Left-hand thread: how to identify, mark on drawings and where to use

Connecting parts and assemblies in mechanisms using screw threads is one of the oldest common types of fasteners. This ingenious invention of mankind has helped in solving many technical problems since antiquity. Individual structural parts to perform certain functions cannot be brought into action without interconnection. Nowadays, it is impossible to imagine the operation of mechanisms without threaded connections, which are versatile and reliable and can be assembled and disassembled.

For fastening products using screws, bolts, nuts, studs and other elements, right-hand threads are mainly used. This threaded connection is observed when screwing in screws and self-tapping screws. However, if there is a possibility of the part being unscrewed from the rotating shaft, non-standard left-hand threads are used in industry.

Types of threaded connections

pkmetiz.ru

The most common method of joining elements of various structures is a threaded connection. It is widely used in construction, pipeline installation, mechanical engineering and many other industries. The popularity of this method is due to the following advantages:

- high reliability and long service life;

- creation of detachable connections, ease of installation and dismantling using publicly available tools;

- control of tightening force during assembly;

- low weight and dimensions of fasteners compared to the structural elements being connected;

- wide availability, large selection of fastener sizes.

Differences between left-handed and right-handed threads

One of the main characteristics of a screw connection is the direction of the thread when the parts rotate. The full operation of the mechanism and the integrity of any structure depend on the quality of the connections, which are considered a responsible and important element.

In mechanics, there are two main types of fastening products. With standard threads, the lines of threads are removed clockwise towards the viewer. With a left-hand thread, the protrusions on the screw approach it from the left, moving counterclockwise.

Thus, the direction of rotation of the turns (helix) on the screw makes it possible to distinguish a right-handed thread from a left-handed one. On hexagon bolts, studs, nuts and fittings, left-hand threads are marked with the letter L.

Standard thread right or left - Metals, equipment, instructions

04.09.2017

Thread refers to the main elements of a threaded connection and has the form of a spiral, formed along a helical line on a conical/cylindrical surface and having a constant pitch.

Pipe threads are divided into classes:

1.According to surface shape: conical and cylindrical

2.By unit of diameter: inch and metric

3. According to the location of the thread: external and internal

4.According to profile shape: round, triangular, rectangular, trapezoidal

5. By purpose: chassis, fastening, fastening and sealing, etc.

6.Thread direction: right and left

7. By number of passes: single and multi-pass

Tapered threads ensure tightness and locking of threads without the use of additional tools. Compaction when mating parts with conical threads occurs due to deformation (creasing) of the thread.

In foreign technology, the most common standard is the ISO metric thread. Other standards are also applicable, differing in different systems of measures and the way of specifying the size of threads in different countries, as well as the specifics of the areas of application of threads.

Internal and external threads are compatible if the pitch and nominal diameter match.

The thread designation usually has a letter designation of the thread type and its nominal diameter. Additionally, the designation may include thread pitch or TPI - the number of turns per 1 inch, for multi-start threads - the number of starts, the diameter of the thread hole, left-handed or right-handed threads.

In threads made according to the DIN standard, the designation of the nominal diameter may be placed forward.

Standard threads. Designations

The standard applies to general purpose metric threads and sets their diameters from 0.25 to 600 mm and pitches from 0.075 to 8 mm Main profile according to GOST 9150-2002 (ISO 68-1-98)

The symbol for the thread size must include: the letter M, the nominal diameter of the thread and the thread pitch, expressed in millimeters and separated by the sign “x”. Example: M8x1.25 The large pitch in the thread designation can be omitted.

Example: M8

The symbol for a left-hand thread must be supplemented with the letters LH Example: M8x1 - LH A multi-start thread must be designated with the letter M, the nominal diameter of the thread, the sign x, the letters Ph, the value of the thread stroke, the letter P and the pitch value. An example of the symbol for a double-start thread with a nominal diameter of 16 mm , stroke 3 mm and pitch 1.5 mm:

М16хРh3Р1.5

The same for left-hand thread:

M16хРh3Р1.5 - LH

For greater clarity, the number of thread starts may be indicated in parentheses in text. Example: M16xPh3P1.5 (two passes)

GOST 11709-81

The standard applies to metric threads with diameters from 1 to 180 mm for plastic parts connected to plastic and metal parts, and establishes the profile, main dimensions, tolerances and maximum deviations of the dimensions of such threads

Source: https://spb-metalloobrabotka.com/standartnaya-rezba-pravaya-ili-levaya/

How to distinguish right-hand threads in fasteners?

