When do knives need to be sharpened?

However, sooner or later, home hairdressers are faced with a serious problem when the blades of hair clippers become so dull that it becomes simply impossible to do a normal hairstyle. There are two ways to solve this problem. Buy a new machine or try sharpening the blades yourself. The second option looks preferable, since there are at least four effective methods that allow you to sharpen any cutting surface yourself.

Modern trimmers are equipped with steel or ceramic knives, the cutting part of which is often coated with a protective layer of diamond, titanium or carbon coating. However, even such durable blades lose their sharpness with frequent use, which leads to the following problems:

- straightening your hair becomes very difficult;

- while cutting, the cutting part of the device begins to tug and wrinkle the hair, causing unpleasant pain;

- At the end of the procedure, the skin on the head is severely irritated, up to small cuts.

There are several ways to fix this problem, but they all start with disassembling the machine:

- disconnect the knife block from the body;

- unscrew the screws;

- separate the blades;

- We clean the cutting and working parts from dirt and hair residues using a special brush or a clean rag soaked in water.

Attention!!!

The process of disassembling the trimmer should be filmed on a mobile phone camera so that when assembling this household unit there are no “extra” parts left. After disassembling the cutting unit and cleaning the blades - a process that should be done after every haircut - you can move on to one of four effective types of sharpening.

When do you need to sharpen hair clipper blades?

There are several signs that indicate that knives need sharpening:

- It is very difficult to draw a hairline. It comes out in uneven pieces

- The hairs do not get cut, but become wrinkled or crumpled

- There is pain, the hair is not cut, but pulled out

- There may be irritation and even cuts on the head. This especially happens to those who cut their hair to zero

All these signs indicate that it is necessary to disassemble the machine, clean it, and also sharpen the knives.

Sharp knives

Using a grinder

This method requires increased caution, as well as the presence of stationary or manual grinding equipment:

- We press the removed and cleaned knives with the cutting part to the grinding wheel;

- turn on the machine;

- sharpen the blades to a mirror shine;

- clean the knives (it is better to rinse) from abrasive materials;

- We assemble the cutting unit and install it on the machine.

Disadvantages: labor-intensive process, expensive equipment and not the highest quality.

Methods

You can sharpen your hair clipper yourself in different ways. On models with self-sharpening blades, it is enough to clean all surfaces of dirt and hair, and the operation of the machine will improve.

Professional kit

A professional kit is an electrical mechanism hidden under the body. On top there is an aluminum circle, the size of which corresponds to the length of the cutting edge. In addition to the equipment, you must have:

- cleaning gel;

- abrasive powder;

- disc oil;

- magnetic holder.

The hair clipper is disassembled, the knives are removed and cleaned. Then they begin to prepare the machine:

- Clean the surface of the disc from dust and abrasive residues.

- Lubricate the surface of the aluminum circle with oil.

- Apply special abrasive powder evenly to the disc.

- Secure the blade in the magnetic holder.

- Turn on the machine.

- Slowly bring the blade towards the circle and press it against the rotating surface.

- Move the part to be sharpened from the edges of the disk to the middle.

- After 90–120 seconds, raise the blade. Turn off the machine.

The surface of the part being sharpened should acquire a steel shine. This means that the dark oxidized layer has been removed. If dull and gray spots remain, the operation must be repeated. The second blade is processed similarly.

On a grinding machine

A knife is attached to the magnetic table. It is set strictly in a horizontal plane with the surface being processed upward. Turning:

- A polishing wheel is installed on the shaft. When stationary, it is brought to the surface of the part with a gap of 0.5–1 mm. Moved to the side.

- The machine turns on.

- The circle is slowly lowered until it touches the surface of the blade.

- The touch marks are used to check the correct installation of the part to be sharpened. The situation is being corrected.

- Several passes are made with the circle fed downwards.

- Sharpening is completed with several passes of the wheel without vertical feed.

Sharpening the clipper knives is done one at a time. The dimensions of the magnetic table allow you to install several knives, but they have different shapes and sizes. It is impossible to place them in the same plane.

On a lathe

Preparing the lathe begins with rearranging the chuck jaws. They should be installed in the opposite direction in order to clamp the disk - an abrasive wheel - instead of the part. Treatment:

- Turn on the machine and check the end for runout. Set the spindle rotation to 1000–1200 revolutions.

- Bring the knife fixed in the magnetic holder to the edge of the circle.

- Move the sharpened part to the center and back.

- Check the sharpness of the blade.

The disadvantage of sharpening on a lathe is the increased danger of the work. Your hand may get caught in the chuck or be damaged by the jaws.

Block and sandpaper

The method of sharpening hair clipper knives on a sharpening stone with sandpaper does not require the use of additional equipment and is suitable for sharpening the cutting edge of a hairdresser's working tool.

