Pipe thread. Classification, designation

04.09.2017

Thread refers to the main elements of a threaded connection and has the form of a spiral, formed along a helical line on a conical/cylindrical surface and having a constant pitch.

Pipe threads are divided into classes:

1.According to surface shape: conical and cylindrical

2.By unit of diameter: inch and metric

3. According to the location of the thread: external and internal

4.According to profile shape: round, triangular, rectangular, trapezoidal

5. By purpose: chassis, fastening, fastening and sealing, etc.

6.Thread direction: right and left

7. By number of passes: single and multi-pass

Tapered threads ensure tightness and locking of threads without the use of additional tools. Compaction when mating parts with conical threads occurs due to deformation (creasing) of the thread.

In foreign technology, the most common standard is the ISO metric thread. Other standards are also applicable, differing in different systems of measures and the way of specifying the size of threads in different countries, as well as the specifics of the areas of application of threads.

Internal and external threads are compatible if the pitch and nominal diameter match.

The thread designation usually has a letter designation of the thread type and its nominal diameter. Additionally, the designation may include thread pitch or TPI - the number of turns per 1 inch, for multi-start threads - the number of starts, the diameter of the thread hole, left-handed or right-handed threads.

In threads made according to the DIN standard, the designation of the nominal diameter may be placed forward.

Thread and its main parameters:

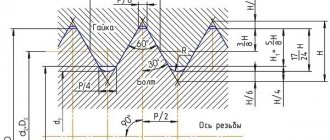

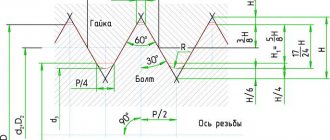

• pitch (P) is expressed as a natural number: 14,17, 19 and 28 and indicates the distance between the same side sides of the profile. The pitch is measured in millimeters, in fractions of an inch, or in the number of threads per inch in the denominator of a common fraction, the numerator of which is the inch;

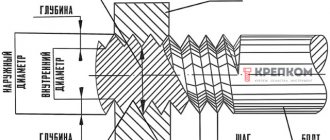

• outer diameter (D, d) is the diameter of the cylinder described around the recesses of the internal thread (D). or outer vertices (d);

• average diameter (D2, d2) is the diameter of the cylinder, the generatrix of which intersects the thread profile so that its sections formed at the intersection with the groove are equal to half the nominal thread pitch;

• internal diameter (D1, d1) is the diameter of the cylinder, which is inscribed in the depressions of the external (d1) or the top of the internal thread (D1);

• stroke (Ph) is the magnitude of the relative movement of the initial midpoint along the helical line of the thread at an angle of 360°.

Metric thread

has a pitch and basic thread parameters in millimeters (M).

Widely applicable with pitch 0.25-6.00mm and nominal diameter 1-600mm. The profile represents an equilateral triangle with a vertex of 60°, the theoretical height of the profile H is equal to 0.866025404Р.

Inch thread

Inch thread parameters are expressed in inches, thread pitch - in fractions of an inch.

The inch thread is based on the BSW thread and corresponds to the BSP thread and has pitch values of 11, 14, 19 and 28 threads per inch. The profile angle at the apex is 55°, with a theoretical profile height H equal to 0.960491Р.

UTS - conventional inch thread, used on the North American continent. The apex angle is 60°, with a theoretical profile height H equal to 0.866025P.

Determining Thread Size

Threads on pipe connections are determined by measuring the main parameters using a caliper and comparing the obtained data with a thread table.

Metric cylindrical thread

It has the letter designation M with a nominal thread diameter, while the large pitch is not indicated: M56; M5, and the fine pitch is indicated additionally M12 x 1.

The left-hand thread has the Latin designation LH: M20 x 1.5LH. The designation contains an accuracy class: M5-6g.

Metric tapered thread

Designated MK: right thread MK x 30; MK20 x 1.5LH - left.

MK 24×1.5LH GOST 25229-82 - internal cylindrical thread screwed with a conical thread, has the standard number of this thread in the designation.

Cylindrical pipe thread

Designated by the letter G, nominal diameter in inches, accuracy class of average diameter. Left-hand thread is designated LH.

