Information about the manufacturer of the sheet bending machine IV2144

The manufacturer of the IV2144 sheet bending machine is the Nelidovsky hydraulic press plant NZGP , founded in 1972, and Kuzlitmash, Pinsk .

Machines produced by the Nelidovo hydraulic press plant NZGP

- IB1430a

– hydraulic press brake 2500 x 4.5 - IV2142

- sheet bending machine with a rotating beam 1600 x 6 - IV2143

- sheet bending machine with a rotating beam 2000 x 5 - IV2144

- sheet bending machine with a rotating beam 2500 x 4.5 - P6330

– single-column hydraulic press 1000 kN

Sheet bending machine model IV2144

The sheet bending machine model IV2144 is a universal equipment that can be used to produce various parts and products using the cold bending method.

This equipment is in demand in various industries and in particular in mechanical engineering.

There are a number of basic elements in the design of a sheet bending machine. The design of sheet-bending equipment includes a bed, bending and pressing beams, a drive for these beams, as well as a back stop. The drive is hydraulic. It is possible to modernize or another version of the IV2144 machine supplemented with some accessories. This will allow you to expand functionality.

The sheet bending machine model IV2144 performs bending operations on steel sheets not exceeding a thickness of 4.5 mm. The length of the table is 2.5 m, which determines the maximum width of the sheet to be bent. The clamping force is 40 tons, the bending force is 30 tons. The area of the equipment in terms of the workshop is about 9 square meters. The weight of the equipment of this model does not exceed 6.5 tons.

The power of the electrical equipment used in the sheet bending machine is 10 kW.

Among the technical characteristics, the important adjustment values for the table and bending beam are 100 mm and the maximum stroke of the clamping beam is 250 mm.

At our company you can separately order a diagram, passport, and documentation for the IV2144 .

Detailed technical specifications can be obtained upon additional request.

Technical specifications for sheet bending machine IV2144

| Model | Nominal press force, kN | Maximum thickness of bent sheet, mm | Maximum width of bent sheet, mm | Maximum stroke of the pressure beam, mm | Maximum rotation angle, rad | Amount of bending beam adjustment, mm | Table adjustment amount, mm | The largest amount of movement ass stop, mm** | Weight, kg* | Power consumption, kW | Dimensions (HxWxD), mm* |

| IV2142 | 40 | 6 | 1600 | 250 | 180 | 100 | 100 | 800 | 5230 | 10 | 2400x2000x2900 |

| IV2143 | 40 | 5 | 2000 | 250 | 180 | 100 | 100 | 800 | 5580 | 10 | 2400x2000x3300 |

| IV2144 | 40 | 4,5 | 2500 | 250 | 180 | 100 | 100 | 800 | 6300 | 10 | 2400x2000x3790 |

| IV2145 | 40 | 4 | 3200 | 250 | 180 | 100 | 100 | 800 | 7800 | 10 | 2400x2000x4500 |

| IV2146 | 40 | 3,5 | 4000 | 250 | 180 | 100 | 100 | 800 | 9280 | 10 | 2400x2000x5300 |

We draw your attention to the fact that all information provided on the site regarding configuration, technical characteristics, color combinations, as well as prices is for informational purposes only and under no circumstances constitutes a public offer as defined by the provisions of Article 437(2) of the Civil Code of the Russian Federation. For detailed information, please contact our sales department.

www.gidropress.ru

Sheet bending machine with rotary bending beam IV2144. Purpose and scope

IV2144 hydraulic sheet bending machine with a rotary bending beam is designed for the manufacture of various parts by cold bending from sheet metal. The material of the bent sheet is thermally untreated steel and non-ferrous metals. The machine can be used in all branches of industry and construction.

Brief description of the operation of the IV2144 : bending of workpieces is carried out using a bending beam around a set of mandrels mounted on a pressure beam.

The sheet bending machine model IV2144 performs bending operations on steel sheets not exceeding a thickness of 4.5 mm. The length of the table is 2.5 m, which determines the maximum width of the sheet to be bent. The clamping force is 40 tons, the bending force is 30 tons. The area of the equipment in terms of the workshop is about 9 square meters. The weight of the equipment of this model does not exceed 6.5 tons.

The power of the electrical equipment used in the sheet bending machine is 10 kW.

