Mechanical processing of metal is a technologically complex process. This is a necessary part of working with parts that will subsequently be used in various fields. The most common is metal milling. The workpiece is processed with a special tool - a milling cutter. It is a drill sharpened at a certain angle, or a circular saw of a non-standard shape. A multi-tooth device, moving at high speed due to the operation of the machine, removes a layer of metal of the required thickness on the workpiece. Milling is a popular method of processing parts.

Milling work from 1 part

With us you can place an order for CNC turning and milling work from one part to a huge series. Piece production allows us to show our capabilities and the quality of our services.

We mainly provide services for milling work to order in Moscow and the region; delivery to remote regions of Russia is possible using transport companies.

The production of prototypes before launching the series is possible in two options:

- Production of a piece sample, without guarantees of launching a series. (Additional cost per piece)

- 50% prepayment of the series before starting sample production (Optimal option)

Classification of milling work

As already mentioned, depending on the cutter used, several types of milling are distinguished, namely:

- Face milling, the essence of which is to obtain a certain shape of parts using an end mill. This is necessary in most cases for cutting out undercuts, grooves, windows, as well as “wells”, grooves, etc. in products. It is also used to reverse milling the end from the inside of different types of products. End milling is needed to obtain parts with more precise dimensions, ease of installation and, in fact, cut ends serve to transmit compressive forces.

- End ones, which are needed to form ledges in vertical or horizontal planes.

- Cylindrical, characterized by obtaining products in planes using a corresponding cutter in the reverse position.

- Serrated.

- Shaped, which consists in creating shaped (spheres, ellipses, etc.) parts of irregular shape. This is milling using special cutters, resulting in shaped products.

Also common in different areas of activity are many other types of cutters, which are distinguished by their versatility, great capabilities and accuracy in performing work. Helical grooves are used to create countersinks, drills and other things; bars of various sizes are cut with a cutting cutter; in addition, it is possible to obtain a complex shape of a part using a curved type of cutter. It is worth noting the difference between milling with double disks, a splined blade for creating grooves in parts, as well as their more complex shapes. You can also create a certain shape with a short use of milling types.

In addition to the classification of milling by types of cutters, there is also a distribution of them into vertical placement in the machine, horizontal and at an angle.

Machines for such work, in turn, are divided into mechanical and laser. There is a direction of the cutting, moving element together with the product, which is called the associated type of processing. If the product moves towards the cutter, then this is considered counter milling.

It is also worth noting the profile milling of parts, both wooden and metal, etc. This differs in products that are convex or concave in shape. In this case, it is necessary to take a more careful approach to the choice of technological type, which depends mainly on the size of the part and the complexity of profiling. This type of process takes place in three stages: preliminary rough and partially clean milling, semi-finish and finally final clean. Often, to obtain high-quality parts, finishing is carried out at high feeds, and previous operations are performed separately on different machines.

Since milling parts using the cylindrical method requires less good fastening, most often profile milling of products is done using the end method. Basically, this is a universal method for multi-batch industrial production. In this case, it is possible to use several methods for milling different flat surfaces. This is the use of two chisels, large diameter cutters and several chisels at the same time.

Working in this mode can happen much faster and calmer, especially when using several cutters at once, located on different sides of the product. For this reason, milling planes using end mills is more used in production.

Milling is also carried out using an ion beam. This is a relatively new and high-tech process that allows you to remove the most precise layer of metal. Ion milling is carried out under the influence of a helium atom on the surface, the main condition is control of voltage and energy. In other words, today it is not necessary to polish or grind parts, this can be done at the atomic level, and additional parts can be inserted onto the hot metal.

CNC milling

CNC milling is usually ordered when high manufacturing precision is required, but a universal machine does not provide such precision.

Or for the production of small-scale and serial parts, the quantity of which starts from at least 10 pieces. It is impractical to make such batches on universal equipment, since the speed, accuracy and repeatability will be significantly lower. Which will lead to an increase in price and call into question the profitability of production. Therefore, you need to understand that the cost of the same part in a piece version and in a serial version will differ significantly. A detailed rationale for pricing and why this happens is described here.

Go to section

Turning and milling work: equipment features

Modern technology development is moving at a very fast pace. Every day, new developments appear in various fields from manufacturing and construction to industrial and transport. Naturally, all these mechanisms, devices and structures require regular replacement or renewal of component metal elements, most of which are manufactured using milling operations.

To carry out high-quality and reliable milling work on metal, there can be no question of using outdated, and especially handicraft, equipment. To ensure high precision in the dimensions of parts, all custom milling work must also be carried out on modern high-tech machines. Mechanical equipment in this area is gradually fading into the background, giving way to units with a computerized control system, or CNC for short.

