Surface grinding is a type of grinding work that is performed using various methods. There are several types of surface grinding, which is performed on surface grinding machines. These include profile grinding, work with the periphery of a wheel, cross-feed of a wheel, creep-feed grinding, etc. Grinding with the end of a wheel is the most effective method, since it involves using the entire surface to be ground. To increase productivity, it is necessary to carefully attach parts to the machine table using a vice, clamping bars or electromagnetic plates.

Types of surface grinding

Each type of surface grinding has advantages and disadvantages. Let's try to consider each of them in detail.

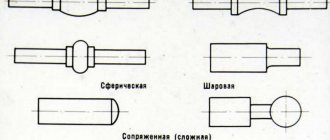

- Flat grinding with the end of a wheel and its periphery is used when processing three-dimensional bodies in the shape of a ball, cylinder, cone and other three-dimensional figures. It is carried out by installing the part into stationary cartridges or recesses.

- Internal grinding is necessary for machining cylindrical and cone-shaped holes. This method allows for centerless grinding, in which the part is not fixed, but is based on the surface being processed.

- Profile grinding is a variant of grinding the surface of parts whose forming line has a curved or broken shape.

- Gear and thread grinding are used in the production of thread-cutting cutting tools, which include lead screws, gears, taps, etc. The lateral cavities and sides of the thread profile are processed.

- High-speed grinding is a method of abrasive processing in which the rotation speed of the grinding wheel reaches 60 meters per second or higher. At this speed, it is possible to achieve a minimum level of roughness of the processed flat surface.

Metal grinding

The processing of metal and various alloys using an abrasive material is usually called grinding. This technology allows you to change the roughness and other parameters of the outer or inner cylindrical, as well as flat surface. Metal grinding can be carried out using various special equipment. When considering the features of such mechanical processing, you need to pay attention to the following points:

- The grinding process is the final stage of processing, which is carried out to obtain a certain roughness.

- This technology is not used to change sizes over a large range.

- Using modern equipment, the surface can be brought to the required roughness after heat treatment of the metal.

When carrying out the operation in question, a fairly large number of features are taken into account:

- Wheel speed is a parameter that depends on the outer diameter of the abrasive and the capabilities of the machine.

- Speed of movement of the part.

- Depth of cut.

- Possibility of cross feeding.

It is worth noting that today such technology is gradually being replaced by fine turning of metal at high speeds and minimal feed.

Surface grinding with wheel periphery

As already mentioned, this type of flat grinding is one of the most common and effective. When using it, it is possible to reduce the number of abrasive grains simultaneously participating in the grinding process, so the level of surface heating and deformation is reduced as much as possible. This makes the method useful for high-precision final polishing of fragile and thin products.

Working on machines using wheel periphery grinding is more versatile. They can be used to work with flat surfaces, profile grooves, hard-to-grind and thin-walled materials that are prone to overheating. Therefore, this method is used in the production of unique individual parts, but in the mass market segment, flat grinding with the periphery of a wheel is used only when other grinding methods are ineffective.

Grinding with the periphery of a wheel is best done on machine tools with a rectangular or round table, which allows you to process long parts whose design includes grooves, grooves, shoulders and other unstable elements.

Flat grinding with the periphery of a wheel is carried out using grinding wheels of the PP type, having a diameter from one hundred to five hundred millimeters, a width from eight to seventy-five millimeters.

To mainFLAT GRINDING

Based on the method of operation, surface grinding machines are divided into machines that work with the cylindrical surface of a wheel, and machines that work with its end surface. Surface grinding machines are manufactured with horizontal and vertical spindles. When flat grinding with the periphery of a wheel (Fig. 137), it is possible to feed both towards the rotation of the wheel and in the direction of its rotation. The machine table has a reciprocating motion. Transverse feed (feed along the axis of the machine spindle) is carried out after each longitudinal movement of the wheel by the width of the layer being removed. In this case, the wheel removes a layer of metal equal to the depth of cut and the width of the cross feed of the wheel. If the entire grinding width of the plane has been completed, the wheel is again fed to the depth of cut, switching the transverse feed in the opposite direction.

