Polyethylene sewer pipe can easily withstand the harshest operating conditions. Polyethylene pipes are not afraid of frost: due to their high elasticity, they expand and contract without damage. Sewage polyethylene pipes are not afraid of rust (the main cause of wear of metal pipes). Laying sewer lines is faster, because polyethylene pipes are many times lighter and do not necessarily require the use of special tools.

Our plant produces sewer polyethylene pipes of small, medium and large diameters from 20 mm to 160 mm. The catalog contains pipes with different wall thicknesses. In addition, we produce polyethylene pipes to order: you can vary the wall thickness and even the shape. The price of sewer polyethylene pipes depends on the diameter and volume of purchase.

The optimal diameter of a polyethylene sewer pipe.

HDPE pipes from our production are presented in a wide range. The company produces pipes with diameters from 20 mm to 160 mm. Small diameter pipes (20 mm, 25 mm) are most suitable for laying cables; also, along with 32 mm and 40 mm pipes, they are used for drainage.

This diameter will not be enough for laying sewer lines. Experts recommend using HDPE pipes for sewerage, the diameter of which ranges from 50-160 mm. A 50 mm polyethylene sewer pipe is considered the minimum acceptable to ensure optimal self-purification of the flow, the speed of liquid movement, and the filling of the section during the transportation of wastewater.

A 110 mm polyethylene sewer pipe is suitable for a larger flow of liquid, in particular for risers, as well as connection to a toilet sewer. To organize external sewerage in a small country house, the above-mentioned diameter of 110 mm will be sufficient. If communications are laid in cottage villages or townhouses, the optimal diameter of sewer pipes is at least 160 mm.

Laying sewerage pipelines from high-density polyethylene pipes with a diameter of 110 mm

LOCAL RESOURCE STATEMENT GESN 16-04-001-02

| Name | Unit |

| Laying sewerage pipelines from high-density polyethylene pipes with a diameter of 110 mm | 100 m pipeline |

| Scope of work | |

| 01. Laying a pipeline from ready-made units with sealing of sockets with O-rings. 02. Installation and sealing of fasteners. 03. Installation of valves. 04. Pipeline testing. |

PRICE VALUES

The price does not contain overhead costs and estimated profits; accordingly, the direct costs of work for the period 2000

(prices of the Moscow region), which are calculated based on

2009

. For further calculations, this cost must be multiplied by the conversion index to current prices.

You can go to the pricing page, which is calculated based on the 2014 edition standards with additions 1

To determine the composition and consumption of materials, machines and labor costs, GESN-2001 was used

LABOR COSTS

| № | Name | Unit Change | Labor costs |

| 1 | Labor costs of construction workers Grade 4.2 | person-hour | 61,6 |

| 2 | Labor costs for drivers (for reference, included in the price of the EV) | person-hour | 0,05 |

| Total labor costs for workers | person-hour | 61,6 | |

| Workers' compensation = 61.6 x 9.91 | Rub. | 610,46 | |

| Payroll for drivers = 0.91 (for calculating invoices and profits) | Rub. | 0,91 |

OPERATION OF MACHINES AND MECHANISMS

| № | Cipher | Name | Unit Change | Consumption | St. unit.Rub. | TotalRub. |

| 1 | 020129 | Tower cranes when working on other types of construction 8 t | mach.-h | 0,03 | 86,4 | 2,59 |

| 2 | 021141 | Truck-mounted cranes when working on other types of construction 10 t | mach.-h | 0,02 | 111,99 | 2,24 |

| 3 | 400001 | Flatbed vehicles, load capacity up to 5 tons | mach.-h | 0,02 | 87,17 | 1,74 |

| Total | Rub. | 6,58 |

CONSUMPTION OF MATERIALS

| № | Cipher | Name | Unit Change | Consumption | St. unit.Rub. | TotalRub. |

| 1 | 101-2449 | Rubber rings for cast iron pressure pipes with a diameter of 50-300 mm | kg | 4 | 24,41 | 97,64 |

| 2 | 101-2576 | Bolts with nuts and washers for sanitary works with a diameter of 16 mm | T | 0,00266 | 14830 | 39,45 |

| 3 | 301-9240 | Fastenings | kg | 0,00 | ||

| 4 | 302-9120 | Valves | PC. | 0,00 | ||

| 5 | 411-0001 | Water | m3 | 1,57 | 2,44 | 3,83 |

| 6 | 302-9661 | Sewage pipelines made of high-density polyethylene pipes with sleeves, diameter 100 mm | m | 99,8 | 0,00 | |

| Total | Rub. | 140,92 |

TOTAL BY RESOURCES: 147.49 RUB.

TOTAL PRICE: 757.95 RUR.

Look at the cost of this standard at current prices open page

Compare the price value with the value of FER 16-04-001-02

To draw up an estimate, the price requires indexation of the transition to current prices. The price is compiled according to the standards of GESN-2001, as amended in 2009

2000

prices . To determine intermediate and final price values, the DefSmeta program was used

Estimate for the construction of a house, renovation and decoration of apartments - DefSmeta

Rental

The program provides an assistant who will turn the preparation of estimates into a game.

Polyethylene sewer pipes from the manufacturer.

Our company produces HDPE sewer pipes. Products are produced at a site in the Moscow region equipped with modern equipment.

The presence of advanced production lines and the use of exclusively high-quality raw materials allows us to produce competitive products, the key characteristics of which fully comply with the requirements and standards.

In the catalog you will find the main types of polyethylene pipes with common diameters and wall thicknesses:

- Designed for laying cables, organizing drainage, as well as sewerage itself;

- HDPE pipes of various diameters, ranging from 20-160 mm;

- Pipes made of high density polyethylene (PE100) with different wall thicknesses.

In addition, we produce pipes of any shape, be it round, square, triangular or any other configuration required by the customer. Working with us is profitable and convenient. Unlike resellers, the manufacturer of polyethylene sewer pipes strives to improve quality and maintain it at a high level. Only from the manufacturer can you get the lowest cost of a polyethylene pipe.

Customers who order sewer pipes receive products of the required diameter in the shortest possible time and have the opportunity to pay for it in any convenient way.

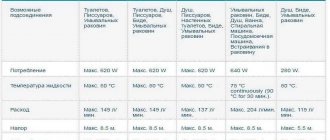

Specifications

Polyethylene sewer pipes have the following characteristics and features:

- temperature range – from minus 80° to plus 90° C, this is enough for cold drainage;

- withstand pressure of 16 - 20 atmospheres, which plays an important role in the construction of sewer collectors;

- excellent sound insulation;

- chemical inertness – not subject to corrosion, as well as to the action of acids and alkalis;

- environmental safety;

- durable and can withstand heavy loads;

- service life – up to 100 years.

Non-pressure sewer polyethylene pipes. Difference from pressure pipes.

Pipes for pressure sewer systems are used when it is necessary to organize the drainage of liquid from basements and other premises that are located below the level of the main system. Such pipes are subject to an additional requirement regarding increased ring rigidity. This is due to a change in the operating conditions of the system due to the presence of a pressure-creating pump in it.

Other sewer communications are created using free-flow pipes. In non-pressure systems, liquid is transported by gravity. According to such a parameter as ring stiffness, free-flow sewer polyethylene pipes have several classes within SN2-SN8. In the catalog of sewer pipes you will find products of various diameters for creating non-pressure communications.

Rostpipe

A risepipe is a socket pipe with a double structured wall. Designed for the construction of non-pressure drainage systems. Features improved ring stiffness SN10.

Pipes are made from polyethylene using the “double coextrusion” method, when the inner and outer walls are simultaneously made, forming a single whole at the exit of the extruder.

The outer wall is corrugated, the inner wall is smooth green, which provides the opportunity for television inspection during operation. The socket is produced separately and welded to the pipe during production, ensuring the tightness of the structure.

| for pipes and fittings Rostpipe SN10 | for pipes and fittings Rostpipe SN16 |

| Technical catalog | ||||

| Organization standard STO 17827241–001–2015 | Order an album of design solutions A cake is delivered with the album for better assimilation of information | ||

| Increased ring stiffness SN10 kN/m2 | Tightness | Ease of installation | High chemical resistance |

| Full range of fittings | High UV resistance | Resistance to water-abrasive wear | Resistance to internal pressure 0.5 atm |

The theoretical and practical knowledge that we have accumulated over many years of working with plastic pipelines has been embodied in the production of the Rostpipe pipe, which is unique for the Russian market.

When producing these pipes, we took into account the advantages and disadvantages of leading European and Russian manufacturers and made our own improvements. Rostpipe pipes with an increased ring stiffness SN10 are analogues of Korsis, Pragma, Peshtan, Magnum, Corex and other brands of corrugated pipes for external sewerage.

Deep drainage system

developed on the basis of Rostpipe pipes and Rostproekt plastic well systems, it is distinguished by a high strength class and a wide range of diameters. The need to develop this system is associated with the complex development of urban infrastructure and difficult geological conditions.

| more about rigid drainage pipes |

| see flexible drainage pipes |

The Rostpipe pipe is manufactured in accordance with TU 4926-001-09283206-2014 as amended No. 1. According to its technical characteristics, the pipe strictly complies with the requirements of Russian and European standards for double-wall plastic pipes for free-flow sewerage EN-13476.

