Prices for steeply curved steel bends according to GOST 17375-2001 welded

| Name | Price with VAT |

| 1 performance | |

| 15(21,3×2,0) | 17.38 rub. |

| 15(21,3×3,2) | 17r. |

| 20(26,9×2,0) | 21.16 rub. |

| 20(26,9×3,2) | 38.6 rub. |

| 25(33,7×2,3) | 29.81 rub. |

| 32(42,4×2,6) | 48.88 rub. |

| 32×2,0 | 37.68 rub. |

| 38×3,0 | 37.04 rub. |

| 40(48,3×2,6) | 60.41 rub. |

| 40(48,3×3,6) | 86.56 rub. |

| 45×2,5 | 50.5 rub. |

| 45×3,0 | 56.5 rub. |

| 50(60,3×2,9) | 74.62 rub. |

| 57×3,0 | 51.27 rub. |

| 76×3,5 | 92.68 rub. |

| 89× 3,5 | 138.25 rub. |

| 89×8,0 | 487 rub. |

| 108×3,5 | 190.74 rub. |

| 114×3,5 | RUB 219.92 |

| 133×3,5 | 338.32 rub. |

| 159×4,5 | 568.64 rub. |

| 219×5,0 | RUB 1,428 |

| 219×6,0 | RUB 1,602.44 |

| Seamless | |

| 57×3,0 | 76.58 rub. |

| 57×3,5 | 81.29 rub. |

| 57×5,0 | 130 rub. |

| 57×6,0 | 154.6 rub. |

| 76×3,5 | 149.1 rub. |

| 76×5,0 | 156 rub. |

| 76×6,0 | 233.96 rub. |

| 89×3,5 | 202.52 rub. |

| 89×6,0 | RUB 316.96 |

| 108×4,0 | 325.01 rub. |

| 108×6,0 | 451.18 rub. |

| 114×4,0 | RUB 309.88 |

| 133×4,0 | 468.81 rub. |

| 133×6,0 | 761.5 rub. |

| 159×4,5 | 721 rub. |

| 159×6,0 | 976.08 rub. |

| 219×6,0 | RUB 1,749 |

| 219×8,0 | RUB 2,601.82 |

| 219×10,0 | RUR 3,571 |

| 273×7,0 | RUB 3,536.19 |

| 325×8,0 | 4,771 rub. |

| 325×10,0 | RUB 6,771 |

| 377×8,0 | 6,601 rub. |

| 377×9,0 | RUR 7,451 |

| 426×8,0 | 8,651 rub. |

| 530×10,0 | RUB 16,981 |

| 720×10,0 | RUB 36,901 |

Construction length of the bend

Construction length is a concept often used in construction. However, there is no explanation of this concept in official documents (GOST, SNIP, etc.). In this case, the concept applied in life is accepted. For example, according to Efremov T.F. “Explanatory Dictionary of the Russian Language,” length is: a) The extent of a line, plane, body, etc. in the direction in which its two extreme points are farthest from each other. b) Extent, the distance between the ends of something. According to Wikipedia [1], length is a physical quantity, a numerical characteristic of the length of lines. In a narrow sense, length is understood as the linear size of an object in the longitudinal direction. Other concepts of “Length” can be found in [2, 3].

In construction, the term "length" is usually used as a synonym for "distance". The following concepts of “construction length” are often used: * Length (in relation to heat-insulating materials): the largest linear dimension of the front face of the sample being measured [4]. * Construction length (in relation to pipeline fittings): the linear size of the fittings between the outer end planes of its connecting parts [5]. * Construction length (in relation to a cable product): the standardized length of a cable product in one section [6].

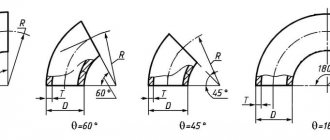

Let's consider the concept of length, construction length in relation to pipeline products. From [5] it follows that this is the linear dimension between the outer end planes of its connecting parts* (see Fig. 1).

Figure 1. Bends: 90°, 60°, 45° and 180°

Let's look at the construction length in examples. So for a 90° bend the distance will be 2F = 2R, F. 1 for a 60° bend the length will be 2W, for a 45° bend the distance will be 2H, and for a 180° bend the length will be 2B+C.