There are simple ways in which someone ignorant of mechanics can determine the type of threaded connection. For visual identification, you need to place the pin, screw or bolt in front of you with the chamfer up on the palm of your hand so that the spiral with turns looks at the observer.

Right hand threads run clockwise from the end of the helix to the right. If the direction of the turns (spiral) is to the left, then the part is twisted to the left counterclockwise.

Metric thread: size table and parameters according to GOST

Metric thread is a screw thread on the external or internal surfaces of products. The shape of the protrusions and depressions that form it is an isosceles triangle. This thread is called metric because all its geometric parameters are measured in millimeters.

It can be applied to surfaces of both cylindrical and conical shapes and used for the manufacture of fasteners for various purposes. In addition, depending on the direction of rise of the turns, metric threads can be right-handed or left-handed. In addition to metric, as you know, there are other types of threads - inch, pitch, etc.

A separate category is made up of modular threads, which are used for the manufacture of worm gear elements.

The reliability of the detachable connection depends on the accuracy of the metric thread.

Main parameters and areas of application

The most common is metric thread, applied to the external and internal surfaces of a cylindrical shape. This is what is most often used in the manufacture of various types of fasteners:

- anchor and regular bolts;

- nuts;

- hairpins;

- screws, etc.

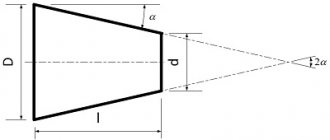

Conical-shaped parts, on the surface of which a metric type thread is applied, are required in cases where the created connection must be given high tightness.

The metric thread profile applied to the conical surfaces allows the formation of tight connections even without the use of additional sealing elements.

That is why it is successfully used in the installation of pipelines through which various media are transported, as well as in the manufacture of plugs for containers containing liquid and gaseous substances. It should be kept in mind that the metric thread profile is the same on cylindrical and conical surfaces.

In which areas are left-handed threads used?

To prevent connections from loosening

Here are simple examples when the use of such non-standard fasteners is necessary:

- In units and parts that rotate to the right, the parts may unwind when the mechanism operates. The powerful rotational force of the mechanism unscrews the nut, therefore, to prevent unwinding, left-handed fasteners are used in the direction of shaft rotation.

- The nipple of the radiators of the heating system is equipped with multi-directional threads. The coupling, when twisted with a special wrench, causes the rubber gasket in the radiator sections to tighten.

- The wheels of GAZ, MAZ, ZIL trucks use left-hand mounts.

- The drill chuck with the drill rotates to the right. To prevent loosening of the connection of parts, the chuck is attached to the shaft with a left-hand thread.

- Home fan blades.

- The gearbox transmits torque from the engine to the blades of the brush cutter.

- Bicycle pedals.

- Fastening the cutter to the shaft, discs of grinding machines.

- Some details in miter saws and circular saws.

In tension structures

Let's imagine this picture: housewives hang wet laundry on a line to dry. The rope begins to sag from constant use. The tension for the laundry has to be adjusted frequently. In such cases, bolts with double-sided threading are used here. One side of the bolt goes to the right and the other goes to the left. That is, in this case, the left-hand thread is used to adjust the degree of tension.

Designation on the drawing of a left-hand thread

The principle of operation can be represented as follows: a right-hand thread is cut at one end of the nut, and a left-hand thread at the other, and the bolts are screwed in. When the nut is rotated in one direction, it lengthens, and in the other direction, it shortens.

The use of left-handed fastening in tie-down structures is a prime example.

Such a device used in rigging work - a lanyard is a type of screw tie. This design features a pair of load-handling elements. One of them has a standard thread, the other, respectively, a left-hand thread. When the structure rotates during operation, the element body rotates, the tie is weakened, and a change in the direction of rotation leads to loading (tension). That is, when rotating, the parts of the mechanism move away from each other or move closer together.

In branding

To protect against the use of counterfeit parts in the automotive industry, manufacturers resort for commercial purposes to the marketing ploy of using left-hand cutting, from which their products acquire uniqueness and individuality.

This idea ensures that customers will only buy spare parts for repair or replacement from the official manufacturer.

Source: stankiexpert.ru

Left and right hand thread. Differentiating, application

There are two types of fasteners, divided according to the direction of rotation of the profile: with a right-hand thread and a left-hand thread. The most widely used products are those with screws directed clockwise, that is, with right-hand threads. But there are a number of elements and parts that are equipped with threads in the opposite direction.