Among the technical characteristics, important values are the vertical adjustment of the table and bending beam - 100 mm and the maximum stroke of the pressure beam - 250 mm.

The frame is detachable and consists of two racks and a table, connected by three ties.

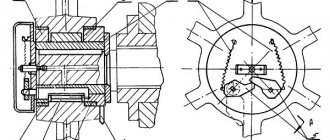

The bending beam is welded, suspended in a vertical position on two screws connected to rotation shafts located in the frame posts. The rotation shafts of the bending beam are connected through a rack and pinion mechanism to the rods of the bending cylinders.

The pressure beam is of a welded structure and moves in the guide posts of the frame. It is connected to the rods of the clamping cylinders.

The machine drive is hydraulic. The hydraulic unit serves to drive the pressing and bending beam.

The hydraulic system contains two main cylinders for driving the bending beam, two cylinders for the pressure beam and a hydraulic station. The hydraulic drive ensures a quick approach of the bending beam to the workpiece, a slow stroke during bending and a quick return to its original position. Adjustment and adjustment of the position of the bending and pressing beams, depending on the thickness of the sheet being bent and the required bending angle, is carried out using manual adjustment mechanisms.

IV2144 sheet bending machine is equipped with a rear mechanized stop with an indicator of the position of the rear edge of the sheet relative to the bending line. The back stop is designed for precise positioning and movement of the sheet being bent by a given amount when performing technological operations.

The back stop mechanism is attached to the machine table on a bracket and has a lead screw driven by an electric motor. The carriage of the back stop mechanism moves along the lead screw.

The rear stop has a mechanical drive and hydraulic grips, which allows you to use buttons to change the position of the workpiece and visually control it using a counter.

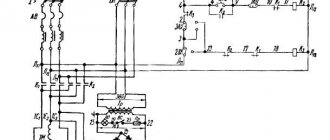

The electrical circuit ensures the machine operates on single strokes and in adjustment mode.

The machine can be controlled from two remote controls: the main one, built into the right rack, and the hinged one, hinged on the right rack.

A mechanical synchronizer protects the pressure beam of the IV2144 sheet bender from distortions when it moves. Synchronization is carried out by a shaft, on the ends of which gears are mounted, meshed by racks. The slats are fixed in brackets mounted on the bed posts. The parallelism of the clamping beam to the table is ensured by adjusting the slats with screws.

The vertical adjustment mechanism of the table and bending beam expands the technological capabilities of the machines and serves to adjust the machine depending on the thickness of the sheet being bent. Adjustment is made manually.

lubricated using a centralized grease lubrication system. The remaining rubbing surfaces are lubricated with a syringe.

The sheet bending machine with a rotary bending beam IV2144 can be equipped with various interchangeable devices, which makes it possible to produce parts of the most varied configurations from sheets, including the manufacture of boxes.

Technological capabilities of sheet bending machine IV2144

Using the tool (bending mandrels) supplied with the machine, you can bend a large number of different parts with an internal angle from 32° to 180° and a radius of 7 mm.

The sheet bending machine can be equipped for an additional fee with various interchangeable devices: for bending pipes, closed loops, U-shapes, boxes and edges.

Main parameters of the sheet bending machine with rotary bending beam IV2144:

The IV2144 machine was developed in 1979 and has been mass-produced since 1980.

Developer: SKB forging and pressing machines and automatic lines, SKB KM, Voronezh.

Manufacturer: Nelidovo Hydraulic Press Plant, NZGP Nelidovo.

- The largest dimensions of a bent sheet of metal are 4.5 x 2500 mm

- Angle of rotation of the bending beam - 180°

- Stroke of the pressure beam - 250 mm

- Bending beam speed - 38 degrees/sec

- The amount of adjustment of the bending beam is 100 mm

- Drive power - 10.07 kW

- Total vehicle weight - 6.46 tons

Press brake with rotary beam IV2144

Specifications

The sheet bending machine with a rotary bending beam, model IV2144, is designed for the production of various parts by cold bending from sheet and strip metal. The material of the bent sheet is thermally untreated steel and non-ferrous materials. The machine can be used in all branches of industry and construction.

