Assortment and technical description

The concept of I-beam means a metal profile with an H-shaped cross section. The material is widely used in construction due to its high load-bearing performance and durability. When drawing up the project, the material, dimensions and weight of the I-beam are taken into account. Let us consider in more detail the characteristics, types and scope of application of individual samples.

Characteristics and Application

As a rule, high-quality steel is used as the material for production. In this case, alloying additives are either absent or present in low percentages.

To simplify the choice of material, product marking has been introduced. Based on this, I-beam tables are compiled with information about the weight and dimensions of I-beam metal beams. The load-bearing capacity of the samples can also be indicated, that is, the permissible load while maintaining the shape and technical characteristics.

I-beam marking Source stpulscen.ru

Craftsmen choose an H-shaped profile because of its undeniable advantages, which include:

- high bending, tearing and compressive strength;

- durability due to the composition and resistance to various types of environmental influences (an exception is an I-beam made of carbon steel for use inside a building);

- good adhesion to concrete, which allows the formation of a reinforced concrete monolith;

- a shape that forms two support platforms convenient for installation work;

- affordable price compared to other analogues (for example, from the reinforced concrete series).

I-beams, as a subtype of rolled metal assortment, are used in the construction of houses, industrial and hydraulic structures, and in mechanical engineering.

Application of an I-beam Source ad-cd.net

The listed objects are considered responsible, therefore the production of assortments of beams is regulated by current standards. These include the following GOSTs:

- 19425 (1974) – production and quality control of specialized beams (hot-rolled profiles for overhead tracks, mine lines, for automotive industrial enterprises);

- 26020 (1983) – production of hot-rolled steel products with parallel edges of shelf elements;

- 8239 (1989 ) - analogues according to GOST 26020-83 are considered here, only the internal edges of the shelves are formed at a slope (from 6 to 12%).

One production point is worth noting. Despite the assembly structure, which is fixed by welding or hot rolling, it is almost impossible to create an I-beam on your own. Note to craftsmen: the former have a lower load-bearing capacity and are cheaper. This can be explained by the heat treatment of the second blanks (blooms) under conditions of +1200 degrees Celsius.

Range of I-beams

The assortment of I-type profiles is represented by products with one or another marking. Let's look at the decoding of the letter designation. The information is presented below in the I-beam table.

| Letter | Short description |

| Rolling precision | |

| A | High |

| IN | Regular |

| Purpose according to GOST 19425 of 1974 | |

| WITH | Pile profile for reinforcing mine shafts |

| M | Beams for the construction of suspended structures |

| Size range relative to shelves | |

| B | Standard beam in normal design |

| D | Medium strip I-beam with medium shelf width |

| TO | Column I-beam with a flange width close to the height of the connecting sheet |

| U | Narrow shelf sample |

| Sh | Beam products with shelves, the width of which is more important compared to analogues |

In addition to the letter marking, there is a numerical identifier. It is placed in front of the letter. Indicates the height of a specific profile. For example, 24M - 240 mm between the outer planes of the shelves, for 36M - 360 mm.

I-beam dimensions and weight table

When considering the physical parameters of I-beams, it is worth noting the difference between hot-rolled and welded products due to different restrictions. Thus, for monolithic samples the height limit is close to 60 cm, for prefabricated ones it is from 2 to 4 meters. Due to strict requirements for the ratio of the dimensions of the wall and flanges, the production of rolled profiles is unacceptable, welded analogues are possible, often a design necessity.

See also: Catalog of companies that specialize in the design and installation of metal structures

I-beam dimensions table

The choice of parameters is regulated by building codes and regulations. It is more convenient to determine the profile using the size tables of certain I-beams. They are presented below depending on the ratio of the height of the walls and the width of the shelves (demanded samples).

