To view the video, you need a modern browser that supports HTML5 video.

Shot blasting in Moscow is an effective and affordable alternative to cleaning metal using sandblasting. Its main advantage is its higher environmental friendliness, since the sand used in sandblasting machines produces fine dust when it hits the surface. Therefore, you can only work with it while wearing a respirator. The shot not only cleans the surface better, but also does not emit harmful particles into the atmosphere.

How to shot blast metal?

For shot blasting of metal structures, both spherical and chipped shot can be used.

Solid pellets are better at removing traces of old paint and rust, but they do not cope with cleaning the polymer layer: in this case, it is better to use crushed pellets. The minimum particle diameter is 8 mm, the maximum is 15. After the shot has completed its work, it is taken to the separator of the device, where it is cleaned of dust and again enters the drum. Thus, the cleaning process is closed and continuous. The dust removed from the pellets does not enter the atmosphere, but settles on the filter. After finishing work, just rinse it.

Depending on the size of the pellets and the material from which they are made, shot blasting of metal, the price of which is very affordable, helps to achieve different effects. You can simply clean the metal surface. Or you can give it a rough, matte effect, and effectively remove scale after welding.

Sandblasting

Sandblasting of metal itself is the effect of materials endowed with varying abrasiveness on the metal surface. At the time of processing, they are endowed with high levels of kinetic energy, which is achieved due to the high pressure under which they are supplied. To ensure high temperatures, the sandblasting unit must be fueled with diesel fuel. After all, it is thanks to this that the acceleration of the process of degreasing surfaces is achieved. This helps remove impurities and debris.

Cleaning using sandblasting plays an important role in the preparation of metal products for painting. It can also be used before priming. Sandblasting is a popular service because it provides many benefits. It greatly simplifies the painting process. Also thanks to it, increased adhesion of paintwork materials to the surface is achieved. And due to this, in turn, it is possible to extend the service life of the coating, its resistance to peeling, and external threats. The price for sandblasting will be an order of magnitude lower than other cleaning processes aimed at preparing metal.

Sandblasting and shot blasting of metal

Unlike sandblasting, the service of shot blasting metal is many times more environmentally friendly.

If, after impact with metal, grains of sand scatter throughout the area, the pellets remain in the installation and can be used an unlimited number of times. This speaks to another advantage of the procedure - its cost-effectiveness. Shot blasting also benefits a lot in productivity. For comparison: if a sandblasting machine is capable of “covering” only 100 square meters of surface per shift, equipment that works with shot is three times more. All these advantages entail one more thing, which is most important for the customer - low cost.

The operating principle of installations with a conveyor belt

Drum type shot blasting machine with conveyor belt

also uses

principle

.

The shot blasting chamber is equipped with a closed drum conveyor in the form of plates, which ensures uniform cleaning of parts. Loading and unloading of products in installations of this type can be done either manually or automatically. Most often, drum-type shot blasting machines

with a belt conveyor are used where there is a need to simultaneously clean a large number of small parts.

So basically it works

There are two main components involved: a hydraulic lift, which loads the workpieces into the chamber, and the belt drum itself, where cleaning occurs. During the operation, a container made of perforated rubber band rotates, allowing products to be processed from different sides. Accordingly, shot blasting using a drum-type installation with a conveyor belt allows you to obtain high-quality cleaned products at the output.

Ads for “shot blasting” in Russia

Thus, with the help of shot blasting, the metal cleaning service turns into an easy and fun process.

Especially with modern equipment, in which the percentage of manual labor is reduced to a minimum. And if until recently not every enterprise offered such a procedure, today in almost any production you can find a shot blasting installation - from the simplest to the complex. Companies actively advertise their capabilities on the Internet, posting information on bulletin boards, social networks and personal platforms. To select a suitable offer, just type the query “shot blasting” in any search engine.

Purpose of the equipment

This equipment is designed to clean metal from rust, paint residues and other contaminants using the principle of shot throwing. This tool helps you perform the following operations:

- removes scale;

- cleans the surface from rust;

- you can create the desired roughness;

- make a matte surface;

- removes pockets of corrosion.

Using a shot blasting machine, you can extend the life of bridge supports and remove rust from structures that cannot be repaired.

Metal shot blasting in Moscow

In the capital, prices for metal shot blasting are also quite reasonable. The main consumers of the service remain the construction and engineering industries, as well as equipment repair services. The cost of processing a specific product will depend on:

- its dimensions;

- complexity of form;

- urgency of the order;

- the nature and thickness of the layer that needs to be removed;

- on the quality of processing that needs to be achieved.

On average, the cost per square meter starts from 300 rubles and can reach 450-500.

Price of services

With a sufficient number of advantages, the question arises of the cost of these services. Basically, the price depends on the area of the metal surface being processed. On average, they can charge 350–400 rubles for one square meter. This cost is not finite and depends on a number of factors, for example, the degree of contamination or processing of the material.