However, to calculate the volume of thermal insulation materials and the coverage area, other calculations are used that take into account the actual dimensions of the parts and the volume (area) of the insulation. To calculate the length of the bend, the formula for the expanded length of the bend L was used:

F. 2

where R is the radius of curvature of the center line (bending radius) of the bends. Radius R is specified in GOST, TU and is usually approximately equal to 1D or 1.5D; θ – angle (in degrees) between the planes of the ends (bending angle) of the bends.

Using the link you can download a file with the calculated lengths of the bends - construction and expanded length of the bends Construction lengths of the bend - 05/18/2020 The length of the bends is used: * when calculating the length of the pipeline, when the construction length of the bend is added to the length of the pipe; * when calculating the volume of thermal insulation and coverage area, the expanded length of the bend is inserted into the Single pipe calculator to calculate the section of the pipeline with the bend.

Calculation of the volume of thermal insulation and the coverage area of a bend can also be done in the Bends calculator. This calculator uses averaged tap values for calculations.

“Estimate Consulting” 01/10/2018, 03/19/2018, 03/25/2018 04/18/2018 05/15/2020

Source

Dimensions of bends according to GOST 17375-2001

| Branch size (mm) DнхS | Conditional pressure Ru (MPa) transported substances | Du | R (mm) | Construction length L (mm) | Bend angle, degrees | Weight of outlet no more than (kg) | ||

