Widespread propane welding is the joining of metal workpieces in a weld pool formed when they are heated by a high-temperature jet of a flammable mixture of two gases.

Acetylene and oxygen are usually used as its components, with the latter acting as a catalyst that accelerates the oxidation process and forms a welding jet.

In some cases, propane is chosen as the second component of the oxygen-combustible mixture, from which the name of this method comes.

Principles and features of the process

Welding with propane begins with the fact that the flammable composition enters the torch and comes out under pressure through a special calibrated nozzle. Then the welder ignites the gas, and after it is ignited, he regulates the pressure and quality of the mixture using valves located on the body.

The very thin jet of flame emanating from the nozzle consists of a core, a recovery zone and a working torch. The highest temperature develops in the core; in this case, propane gas welding itself occurs in the gap between it and the reduction zone.

At the same time, due to the effect of high temperatures on the metal being processed, the weld pool is protected from unwanted contact with air.

The possibility of spot processing of metal with a thin jet allows the use of propane welding not only for shaped cutting of initial workpieces, but also in the manufacture of a whole range of decorative products and jewelry.

Welding using this method requires special professional skills from the performer, which can only be obtained after completing a preliminary training course and subsequent long-term practical work with propane.

Operating principle and types

Regardless of the size of the autogen and the type of heating gas mixture, cutting occurs due to the combustion of metal in a stream of pure oxygen pumped through the head nozzle into the working area.

The main and fundamental condition for gas cutting is that the combustion temperature must be less than the melting temperature. Otherwise, the metal, before it starts to burn, will melt and drain. Low-carbon steels meet this condition, but non-ferrous metals and cast iron do not.

Most alloy steels are also not amenable to gas cutting - there are restrictions on the maximum permissible doses of alloying elements, carbon and impurities, above which the process of metal combustion in oxygen becomes unstable or is completely interrupted.

The cutting process itself can be divided into two phases:

- Heating a limited area of a part to a temperature at which the metal begins to burn. And in order to obtain a torch of a heating flame, part of the technical oxygen is mixed in a certain proportion with combustible gas.

- Combustion (oxidation) of heated metal in a stream of oxygen and removal of combustion products from the cutting zone.

If we consider the classification of only hand cutters, then the following features are of fundamental importance:

- type of fuel, power and method of producing a mixture of gases for a heating flame;

- classification by type of flammable gas: acetylene, propane-butane, methane, universal, MAF.

Kerosene cutters and gas cutters, although they have the same purpose, are classified as liquid fuel cutters.

- By power: low (cutting metal with a thickness of 3 to 100 mm) - marking P1, medium (up to 200 mm) - P2, high (up to 300 mm) - P3. There are samples with increased cutting thickness - up to 500 mm.

- According to the method of producing flammable gas: injection and non-injector.

And if the first sign affects only the temperature of the heating flame, and the power affects the maximum thickness of the metal, then the third sign is determined by the design of the cutter.

Design

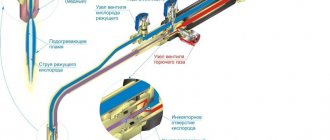

1. An injection or two-pipe gas cutter is the most common type of design. Technical oxygen in the cutter is divided into two streams.

Part of the flow through the top tube moves into the tip head and exits at high speed through the central nozzle of the inner mouthpiece. This part of the structure is responsible for the cutting phase of the process. The control valve or lever valve is located outside the housing.

The other part goes into the injector. The operating principle of which is that the injected gas (oxygen), entering the mixing chamber under high pressure and at high speed, creates a rarefaction zone there and draws in flammable (injected) gas through the peripheral holes. Thanks to mixing, the velocities are equalized, and at the exit of the chamber a flow of a mixture of gases is formed at a speed lower than that of the injected oxygen, but higher than that of the ejected combustible gas.

Next, the mixture of gases moves along the lower tube into the head of the tip, exits through the nozzles between the inner and outer mouthpiece, and forms a torch of a heating flame. Each channel has its own valve on the body, which regulates the supply of oxygen and combustible gas to the injector.

2. A non-injector or three-pipe cutter has a more complex design - both oxygen flows and gas flow to the head through separate tubes.

Mixing of the heating mixture occurs inside the head. But it is precisely the absence of a mixing chamber that provides a higher level of safety and does not create conditions for “backlash” (propagation of burning gases in the cutter channels and pipes in the opposite direction).

Welding technique

Propane welding involves the use of the following two techniques:

- high-temperature heating of the edges of the workpieces, their subsequent melting and final joining;

- formation of a working seam by surfacing or spraying.