Therefore, before ordering milling work from any company, you should make sure that this organization has modern equipment and experience in performing milling work. How . Only then can you be one hundred percent sure that you will receive a high-quality product, and your money will not be in vain.

We have our own production base, equipped with all the necessary modern machines for milling work in Moscow.

When may you need it?

Working on a milling machine will be useful both in industrial production and in everyday life. We have given a few examples below.

Part broke

Need a flat surface

Need a mirror surface

Need to make a set of parts

- When a part is cracked or broken;

- The new part is no longer produced or the cost of the original part is too high, or is only available to order with a long delivery time.

- If you decide to modernize or strengthen the structure of your equipment, for example, a car, motorcycle, machine tool, garden equipment, and you need a metal part or a part made of a more durable material.

- If you need to make the surface smooth;

- If a surface close to a mirror is required;

- If you have a sample, sketch or drawing and you require single or serial production.

Milling parts production

In addition to the full production of a part, a milling machine can perform milling operations to more accurately process a part obtained by laser cutting or refine grooves of complex shapes on turning parts.

To obtain precise threaded connections, we use thread milling. Unlike tapping, this method allows you to produce precise fine and deep threads.

- The maximum workpiece weight is up to 600 kg.

- The maximum dimensions of the workpiece are 500x500x800 mm.

- Processing accuracy up to 0.01 mm.

What parts can be made on milling machines?

Below are some examples of parts that can be made using milling. Modern CNC machining centers allow you to perform enormous volumes of work; almost anything can be made to order.

Board installation plate

Asterisks

Supports

Housing with supports

Lids

Plates

Press forms

Stops

Flanges

Fasteners

milling work to order

What materials is milling suitable for processing?

Products made from a wide variety of materials can be shaped using this method: wood, plastic, marble, etc. If we talk about metal milling, then most often they process in this way:

- steel

- bronze

- aluminum

- brass

- copper

What material can it be made from?

An experienced milling machine operator can make a part from almost any material. Typically the following are used:

Steel plates

Aluminum plates

Stainless steel sheets

Caprolon sheets

Brass plates

Copper plates

Bronze plates

Textolite sheets

Textolite slabs

Fluoroplastic plates

What is required of you to produce parts?

To put your product into production you need to provide us with:

- Sample part (we will make a drawing ourselves);

- Or a sketch;

- Or a drawing;

- Pay for the order (from 50 to 100%, by agreement).

Sample

Sketch

Drawing

Pay for the order

Prices for milling work from 15,000 rubles

Prices for milling are usually individual, since the production of each new part means building all production processes from scratch. Why one small part cannot be cheap is described in detail below.

Pricing Examples

| Description | Price for 1 piece | Photo |

| Housing assembly Material - D16T Works: CNC milling and metalworking Quantity in order - 30 pieces. | 21,000 rub. + VAT | |

| Coated body Material - D16T Works: CNC milling, metalworking, special. enamel + tin-bismuth Order quantity: 16 pieces. | 157,000 rub. + VAT | |

| Semi-matrix bronze Material - mash 9-4 bronze Works: CNC milling and metalworking. Order quantity: 15 pieces. | 25,000 rub. + VAT | |

| Bracket Material - D16T Works: CNC milling, metalworking, Quantity in order - 90 pieces. | 7,400 rub. + VAT | |

| Pyramid Material - D16T Works: CNC milling, metalworking, Quantity in order - 53 pieces. | 5,600 rub. + VAT | |

| Holder Material - D16T Works: CNC milling, metalworking, Quantity in order - 800 pieces. | 3,100 rub. + VAT | |

| Horseshoes Material - D16T Works: CNC milling and metalworking. Order quantity: 300 pieces. | 4,000 rub. + VAT | |

| Cube with lid Material - 12x18n10T Works: Turning, milling and metalworking Quantity in order - 20 pieces. | 9,900 rub. + VAT | |

| Stainless steel plate size 1191x710x28 mm Material - 12x18n10T after waterjet cutting Work: CNC milling (custom raw materials) Quantity in order - 11 pieces. | RUB 246,000 + VAT | |

| Radiators Material - D16T Works: CNC milling and metalworking. Order quantity: 33 pieces. | 4,500 rub. + VAT | |

| Water block fixing Material - AMg6 aluminum Works: CNC milling and metalworking. Order quantity: 390 pieces. | 1700 rub. + VAT | |

| Containers Material - AMg5 Works: CNC milling and metalworking. Order quantity: 55 pieces. | 5,300 rub. + VAT | |

| Keyboard stand Material - PA6 polyamide (supplied) Works: CNC milling and metalworking. Order quantity: 320 pieces. | 1,300 rub. + VAT | |

| Base BI-NGI Material - PVC Works: CNC milling and metalworking. Order quantity: 640 pieces. | 1,100 rub. + VAT |