| non-aggressive. | medium aggressive. | steam, hot water | ||||||

| 45×2,5 | 10,0 | 2,5 | 10,0 | 40 | 60 | 25 | 45º | 0,2 |

| 35 | 60º | 0,2 | ||||||

| 60 | 90º | 0,3 | ||||||

| 45×4,0 | 10,0 | 10,0 | 10,0 | 40 | 60 | 25 | 45º | 0,3 |

| 35 | 60º | 0,3 | ||||||

| 60 | 90º | 0,5 | ||||||

| 57×3,0 | 10,0 | 4,0 | 10,0 | 50 | 75 | 30 | 45º | 0,3 |

| 43 | 60º | 0,3 | ||||||

| 75 | 90º | 0,5 | ||||||

| 57×5,0 | 10,0 | 10,0 | 10,0 | 50 | 75 | 30 | 45º | 0,4 |

| 43 | 60º | 0,5 | ||||||

| 75 | 90º | 0,8 | ||||||

| 76×3,5 | 10,0 | 4,0 | 10,0 | 65 | 100 | 41 | 45º | 0,5 |

| 57 | 60º | 0,7 | ||||||

| 100 | 90º | 1,0 | ||||||

| 76×6,0 | 10,0 | 10,0 | 10,0 | 65 | 100 | 41 | 45º | 0,9 |

| 57 | 60º | 1,1 | ||||||

| 100 | 90º | 1,7 | ||||||

| 89×3,5 | 10,0 | 4,0 | 6,3 | 80 | 120 | 50 | 45º | 0,7 |

| 69 | 60º | 0,9 | ||||||

| 120 | 90º | 1,4 | ||||||

| 89×6,0 | 10,0 | 10,0 | 10,0 | 80 | 120 | 50 | 45º | 1,2 |

| 69 | 60º | 1,6 | ||||||

| 120 | 90º | 2,4 | ||||||

| 108×4,0 | 10,0 | 4,0 | 6,3 | 100 | 150 | 62 | 45º | 1,3 |

| 87 | 60º | 1,7 | ||||||

| 150 | 90º | 2,5 | ||||||

| 108×6,0 | 10,0 | 10,0 | 10,0 | 100 | 150 | 62 | 45º | 1,9 |

| 87 | 60º | 2,5 | ||||||

| 150 | 90º | 3,8 | ||||||

| 108×8,0 | 10,0 | 10,0 | 10,0 | 100 | 150 | 62 | 45º | 2,4 |

| 87 | 60º | 3,1 | ||||||

| 150 | 90º | 4,7 | ||||||

| 114×6,0 | 10,0 | 10,0 | 10,0 | 100 | 150 | 62 | 45º | 1,9 |

| 87 | 60º | 2,5 | ||||||

| 150 | 90º | 3,8 | ||||||

| 133×4,0 | 6,3 | 4,0 | 4,0 | 125 | 190 | 79 | 45º | 1,9 |

| 110 | 60º | 2,5 | ||||||

| 190 | 90º | 3,8 | ||||||

| 133×5,0 | 10 | 4 | 6,3 | 125 | 190 | 79 | 45º | 2,4 |

| 110 | 60º | 3,2 | ||||||

| 190 | 90º | 4,8 | ||||||

| 133×6,0 | 10,0 | 6,3 | 8,0 | 125 | 190 | 79 | 45º | 2,9 |

| 110 | 60º | 3,9 | ||||||

| 190 | 90º | 5,8 | ||||||

| 133×8,0 | 10,0 | 10,0 | 10,0 | 125 | 190 | 79 | 45º | 4,1 |

| 110 | 60º | 5,5 | ||||||

| 190 | 90º | 8,2 | ||||||

| 133×10,0 | 10,0 | 10,0 | 10,0 | 125 | 190 | 79 | 45º | 5,2 |

| 110 | 60º | 6,9 | ||||||

| 190 | 90º | 10,3 | ||||||

| 159×4,5 | 6,3 | 4,0 | 4,0 | 150 | 225 | 93 | 45º | 3,1 |

| 130 | 60º | 4,1 | ||||||

| 225 | 90º | 6,1 | ||||||

| 159×5,0 | 6,3 | 4,0 | 4,0 | 150 | 225 | 93 | 45º | 3,5 |

| 130 | 60º | 4,7 | ||||||

| 225 | 90º | 7,0 | ||||||

| 159×6,0 | 10,0 | 6,3 | 6,3 | 150 | 225 | 93 | 45º | 4,2 |

| 130 | 60º | 5,6 | ||||||

| 225 | 90º | 8,4 | ||||||

| 159×8,0 | 10,0 | 10,0 | 10,0 | 150 | 225 | 93 | 45º | 5,3 |

| 130 | 60º | 7,0 | ||||||

| 225 | 90º | 10,5 | ||||||

| 159×10,0 | 10,0 | 10,0 | 10,0 | 150 | 225 | 93 | 45º | 6,6 |

| 130 | 60º | 8,7 | ||||||

| 168×6,0 | 10,0 | 6,3 | 6,3 | 150 | 225 | 93 | 45º | 4,9 |

| 130 | 60º | 6,5 | ||||||

| 225 | 90º | 9,7 | ||||||

| 168×8,0 | 10,0 | 10,0 | 10,0 | 150 | 225 | 93 | 45º | 6,7 |

| 130 | 60º | 8,9 | ||||||

| 225 | 90º | 13,3 | ||||||

| 219×6,0 | 6,3 | 4,0 | 4,0 | 200 | 300 | 124 | 45º | 7,5 |

| 173 | 60º | 10,0 | ||||||

| 300 | 90º | 14,9 | ||||||

| 219×8,0 | 10,0 | 6,3 | 6,3 | 200 | 300 | 124 | 45º | 10,0 |

| 173 | 60º | 13,3 | ||||||

| 300 | 90º | 19,9 | ||||||

| 219×10,0 | 10,0 | 10,0 | 10,0 | 200 | 300 | 124 | 45º | 12,7 |

| 173 | 60º | 16,9 | ||||||

| 300 | 90º | 25,3 | ||||||

| 219×12,0 | 10,0 | 10,0 | 10,0 | 200 | 300 | 124 | 45º | 14,5 |

| 173 | 60º | 19,3 | ||||||

| 300 | 90º | 28,9 | ||||||