Main technical characteristics

| Name of parameters | Data |

| Maximum width of bent sheet, mm | 2500 |

| Maximum thickness of bent sheet at Ϭ in =500 MPa, mm | 4,6 |

| Maximum internal bending radius, mm | 1.25 sheet thickness |

| Smallest bendable edge size, mm | 6 sheet thicknesses |

| Maximum movement of the back stop, mm | 800 |

| Machine dimensions, mm | |

| from left to right | 3790 |

| front to back | 2000 |

| Machine height above floor level, mm | 2000 |

| Machine weight | 6350 |

Contents of delivery:

Plate bending machine with rotary bending beam; Manual; Hydraulic unit.

Available upon customer request for an additional fee:

Assembly for circular bending; Assembly device for bending closed circuits; Mandrel for flexible boxes assembled; Mandrel for bending U-shaped profiles assembled; Mandrel for bending edges assembled; Reception table assembled.

General layout of the machine

The basis of the machine is a frame consisting of two racks with a table placed between them. The table and the stand are connected to each other by 3 ties. A clamping beam moves in the guide posts above the table, connected directly to the rods of the hydraulic clamping cylinders; the posts also contain the rotation shafts of the bending beam, which is suspended in a vertical position on 2 screws connected to the rotation shafts. The rotation shafts of the bending beam are connected through a rack and pinion mechanism to the rods of the bending cylinders. A bracket for the back stop mechanism is attached to the rear table, in which a lead screw driven by an electric motor is mounted. The back stop carriage with spring-loaded grips moves along the lead screw, opening under the action of a hydraulic cylinder. The design of the machine provides options for driving the back stop lead screw from an electric motor.

Operating principle of the machine

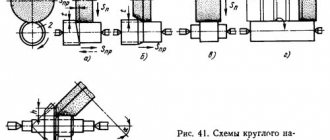

The sheet to be bent is placed on the machine table, sent all the way, grabbed by grippers, then a pressure beam is lowered down, which presses the sheet during bending. The sheet is bent around a mandrel fixed to a pressure beam. The mandrels can be replaceable for bending parts of various shapes. The bending process itself is carried out by a bending beam, the tool bars of which are located under the sheet being bent. When turning the bending beam, the tool bars touch the sheet and bend it around the mandrel. After turning through a given angle, the bending beam returns down to its original position. Then the pressure beam rises up and the cycle repeats. The clamping beam moves forward under the action of the cylinders. The bending beam rotates from the cylinders through the rack and pinion transmission and shafts. The back stop moves along a lead screw that rotates from an electric motor through a chain drive. Manual adjustment of the back stop is carried out by turning the flywheel, which is connected to the lead screw through a chain drive. The height of the table is adjusted by turning the handle, which transmits rotation through a worm gear to the table support screws. The position of the beam is adjusted by rotating the handle, which, through bevel gears and worm gears, transmits rotation to the nuts and screws on which the bending beam is suspended.

bed

The prefabricated machine bed consists of 2 racks and a table, tied together by 2 lower ties and an upper ties. The stands and table are of welded construction. The table has rectangular projections on both sides for guidance in the racks during adjustment. Brackets for mounting the housings of the table adjustment mechanism are attached to the racks below. At the top of the racks there are brackets in which the clamping cylinders are mounted. Below the bracket, guides for the pressure beam and table and wedges for adjusting the gap in the guides are attached to the rack. Inside each of the racks there are cylinders of the bending beam and a rack and pinion mechanism for driving the bending beam. The bores of the racks accommodate the supports for the rotation shafts of the bending beam. When adjusting the table, it is necessary to lower the tie passing through the table to create a gap between the table and the guides of the racks. To do this, loosen the nuts at the end of the tie. After adjustment, the nuts must be tightened again. To make such adjustment possible, it is necessary to install the clamping cylinders of the table adjustment mechanism and secure the lower couplers while the upper coupler is tightened.

Table adjustment mechanism

Designed to change the position of the table at height. Adjustment is carried out using a handle located on the outer side of the right pillar. When the handle is turned, the shaft transmits rotation through worm gears to the support screw nuts, and the screws begin to move up or down, respectively raising or lowering the table.

Bending beam

The bending beam directly bends the sheet. It is a welded box-section structure, on the top of which tool strips are fixed. The bending beam is suspended on 2 screws, the heads of which are connected to the drive shafts of the bending beam. When the shafts turn, the screws turn along with the beam. The sheet bending process takes place.

Rear stop

Designed to support the rear edge of the sheet during bending.