Why is that? Clients often come to us who need to produce one small part. In their opinion, it should cost little money, for example 500 rubles, since they bought it or saw it in a store for that money. In a store this may indeed be the case, but they purchase their products at wholesale prices! This means that they order it in large quantities (1000 or more pieces), so the price is lower. Manufacturers who sell these parts in serial quantities (from 1,000 pieces or more) have long ago had everything set up and debugged from a production point of view!

When dealing with a small or piece order, the following situation often arises:

- As a rule, there is no drawing (there is only a broken part);

- For manufacturing you need to take all dimensions;

- Make a drawing;

- Think about what equipment and how best to do it;

- Purchase material in small quantities (suppliers do not sell in small quantities);

- Set up the machine;

- Make a part (and it may not work out the first time, since the part is unique and there is no experience in making it yet);

- And a bunch of other little things that we won’t cover here.

Therefore , it turns out that a small piece made in pieces costs more than in a store, and the main reason for this is individual and piece production! For a larger batch the price will naturally be lower.

Well, let's be completely honest, if you could buy the part you need in a store, you would do it.

If you contact us, then most likely:

- The part has been discontinued;

- It has a long delivery time from Europe;

- Do you want to modernize it;

- Made from more durable material;

- you can get it cheaper (but in piece production this is rare. However, you need to look at the specific part, since everything is individual.)

All of the above, as a rule, applies to individuals or small companies who have never encountered milling work. Large companies that are already working with us or are coming for the first time know this very well.

Based on the above, the management of the company PSK Zelmatik LLC decided that the minimum order amount in current realities is from 15,000 rubles.

Order metalworking in Moscow

We carry out the following types of work:

- Milling work in Moscow, production of parts of any complexity

- Turning work of any complexity. Diameter of parts from 3 to 1000 mm

- Electroplating of products: we do aluminum anodizing and others

Our company will be able to fulfill an order of any complexity, using the customer’s drawings and models, within a reasonable time.

The price for all types of services is lower than competitors in Moscow and the Moscow region. From us you can order parts and components for any equipment.

You can place an order in the city of Moscow at the address indicated on the website, or by filling out the order form. By calling the phone number, you will receive complete information about our services and their costs.

If you have a need for milling parts, but do not have the necessary equipment for precision metal processing and modern milling machines, you should contact our company for help. Extensive professional experience of our employees and high-precision equipment will help solve all metalworking problems. We are ready to mill parts according to drawings of any complexity, with high quality and within the stated time frame.

Standard hour cost

For an approximate understanding of the cost of milling work, the concept of standard hour has been introduced; in our company it is fixed and amounts to 1,200 rubles, but you need to clearly understand that the final cost of the part is determined by many factors. Here are some of them: volume, complexity, material, need for mandrels, required production speed and much more. Therefore, for all the usual prices there is not and cannot be.

| Kind of work | Price with VAT |

| Creating a 3D model from a drawing | from 1,000 rub. / hour |

| Technology development and tool selection | from 700 rub. / hour |

| Writing control programs | from 1,100 rub. / hour |

| Milling on universal machines | from 900 rub. / hour |

| CNC milling | from 1,200 rub. / hour |

| CNC milling for materials with hardness up to HRC 45 | from 1,400 rub. / hour |

| Urgent milling work | from 2,000 rub. / hour |

Made for our clients

In 2021, we produced more than 1,000 different parts.

The type of milling processing is also determined by the movement pattern of the cutting tool and the workpiece. Climb milling assumes that the feed of the workpiece is aligned with the direction of the cutter speed. As a result, high-quality surface treatment occurs and the cutter becomes duller more slowly. This method requires the use of a special machine. The high complexity of the method makes it mainly used at the stage of finishing the surfaces of parts.

During counter milling, the feed and direction of the cutter are oppositely directed towards each other. It is difficult to cut into the cutter; more heat is generated, which accelerates the dulling of the cutter teeth. However, the productivity of milling work using this method is high and is well suited for rough processing of workpieces.

Time to complete work

The Moscow regions, with which we mainly work, are known for their dynamic way of life, they are used to working quickly and urgently, but these concepts are not always applicable to production; even the most experienced turner or milling operator cannot work faster than a machine that has certain cutting modes.