Beam 10 dimensions:

| I-beam type (GOST) | Physical parameter with mm | |||

| Height (h) | Width (b) | Thickness Art. (s) | Thickness (t) | |

| 8239-89 | 100 | 55 | 4,5 | 7,2 |

| 26020-83 (B1) | 117,6 | 64 | 3,8 | 5,1 |

| STO ASChM 20-93 (B1) | 100 | 55 | 4,1 | 5,7 |

Beam 12 sizes:

| I-beam type (GOST) | Physical parameter with mm | |||

| Height (h) | Width (b) | Thickness Art. (s) | Thickness (t) | |

| 8239-89 | 120 | 64 | 4,8 | 7,3 |

| 26020-83 (B1) | 117,6 | 64 | 3,8 | 5,1 |

| STO ASChM 20-93 (B1) | 117,6 | 64 | 3,8 | 5,1 |

| 26020-83 (B2) | 120 | 64 | 4,4 | 6,3 |

| STO ASCHM 20-93 (B2) | 120 | 64 | 4,4 | 6,3 |

Beam 14 sizes:

| I-beam type (GOST) | Physical parameter with mm | |||

| Height (h) | Width (b) | Thickness Art. (s) | Thickness (t) | |

| 8239-89 | 140 | 73 | 4,9 | 7,5 |

| 19425-74 (C) | 140 | 80 | 5,5 | 9,1 |

| 26020-83 (B1) | 137,4 | 73 | 3,8 | 5,6 |

| STO ASChM 20-93 (B1) | 137,4 | 73 | 3,8 | 5,6 |

| 26020-83 (B2) | 140 | 73 | 4,7 | 6,9 |

| STO ASCHM 20-93 (B2) | 140 | 73 | 4,7 | 6,9 |

Beam 16 dimensions:

| I-beam type (GOST) | Physical parameter with mm | |||

| Height (h) | Width (b) | Thickness Art. (s) | Thickness (t) | |

| 8239-89 | 160 | 81 | 5 | 7,8 |

| 26020-83 (B1) | 157 | 82 | 4 | 5,9 |

| STO ASChM 20-93 (B1) | 157 | 82 | 4 | 5,9 |

| 26020-83 (B2) | 160 | 82 | 5 | 7,4 |

| STO ASCHM 20-93 (B2) | 160 | 82 | 5 | 7,4 |

Beam 18 dimensions:

| I-beam type (GOST) | Physical parameter with mm | |||

| Height (h) | Width (b) | Thickness Art. (s) | Thickness (t) | |

| 8239-89 | 180 | 90 | 5,1 | 8,1 |

| 26020-83 (B1) | 177 | 91 | 4,3 | 6,5 |

| STO ASChM 20-93 (B1) | 177 | 91 | 4,3 | 6,5 |

| 26020-83 (B2) | 180 | 91 | 5,3 | 8 |

| STO ASCHM 20-93 (B2) | 180 | 91 | 5,3 | 8 |

Calculation of I-beams

One of the important characteristics that needs to be taken into account is the type of fixation of the beam in combination with the distribution of the load on it. The most common types are:

- hinged-supported structures - the load can be distributed evenly, or be concentrated in one or two areas;

- option with rigid termination of one of the ends and uniform load distribution;

- option with one span, one-sided console, additional support and uniform force distribution;

- rigidly embedded console with a load focused at one point.

It is also necessary to calculate the total load acting on the building . It includes components of several types. The constant load (in the case of a conventional interfloor beam in a residential building) is created by the mass of the element itself, the floor and the cement screed, while the variable load is created , for example, by snow and pieces of furniture. Having calculated the total amount, it is multiplied by the reliability coefficient (it depends on the type of I-beam and is most often equal to 1.2 or 1.3). The resulting value should be used in the future.

To select the profile size, you can use the table , which shows the recommended beam numbers depending on the total load, span length and pitch . For example, with a pressure of 300 kg/m² and a three-meter span in increments of 1 m, you can take profile No. 10. For larger loads and lengths, the I-beam number will also be larger.

Another way is to select the moment of resistance from the table value , based on the total mass multiplied by the reliability factor. Based on its value, you can determine the recommended profile number according to the assortment. To be safe, it is better to take an I-beam 2 numbers larger than the one you got.

Briefly about the main thing

I-beam is a beam profile made of high-strength steel with an H-shaped cross section.