Bending angle setting mechanism

Serves to indicate the current angle of rotation of the bending beam and set the specified bend angle.

Pipe bending device

To bend pipes, a special device is installed, consisting of brackets fixed to the front surface of the pressure beam and hammers, in which a replaceable round mandrel is installed.

Device for bending closed profiles

Structurally, the device is similar to a pipe bending device, but instead of a round mandrel, a rectangular mandrel is used.

Mandrel for bending U-shapes, boxes and edges

simple in structure and design.

Reception table

The assembled receiving table serves to facilitate the loading of large sheets onto the machine table and unloading of products.

- 18 month warranty

- Temperature up to 25 degrees

- Repair base Russia and CIS

- Delivery of spare parts 5-15 days

- Service life 10-20 years

Actual appearance may differ slightly from that shown on the website. Changes in the technical characteristics of the product are possible depending on the modification. The information on this site is for informational purposes only and under no circumstances constitutes a public offer as defined by the provisions of Article 437 of the Civil Code of the Russian Federation.

Operating principle of sheet bending machine IV2144

The sheet to be bent is placed on the machine table, pushed as far as it will go and grabbed by the grippers.

A pressure beam is lowered onto the sheet and the sheet is bent around a replaceable mandrel fixed to the pressure beam. The shape of the replacement mandrels can be different for each type of part.

The bending process is carried out by a bending beam, which is located under the workpiece.

After turning at a given angle, the bending beam returns down to its original position, the clamping beam rises and releases the sheet.

Sheet bending machine IV2146

The sheet bending machine model IV 2146 differs from other models in that its work table size is four meters. And this makes it possible to use a sheet to prepare a part for the same width.

Thus, those parts that could not be made on other models of sheet bending machines can be made on the IV2146 model. And with additional accessories, this machine becomes even more functional.

Moreover, with such a large table size (the width of the workpiece for bending), the sheet thickness can reach 3 - 3.5 mm. Which is very good. For a serious, powerful enterprise, pressing equipment of this model is very desirable. With all this, this machine is not manual, but hydraulic.

Thus, the sheet bending machine model IV2146 is a universal, powerful equipment that uses the cold bending method to produce many products or parts required in the technological process of enterprises in a wide variety of industries.

The weight of the equipment is 9.28 tons. The area of the sheet bending machine model IV2146 in the workshop plan occupies thirteen square meters. Its height is about 2.5 meters. Electricity consumes a total power of ten kilowatts.

Detailed technical specifications can be obtained upon additional request.

Technical specifications for sheet bending machine IV2146

| Model | Nominal press force, kN | Maximum thickness of bent sheet, mm | Maximum width of bent sheet, mm | Maximum stroke of the pressure beam, mm | Maximum rotation angle, rad | Amount of bending beam adjustment, mm | Table adjustment amount, mm | The largest amount of movement ass stop, mm** | Weight, kg* | Power consumption, kW | Dimensions (HxWxD), mm* |

| IV2142 | 40 | 6 | 1600 | 250 | 180 | 100 | 100 | 800 | 5230 | 10 | 2400x2000x2900 |

| IV2143 | 40 | 5 | 2000 | 250 | 180 | 100 | 100 | 800 | 5580 | 10 | 2400x2000x3300 |

| IV2144 | 40 | 4,5 | 2500 | 250 | 180 | 100 | 100 | 800 | 6300 | 10 | 2400x2000x3790 |

| IV2145 | 40 | 4 | 3200 | 250 | 180 | 100 | 100 | 800 | 7800 | 10 | 2400x2000x4500 |

| IV2146 | 40 | 3,5 | 4000 | 250 | 180 | 100 | 100 | 800 | 9280 | 10 | 2400x2000x5300 |

We draw your attention to the fact that all information provided on the site regarding configuration, technical characteristics, color combinations, as well as prices is for informational purposes only and under no circumstances constitutes a public offer as defined by the provisions of Article 437(2) of the Civil Code of the Russian Federation. For detailed information, please contact our sales department.