| 273×8,0 | 6,3 | 4,0 | 4,0 | 250 | 375 | 155 | 45º | 15,4 |

| 217 | 60º | 20,5 | ||||||

| 375 | 90º | 30,8 | ||||||

| 273×10,0 | 10,0 | 6,3 | 6,3 | 250 | 375 | 155 | 45º | 19,7 |

| 217 | 60º | 26,3 | ||||||

| 375 | 90º | 39,4 | ||||||

| 273×12,0 | 10,0 | 10,0 | 10,0 | 250 | 375 | 155 | 45º | 23,4 |

| 217 | 60º | 31,1 | ||||||

| 375 | 90º | 46,7 | ||||||

| 273×16,0 | 10,0 | 10,0 | 10,0 | 250 | 375 | 155 | 45º | 31,0 |

| 217 | 60º | 41,3 | ||||||

| 375 | 90º | 62,0 | ||||||

| 325×8,0 | 6,3 | 4,0 | 4,0 | 300 | 450 | 186 | 45º | 22,0 |

| 260 | 60º | 29,3 | ||||||

| 450 | 90º | 43,9 | ||||||

| 325×10,0 | 8,0 | 6,3 | 6,3 | 300 | 450 | 186 | 45º | 27,5 |

| 260 | 60º | 36,6 | ||||||

| 450 | 90º | 54,9 | ||||||

| 325×12,0 | 10,0 | 8,0 | 8,0 | 300 | 450 | 186 | 45º | 33,0 |

| 260 | 60º | 48,9 | ||||||

| 450 | 90º | 65,9 | ||||||

| 325×14,0 | 10,0 | 8,0 | 8,0 | 300 | 450 | 186 | 45º | 38,5 |

| 260 | 60º | 51,3 | ||||||

| 450 | 90º | 76,9 | ||||||

| 325×16,0 | 10,0 | 10,0 | 10,0 | 300 | 450 | 186 | 45º | 43,7 |

| 260 | 60º | 58,2 | ||||||

| 450 | 90º | 87,3 | ||||||

| 377×9,0 | 4,0 | 2,5 | 2,5 | 350 | 525 | 217 | 45º | 33,6 |

| 303 | 60º | 44,8 | ||||||

| 525 | 90º | 67,2 | ||||||

| 377×10,0 | 6,3 | 4,0 | 4,0 | 350 | 525 | 217 | 45º | 37,3 |

| 303 | 60º | 49,7 | ||||||

| 525 | 90º | 74,6 | ||||||

| 377×12,0 | 8,0 | 6,3 | 6,3 | 350 | 525 | 217 | 45º | 44,5 |

| 303 | 60º | 59,3 | ||||||

| 525 | 90º | 89,0 | ||||||

| 377×16 | 10,0 | 10,0 | 8,0 | 350 | 525 | 217 | 45º | 58,8 |

| 303 | 60º | 78,3 | ||||||

| 525 | 90º | 117,5 | ||||||

| 426×9,0 | 4,0 | 2,5 | 2,5 | 400 | 600 | 248 | 45º | 54,5 |

| 346 | 60º | 72,7 | ||||||

| 600 | 90º | 109,0 | ||||||

| 426×10,0 | 6,3 | 4,0 | 4,0 | 400 | 600 | 248 | 45º | 60,5 |

| 346 | 60º | 80,7 | ||||||

| 600 | 90º | 121,0 | ||||||

| 426×12,0 | 8,0 | 6,3 | 6,3 | 400 | 600 | 248 | 45º | 72,6 |

| 346 | 60º | 96,8 | ||||||

| 600 | 90º | 145,2 | ||||||

| 426×14,0 | 8,0 | 6,3 | 6,3 | 400 | 600 | 246 | 45º | 84,7 |

| 346 | 60º | 112,9 | ||||||

| 600 | 90º | 169,4 | ||||||

| 426×16,0 | 10,0 | 8,0 | 8,0 | 400 | 600 | 248 | 45º | 86,8 |

| 346 | 60º | 115,7 | ||||||

| 300 | 90º | 173,5 | ||||||

| 530×9,0 | 2,5 | 1,6 | 1,6 | 500 | 500 | 207 | 45º | 54,0 |

| 289 | 60º | 72,0 | ||||||

| 500 | 90º | 108,0 | ||||||

| 530×10,0 | 4,0 | 2,5 | 2,5 | 500 | 500 | 207 | 45º | 60,0 |

| 289 | 60º | 80,0 | ||||||

| 500 | 90º | 120,0 | ||||||

| 530×12,0 | 4,0 | 4,0 | 4,0 | 500 | 500 | 207 | 45º | 65,0 |

| 289 | 60º | 86,7 | ||||||

| 500 | 90º | 130,0 | ||||||

| 530×14,0 | 4,0 | 4,0 | 4,0 | 500 | 500 | 207 | 45º | 75,9 |

| 289 | 60º | 101,2 | ||||||

| 500 | 90º | 151,7 | ||||||

| 530×16,0 | 6,3 | 4,0 | 4,0 | 500 | 500 | 207 | 45º | 86,7 |

| 289 | 60º | 115,5 | ||||||

| 500 | 90º | 173,3 | ||||||

Steeply curved bends GOST 17375-2001, GOST 30753-2001

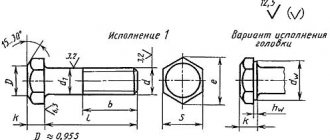

Steeply curved, seamless bends are manufactured by stamping or drawing along a horn-shaped core. Such steel bends have a small radius of curvature (1-1.5 nominal diameters) as a result of which they have low weight and dimensions. Steeply curved bends are manufactured at angles of 30, 45, 60, 90, as well as 180 degrees (kalachi). In the figure below, you can see how steeply curved seamless bends :