G1 ½ LH - A - left-hand cylindrical pipe thread with a nominal diameter of 1 ½ inches (without the “sign”), accuracy class A.

G1 ⅛ - B - cylindrical pipe thread with a nominal diameter of 1 ⅛ ", accuracy class B.

The make-up length is indicated in mm after the accuracy class: G1⅛-B-40. Make-up lengths are divided into long L and normal N. Make-up length L is indicated in mm, N is not indicated.

Conical pipe thread

It is designated by the letter G with a nominal diameter in inches, R. For pipe conical internal threads, the designation Rc is used. Left-hand thread is designated LH.

R¾ is an external tapered pipe thread with a nominal diameter of ¾ inch. R¾LH - pipe conical external thread left, nominal diameter ¾ inch.

Trapezoidal thread

Denoted by the letters Tr, nominal thread diameter in mm, thread pitch (lead and pitch for multi-start threads) + LH for left-hand threads and accuracy class of trapezoidal threads.

Tr 20 x 4 (P2) - 8e - external trapezoidal thread with a nominal diameter of 20 mm, stroke 4 mm, pitch 2 mm, two-start, 8e accuracy class, right-handed.

Tr 20 x 4 (P2)LH - 8H - internal trapezoidal thread with a nominal diameter of 20 mm, stroke 4 mm, pitch 2 mm, double-start left, accuracy class 8H.

Tr 80 x 4 - 6h – right-hand trapezoidal thread with a nominal diameter of 80 mm, pitch 4 mm, 6h accuracy class.

Main settings

It is difficult to match a bolt and nut to each other if they had different sizes and designs. But they mirror each other, so we can talk about characteristics that are suitable for both parts:

- Outside diameter. Most procedures are determined by it, including when it is necessary to drill a hole for a tap. In diagrams it is written as d or D for a bolt and nut, respectively.

- Medium – d2 and D2. If you take the basic unit of coil, you need to divide it in half to find these points.

- Internal – d1 and D1. Determined by the upper edges. If you draw an imaginary line along them, you can see a cylinder that will display this size.

- Step (P) - if we take a thread, then each rotation of it leads to the formation of a line on one of the sides. The distance between two points (ridges, blades) is the parameter. You can find it by marking 10 mm on the surface with a ruler (measurements can also be made in centimeters), then count how many turns are within these limits and divide the resulting number by 10.

- Stroke – (t) it is equal to the previous value, if we consider single-thread bolts, with one thread. But since two-start ones are more common, then t = 2P. Or 3P, if there is a three-lead element. That is, this is a full turn to the starting point of one turn.

- Profile angle – it is very important to calculate it. It is individual for different workpieces depending on the thickness and density of the material. Cannot exceed 140 degrees.

- The screwing length or nut height is the distance over which there are turns that interact with the mirror internal thread.

Standard thread right or left - Metals, equipment, instructions

04.09.2017

Thread refers to the main elements of a threaded connection and has the form of a spiral, formed along a helical line on a conical/cylindrical surface and having a constant pitch.

Pipe threads are divided into classes:

1.According to surface shape: conical and cylindrical

2.By unit of diameter: inch and metric

3. According to the location of the thread: external and internal

4.According to profile shape: round, triangular, rectangular, trapezoidal

5. By purpose: chassis, fastening, fastening and sealing, etc.

6.Thread direction: right and left

7. By number of passes: single and multi-pass

Tapered threads ensure tightness and locking of threads without the use of additional tools. Compaction when mating parts with conical threads occurs due to deformation (creasing) of the thread.

In foreign technology, the most common standard is the ISO metric thread. Other standards are also applicable, differing in different systems of measures and the way of specifying the size of threads in different countries, as well as the specifics of the areas of application of threads.

Internal and external threads are compatible if the pitch and nominal diameter match.

The thread designation usually has a letter designation of the thread type and its nominal diameter. Additionally, the designation may include thread pitch or TPI - the number of turns per 1 inch, for multi-start threads - the number of starts, the diameter of the thread hole, left-handed or right-handed threads.

In threads made according to the DIN standard, the designation of the nominal diameter may be placed forward.