Fine-grit sandpaper is secured to a wooden block. It should be well stretched along the upper plane. The knife is moved along the surface, along the block, until a shiny polished surface is formed.

The sharpening quality is worse than on a professional machine. The costs of preparation and equipment are minimal. Necessary items are always at hand.

Knife sharpening stone

The blades that work in a hair clipper are sharpened on a whetstone that is used to straighten the blades of kitchen tools. The process is similar to restoring a cutting edge with sandpaper. Bar requirement:

- fine grain;

- the thickness is greater than the blade size.

For home restoration of parts, you should take a wide block. The knife should lie completely on its surface.

On an emery machine

A platform is placed under the sandpaper belt rotating on rollers. It serves as a support for paper and the knife being sharpened.

The blade is secured in the holder and pressed against the sandpaper. The direction of the teeth is against the movement of the abrasive belt.

The operation lasts about a minute. The quality of sharpening is inferior to machine-made.

Using a whetstone

With this method, you need a double-sided block, one side of which is intended for direct sharpening, and the other for final finishing:

- Place the whetstone on a flat surface with the “rough” side up;

- secure the blade using a magnetic holder;

- smoothly and without much pressure we move the cutting part of the knife at an angle of 30 to 45 degrees (depending on the manufacturer) from one edge to the other of the block at least seven times;

- turn the block over with the fine-grained side up;

- We carry out the final finishing of the blades to a mirror shine;

- thoroughly wash, dry and install the lubricated knives on the machine.

Disadvantages: a rather labor-intensive process and not an ideal result. However, this method is more effective than sharpening on a grinding machine.

When is sharpening necessary?

Manufacturers may recommend sharpening frequency based on average data. This is influenced by several factors:

- tool use activity;

- hair stiffness;

- cleanliness of the head.

It is easier for a master to work with wet hair. The machine becomes clogged with dust from moisture and the metal parts become corroded.

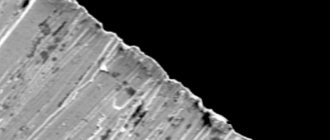

The first sign of decreased blade sharpness is a deterioration in the hair cutting process. The hairdresser has to go over one area 2-3 times. The engine begins to hum louder. The client complains that the machine is pulling his hair.

On a professional machine

This option is more suitable for hairdressers whose working tools require regular – at least 4 times a year – and high-precision sharpening. At the same time, the high quality of this process can only be ensured by a special machine, which significantly reduces the time for this procedure.

The algorithm of actions in this case looks like this:

- remove the knives from the trimmer;

- cover the sanding disc, cleaned of dust and dirt, with an even layer of abrasive paste;

- fix the knife on the magnetic holder with the cutting edge down;

- we start the machine at a certain speed (indicated in the instructions);

- We bring the knife to the wheel and begin the sharpening process, using smooth movements of the blade, the teeth of which should be directed against the movement of the grinding disc, from the edge to the central part.

The main disadvantage of this method is the high cost of a professional machine and consumables.

Sharpening machine knives on a machine

If this does not work, then you can sharpen it using special devices. It is a metal disk that is mounted on a small rotating motor. It is made of aluminum.

Instructions:

- An abrasive is applied to the surface of this disk, most often it is GOI paste or another substance that has a high degree of polishing. Next, the knives are secured with a magnet and sharpened for several minutes on each side.

- After this, the polishing paste is removed. To do this, you can use a regular brush or soft flannel. Please note that after sharpening the knives become quite sharp, beware of cuts.

Of course, it is best to carry out sharpening in a special workshop, which is carried out by professionals. They have special equipment in their arsenal that will help make your blade perfectly smooth and very sharp. Usually, in such conditions, machines with special abrasive pastes or laser equipment are also used, with the help of which skates are sharpened and sharp knives are obtained.

Sharpening on a machine

Adjustment

Each of these four options for sharpening hair clipper blades is available at home. However, even perfectly sharpened blades will not work correctly if they were installed without adjustment when assembling the cutting part:

- the serrated edge of the upper blade should be shifted 1-2 millimeters horizontally relative to the serrated edge of the lower knife;

- the cutting part of the first tooth of the moving knife in the longitudinal plane is in line with the serrated edge of the stationary blade.

The service life of a modern trimmer can really be significantly extended. To do this, you need very little - remove, remove dirt and lubricate the blades after each haircut, and also master simple techniques for sharpening and adjusting knives.

Blade lubrication

Immediately after sharpening, knives should be lubricated with oil. You can use both professional (sold in hairdressing stores) and regular silicone grease for electrical appliances. Do not lubricate knives with sunflower, olive or other edible oils. If you do not have a suitable lubricant at hand, it is better to abandon the treatment altogether, postponing it for later.