Production time depends on many factors. The main ones:

- Complexity of the product;

- Availability of well-drawn drawings that show all dimensions!;

- Number of products;

- The workload of our production;

- Availability of necessary materials for production.

Maximum dimensions of the workpiece

| Characteristics | Maximum value |

| X-axis movement | 850 mm. |

| Y axis movement | 600 mm. |

| Z axis movement | 600 mm |

| Number of revolutions | 20,000 rpm |

| Weight Limit | 800 kg. |

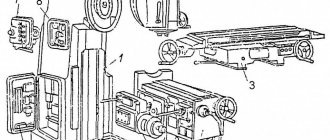

Types of milling

For the production of parts, milling with computer numerical control (CNC) is simply necessary, especially relevant in mass production. Below are images that clearly show how the cutter processes metal surfaces from different sides.

Types of milling processing:

- Milling of horizontal surfaces;

- Milling of vertical surfaces;

- Milling of inclined surfaces;

- Milling of grooves and grooves;

- Milling of shaped surfaces.

Technological stages of the process

The work of a milling machine begins with an analysis of the part and type of work. In accordance with the data obtained, the type of cutter is selected. The cutting element is securely fixed on the machine spindle. After this, the following technological steps occur:

- a metal blank is fixed to the frame;

- the spindle of the milling machine is turned on at low rotation speed;

- the part on the bed is brought to the cutter to minimal contact for checking before starting work;

- the bed moves away, the spindle is stopped;

- the necessary cutting parameters are set (depth, spindle speed);

- After turning on the machine, the workpiece is again brought under the cutter, and the processing process begins.

If we are talking about a CNC laser machine, the process can take place in two variations:

- in the designated place, the laser beam burns the required shape, after which the edge is polished;

- the laser removes layers of metal from the workpiece by passing over the same place several times.

The financial and time costs of milling metal blanks depend on the complexity of the geometry of the future part. It is also necessary to always take into account the experience of the master and the availability of the necessary equipment. Only employees who have undergone special training have access to these machines.

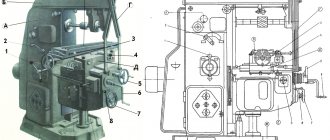

Equipment

CNC Machining Center

CNC Router Stand Vacuum Table

Machining Center Drum

Below are the CNC and universal milling machines that we use for metal processing.

| Machine name | Manufacturer | Model |

| Milling machining center VDF850 | DMTG | VDF850 |

| CNC Machining Center | FAMU Parpas | PHS - 812 |

| CNC vertical milling | Leadwell | V-30 |

| Universal milling | Visprom | fvx-125w with uds |

| Milling and engraving | Beaver | victor 9A |

| Universal milling machine | Poland | FWD-32 |

Photo, Video, Characteristics

Work examples

Below are several types of milling work that were performed in our production.

Stainless steel plate size 1191x710x28 mm, 12x18n10t

Housing assembly

Housing assembly with coating

Case base

Fixing boards

fixing horseshoe Fixing water block

Fixing corners

Keyboard stand, made of polyamide PA6 Base BI-NGI made of PVC

Panel UI-01 made of polyamide Bracket

Upper part of the case (dimensions) Plate for installing the board

Nickel plated aluminum plates

Oval plate with holes

case cover

Case insert

Plate D16AT

Stainless steel stops holder for radiator

Stainless steel sponges

Housing covers

You can view all of our metalworking work by clicking on the button below.

All our works

Nashi preimushchestva

Why choose custom milling work in our company?

Among all similar organizations, most clients choose to place an order with our company because we have the most affordable prices with the highest quality of work. The raw materials that we use to fulfill orders are purchased only from trusted suppliers and have all the documents confirming compliance with Rosstandart requirements.

Since we have been working in this field since 1993, raw materials are supplied to us at a minimum cost without markups, and accordingly, we, in turn, give good discounts to our clients. We have no restrictions on order volumes or the number of manufactured products. We carry out both small-scale orders for the production of one part, and large-scale orders for the serial production of thousands of samples.

Call and order high-quality milling work at the most affordable price in the capital. To order, call +7 (495) 723-22-74, fill out the feedback form on the website or come to us at Moscow, Batyuninsky proezd, building 6.

Assembly and delivery of finished products

In order to save the customer as much hassle as possible and provide a full range of services, PSK Zelmatik LLC can do everything on a turnkey basis, namely:

- Develop drawings;

- Make parts;

- Assemble the final product;

- Arrange for its delivery.