How to distinguish right-handed from left-handed threads

There are several methods that can help in solving this problem, but the simplest, “everyday” one that most modern craftsmen use is the following:

Place the product whose thread direction you want to determine on your palm with the chamfer facing up (thread facing you) and pay attention to the end of the spiral. If you trace the rotation of the thread from its base to the “tail”, and this “tail” will be directed to the right, then you have a right-hand thread (clockwise). Accordingly, if it’s the other way around, then it’s left.

Right-hand threads are most often found in the industrial sector, however, it is not always advisable to use it. Let's consider several options when a right-handed thread cannot satisfy all design requirements, and it would be more rational to use a left-handed thread.

Preventing self-unscrewing and loosening of connections

The rotating shaft or any other rod on which nuts and bolts are screwed determines the direction of rotation of the hardware used: the screws or nuts must be tightened according to the direction of movement of the shaft. This is done so that during operation the fastening does not weaken or unwind.

Screed

There are a number of tightening devices, such as lanyards, the design of which implies the presence of a part with a right-hand thread and a part with a left-hand thread. Rotation of the element body allows you to loosen the tie or, on the contrary, load it, depending on the direction of rotation.

As a way to protect against dangerous operations

In some of the most critical operations, the incorrect implementation of which can result in casualties or pose a threat to health, it is recommended to use left-handed threads. Thus, the likelihood of dangerous actions is reduced. For example, working with cylinder equipment requires careful monitoring of the gas in the container. Therefore, propane cylinders are produced with a left-hand thread, and oxygen cylinders with a right-hand thread, in order to prevent emergency situations of improper use of this cylinder.

Branding

Some manufacturers produce products with counterclockwise threads in order to uniqueize their product and protect the buyer from purchasing non-original products.

Source: krepsila.com

Pipe thread. Classification, designation

04.09.2017

Thread refers to the main elements of a threaded connection and has the form of a spiral, formed along a helical line on a conical/cylindrical surface and having a constant pitch.

Pipe threads are divided into classes:

1.According to surface shape: conical and cylindrical

2.By unit of diameter: inch and metric

3. According to the location of the thread: external and internal

4.According to profile shape: round, triangular, rectangular, trapezoidal

5. By purpose: chassis, fastening, fastening and sealing, etc.

6.Thread direction: right and left

7. By number of passes: single and multi-pass

Tapered threads ensure tightness and locking of threads without the use of additional tools. Compaction when mating parts with conical threads occurs due to deformation (creasing) of the thread.

In foreign technology, the most common standard is the ISO metric thread. Other standards are also applicable, differing in different systems of measures and the way of specifying the size of threads in different countries, as well as the specifics of the areas of application of threads.

Internal and external threads are compatible if the pitch and nominal diameter match.

The thread designation usually has a letter designation of the thread type and its nominal diameter. Additionally, the designation may include thread pitch or TPI - the number of turns per 1 inch, for multi-start threads - the number of starts, the diameter of the thread hole, left-handed or right-handed threads.

In threads made according to the DIN standard, the designation of the nominal diameter may be placed forward.

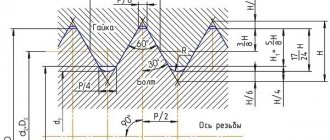

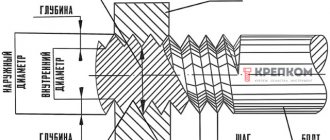

Thread and its main parameters:

• pitch (P) is expressed as a natural number: 14,17, 19 and 28 and indicates the distance between the same side sides of the profile. The pitch is measured in millimeters, in fractions of an inch, or in the number of threads per inch in the denominator of a common fraction, the numerator of which is the inch;

• outer diameter (D, d) is the diameter of the cylinder described around the recesses of the internal thread (D). or outer vertices (d);

• average diameter (D2, d2) is the diameter of the cylinder, the generatrix of which intersects the thread profile so that its sections formed at the intersection with the groove are equal to half the nominal thread pitch;

• internal diameter (D1, d1) is the diameter of the cylinder, which is inscribed in the depressions of the external (d1) or the top of the internal thread (D1);

• stroke (Ph) is the magnitude of the relative movement of the initial midpoint along the helical line of the thread at an angle of 360°.

Metric thread

has a pitch and basic thread parameters in millimeters (M).

Widely applicable with pitch 0.25-6.00mm and nominal diameter 1-600mm. The profile represents an equilateral triangle with a vertex of 60°, the theoretical height of the profile H is equal to 0.866025404Р.