Steeply curved steel bends, seamless:

Seamless seamless bends are manufactured in accordance with GOST 17375-2001 and GOST 30753-2001 and come in the first and second versions. Bends in accordance with GOST 17375-2001 have a radius of curvature equal to 1.5 of the nominal diameter, and bends in accordance with GOST 30753-2001 have a radius of curvature equal to the nominal diameter. Bends manufactured in accordance with GOST 17375-01 and GOST 30753-01 can withstand pressure up to 16 MPa, due to the fact that they do not have a single weld, therefore, if high pressure is expected in the pipeline being installed, then seamless bends are used for this pipeline in accordance with GOST 17375 -01 or GOST 30753-01. The tables below indicate all types of steeply curved bends of the first and second design according to GOST 17375-2001 and GOST 30753-2001 supplied by our company, as well as all the characteristics of these bends:

Bends according to GOST 17375-01:

Version 1:

| DN | D | T | F = R | H | WITH | IN | Weight, kg, 1 bend 90° | |||||

| 15 | 21,3 | 2/3,2/4 | 28 | 14 | 56 | 38 | 0,04 | 0,06 | 0,07 | |||

| 20 | 26,9 | 2/3,2/4 | 29 | 14 | 58 | 43 | 0,06 | 0,08 | 0,10 | |||

| 25 | 33,7 | 2,3/3,2/4,5 | 38 | 18 | 76 | 56 | 0,11 | 0,16 | 0,19 | |||

| 32 | 42,4 | 2,6/3,6/5 | 48 | 23 | 96 | 69 | 0,19 | 0,26 | 0,35 | |||

| 40 | 48,3 | 2,6/3,6/5 | 57 | 29 | 114 | 82 | 0,26 | 0,36 | 0,47 | |||

| 50 | 60,3 | 2,9/4/5,6 | 76 | 35 | 152 | 106 | 0,50 | 0,67 | 0,89 | |||

| 65 | 76,1 | 2,9/5/7,1 | 95 | 44 | 190 | 133 | 0,79 | 1,50 | 1,80 | |||

| 80 | 88,9 | 3,2/5,6/8 | 114 | 51 | 228 | 159 | 1,20 | 2,10 | 2,80 | |||

| 100 | 114,3 | 3,6/6,3/8,8 | 152 | 64 | 304 | 210 | 2,40 | 4 | 5,40 | |||

| 125 | 139,7 | 4,0/6,3/10 | 190 | 79 | 380 | 260 | 4,00 | 6,20 | 9,60 | |||

| 150 | 168,3 | 4,5/7,1/11 | 229 | 95 | 457 | 313 | 6,50 | 10 | 15 | |||

| 200 | 219,1 | 6,3/8/12,5 | 305 | 127 | 610 | 414 | 16 | 20 | 31 | |||

| 250 | 273,0 | 6,3/10 | 381 | 159 | 762 | 518 | 25 | 39 | ||||

| 300 | 323,9 | 7,1/10 | 457 | 190 | 914 | 619 | 40 | 56 | ||||

| 350 | 355,6 | 8/11 | 533 | 222 | 1066 | 711 | 57,00 | 78 | ||||

| 400 | 406,4 | 8,8/12,5 | 610 | 254 | 1220 | 813 | 82,00 | 117 | ||||

| 450 | 457,0 | 10,0 | 686 | 286 | 1372 | 914 | 119,00 | |||||

| 500 | 508,0 | 11,0 | 762 | 318 | 1524 | 1016 | 162,00 | |||||

| 600 | 610,0 | 12,5 | 914 | 381 | 1828 | 1219 | 266,00 | |||||

| 700 | 711,0 | — | 1067 | 444 | 2134 | 1422 | — | |||||

| 800 | 813,0 | — | 1219 | 507 | 2238 | — | — | |||||

| 900 | 914,0 | — | 1372 | 570 | 2744 | — | — | |||||

| 1000 | 1016,0 | — | 1524 | 634 | 3048 | — | — | |||||

Version 2:

| DN | D | T | F = R | W | N | WITH | IN | Weight, kg, 1 bend 90° |

| 25 | 32 | 2/2,5/3/3,5 | 38 | 22 | 18 | 76 | 56 | 0,1/0,2/0,2/0,2 |

| 32 | 38 | 2/2,5/3/3,5/4 | 48 | 28 | 23 | 96 | 69 | 0,2/0,2/0,2/0,3/0,3 |

| 40 | 45 | 2,5/3/3,5/4/5 | 60 | 35 | 25 | 120 | 83 | 0,3/0,3/0,4/0,4/0,5 |

| 50 | 57 | 2,5/3/3,5/4/4,5/5/5,5/6 | 75 | 43 | 80 | 150 | 104 | 0,4/0,5/0,6/0,7/0,7/0,8/0,9/1 |

| 65 | 76 | 3/3,5/4/4,5/5/5,5/6/7/8 | 100 | 57 | 41 | 200 | 138 | 0,8/1/1,1/1,3/1,4/1,6/1,7/2/2,2 |

| 80 | 89 | 3/3,5/4/4,5/5/5,5/6/7/8 | 120 | 69 | 50 | 240 | 165 | 1,2/1,4/1,5/1,7/1,9/2,1/2,3/2,7/3 |

| 100 | 102 | 3,5/4/4,5/5/6/7/8/9/10 | 150 | 87 | 62 | 300 | 201 | 2,1/2,4/2,6/2,9/3,4/3,9/4,5/5/5,5 |

| 108 | 3,5/4/4,5/5/6/7/8/9/10 | 204 | 2,2/2,5/2,8/3,1/3,6/4,1/4,75,3/5,8 | |||||

| 114 | 3,5/4/4,5/5/6/7/8/9/10 | 207 | 2,2/2,6/2,9/3,3/3,8/4,4/5/5,7/6,1 | |||||

| 125 | 133 | 3,5/4/4,5/5/6/7/8/9/10/11/12 | 190 | 110 | 79 | 380 | 257 | 3,3/3,8/4,3/4,8/5,7/6,5/7,4/8,2/9,1/10/11 |

| 150 | 159 | 4/4,5/5/6/7/8/9/10/11/12/13/14 | 225 | 130 | 93 | 450 | 305 | 5,4/6,1/6,7/8,1/9,4/11/12/13/14/16/17/18 |

| 168 | 4/4,5/5/6/7/8/9/10/11 | 5,6/6,4/7,1/8,5/9,8/11,2/12,5/14/15 | ||||||

| /12/13/14 | /16/17,5/19 | |||||||

| 200 | 219 | 5/6/7/8/9/10/11/12/13/14 | 300 | 173 | 124 | 600 | 410 | 13/15/17/20/22/25/27/29/32/34 |

| /15/16/17/18 | /37/39/42/44 | |||||||

| 250 | 273 | 6/7/8/9/10/11/12/13/14/15 | 375 | 217 | 155 | 750 | 512 | 23/27/31/35/39/43/46/50/54/58 |

| /16/17/18/20/22 | /61/66/70/78/85 | |||||||

| 300 | 325 | 7/8/9/10/11/12/13/14/15 | 450 | 260 | 186 | 900 | 613 | 39/45/50/56/61/66/72/77/82 |

| /16/17/18/20/22/24/26/28 | /87/92/96/107/118/130/141/150 | |||||||

| 350 | 377 | 9/10/11/12/13/14/15/16/18 | 525 | 303 | 217 | 1050 | 714 | 68/75/83/90/97/104/112/119/133 |

| /20/22/24/26/28/30/32 | /147/161/175/188/201/214/228 | |||||||

| 400 | 426 | 8/9/10/11/12/13/14/15/16/17 | 600 | 346 | 248 | 1200 | 813 | 78/87/97/107/117/126/135/145/154/164 |

| /18/20/22/24/26/28/30/32/34 | /173/192/210/230/249/268/286/306/324 | |||||||

| 500 | 530 | 9/10/11/12/13/14/15/16/17/18 | 750 | 433 | 310 | 1500 | 1015 | 138/153/168/183/198/212/227/242/256/270 |

| /20/22/24/26/28/30/32/34/36 | /298/327/356/385/413/440/467/494/520 | |||||||

| 600 | 630 | 9/10/11/12/13/14/15/16/17/18 | 900 | 519 | 373 | 1800 | 1215 | 198/219/245/261/282/302/324/345/366/387 |