Standard threads. Designations

The standard applies to general purpose metric threads and sets their diameters from 0.25 to 600 mm and pitches from 0.075 to 8 mm Main profile according to GOST 9150-2002 (ISO 68-1-98)

The symbol for the thread size must include: the letter M, the nominal diameter of the thread and the thread pitch, expressed in millimeters and separated by the sign “x”. Example: M8x1.25 The large pitch in the thread designation can be omitted.

Example: M8

The symbol for a left-hand thread must be supplemented with the letters LH Example: M8x1 - LH A multi-start thread must be designated with the letter M, the nominal diameter of the thread, the sign x, the letters Ph, the value of the thread stroke, the letter P and the pitch value. An example of the symbol for a double-start thread with a nominal diameter of 16 mm , stroke 3 mm and pitch 1.5 mm:

М16хРh3Р1.5

The same for left-hand thread:

M16хРh3Р1.5 - LH

For greater clarity, the number of thread starts may be indicated in parentheses in text. Example: M16xPh3P1.5 (two passes)

GOST 11709-81

The standard applies to metric threads with diameters from 1 to 180 mm for plastic parts connected to plastic and metal parts, and establishes the profile, main dimensions, tolerances and maximum deviations of the dimensions of such threads

Source: https://spb-metalloobrabotka.com/standartnaya-rezba-pravaya-ili-levaya/

Tolerance fields

For a number of production cycles, maximum compliance of the parts being connected is important. Such values are called exact. It leads to:

- increased tightness - no extra gaps;

- strength;

- no vibration.

Manufacturing takes place exclusively on metalworking machines, which are based on a remote control. Here the operator is not responsible for the process, but only enters the design developed using a computer-aided design program into the computer. Tools grind teeth with high precision up to 0.001 mm.

The second standard accuracy size for metric threads is medium. It is the norm and is used most often. It is this category that includes the fasteners that are supplied to the shelves of hardware stores. Manufacturing is machine-made, but with the use of manual installation and fastening of the part, drill direction, etc.

Third class is rough. This includes cuts that are made by craftsmen at home. Often do not have three-layer processing, in many cases the ends of the turns are broken or ready to crumble.

Read also: Engraving - what is it?

Metric thread: size table and parameters according to GOST

Metric thread is a screw thread on the external or internal surfaces of products. The shape of the protrusions and depressions that form it is an isosceles triangle. This thread is called metric because all its geometric parameters are measured in millimeters.

It can be applied to surfaces of both cylindrical and conical shapes and used for the manufacture of fasteners for various purposes. In addition, depending on the direction of rise of the turns, metric threads can be right-handed or left-handed. In addition to metric, as you know, there are other types of threads - inch, pitch, etc.

A separate category is made up of modular threads, which are used for the manufacture of worm gear elements.

The reliability of the detachable connection depends on the accuracy of the metric thread.

Main parameters and areas of application

The most common is metric thread, applied to the external and internal surfaces of a cylindrical shape. This is what is most often used in the manufacture of various types of fasteners:

- anchor and regular bolts;

- nuts;

- hairpins;

- screws, etc.

Conical-shaped parts, on the surface of which a metric type thread is applied, are required in cases where the created connection must be given high tightness.

The metric thread profile applied to the conical surfaces allows the formation of tight connections even without the use of additional sealing elements.

That is why it is successfully used in the installation of pipelines through which various media are transported, as well as in the manufacture of plugs for containers containing liquid and gaseous substances. It should be kept in mind that the metric thread profile is the same on cylindrical and conical surfaces.

Parameters of tapered metric thread

Types of threads belonging to the metric type are distinguished according to a number of parameters, which include:

- dimensions (diameter and thread pitch);

- direction of rise of turns (left or right thread);

- location on the product (internal or external thread).

There are also additional parameters, depending on which metric threads are divided into different types.

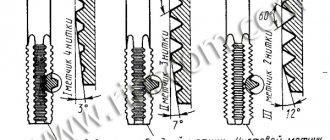

Internal metric thread

External metric thread

Geometric parameters

Let's consider the geometric parameters that characterize the main elements of metric threads.