In addition to the indicated method, there is also a method of grinding with a set wheel, in which the wheel is fed to the cutting depth for each table stroke. After removing the allowance, the circle is moved along the axis of the spindle to 4/5 of its width. The transitions are repeated in this way until the allowance on the plane is completely removed. In this case, the final pass is carried out by transverse feed of the circle. By grinding the periphery of the wheel, high precision of the planes of the parts being ground is achieved. Slight heating of the parts when grinding with the periphery of the wheel does not cause deformation of the part during the grinding process. The most productive grinding method is grinding with the end of a wheel (Fig. 138), since this involves grinding a large surface. The machine table receives reciprocating or rotary motion depending on the type of grinding machine. Fastening of workpieces can be done directly on the machine table using clamping bars. To quickly secure parts, machine vices or electromagnetic plates are used.

The electromagnetic plate works on the principle of core magnetization. If a direct current is passed through a wound coil with a core, then from the action of the passing current its iron core is magnetized, acquiring the property of attracting steel and cast iron. If the iron core is bent into a horseshoe shape, stronger magnetization is observed. Horseshoe-shaped magnets connected in a group form a magnetic plate (Fig. 139).

In a magnetic plate, the magnetic poles are insulated from each other by copper or other antimagnetic metal, so the magnetic lines of force are not dissipated in the plate, but are directed to the workpiece being ground, closing the magnetic flux. The speed values of grinding wheels for surface grinding are given in table. 24.

Table 24

Grinding wheel speeds for surface grinding

Grinding method

| Sanding material | Grinding wheel speeds in m/sec | ||

| During pre-grinding | During final sanding | ||

| Periphery grinding Wheel end grinding | Cast Iron Steel Cast Iron Steel | 20-22 23-25 15-18 18-20 | 22-25 25-30 18-20 20-25 |

Dressing grinding wheels.

With prolonged use of a grinding wheel, the surface of the workpiece or tool being processed becomes rougher, and tarnished colors (burns) appear.

This phenomenon is explained by the fact that the grain of the wheel being ground has become dull or worn out. You can often observe contamination or “greasing” of the wheel; the pores of the wheel become clogged with metal dust, while the abrasive grains stop cutting it, and the workpiece heats up more than normal. This can be explained by the fact that the wheel was selected incorrectly or the grinding modes were selected incorrectly. “Salting” of the wheel is most often observed when processing non-ferrous metals and their alloys (brass, bronze, aluminum). To eliminate these phenomena, it is necessary to edit the grinding wheel, change the cutting speed, and if this does not help, then replace the grinding wheel with a softer one or with a larger grain size. By editing, the profile of the wheel is leveled and sharpened, i.e., the removal of dull abrasive grains is achieved. If the wheel is selected correctly for a given job, then self-sharpening of the wheel is observed during operation. The dull grains of the wheel are chipped during the grinding process, exposing new sharp abrasive grains. Grinding wheels are edited using diamonds, diamond metal pencils, carborundum wheels and other diamond substitutes. In terms of hardness, diamond ranks first among known minerals. Diamond is used to edit grinding wheels when grinding precision parts, as well as when it is necessary to profile the wheel during finishing shaped grinding. To edit the wheels, the diamond is fixed (chased) into a special mandrel. When editing, it is necessary that the thickness of the layer removed from the wheel in one pass is no more than 0.01 - 0.03 mm

.

The diamond is installed on the machine table below the center of the circle by 2 - 3 mm

with an angle of 15 - 20° (Fig. 140). Due to their high cost, large grains of diamonds are replaced with small grains or diamond chips, from which diamond-metallic pencils are made. Diamond grains in a diamond-metal pencil are arranged several in a layer and cemented with refractory metals (cobalt, nickel, tungsten in the form of a cylinder). A diamond-metallic pencil can be used to edit circles of all categories of hardness, any grain size and size.

| Previous page | table of contents | Next page |

Surface grinding wheels

For effective sanding, it is important to choose the right tool. Today, manufacturers offer tools using various abrasive grains of natural and artificial origin. Grinding wheels are created on the basis of a mineral, synthetic or ceramic binder. They effectively cope with the processing of metal, stone and wooden surfaces and are used both on production machines and in household home workshops.

A ceramic-based grinding wheel is designed for working with hard alloys and metals. As a result of its use, a low degree of roughness of the workpiece can be achieved.

Abrasive grain on a bakelite bond is used when processing stone surfaces - granite, marble, concrete, grinding brick and cast iron.