Rostpipe corrugated pipes can be produced upon individual order with an increased ring stiffness of 16 kN/m2 (SN16).

| look in the catalog |

Supply of improved corrugated pipes Rostpipe

view all objects

Polyethylene sewer pipe in lengths (by the meter) and in coils.

For the convenience of our customers, we sell our products in any chosen way: by the meter (pieces) and in coils. HDPE pipes of large diameter (from 75 mm) are cut into sections up to 12 m long. You can order HDPE pipes of the required diameter in coils and by footage by phone or email.

Our plant, in cooperation with trusted transport companies, organizes delivery to the regions. Delivery by our own transport is also possible.

We are engaged in retail and wholesale sales of sewer polyethylene pipes. When purchasing a large batch of pipes, customers are provided with the most favorable conditions for both short-term and long-term cooperation.

HDPE pipes for sewage system

How to choose HDPE pipes for a sewerage system and rules for their installation

Pipes for the production of which polyethylene was used are a modern and very convenient material to use.

Polyethylene is resistant to various adverse factors, chemically inert and quite durable, so it is widely used for the manufacture of pipes for various purposes. HDPE pipes are perfect for sewage, and the method of connecting such pipes is so simple that the installation of the pipeline can be carried out by a non-specialist. Sewer pipes made of polymers are widely used for the construction of pipelines for domestic purposes. However, it can be difficult for the average consumer to figure out which pipes should be chosen to solve certain problems.

HDPE sewer pipe is one of the best options for the construction of household drainage pipelines. Pipes made from this material have many undeniable advantages that set them apart from other plastic pipes. Their technical characteristics allow you to create reliable and durable communications.

Pipe material and technology

Polyethylene is a polymer obtained from ethylene, which under normal conditions is in a gaseous state. Catalysts are used to carry out the polymerization reaction; in addition, the process takes place under conditions of elevated temperature and pressure.

Depending on the pressure used during the polymerization reaction, it is possible to obtain a material with different properties:

- If the reaction takes place at high temperature and under significant pressure, then the resulting polyethylene has a low density.

- The material, produced at a relatively low temperature (120-150 degrees) and low pressure (0.1-20 mPa), is characterized by high density. This polymer is designated by the abbreviation HDPE (low-density polyethylene). Its density is 0.941 g/cm³, the material has a crystalline structure, that is, products made from it are rigid.

It is HDPE that is widely used for the manufacture of sewer pipes, as well as pipes for water supply systems, since products made from this polymer are more durable.

Pipe making process

During the polymerization process, polyethylene granules are obtained from a gaseous substance. How then is this raw material turned into pipes? As a rule, production uses the extrusion method, when the molten polymer is “squeezed out” through the holes of a mold in the form of a ring. To preserve the shape of the pipe, the process is carried out in a vacuum chamber.

The formed pipes are equipped with rubber seals

(if provided by the technology), packaged and sent to the consumer.

In the production of corrugated pipes,

a more complex technology is used, since such pipes are two-layer.

Pipe Manufacturing Standards

Sewage non-pressure HDPE pipes are produced in accordance with the requirements of GOST 22689.2-89. Corrugated HDPE pipes are produced according to technical specifications agreed with the customer. According to GOST, HDPE pipes have the following dimensions:

- Product diameter 40, 50, 90, 110 mm

- Their length can be 2, 3, 5.5, 6 or 8 meters.

GOST regulates the length and diameter of pipe sockets

, as well as the dimensions of shaped parts - crosses, bends, tees, etc.

Each pipe must be marked, indicating the main characteristics of the pipe. For example, the marking “TK 110 - 6000 - HDPE GOST 22689.2-89” means that we have a sewer pipe made of low-density polyethylene, its diameter is 110 mm and its length is 6 meters.

Pros and cons of HDPE pipes

These types of pipes have many advantages. Properties of HDPE pipes for sewerage:

- Long service life. According to calculations, a plastic pipe can last up to 300 years, although in practice, of course, these calculations have not yet been confirmed.

- Resistance to corrosion processes and aggressive environments.

- Maintained linear and radial dimensions throughout the entire service life.

- Low thermal conductivity coefficient.

- High degree of elasticity.

- Possibility of operation at temperatures below zero. Polyethylene becomes brittle only at minus 70 degrees.

- Low weight of pipes.

- Ability to withstand hydraulic shocks.

- Environmental Safety.

- Easy to install.

The disadvantages of HDPE pipes include:

- Insufficient resistance to high temperatures.

This disadvantage does not apply to pipes made of cross-linked polyethylene, which can withstand temperatures up to 400 degrees.