- The nominal thread diameter is designated by the letters D and d. In this case, the letter D refers to the nominal diameter of the external thread, and the letter d refers to a similar parameter of the internal thread.

- The average diameter of the thread, depending on its external or internal location, is designated by the letters D2 and d2.

- The internal diameter of the thread, depending on its external or internal location, is designated D1 and d1.

- The inside diameter of the bolt is used to calculate the stresses created in the structure of such a fastener.

- The thread pitch characterizes the distance between the crests or valleys of adjacent threaded turns. For a threaded element of the same diameter, a basic pitch is distinguished, as well as a thread pitch with reduced geometric parameters. The letter P is used to denote this important characteristic.

- The thread lead is the distance between the crests or valleys of adjacent threads formed by the same helical surface. The progress of the thread, which is created by one screw surface (single-start), is equal to its pitch. In addition, the value to which the thread stroke corresponds characterizes the amount of linear movement of the threaded element performed by it per revolution.

- A parameter such as the height of the triangle that forms the profile of the threaded elements is designated by the letter H.

Tapered, round and trapezoidal threads

Conical parts differ from ordinary ones in that a conical thread is applied to their surface. The angle is 1/16. Such products are used when it is necessary to seal connections. Manufacturers must comply with the requirements specified in GOST 25229–85. To designate parts, the letter marking MK is used. After this there are numerical parameters that correspond to geometric indicators.

The round profile is used in the manufacture of various pipeline valves and other shut-off valves. All standards for this type can be found in GOST 13536–68. In documentation, drawings and diagrams, the designation of the letters Kr is used. The angle near the top of the turns is 30 degrees.

The peculiarity of trapezoidal threads is that they are self-tapping. As the nut moves, a very high frictional force is created. Thanks to this, no additional fixation is required. Products of this type are produced in sizes 8–640 mm. The pitch of the turns varies from 1.5 to 12 mm. All requirements for finished parts are specified in GOST 24738−81.

Left-hand thread: how to identify, mark on drawings and where to use

Connecting parts and assemblies in mechanisms using screw threads is one of the oldest common types of fasteners. This ingenious invention of mankind has helped in solving many technical problems since antiquity. Individual structural parts to perform certain functions cannot be brought into action without interconnection. Nowadays, it is impossible to imagine the operation of mechanisms without threaded connections, which are versatile and reliable and can be assembled and disassembled.

For fastening products using screws, bolts, nuts, studs and other elements, right-hand threads are mainly used. This threaded connection is observed when screwing in screws and self-tapping screws. However, if there is a possibility of the part being unscrewed from the rotating shaft, non-standard left-hand threads are used in industry.

Differences between left-handed and right-handed threads

One of the main characteristics of a screw connection is the direction of the thread when the parts rotate. The full operation of the mechanism and the integrity of any structure depend on the quality of the connections, which are considered a responsible and important element.

In mechanics, there are two main types of fastening products. With standard threads, the lines of threads are removed clockwise towards the viewer. With a left-hand thread, the protrusions on the screw approach it from the left, moving counterclockwise.

Thus, the direction of rotation of the turns (helix) on the screw makes it possible to distinguish a right-handed thread from a left-handed one. On hexagon bolts, studs, nuts and fittings, left-hand threads are marked with the letter L.

How to distinguish right-hand threads in fasteners?

There are simple ways in which someone ignorant of mechanics can determine the type of threaded connection. For visual identification, you need to place the pin, screw or bolt in front of you with the chamfer up on the palm of your hand so that the spiral with turns looks at the observer.

Right hand threads run clockwise from the end of the helix to the right. If the direction of the turns (spiral) is to the left, then the part is twisted to the left counterclockwise.

Areas of use

Left-handed threads are used in mechanical engineering to secure parts to a shaft rotating to the right. If the nut is tightened in the direction of rotation of the shaft, then it will be tightened under the influence of the rotational force. When tightened in the opposite direction, the nut will come loose. The connection using left-handed fasteners prevents the possibility of unscrewing during operation of the mechanism.