Inch thread

Inch thread parameters are expressed in inches, thread pitch - in fractions of an inch.

The inch thread is based on the BSW thread and corresponds to the BSP thread and has pitch values of 11, 14, 19 and 28 threads per inch. The profile angle at the apex is 55°, with a theoretical profile height H equal to 0.960491Р.

UTS - conventional inch thread, used on the North American continent. The apex angle is 60°, with a theoretical profile height H equal to 0.866025P.

Determining Thread Size

Threads on pipe connections are determined by measuring the main parameters using a caliper and comparing the obtained data with a thread table.

Metric cylindrical thread

It has the letter designation M with a nominal thread diameter, while the large pitch is not indicated: M56; M5, and the fine pitch is indicated additionally M12 x 1.

The left-hand thread has the Latin designation LH: M20 x 1.5LH. The designation contains an accuracy class: M5-6g.

Metric tapered thread

Designated MK: right thread MK x 30; MK20 x 1.5LH - left.

MK 24×1.5LH GOST 25229-82 - internal cylindrical thread screwed with a conical thread, has the standard number of this thread in the designation.

Cylindrical pipe thread

Designated by the letter G, nominal diameter in inches, accuracy class of average diameter. Left-hand thread is designated LH.

G1 ½ LH - A - left-hand cylindrical pipe thread with a nominal diameter of 1 ½ inches (without the “sign”), accuracy class A.

G1 ⅛ - B - cylindrical pipe thread with a nominal diameter of 1 ⅛ ", accuracy class B.

The make-up length is indicated in mm after the accuracy class: G1⅛-B-40. Make-up lengths are divided into long L and normal N. Make-up length L is indicated in mm, N is not indicated.

Conical pipe thread

It is designated by the letter G with a nominal diameter in inches, R. For pipe conical internal threads, the designation Rc is used. Left-hand thread is designated LH.

R¾ is an external tapered pipe thread with a nominal diameter of ¾ inch. R¾LH - pipe conical external thread left, nominal diameter ¾ inch.

Trapezoidal thread

Denoted by the letters Tr, nominal thread diameter in mm, thread pitch (lead and pitch for multi-start threads) + LH for left-hand threads and accuracy class of trapezoidal threads.

Tr 20 x 4 (P2) - 8e - external trapezoidal thread with a nominal diameter of 20 mm, stroke 4 mm, pitch 2 mm, two-start, 8e accuracy class, right-handed.

Tr 20 x 4 (P2)LH - 8H - internal trapezoidal thread with a nominal diameter of 20 mm, stroke 4 mm, pitch 2 mm, double-start left, accuracy class 8H.

Tr 80 x 4 - 6h – right-hand trapezoidal thread with a nominal diameter of 80 mm, pitch 4 mm, 6h accuracy class.

Left hand thread. Features of application

If you have questions about fasteners with left-hand threads,

call us and we will advise you!

One of the main characteristics of the thread is the direction of rotation of the profile. There are two main types of fasteners that correspond to this feature - with right-hand and left-hand threads. The thread is right-handed if, with clockwise rotation, the projections move away from the observer. On a left hand thread with clockwise rotation the lugs get closer. Right-hand thread is considered standard. The lion's share of fasteners are produced with just this. In what cases is left-hand thread used?

In coupling structures, multidirectional threads are provided on the rotating part. On one side is left, and on the other is right. By rotating such a device, the attached parts will either move closer or move away. A striking example of such a device is a lanyard. The lanyard body (it can be open or closed) has a left-hand thread on one side and a right-hand thread on the other. As it rotates, the mating parts—this can be a screw with a hook, ring, or eye—either move closer together or move away. So, with the help of a left-hand thread, cables are tensioned, masts or canopies are installed, and equipment or equipment is secured to the platform. Another example is a nipple for a sectional radiator. Having multi-directional threads on both sides, they use a special wrench to tighten sections of aluminum, bimetallic, and cast iron radiators.

TOLERANCES

3.1. The axial displacement of the main plane of the external and internal threads (Fig. 4) relative to the nominal location should not exceed the values specified in Table 3.

Damn.4. Axial displacement of the main plane of external and internal threads

Note. In the main plane, the average diameter has a nominal value.

The displacement of the main plane is total, including deviations of the average diameter, pitch, angle of inclination of the side of the profile and cone angle.