| /20/22/24/26/28/30/32 | /429/471/513/554/595/636/678 | |||||||

| 700 | 720 | 9/10/11/12/13/14/15/16/17 | 1000 | 577 | 404 | 2000 | 1360 | 248/275/302/329/356/383/410/436/462 |

| /18/20/22/24/26/28/30/32 | /489/542/595/647/698/750/801/852 | |||||||

| 800 | 820 | 9/10/11/12/13/14/15/16/17 | 1200 | 693 | 485 | 2400 | 1610 | 339/376/413/450/487/524/561/598/636 |

| /18/20/22/24/26/28/30/32 | /670/743/815/887/959/1030/1101/1171 |

Below are examples of symbols for bends in accordance with GOST 17375-2001:

Bend 90° , version 2, diameter 108 mm, thickness 5 mm, made of steel grade 09G2S: Bend 90-2-108x5-09G2S GOST 17375-2001

Bend 45° , version 1, diameter 60.3 mm, wall thickness 2.9 mm, made of steel grade 20: Bend 45-1-60.3x2.9-20 GOST 17375-2001

Bends according to GOST 30753-01:

Version 1:

| DN | D | T | F | WITH | IN | Weight, kg, 1 bend 90° |

| 50 | 60,3 | 4,0 | 51 | 102 | 81 | 0,44 |

| 65 | 76,1 | 5,0 | 63 | 127 | 102 | 0,87 |

| 80 | 88,9 | 5,6 | 76 | 152 | 121 | 1,40 |

| 100 | 114,3 | 6,3 | 102 | 203 | 159 | 2,60 |

| 125 | 139,7 | 6,3 | 127 | 254 | 197 | 4,10 |

| 150 | 168,3 | 7,1 | 152 | 305 | 237 | 6,70 |

| 200 | 219,1 | 8,0 | 203 | 406 | 313 | 13,00 |

| 250 | 273,0 | 10,0 | 254 | 508 | 391 | 26,00 |

| 300 | 323,9 | 10,0 | 305 | 610 | 467 | 37,00 |

| 350 | 355,6 | 11,0 | 356 | 711 | 533 | 52,00 |

| 400 | 406,4 | 12,5 | 406 | 813 | 610 | 77,00 |

| 450 | 457,0 | — | 457 | 914 | 686 | — |

| 500 | 508,0 | — | 508 | 1016 | 762 | — |

| 600 | 610,0 | — | 610 | 1220 | 914 | — |

Version 2:

| DN | D | T | F = R | W | H | WITH | B | Weight, kg, 1 bend 90° |

| 50 | 57 | 4/5/6 | 50 | 29 | 21 | 100 | 79 | 0,4/0,5/0,6 |

| 65 | 76 | 5/6/7 | 65 | 37 | 27 | 130 | 103 | 0,9/1,1/1,2 |

| 80 | 89 | 5/6/7/8 | 80 | 46 | 33 | 160 | 125 | 1,3/1,6/1,8/2,1 |

| 100 | 102 | 5/6/8/10 | 100 | 58 | 41 | 200 | 151 | 1,9/2,3/3,0/3,7 |

| 108 | 5/6/8/10 | 154 | 2,1/2,4/3,1/3,9 | |||||

| 114 | 5/6/8/10 | 203 | 159 | 2,2/2,5/3,3/4,1 | ||||

| 125 | 133 | 5/6/8/10/12 | 125 | 72 | 52 | 250 | 192 | 3,0/3,6/4,9/6,1/7,3 |

| 150 | 159 | 5/6/8/10/12/14 | 150 | 87 | 62 | 300 | 230 | 4,5/5,4/7,1/8,7/11/12 |

| 168 | 5/6/8/10/12/14 | 234 | 4,7/5,6/7,5/9,4/11/13 | |||||

| 200 | 219 | 7/8/10/12/16/18 | 200 | 115 | 83 | 400 | 310 | 12/13/16/19/25/29 |

| 250 | 273 | 9/10/12/16/18/20/22/24 | 250 | 158 | 103 | 500 | 387 | 24/26/31/42/47/52/57/60 |

| 300 | 325 | 9/10/12/14/16/18/20/22/24/26/28 | 300 | 173 | 124 | 600 | 463 | 34/37/45/52/59/67/74/81/89/96/102 |

| 350 | 377 | 10/12/16/18/20/24/26/30 | 350 | 202 | 145 | 700 | 539 | 47/57/76/85/94/113/122/141 |