To prevent connections from loosening

Here are simple examples when the use of such non-standard fasteners is necessary:

- In units and parts that rotate to the right, the parts may unwind when the mechanism operates. The powerful rotational force of the mechanism unscrews the nut, therefore, to prevent unwinding, left-handed fasteners are used in the direction of shaft rotation.

- The nipple of the radiators of the heating system is equipped with multi-directional threads. The coupling, when twisted with a special wrench, causes the rubber gasket in the radiator sections to tighten.

- The wheels of GAZ, MAZ, ZIL trucks use left-hand mounts.

- The drill chuck with the drill rotates to the right. To prevent loosening of the connection of parts, the chuck is attached to the shaft with a left-hand thread.

- Home fan blades.

- The gearbox transmits torque from the engine to the blades of the brush cutter.

- Bicycle pedals.

- Fastening the cutter to the shaft, discs of grinding machines.

- Some details in miter saws and circular saws.

Let's imagine this picture: housewives hang wet laundry on a line to dry. The rope begins to sag from constant use. The tension for the laundry has to be adjusted frequently. In such cases, bolts with double-sided threading are used here. One side of the bolt goes to the right and the other goes to the left. That is, in this case, the left-hand thread is used to adjust the degree of tension.

Designation on the drawing of a left-hand thread

The principle of operation can be represented as follows: a right-hand thread is cut at one end of the nut, and a left-hand thread at the other, and the bolts are screwed in. When the nut is rotated in one direction, it lengthens, and in the other direction, it shortens.

The use of left-handed fastening in tie-down structures is a prime example.

Such a device used in rigging work - a lanyard is a type of screw tie. This design features a pair of load-handling elements. One of them has a standard thread, the other, respectively, a left-hand thread. When the structure rotates during operation, the element body rotates, the tie is weakened, and a change in the direction of rotation leads to loading (tension). That is, when rotating, the parts of the mechanism move away from each other or move closer together.

Masts on ships are installed by pulling cables.

To protect against dangerous activities

Some operations require careful monitoring of work equipment to protect against increased hazards. In the gas industry, the reducer valve of a compressed propane cylinder is equipped with a left-hand thread, and the oxygen cylinder is equipped with a right-hand thread. Therefore, it is not possible to attach a propane tank to an oxygen tank. Using this method helps reduce the likelihood of dire consequences.

Geometric dimensions

The performance characteristics depend on the parameters listed above. All three diameters determine which hole needs to be made with a drill when working with a tap. From the pitch and stroke - how firmly the screwing will occur, the more turns, and the more often they are, the better. This kind of work is more delicate, so it is virtually impossible to do it at home, only with special equipment.

Read also: Solder pastes and fluxes

The strength of the connection depends on how deep the grooves are. There are limitations here too. If the bolt is made in miniature, then there should not be too much of a difference between the recesses and ridges, as this increases fragility.

The profile angle determines how well the front of the tap will penetrate the material. It’s not so easy to start rotations, and besides, to do it quite smoothly, without distortions. The softer the material (for example, copper or aluminum), the better the screwing. The proportionality of the two elements that come into interaction is very important.

Application

Metric threads are widespread in the countries of the former Soviet Union. Used for application to both internal and external planes of fasteners. Typically used for fastening metal structures of various types. For these purposes, a variety of bolts (anchor and conventional) and other types of fasteners are manufactured. She found a particular purpose in mechanical engineering, construction of engineering communications, especially in the plumbing sector. Most pipe and container fittings are manufactured with this type of thread.

Most often, this type of carving is applied to cylindrical objects. But in some cases, when it is necessary to achieve tightness, a conical shape is used. This form, with a metric thread applied, allows you to achieve maximum tightness, even without the use of additional sealing agents. Most often used for installation of pipelines.

Read also: Longitudinal and transverse feed

State standards, certification

Description of the profile, main dimensions and tolerances of conical threads and tolerances for internal pipe cylindrical connections with a set of external conical ones are regulated by GOST 6211-81. Standards regarding interchangeability are described in GOST 6357-81.

Interchangeability standards for metric tapered threads are prescribed in GOST 5229-82. In turn, the basic standards of interchangeability regarding the diameter and pitch of threaded connections are regulated by state standard 8724-2002.