3.2. The maximum deviations of the average diameter of the internal cylindrical thread must correspond to those indicated in Table 3.

3.3. It is allowed to connect an external conical thread with an internal cylindrical thread of accuracy class A according to GOST 6357.

3.4. Recommended maximum deviations of individual thread parameters are given in the reference appendix.

Why (why) do you need a left-hand thread, where is it used, how and with what to cut a left-hand thread?

Why do you need a left-hand thread at all, where a left-hand thread is used.

There are quite a few examples of the use of left-hand threads; left-hand threads are mainly used in lanyards and other various ties. The principle is quite simple, take a tube (nut), cut a left-hand thread at one end and a right-hand thread at the other, screw in the corresponding bolts, and when the tube is rotated in one direction, the product is lengthened and shortened in the other.

The same system is used when assembling cast iron batteries; the coupling has 2 threads at once and, when twisted, tightens the rubber gasket.

An exception to the rule, so to speak, is the use of left-hand threads on the left side of the wheel mounts on heavy-duty GAZ, ZIL, MAZ vehicles.

You can cut left-handed threads only on a lathe; maybe there are tap dies, but I haven’t seen them.

It is needed in those units and parts that rotate to the right and can unwind, that is, it prevents the unit from unscrewing itself.

As an example, we can give a drill chuck; it rotates to the right and is secured with a screw (to the shaft) with a left-hand thread to prevent it from unwinding.

Also, left-hand threads are used in various tie-down structures, as an example of a lanyard, a device with the help of which the slack of rigging (cable), cables, etc. is removed.

In this device, there is a left-hand thread on one side and a right-hand thread on the other.

Grinder circular saws (angle grinders), various machines (lathes, for example) and here fasteners with left-hand threads are used.

Bicycle pedals (from the mount) of the fan blades (they rotate to the right) and here a fastener with a left-hand thread is used.

Some (but not all) gas cylinders have valves with left-hand threads, or the mounting of the reducer to the cylinder has a left-hand thread.

In automobile construction, left-hand threads are often used.

Entire units are assembled on fasteners with left-hand threads, the goal is one, when repairing a car, use only original fasteners from a specific manufacturer.

how and with what to cut a left-hand thread?

There are simply a huge number of types of threads, in addition to the fact that the thread can be external or internal.

Symbols and tables for tapered threads

The tapered thread and its designation in the presented table must comply with established state GOSTs, since it is used to create a strong connection of pipes where there is high pressure or external high mechanical loads are imposed. Examples of application include factors such as:

- Obtaining a strong connection of pipes that are laid under a dirt road at an insignificant depth, the whole point is that loads are placed on them by vehicles passing along the road.

- Also, tapered threads are used to connect pipelines in places where welding cannot be used or it is not possible to use it. This may be an explosive environment, which precludes the use of welding equipment.

- In addition, it is used in cases where the cutting has signs of wear or it is not possible to completely replace this element. But it is worth noting that this type of product is not permanent, since replacing a worn-out element is an inevitable measure.

It is mainly used for sealing pipes used in laying water and gas pipelines, providing greater reliability of the connection even in the most extreme conditions.

Left or right hand thread.

It’s funny to watch how in a specialized store, in response to my request to give me a fitting for radiators with a left-hand thread, the seller begins to twist and peer into the unfortunate fitting, trying to determine the direction of its thread. And often he doesn’t give me what I asked for.

It seems to me that it is impossible to make a mistake here. But this site is not for professionals, so I’ll tell you a little secret: how to determine the direction of the thread? Take the futor (or whatever you have) in your hand, with the beginning of the thread (chamfer) facing up. Find the very beginning of the thread, the so-called. the beginning of the thread, determine where the “tail” is directed. If it's to the right, it's a right-hand thread; if it's to the left, it's a left-hand thread. As you can see, everything is simple, and you don’t need to twist anything. The same rules apply for radiators. Those. if you place the radiator with its front side facing you and orient it correctly vertically (bottom on the floor, top at the top), then the radiator will have a right-hand thread on the right, and a left-hand thread on the left. And only with cast iron (our) radiators can you get confused, because they do not have a front side, and it is not always possible to determine the top and bottom. Now, I think you will never be mistaken.

Unfortunately, this article is unique..

Reviews (3) for “Left or right thread.”

THANK YOU. PUT REMEMBERED 8 YEARS PASSED FORGOT THANK YOU

then the radiator will have a right-hand thread on the right, and a left-hand thread on the left. Incorrect. Yesterday I found out that the bimetallic radiator has different threads. I wanted to connect the two, but it turned out they had different directions! and that's for sure!