| 400 | 426 | 10/12/16/18/22/24/26 | 400 | 231 | 166 | 800 | 613 | 64/77/103/116/142/155/167 |

| /28/32/34/36 | /180/206/219/130 | |||||||

| 500 | 530 | 9/10/12/14/16/18/20/22 | 500 | 289 | 207 | 1000 | 765 | 92/102/122/143/161/184/204/223 |

| /24/26/28/30/32/34/36 | /243/262/282/300/320/340/365 | |||||||

| 600 | 630 | 9/10/12/14/16/18/20/22 | 600 | 346 | 248 | 1200 | 915 | 131146/174/200/230/261/290/319 |

| /24/26/28/30/32/36 | /346/371/400/428/460/489/518 | |||||||

| 700 | 720 | 9/10/12/14/16/18/20/22 | 700 | 405 | 283 | 1400 | 1060 | 174/193/230/268/306/343/380/416 |

| /24/26/28/30/32/36 | /453/489/525/561/596/632/667 | |||||||

| 800 | 820 | 9/10/12/14/16/18/20/22 | 800 | 462 | 324 | 1600 | 1220 | 226/251/301/350/399/447/496/544 |

| /24/26/28/30/32/36 | /592/640/687/734/781/828/874 |

Below are examples of symbols for bends in accordance with GOST 30753-2001:

Bend 90° , version 2, diameter 159 mm, wall thickness 6 mm, made of steel grade 09G2S: Bend 90-2-159x6-09G2S GOST 30753-01

Bend 45° , version 1, diameter 76.1 mm, wall thickness 5 mm, made of steel grade 20: Bend 45-1-76.1x5-20 GOST 30753-01

Thus, it is clear that the bending radius, and therefore the construction length of bends manufactured in accordance with GOST 30753-2001, is less than that of bends manufactured in accordance with GOST 17375-2001, this is the difference between GOST 17375-01 and GOST 30753-01.

Despite the fact that seamless bends can withstand greater pressure than bends made by any other method, their cost compares favorably to a lesser extent due to the manufacturing technology, which leaves virtually no waste.

If you need to know the weight of bends made at angles of 30°, 45° or 60°, you simply need to multiply the weight of the bend indicated in the table by factors of 0.4, 0.5 and 0.7, respectively, and you can always accurately calculate cost of transportation costs using the above tables.

Our company can supply bends in accordance with GOST 17375-2001 and GOST 30753-2001 from various steel grades, such as: steel 20 and 09g2s (steel bends), steel 12x18n10t, 10x17n13m2t (stainless bends), steel 15x5m (heat-resistant bends), etc. R.

All seamless elbows supplied by our company are issued quality certificates, permission to use, and a certificate of conformity.

If you still have questions related to steeply curved seamless bends, you can ask them to the managers of our company by email [email protected] or by phone +7 (343) 361 2377

Manufactured products: Steeply curved, seamless bends

Might be interesting

1) Stamp-welded bends (TU 102-488-05)

2) Welded sector bends (OST 36-21-77, OST 34.10.752-97)

3) Bent bends (TU 51-515-91, OST 36-42-81, GOST 22793-83, etc.)

4) Turned bends (seamless) (according to drawing)

Differences in characteristics according to GOST 17375 and GOST 30753

The APEX METAL company supplies seamless bends for general-purpose pipelines with operating pressures up to 16 MPa and operating temperatures from -70 0 C to +450 0 C. Technical requirements are regulated by GOST 17380-2001.

Differences in tap sizes:

- according to GOST 17375-2001 - nominal diameter DN from 15 to 1000 mm, wall thickness 2 - 36 mm

- according to GOST 30753-2001 - nominal diameter DN 50 to 800 mm, wall thickness 4 - 36 mm

The table of bend sizes according to GOST 17375-2001 and GOST 30753-2001 includes the main characteristics:

- end diameter (external and nominal bore)

- wall thickness at the ends and outside the end zone

- bending radius of the bend.

The table of steel bends also contains such a parameter as weight, and:

- GOST 17375-2001 indicates masses for rotation angles of 45, 90 and 180 degrees

- in GOST 30753-2001 - only for an angle of 90 degrees. The mass for other angles is calculated by proportion.

For example, a bend with a size of 530x10 mm and a rotation angle of 90 0 weighs 102 kg, 45 0 - 102/2 = 51 kg, 180 0 - 102x2 = 204 kg.