Beams are used in the construction of buildings for various purposes, suspended structures, and in the automotive industry.

The production of products is regulated by current state standards.

The dimensions of monolithic beams are strictly standardized relative to the cross section; welded elements can have different parameters.

Basic criteria for choosing an I-profile: dimensions, weight and purpose (depending on the physical design).

Ratings 0

I-beams with a slope of the internal edges of the shelves GOST 8239-89 (instead of GOST 8239-72), assortment

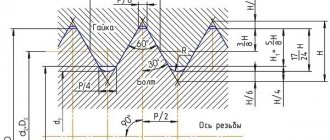

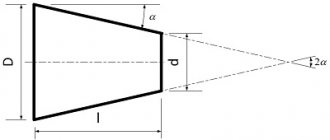

GOST 8239-89 applies to hot-rolled I-beams, the internal edges of the flanges of which are located at an angle to the beam wall. They are produced in accordance with the size range:

- height 100-600 mm;

- shelf width 55-190 mm

- angle of inclination of shelves edges 6-12%

The number in the I-beam assortment according to GOST 8239-89 shows the exact height of the beam in cm, the letters indicate the rolling accuracy:

- B - increased accuracy;

- B - normal accuracy.

I-beams with a slope of the internal edges of the shelves GOST 8239-89 (instead of GOST 8239-72)

| I-beam profile number | Height h, mm | Shelf width, b, mm | Weight, kg m/p | Quantity m in 1 t | I-beam profile number | Height h, mm | Shelf width, b, mm | Weight, kg m/p | Quantity m in 1 t |

| 12 | 120 | 64 | 11,5 | 86,96 | 20 | 200 | 100 | 21,0 | 47,62 |

| 14 | 140 | 73 | 13,7 | 72,99 | 22 | 220 | 110 | 24,0 | 41,67 |

| 16 | 160 | 81 | 15,9 | 62,89 | 24 | 240 | 115 | 27,3 | 36,63 |

| 18 | 180 | 90 | 18,4 | 54,35 | 27 | 270 | 125 | 31,5 | 31,75 |

Due to the specific shape of the section, an I-beam with flange slopes works mainly in bending, which allows it to withstand heavy loads. It is used in load-bearing structures of industrial buildings, bridges, civil engineering, etc.

Product advantages

The original cross-section of the rolled product – wide flanges with parallel internal edges – provides:

- strength and rigidity of the created structure;

- high coefficient of compressive resistance;

- Possibility of use without additional fastening during installation;

- when used in the production of low-carbon steels - good weldability.

These metal products are used as blanks for the manufacture of a brand - a rolled profile with a cross section in the shape of the letter T. An I-beam can be continuous, that is, laid over several spans with several support points.

Application areas of wide-flange I-beam

Due to their high strength and durability, these metal products are widely used in the national economy and are in demand:

- to create load-bearing structures;

- as supporting guides;

- when constructing buildings of considerable height;

- during the construction of large-sized bridge structures and overpasses;

- for the construction of coastal fortifications;

- in the production of transport ships, railway cars, cargo platforms;

- for the production of T-profiles.

To increase the service life, the surface of rolled metal is coated with zinc, aluzinc compounds, and paints and varnishes. Products are usually transported in open transport; the steel grade is applied to the ends with indelible paint.

Interactive I-beam tables

All data is entered into interactive I-beam tables, with functions for sorting and retrieving data. You can choose how many rows the table should display, and most importantly, I-beam assortments are equipped with a search function.

For example, when calculating an I-beam, you learned that in order for the beam to pass through strength and normal stresses, you need an I-beam with a moment of resistance greater than 100 cm3. According to the assortment, I-beam No. 16 is suitable for you, with Wx = 109 cm3.

After which you need to write down all its parameters for further calculations or, perhaps, for making a drawing. So, to make it more convenient to do this, you can display only the data that you need. To do this, just enter into the table search the moment of resistance that is suitable for your design scheme, and the smart table will give only one required line:

After which, you can comfortably rewrite all the parameters of the I-beam that interest you. Agree, is it convenient? Use it!