNC | 0,099 | 2,515 | 2,10 | 48 | 0,529 |

| N 4 – 40 UNC | 0,112 | 2,845 | 2,35 | 40 | 0,635 |

| N 5 – 40 UNC | 0,125 | 3,175 | 2,65 | 40 | 0,635 |

| N 6 – 32 UNC | 0,138 | 3,505 | 2,85 | 32 | 0,794 |

| N 8 – 32 UNC | 0,164 | 4,166 | 3,50 | 32 | 0,794 |

| N 10 – 24 UNC | 0,190 | 4,826 | 4,00 | 24 | 1,058 |

| N 12 – 24 UNC | 0,216 | 5,486 | 4,65 | 24 | 1,058 |

| 1/4″ – 20 UNC | 0,250 | 6,350 | 5,35 | 20 | 1,270 |

| 5/16″ – 18 UNC | 0,313 | 7,938 | 6,80 | 18 | 1,411 |

| 3/8″ – 16 UNC | 0,375 | 9,525 | 8,25 | 16 | 1,587 |

| 7/16″ – 14 UNC | 0,438 | 11,112 | 9,65 | 14 | 1,814 |

| 1/2″ – 13 UNC | 0,500 | 12,700 | 11,15 | 13 | 1,954 |

| 9/16″ – 12 UNC | 0,563 | 14,288 | 12,60 | 12 | 2,117 |

| 5/8″ – 11 UNC | 0,625 | 15,875 | 14,05 | 11 | 2,309 |

| 3/4″ – 10 UNC | 0,750 | 19,050 | 17,00 | 10 | 2,540 |

| 7/8″ – 9 UNC | 0,875 | 22,225 | 20,00 | 9 | 2,822 |

| 1″ – 8 UNC | 1,000 | 25,400 | 22,25 | 8 | 3,175 |

| 1 1/8″ – 7 UNC | 1,125 | 28,575 | 25,65 | 7 | 3,628 |

| 1 1/4″ – 7 UNC | 1,250 | 31,750 | 28,85 | 7 | 3,628 |

| 1 3/8″ – 6 UNC | 1,375 | 34,925 | 31,55 | 6 | 4,233 |

| 1 1/2″ – 6 UNC | 1,500 | 38,100 | 34,70 | 6 | 4,233 |

| 1 3/4″ – 5 UNC | 1,750 | 44,450 | 40,40 | 5 | 5,080 |

| 2″ – 4 1/2 UNC | 2,000 | 50,800 | 46,30 | 4,5 | 5,644 |

| 2 1/4″ – 4 1/2 UNC | 2,250 | 57,150 | 52,65 | 4,5 | 5,644 |

| 2 1/2″ – 4 UNC | 2,500 | 63,500 | 58,50 | 4 | 6,350 |

| 2 3/4″ – 4 UNC | 2,750 | 69,850 | 64,75 | 4 | 6,350 |

| 3″ – 4 UNC | 3,000 | 76,200 | 71,10 | 4 | 6,350 |

| 3 1/4″ – 4 UNC | 3,250 | 82,550 | 77,45 | 4 | 6,350 |

| 3 1/2″ – 4 UNC | 3,500 | 88,900 | 83,80 | 4 | 6,350 |

| 3 3/4″ – 4 UNC | 3,750 | 95,250 | 90,15 | 4 | 6,350 |

| 4″ – 4 UNC | 4,000 | 101,600 | 96,50 | 4 | 6,350 |

Tightening torques

Tightening torques for UNC inch fasteners for SAE grade 5 and higher bolts and nuts are shown in the following table.

Thread Size, in. Torque for Standard Bolts and Nuts N*m*lbf-ft**

| 1/4 | 12± 3 | 9±2 |

| 5/16 | 25 ± 6 | 18± 4,5 |

| 3/8 | 47± 9 | 35 ± 7 |

| 7/16 | 70± 15 | 50± 11 |

| 1/2 | 105± 20 | 75±15 |

| 9/16 | 160 ± 30 | 120± 20 |

| 5/8 | 215± 40 | 160 ± 30 |

| 3/4 | 370 ± 50 | 275 ± 37 |

| 7/8 | 620± 80 | 460 ± 60 |

| 1 | 900 ± 100 | 660 ± 75 |

| 11/8 | 1300 ± 150 | 950 ± 100 |

| 1 1/4 | 1800 ±200 | 1325 ±150 |

| 1 3/8 | 2400 ± 300 | 1800 ± 225 |

| 1 1/2 | 3100 ± 350 | 2300 ± 250 |

Source: https://avto-bolt.ru/dyuymovaya-rezba/

Slicing technologies

Cylindrical pipe threads, which are of the inch type (both internal and external), can be cut manually or mechanically.

Manual thread cutting

Cutting a thread using a hand tool, which uses a tap (for internal) or a die (for external), is performed in several steps.

- The pipe being processed is clamped in a vice, and the tool used is fixed in a driver (tap) or in a die holder (die).

- The die is put on the end of the pipe, and the tap is inserted into the inside of the latter.

- The tool used is screwed into the pipe or screwed onto its end by rotating a driver or die holder.

- To make the result cleaner and more precise, you can repeat the cutting procedure several times.

Cutting threads on a lathe

Mechanically, pipe threads are cut according to the following algorithm:

- The pipe being processed is clamped in the machine chuck, on the support of which a thread-cutting tool is fixed.

- At the end of the pipe, using a cutter, a chamfer is removed, after which the speed of movement of the caliper is adjusted.

- After bringing the cutter to the surface of the pipe, the machine turns on the threaded feed.

It should be borne in mind that inch threads are cut mechanically using a lathe only on tubular products whose thickness and rigidity allow this to be done. Making pipe inch threads mechanically allows you to obtain a high-quality result, but the use of such technology requires the turner to have the appropriate qualifications and certain skills.