In the second case, a special soft metal filler wire is used to ensure that the weld pool remains fully saturated.

When carrying out work operations using the first of these methods, a large amount of propane is consumed, since high temperatures are required to melt the metal edges. Therefore, preference is most often given to the second welding method, in which noticeably less energy is spent on heating the filler wire made of low-melting metals.

Both of these approaches when working with propane generally lead to the same result. However, they differ fundamentally in terms of gas mixture consumption, time spent on operation and functionality (in other words, in their efficiency).

Welding by surfacing, in addition to saving money and time, provides increased strength of the seam and looks more aesthetically pleasing. It is this technique that is used when laying and equipping main pipelines, as well as when welding various products and elements of building structures.

Propane welding

The main advantages of propane welding are its versatility both for welding metals of various thicknesses and for welding metals with different physical and chemical properties. Gas welding can produce all types of welded joints and most types of seams in various spatial positions. In this regard, propane welding is as versatile as arc welding.

Propane welding technology makes it possible to process all metals used in mechanisms. Propane welding of copper, cast iron, brass, lead, bronze, and aluminum alloys has a good effect. Propane welding is used in the manufacture and repair of products made of thin-sheet steel, repair welding of cast products and installation welding of joints of pipelines of small and medium diameters with a wall thickness of up to 5 mm and fittings for them, welding of structural units made of thin-walled pipes, when surfacing brass and bronze on parts made of steel and cast iron, surfacing of hard and wear-resistant alloys, soldering and welding of malleable and high-strength cast iron. Due to the simplicity of the equipment, independence from the power supply source, and the ability to widely regulate the rate of heating and cooling of the metal, propane welding technology is used in repair and installation work.

Advantages and disadvantages

The main advantages of any gas welding (including welding with propane and oxygen) include the following points:

- independence from a stationary or mobile source of supply current, which requires a centralized power supply for its operation. Gas welding using propane is usually used when carrying out installation work at rural sites and remote sites without a constant power supply;

- proper use of propane welding methods and compliance with all temperature conditions prescribed by regulations allows you to obtain a high-quality weld and avoid the formation of burns;

- equipment for gas welding (the cutter itself or a propane torch, supply hoses and gas cylinders placed on a trolley) are quite mobile and convenient for local movements and long-distance transportation.

The disadvantage of the method of processing metal workpieces with propane is the low productivity of installation work, the large amount of time spent on high-precision welding and the need for skills in carrying out these operations. To this should be added the increased consumption of material, as well as the danger of high-temperature conditions, covering large areas of the welding zone.

Burner device

A torch for welding with propane consists of a handle with valve devices located on it, which provide regulation of the supply of gases and mixing them in the required proportion. Gas supply hoses that comply with current standards (GOST 9356) are connected to them using special nipples.

According to this standard, each of the hoses (sleeves) is equipped with a replaceable tip with a mixing chamber, which in turn is equipped with a built-in injector.

The hose chamber indicates the type (number) of the tip and the name of the gas for which it is designed to work. The convenient and ergonomic arrangement of the valves allows you to hold the torch handle with one right hand, while performing all the necessary work operations during the welding process with the other.

The tip of a typical gas burner consists of a mouthpiece, an injector and a special supply tube. The dimensions of the holes in the mouthpiece and in the injector (more precisely, their ratio) are designed for the use of these units only for a specific type of gas (propane or oxygen).

The temperature developed in the combustion zone of propane with oxygen can reach approximately 2300 °C, and therefore the mouthpieces of these prefabricated structures are most often made of copper.

This is explained by the fact that copper materials have greater thermal conductivity (compared to brass mouthpieces, for example), and cool faster during the welding process.

Propane welding equipment

Burners for welding with propane can be divided into the following groups: with heating of the combustible mixture until it leaves the mouthpiece; conventional for oxy-acetylene welding, equipped with injectors, mixing chambers and nozzles with expanded flow sections; chamber-vortex.

Burners with heating of propane before it leaves the mouthpiece are equipped by industry on the basis of serial oxy-acetylene burners. Part of the gas (5-10%) exits through additional heater nozzles and burns, forming torches that heat the chamber made of corrosion-resistant steel. The temperature of the mixture at the outlet of the mouthpiece increases by 300-350°C and the combustion rate and temperature of the main flame increase accordingly. Propane-butane torches can weld steel up to 5 mm thick (in some cases up to 12 mm) with satisfactory performance and welding quality.

When converting torches designed to operate on acetylene to propane-butane, you should take a tip two numbers larger and screw into it a mouthpiece one number larger, and an injector one number smaller than when welding metal of the same thickness using an acetylene-oxygen mixture.