- Less mechanical strength compared to cast iron pipes.

- Insufficient resistance to UV rays.

Scope of application of HDPE pipes

- Creation of internal sewerage systems, including pressure ones.

- Assembling an external sewerage pipeline, a thick-walled pipe is used for this, which can be laid in the ground.

- Water supply for technical and drinking water.

- Hot water supply and heating, including the construction of heated floors (cross-linked polyethylene pipes are used) Transportation of various industrial media, including aggressive ones.

- Performing waterproofing of heating mains.

Methods for connecting HDPE pipes

The choice of pipe connection method depends on the purpose of the pipeline. There are two types of connections:

- Detachable, which is used for pipelines operating without pressure.

- One-piece (diffuse welding). This connection is used if pipes are used for pressure sewerage or a water main is being assembled.

Detachable connections

This method is used quite often when installing sewer systems. Its advantages:

- Economical. There is no need to purchase special equipment or tools.

- Simplicity and accessibility.

- High installation speed.

A detachable connection can be made into a socket or using special fittings - fasteners ( fittings for sewer pipes

). Fittings are selected depending on the diameter of the pipes; for example, a HDPE 110 sewer pipe requires a coupling of the appropriate size for connection. There are several types of couplings:

- Connective. Used on pipelines operating without pressure.

- Compression. Used to create reliable and tight connections on pressure pipelines. Can be used when it is necessary to join steel and polymer pipes.

- Reduction. A special type of fitting used for joining pipes of different diameters.

Permanent connections

Sewer adhesive pipes, as a rule, are not made from HDPE. This type of connection (with glue) is more often used for PVC pipes. To make permanent connections on polyethylene pipes, it is more convenient to use the diffuse welding method.

This joining method involves heating the ends of the parts to be joined and their subsequent connection. After the plastic cools, a strong connection is formed with bonds at the molecular level.

So, pipes made from HDPE are an excellent material for installing sewerage systems. They are suitable for both the assembly of internal networks and the installation of external ones. In the latter case, it is recommended to use corrugated two-layer products.

Polyethylene sewer pipes in accordance with GOST are a guarantee of quality and reliability.

Several decades ago, when metal was used to make sewer pipes, laying communications and their further maintenance caused a lot of trouble. The difficulty of transportation due to the large weight, demanding installation conditions, further low wear resistance and a relatively short service life - all this did not make it possible to consider metal pipes as the best option for sewerage. All these difficulties were eliminated by the appearance on the market of technical sewer polyethylene pipes, the characteristics of which were far ahead of all existing analogues.

Key advantages and benefits of PE pipes:

- Low susceptibility to corrosion due to temperature fluctuations;

- Rust resistance;

- Resistance to aggressive household chemicals;

- High abrasion resistance, which makes it possible to work with liquids containing solid particles;

- Flexibility and lightness, which significantly simplifies the process of laying sewers;

- Long service life.

Manufactured in accordance with GOST, in compliance with strict quality requirements, HDPE polyethylene sewer pipes are the best option for laying truly durable, reliable communications that do not have to be replaced every 10-15 years.

Call any time! Experienced specialists will answer any questions about polyethylene pipes. With the help of our pipes, many projects have been implemented to replace and lay sewer lines: the reviews are only positive. A significant part of our clients become regular partners, because we offer excellent prices and high quality products. Join us for mutually beneficial cooperation!

Gravity sewer lines: application features

Gravity pipelines are used for laying a variety of utility networks, as well as their repair in various places, including underground, the only limitation is the operating pressure, which cannot exceed the maximum value of 0.16 MPa. These characteristics allow the use of non-pressure pipelines for the removal of wastewater, liquids and gaseous media. Also, these pipes have high chemical resistance, with an optimal operating temperature of 0 - 45 ° C (zone U).

An important characteristic is that non-pressure pipelines have excellent flexibility, which allows routes to be laid using the bending method, without the use of fittings, which in turn significantly saves money, effort and time spent during installation work.

Gravity pipelines are manufactured in accordance with GOST with diameters of 110 mm - 200 mm (hardness class SN2), they are very popular in private homes, since the price is affordable for the buyer.

Gravity sewer lines

A limitation in the use of HDPE is its use for central heating and hot water supply.

Summarizing all of the above, we can say that polyethylene products meet the sanitary and hygienic standards.

They also have:

- High resistance to chemical and corrosive influences;

- Low thermal conductivity;

- Constant pipe diameter throughout the entire service life;

- Absolute smoothness of the surface and complete absence of deposits during use;

- Tightness;

- Easy to maintain (simply repaired and replaced);

- Optimal ratio of cost and quality.