The vulcanite bond is used for more thorough processing of fragile surfaces, which include non-ferrous metals. It can be used to polish and bring metal products to an ideal presentable state.

Another abrasive tool is a sanding belt, which consists of abrasive grain of synthetic origin, mounted on a paper or fabric backing. The sanding belt is used both for independent use and as a consumable material on grinding machines.

Grinding Techniques

When working on a surface grinding device, the following techniques can be distinguished:

- Multi-pass processing. This technique requires fixing the element on the surface. The speed of its movement during processing reaches 45 meters per minute. The processing method is reduced to repeatedly moving the product under the circle until the allowance is completely removed. In this case, the machine performs the last moves without feed or with a small vertical feed.

- Single pass processing. Used for machines with round tables. With this method, the machine passes vertically to its entire depth in one go. As a result, the entire allowance from the part is removed in one revolution. Devices with three heads allow you to remove large allowances with maximum grinding precision. Such devices are used mainly in mass production.

- Double-sided processing. This technology involves grinding two ends of a part at the same time. With this method, more than one pass of the product will be required to completely remove the allowance. The essence of the method is linear or circular feeding of the part. Due to the rotation of the tool, metal is cut. The periphery of the circle should be used to process products with medium hardness. With the end processing method, productivity will be higher than with the peripheral method.

Machine repair and modernization

During operation and production of parts put into production, all mechanisms begin to wear out over time . Parts are replaced after the service life of each specific element has expired. This attitude towards equipment increases the accuracy of work and personnel safety. Machines are subject to major overhaul after twenty years of operation.

The manufacturer provides a service life warranty for each element of the machine, but depending on the workload of the equipment, replacement may be required earlier. Modernization of equipment makes it possible to increase the number of parts produced.

Grinding methods

Metal processing on surface grinding machines is carried out in two ways:

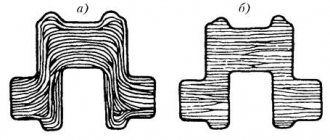

In the first case, the high productivity of the surface grinding machine is noted. With this type of grinding, the arc of contact between the part and the apparatus is described by an insignificant value. As a result, a fairly high temperature is created in the grinding zone, which somehow reduces the accuracy of the operation (circular feed contributes to a significant decrease in accuracy). In addition, there are some difficulties with removing chips from the surface grinding machine.

Machining the workpiece with the end of the wheel

There are the following grinding techniques using a surface grinder.

The element is fixed on the surface and moves at a speed of about 45 meters per minute. The product is repeatedly moved under the circle, which gradually moves deeper until the allowance is completely removed. The last moves take place without feed or with a small vertical feed.

This method is applicable for devices with round tables, when the surface grinding machine runs vertically to its full depth in one pass. Due to this, one revolution of the surface removes the entire allowance. If you need to remove a larger allowance with maximum grinding precision, it is better to take devices with three heads. They are suitable for use in large facilities where mass production is carried out.

The technique involves synchronous grinding of two ends of the part. It takes more than one pass to completely remove the allowance. With this method, the main feed occurs due to the circular or linear feed of the part, and cutting is carried out due to the rotation of the tool.

Regardless of which type of metal peripheral machining is chosen, it will differ from the previously described techniques in that it produces little heat and low cutting force. For this reason, products that are not too hard are processed with the periphery of the circle. It should be noted that the productivity of grinding with the end is always greater than with the periphery.

The following methods of grinding with the periphery of a wheel are distinguished.

With each stroke, a significant allowance is removed, and the longitudinal feed speed in this case is minimal. Due to the fact that the abrasives located at the end bear the brunt of removal, the circle wears out quite quickly.

With continuous feed

Grinding is carried out if the surface to be processed is limited by shoulders, and is also used to process elements whose height exceeds their width. There is no cross feed with this method, and the accuracy of the work is low. Wear occurs unevenly, so constant adjustment is required.

With transverse intermittent feed

With this technique, even large surfaces are processed efficiently. The height of the grinding tool must always be higher than the cross feed. Transverse reverse and feed of the circle deeper usually occur simultaneously. This technique is characterized by high precision; it is used on surface grinding machines with a round table and a horizontal spindle.

Benchtop Surface Grinder