Popular manufacturers of clippers (for example, Moser or Oster) also produce oils for lubricating knives

To apply oil, prepare a container with a narrow spout (professional products are sold in such packages) or a syringe with a needle.

Lubrication of knives is carried out as follows:

- Remove the blade block and extend the blade.

- Using a brush, clean the knife block from dirt (hairs or dust after sharpening).

- Wipe the knives with a soft, dry cloth (for example, microfiber or glasses).

- Apply 3-4 drops of oil to the surface of the blades, as well as two drops on each side of the base of the knife block.

- Insert the blade block back into the machine.

- Turn on the machine for half a minute. The oil will be evenly distributed over the surface of the blades.

Lubrication is best done regularly, every two to three haircuts. This way the machine will serve you for a very long time - the oil protects the knives from rapid dulling, overheating and contamination.

Prices for sharpening knives for animal grooming

We strive to make our service as convenient and profitable for you as possible, so the cost of the services of our workshop specialists, we are sure, will seem very low to you. High-quality sharpening will give a second life to the tool, simplify your work and save money (after all, the purchase of new knives can be postponed for some time). Sharpening prices are shown in the price list.

Block of knives for grooming cats/dogs

Sheep/horse shearing knife block

We are always glad to see you among our clients! We are waiting for you in our Blade workshop!

Instrument care

The dog clipper does not require special care. It is enough to follow a few simple rules: every five haircuts you should clean the tool with a special brush, but only after the machine has cooled down. After cleaning is completed, the moving parts must be lubricated. To prevent the blades from becoming clogged with dirt and dust, only clip animals that have been washed.

If you follow these simple rules, a dog clipper will help keep your pet in proper shape for a long time.

Properly preparing for sharpening

First of all, you need to prepare the equipment that will be needed for sharpening. In general, the set of tools depends on the sharpening method. You may need:

- professional sharpening set;

- sandpaper;

- grinding stone;

- cloth or paper napkin;

- water;

- silicone grease, immersion or machine oil (in no case vegetable oil);

- durable glass or mirror as a base.

Is it possible to sharpen knives yourself?

The main element of a cutting machine is the knives. Their sharpening should be sharp so as not to cause discomfort to the animal. To keep knives sharp, they should be replaced or sharpened in a timely manner.

It is impossible to sharpen knives efficiently on your own, since they have a complex shape and can become unusable if not professionally sharpened. To give them the necessary spiciness, special equipment and experience are required. Therefore, it is better to entrust this matter to specialists, especially since such a service will cost you very little.

Is it possible to sharpen knives on sheep and dog clippers yourself?

Conventional clippers are not suitable for cutting the wool of sheep and dogs. This is due to the fact that their fur is coarser than human hair. Animals are cut with devices of a different design. Therefore, the question may arise about the possibility of sharpening knife blades from such devices yourself at home. This problem is especially relevant for owners of flocks and a number of dog breeds. In such cases, there is a lot of work involved in cutting hair, and each time buying new blades or contacting specialists is associated with costs and is simply inconvenient.

You can sharpen the cutting parts of the device yourself using the equipment discussed above. At the same time, there should be a fine abrasive on the grinding machine, emery block, sandpaper.

It is not recommended to make various sharpening devices yourself, because they require great precision in assembling the structure in order to obtain a result of suitable quality.

The process of sharpening knife blades for grooming animals is practically no different from sharpening the blades of clippers intended for people. Some difficulties may arise with the different shape of the cutting parts. The quality of work will depend directly on personal skills.

Tips for using the tool

Each device requires proper operation and maintenance in order to function well. The clipper is no exception to the rule. The following recommendations will help extend its service life without repairs:

- The device should only be used for its intended purpose;

- Excessive mechanical impacts on cutting parts should be avoided;

- You should regularly apply lubricant to working units, and it is better to use light oil rather than dark oil;

- after sharpening, it is necessary to thoroughly clean the blades from any remaining abrasive;

- cutting wet hair accelerates the loss of sharpness of blades;

- After cutting, you should remove any remaining hair on the cutting edge;

- the machine must be kept in dry conditions;

- When sharpening, you cannot skimp on the quality of the abrasive, because the final result will depend on it.

When grooming animals, an important point is the cleanliness of their fur. If it is dirty, the device will quickly become dull. When working with animals, you should clean the blades every 5 haircuts, removing them and rinsing them from dirt and grease, only then lubricating them with oil.

It is relatively easy to sharpen knives from a Philips machine and other models with your own hands. It is important to take precautions at all times to avoid injury. If you need to constantly sharpen cutting blades, it is better to purchase a professional kit, and one-time work can be easily done using a sharpening stone or sandpaper. It may not be possible to achieve high quality sharpening, but useful experience will definitely appear, and next time the result will be better.