Shot blasting is a complex technological process. It has a number of advantages and allows for cleaning in a short time. However, it is better to trust professionals in this matter.

Shot blasting of metal: features of abrasives

We have already mentioned that the cleaning effect is determined by the type of abrasive.

Let's look at what particles the shot blasting machine works with. Cast iron shot is used not solid, but split. It removes traces of corrosion and scale well. It can also be used for aesthetic purposes - to matt the surface and create the effect of its roughness.

Steel - cast and pounded. The hardness of the pellets will depend on the characteristics of the alloy. Cast particles, especially large diameter ones, are used for shot blasting in Moscow of dimensional rolled steel and structures assembled from it. Due to their increased rigidity, crushed steel abrasives are used for deep cleaning of surfaces.

Aluminum shot cleans the surface as delicately as possible, but it cannot remove every stain or rust. It is not suitable for cleaning products made of aluminum and its alloys, as well as other soft metals.

Glass shot is made from particularly impact-resistant glass and practically does not crumble during operation. However, it can only clean metals of medium and low strength. The indisputable advantage of the material is that it itself requires minimal cleaning, since it practically does not become dirty.

Our equipment

Our plant operates a Gostol P-2000×500 through-type shot blasting machine with a power of 15 kW.

Shot blasting machine Gostol P-2000×500

Technical characteristics of the Gostol P-2000×500 shot blasting machine

| Maximum working width of steel sheets, mm | 2000 |

| Maximum working width of profiles, mm | 1200 |

| Maximum working height of profiles, mm | 500 |

| Minimum sheet thickness, mm | 6 |

| Maximum sheet thickness, mm | 60 |

| Passage speed, m/min | 0,5–2,5 |

| Turbine motor power, kW | 15 |

| Number of turbines | 6 |

| Turbine diameter, mm | 380 |

Equipment for shot blasting metal

The simplest equipment for shot blasting metal structures is considered to be a device powered by an electric compressor.

The treatment is carried out manually, in special suits and with the mandatory use of devices that protect the respiratory system from particles of dirt, paint and rust that fly off the metal. Automatic cameras are also used to clean rolled products. These devices operate on the principle of a conveyor and allow processing large volumes of rolled products. They can be stationary or portable.

The shot blasting unit is considered the largest, but also has many advantages. This is an isolated type design, all processes in which occur in a closed mode. Human participation comes down to changing parameters: for example, the speed of shot spraying.

Process Features

Shot blasting is a mechanical method of processing metal surfaces using metal particles. Special equipment accelerates the shot to enormous speeds (100 m/s) and delivers it to the working surface through a shot blasting nozzle. In this way, the excess layer is removed from the metal. Its depth depends on the size of the abrasive particles and the power of the equipment.

Shot blasting involves the use of an abrasive material (shot). There are several types of abrasive particles that are suitable for different types of metals and alloys:

- Glass is the most economical type of shot that does not contaminate the surface being processed.

- Electrocorundum is the most expensive and effective type of abrasive material. Used to clean serious stains.

- Ceramic is a rarely used material for making shot. Used for final cleaning of metal surfaces.

- Plastic - this abrasive is used to clean glossy parts. Does not leave marks on the material.

- Cast iron - with this shot metal surfaces are cleaned of rust, plaque, and scale. This abrasive material is made from white cast iron.

- Aluminum is a type of abrasive material for shot blasting. Used for cleaning soft alloys.

- Steel - after processing metal surfaces with this type of shot, not only the layer of dirt, plaque, and rust is removed, but also the characteristics of the material are improved.

When working with high-hardness materials, you need to choose an abrasive that is not inferior in strength to the surface being processed.

Equipment used for processing, metal cleaning

There are 2 options for impacting metal: through a manual mechanism and a shot blasting chamber. Each of them has its own specific functioning:

- Manual units make it possible to process parts in places with the most difficult access: in ship hulls, on bridges and on many other structures with impressive dimensions. Modern mobile models are equipped with special vacuum cleaners designed to suck in shot particles for cleaning and recycling.

- Shot blasting chambers are most often fully automated, which has a positive effect on their productivity (up to 200 m2). Such equipment is used for industrial processing of products of the same type.

5Conclusions

The results of surface treatment by two methods will be almost the same - high quality and effective.

However, shot blasting and shot blasting differ from each other:

- The principle of operation and the supply of abrasive material to the surface to be cleaned (compressed air under high pressure - shot blasting; mechanical supply of shot by turbine - shot blasting).

- Design differences between shot blasters and shot blasters.

- Type of products to be cleaned (large-sized, complex configurations - shot blasting machines; rolled metal, castings, blanks, pipes - shot blasters).

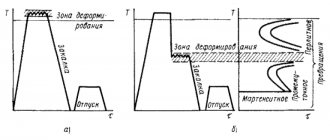

Rice. 1. Quality of surfaces cleaned using shot blasting or shot blasting units: