Turning and rotary machining inexpensively at Turning Processing LLC on okuma B400, 16K20, 1K63, DIP500 and automatic lathes. From 3 days. There is hardening and galvanizing. Send a request with drawings by email:

Our company is pleased to offer you services for rotary turning of parts. In this article we will look at the scope of its application, advantages and useful information about this type of processing.

To calculate the cost of rotary turning, send a request with drawings by email. We will answer any questions, delivery throughout Russia.

Features of turning-turret processing.

Vertical turning machines are used for processing parts of various configurations with a diameter much greater than their length. These can be various disk parts, for example, flywheels or gears. Vertical turning is performed for grooving and boring internal and external conical and cylindrical surfaces, reaming central holes, countersinking, drilling, threads are cut using thread cutters, fillets, grooves and chamfers are also processed, and flat ends are turned. Vertical turning equipment can be additionally equipped with special grinding or milling devices that allow grinding and milling of surfaces.

The main difference between a rotary lathe and a conventional lathe is the vertical location of the axis of rotation of the faceplate. Such equipment can have a two-post or single-post layout. Vertical lathes with a single-column layout have a vertical support on which the turret is mounted and a side support on which there is a tool holder. Vertical turning machines with a two-column layout are complemented by an upper cutting support, which has a horizontal feed. All cutting tools are installed in tool holders on the side and top supports and in the seats of the turret.

On such machines, due to their design features, it is possible to simultaneously process several surfaces of a part. For example, you can bore a hole, trim the end and grind the outer cylindrical surface. It is allowed to process threads, shaped and conical surfaces, and install grinding and milling devices.

Turning work to order in Moscow

Turning work on CNC machines to order in Moscow

Turning work on CNC machines to order in Moscow in our company and the client receives significant advantages: all work is carried out on a turnkey basis. This will significantly save your time and money, because you receive significant discounts for ordering several services and operations. To obtain prices for turning work on custom-made CNC machines in Moscow and production times for products, contact the company’s specialists. We will coordinate a meeting with our technical staff to carry out design improvements to the product. We will prepare a working sketch of the product and start production - turning work on CNC machines to order in Moscow. If there is no drawing from the customer, we will carry out a full development of the part, approve the drawing, and make adjustments.

Turning work on CNC machines to order in Moscow in our company and you receive high-quality products that fully correspond to their purpose. The specific production time for the order is determined after reviewing the application for turning and laser cutting of metal. Turning work on CNC machines to order in Moscow is fast and convenient!

Turning, milling, carousel, metalwork

Turning and milling work

Where is the best place to order metal turning and turning and milling work ? Our company employs professionals who perform all types of turning work with high quality, at a low price and on time. Turning and milling work is cutting of internal and external surfaces of rotation, including conical and cylindrical, cutting, facing, chamfering, cutting grooves, processing fillets, cutting threads on machines. Turning and milling work is one of the oldest operations. There are auxiliary movements, they provide securing and transporting the workpiece on the machine, changing the speed of rotation of the workpiece or the speed of translational movement of the tool, turning it on, etc. - examples of turning and milling work .

Carousel turning works

Vertical turning work on machines that are designed for processing cylindrical and conical surfaces, and when using devices - for shaped turning, thread cutting, etc., including milling and grinding. Carousel turning operations - the production and turning of large-sized and heavy parts are associated with certain difficulties. Rotary turning operations meet these requirements . Their design features make it possible to effectively process massive products of large diameters that are relatively short in length. Carousel turning is superior in productivity to loboturning and is widely used in single and large-scale production. Turning of large-sized parts with a cylindrical, conical and shaped surface is performed with a given accuracy and roughness during rotary turning operations .

Turning and metalworking works

The qualifications of our craftsmen and an extensive list of modern equipment are the guarantee that turning and plumbing work will be performed with impeccable quality and in the shortest possible time. Custom-made turning and locksmith work allows you to satisfy the customer’s requirements as much as possible . Modern turning and locksmith work covers various types of production. In the metalworking , they are sometimes simply necessary. Turning and metalworking to the processing of predominantly metal workpieces and products, carried out manually with a metalworking and assembly tool, using fixtures and machine tools. All turning and metal work must be performed on equipment specifically designed for this purpose. Carrying out metalworking and turning work is a serious matter that cannot be approached carelessly. Any negligence can spoil an important part, and the defects may not be noticeable at first glance, but during operation the defect will definitely make itself felt. By ordering metalworking and metalworking services, you will be protected from such troubles.

Order turning work

The company offers to order turning work at an excellent price. Experienced craftsmen working on modern CNC (computer numerical control) lathes quickly and accurately perform custom-made turning work of varying complexity . We are aimed at long-term cooperation, therefore our company has a flexible pricing policy, and our work is based on an individual approach. Order turning work in Moscow (Moscow is the main customer, we also work with other cities), production of parts from ferrous and non-ferrous metals. Our machine park will allow you to order large volumes of turning work . In our company you can order turning work of any complexity:

- Drilling

- Boring of central holes

- Threading

- Other turning and milling work

Vertical turning on single-spindle semi-automatic and automatic machines.

Automatic lathes process parts from rods, while semi-automatic machines process piece workpieces and parts. On semi-automatic machines, all work is carried out in a fully automatic mode, except for the removal of machined parts and the installation of workpieces.

On multi-cutting single-spindle semi-automatic turning machines, only end, shaped, conical and cylindrical outer surfaces can be processed. This equipment has two supports. The transverse support is used for the transverse feed of cutting tools (grooving, cutting, shaped, scoring and other cutters). The through cutters are mounted on longitudinal supports.

Correct adjustment of automatic lathes allows for simultaneous operation of tools that are installed on transverse and longitudinal supports, which in turn significantly increases the level of productivity of rotary turning.

Multi-cutting semi-automatic rotary turning equipment is widely used in mass and serial production.

The use of turning single-spindle hydrocopying machines makes it possible to process the surfaces of parts with complex profiles that represent a combination of shaped, conical and cylindrical surfaces. Such equipment has an additional upper hydrocopying support located directly above the workpiece.

On shape-cutting single-spindle lathes, small-sized parts are processed, made of wire or rod, which are passed through the spindle. It can have up to 5 supports, which are equipped with shaped and cutting cutters. This tool works without longitudinal feeds. Also, such machines may have an additional spindle, which has translational and rotational motion, located along the axis of the workpiece. This allows you to cut threads, drill holes, etc. After rotary turning, the part is automatically cut off, the next workpiece is advanced and the whole process is repeated.

Construction of rotary lathes

There are many different modifications of rotary lathes (Fig. 1). Each of the models is designed to perform a specific set of operations. Although recently, universal versions of rotary lathes have become increasingly popular.

Figure 1. Vertical lathe.

1 – racks; 2 – feed drive transmission mechanism; 3 – speed change box; 4 – casing; 5 – cradle for mounting the faceplate; 6 – faceplate; 7 – console for moving the spindle; 8 – console drive; 9 – right caliper; 10 – left caliper; 11 – manual drive for caliper control; 12 – left feed box; 13 – right feed box; 14 – control panel; 15 – control panel suspension; 16 – power control device; 17 – electrical panel.

In general, rotary-turning tanks are capable of producing the following types of metal processing:

- turning the external and internal surfaces of cylindrical or conical workpieces;

- drilling holes;

- grooving;

- countersinking and reaming;

- turning flat surfaces;

- thread cutting both with taps and with a cutter;

- creation of shaped surfaces;

- cutting off cylindrical and conical parts from the workpiece.

Machining on multi-spindle machines.

Multi-spindle turning equipment allows you to process complex parts at a higher speed, but, as a rule, the accuracy of such rotary turning is slightly inferior to the accuracy of processing on single-spindle equipment.

Automatic machines are divided into several types, depending on the type of workpiece: magazine-type (special magazines are used to install workpieces), rod-type (the workpieces are rods of different diameters), and storage machines (for processing forgings and cast workpieces).

Such machines contain special drums in which spindles are located parallel to the axis of rotation. Rotation is carried out by one drive. Next to each spindle there are transverse supports on which three cutters are mounted, designed for cutting, trimming, slotting and shaping. The axial support, which has longitudinal movement, is equipped with a carriage with tools such as boring cutters, reamers, countersinks, drills, etc. The entire process of working on such equipment occurs in a fully automatic mode; for this you only need to set up the machine correctly.

If you have any questions, you can contact our managers - they will help you choose the optimal processing method at a price that is acceptable to you.

Classification of rotary lathes

There are several classification criteria by which rotary lathes are divided. Let's look at the main ones.

1. By purpose:

2. By the number of support points:

- single-column – designed for processing workpieces with a maximum diameter of up to 2000 mm (Fig. 2);

Figure 2. Single-column rotary lathe.

- two-column - designed for processing parts with a diameter exceeding 2000 mm (Fig. 3).

Figure 3. Two-column rotary lathe.

3. By the number of calipers:

- with one caliper;

- with several calipers;

4. By type of spindle head:

- with a regular head for one cutter;

- with a turret head.

5. By type of control of working movements:

- with manual control;

- with numerical program control.

Vertical turning machines also differ according to the following criteria:

- power of drive electric motors;

- spindle and faceplate rotation speeds;

- the maximum height of the workpiece that the machine can process;

- accuracy of workpiece processing.

There are many small groups of vertical lathes that are made to order to perform certain highly specialized jobs. For example, machines for the manufacture of slewing bearings for portal cranes operating in large seaports. In them, the diameter of the workpiece can reach several tens of meters.

Operating principle of rotary lathes

Today, an increasing number of vertical lathes are controlled by software. This eliminates the human factor from influencing the quality of the final product, and also increases the accuracy and speed of processing parts. Manually operated machines are used mainly for simple turning operations or rough processing of workpieces.

The workpiece is secured on the table in the faceplate holders. The rotation mechanism is started at a reduced speed to check the correct alignment of the workpiece. The spindle head is brought in and moves along the traverse. The supply of lubricant and cooling fluid is turned on. The cutter is brought into working position. The turning process begins (Fig. 4). Depending on the technical conditions, the feed speed of the cutter and rotation of the workpiece in the faceplate is selected.

Figure 4. The operating process of a rotary lathe.

If the machine supports drilling holes evenly spaced around the circumference of the workpiece at a distance equidistant from the axis, the diameter and pitch through which the holes will be drilled are specified.

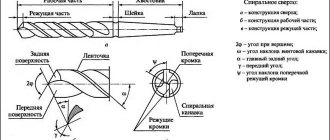

In the case of creating shaped surfaces, a shaped cutter is fixed in the spindle (Fig. 5).

Figure 5. Shaped cutters.

Here, precise control over the vertical feed is exercised, since in the process of deepening the shaped cutter, the contact area of the cutting surface with the workpiece increases. In this case, to avoid overheating and destruction of the cutter, the feed is reduced.