That's right, Alexander. If you place two radiators side by side, then one of them will have a right-hand thread at the junction, and the other will have a left-hand thread. And in order to connect them, you either need to take a special nipple for radiators, which also has multi-directional threads, right on one side, left on the other. Or avoid different threads using radiator sleeves. Then the threads will be right-handed everywhere, and the radiators can be connected using connectors or American ones. Or turn the radiators upside down: place one with its “face”, the other with its rear, back... :).

your feedback

2.1.2. THREAD DESIGNATION

In general, the thread designation includes

1.letter carving mark;

2.nominal size in millimeters or inches;

3.step size;

4. for multi-start threads - the stroke value indicating the pitch;

5.letters LH

for left-hand thread;

6. alphanumeric designation of the tolerance field or letter designation of the accuracy class;

7. digital value or letter designation of the make-up length, if it differs from normal.

Symbol for metric thread

regulated by GOST 8724-81.

It consists of the letter M (symbol of a metric thread), the nominal diameter of the thread, the pitch and direction of the thread (if it is left-handed). Multi-start metric threads are designated (after the nominal diameter) by the letters P

h, the value of the thread stroke, the letter

P

and the numerical value of the pitch.

An example of the designation of a three-start left-hand metric thread with a nominal diameter of 24 mm, with a pitch of 1 mm and a stroke value of 3 mm: M24´ Р

h3

Р

1-

LH

.

Examples of the designation of metric threads and options for its application in the drawing are shown in Fig. 2.14. Options for marking in Fig. 2.14, a

and 2.14,

preferably

.

Symbol for metric tapered thread

(GOST 25229-82) includes the letter designation (MK), thread diameter in the main plane, pitch and direction (if it is left-handed).

The designation is applied as shown in Fig. 2.15, 2.16. Options for applying the designation in Fig. 2.15, a

and 2.16,

a

are preferable.

Symbol for cylindrical pipe thread

regulated by GOST 6357-81.

It consists of the letter G

and a conditional size - the internal diameter of the pipe in inches.

The designation is applied to the image, as shown in Fig. 2.17, 2.18. Options for applying the designation in Fig. 2.17, a

and 2.18,

a

are preferable.

Symbol for pipe tapered thread

(GOST 6211-81) consists of the letter designation

R

(external thread) and

R c

(internal thread), the diameter of the thread in the main plane in inches (Fig. 2.19 and 2.20).

Options for applying the designation in Fig. 2.19, a

and 2.20,

a

are preferable.

Symbol for trapezoidal thread.

The designation of a single-start trapezoidal thread (GOST 9484-81) consists of the letters

Tr

, outer diameter and pitch (Fig. 2.21 and 2.22).

Options for applying the designation in Fig. 2.21, a

and 2.22,

a

are preferable.

The designation of multi-start trapezoidal thread (GOST 24739-81) consists of the letters Tr

, outer diameter, stroke and pitch (Fig. 2.23 and 2.24).

Options for applying the designation in Fig. 2.23, a

and 2.24,

a

are preferable.

Symbol for thrust thread

(GOST 10177-82) consists of the letter

S

, outer diameter and thread pitch:

S

28×5.

For multi-start threads, the designation consists of the letter S

, outer diameter, stroke and pitch:

S

28 × 10 (

P

5)

LH

.

Options for applying the designation in Fig. 2.25, a

and 2.26,

a

are preferable.

Symbol for round thread

for electrical fittings according to GOST 28108-89 consists of the letters

E

(series) and the outer diameter, for example, E27 (Fig. 2.27).

rectangular

thread in the drawings is specified by all design dimensions: external and internal diameters, pitch, tooth width.

Options for applying thread sizes with a rectangular profile are shown in Fig. 2.28, a

,

b

,

c

. It is recommended to show the profile of a given thread and all its dimensions on an enlarged scale.

All the news, hurry up to visit us.

New on the site

How to test a pump on a bench.

Latest reviews

- Senovad : Hello, Yuri. You put in a not entirely correct technical statement.

- Yuri : Good afternoon. Help with choosing a pump and hydraulic tank size d.

- Senovad : Hello, Oleg. For complete clarity, parameters are needed.

- Oleg : Good afternoon. Please tell me if possible.. Which one are we?

- Senovad : Andrey, alas, on planet Earth, due to its poor atmospheric conditions.