www.gidropress.ru

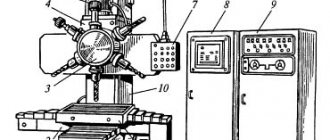

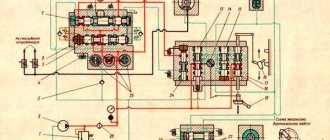

Location of the components of the sheet bending machine IV2144

Location of the components of the sheet bending machine IV2144

List of components of the sheet bending machine IV2144

- bed

- Bending beam drive

- Bending beam cylinder

- Pressure beam cylinder

- Table adjustment mechanism

- Pressure beam synchronizer

- Bending beam

- Pressure beam

- Rear stop

- Mechanism for setting the lifting height of the pressure beam

- Bending angle setting mechanism

- Remote Control

- Lamp

- Oil line

- Pipeline

- Electrical equipment

- Main control panel

- Pendant panel

- Electrical equipment of the cabinet - IV2144-94-001

- Hydraulic unit - K34007EM

Location of controls for sheet bending machine IV2144

Location of controls for the sheet bending machine IV2144

List of controls for the sheet bending machine IV2144

- Emergency stop button

- Handle for setting the lifting height of the pressure beam

- Pressure beam lift height indicator

- Bending beam position adjustment handle

- Bending beam position indicator

- Table height adjustment handle

- Table position indicator

- Handwheel for manual adjustment of the back stop position

- Back gauge position indicator

- Handle for setting the angle of rotation of the bending beam

- Angle indicator for bending beam

- Mounted control panel

- Main control panel

- Local lighting switch

Description of the kinematic diagram of the sheet bending machine IV2144

The pressure beam moves translationally under the action of cylinders 1.

The bending beam performs a rotational movement from the cylinders 2 through the rack and pinion gear 3 and the shafts 4.

The back stop moves along a lead screw 5, which rotates from an electric motor through a chain drive 7.

Manual adjustment of the back stop is carried out by turning the handwheel 8, which is connected to the lead screw 5 through a chain drive 9.

The position of the back stop is determined by a counter, which is connected to the lead screw 5 through bevel gear 10 and chain gears 11 and 9.

The height of the table is adjusted by turning the handle 12, which transmits rotation through the worm gears 13 and the nut 14 to the support screws of the table 15.

The height of the bending beam is adjusted by rotating the handle 16, which, through bevel gears 17 and worm gears 18, transmits rotation to the nuts 19 and screws 20 on which the bending beam is suspended.

Sheet bending machine IV2143

The sheet bending machine model IV2143 allows you to bend steel sheets up to five millimeters thick. And at the same time obtain parts of the most varied shapes.

The working table of the machine is 2 meters, which sets the maximum width of the steel sheet of the workpiece processed by the press.

The rotary drive of the bending and pressing beams is hydraulic. The design of the main elements includes, in addition to the drive, the beams themselves, a bed and a back stop, and there may also be additional devices that increase the functionality of the sheet bending machine model IV2143.

There are no accessories included in the standard delivery and are supplied when specified in the order.

The product model IV2143 received a positive assessment from manufacturing enterprises in various industries. The weight of the sheet bending machine model IV2143 is 5.58 tons. The area of this pressing equipment in terms of the workshop occupies eight square meters.

The clamping force is 40 tons, bending force is ? 30. The sheet bending machine model IV2143 consumes 10 kW of electricity. The pressure beam in its movement does not exceed the stroke size of 250 mm. Its rotation angle is up to 180 degrees. The bending beam can be adjusted to a size of up to 100mm.

Technical specifications for sheet bending machine IV2143

| Model | Nominal press force, kN | Maximum thickness of bent sheet, mm | Maximum width of bent sheet, mm | Maximum stroke of the pressure beam, mm | Maximum rotation angle, rad | Amount of bending beam adjustment, mm | Table adjustment amount, mm | The largest amount of movement ass stop, mm** | Weight, kg* | Power consumption, kW | Dimensions (HxWxD), mm* |

| IV2142 | 40 | 6 | 1600 | 250 | 180 | 100 | 100 | 800 | 5230 | 10 | 2400x2000x2900 |

| IV2143 | 40 | 5 | 2000 | 250 | 180 | 100 | 100 | 800 | 5580 | 10 | 2400x2000x3300 |

| IV2144 | 40 | 4,5 | 2500 | 250 | 180 | 100 | 100 | 800 | 6300 | 10 | 2400x2000x3790 |

| IV2145 | 40 | 4 | 3200 | 250 | 180 | 100 | 100 | 800 | 7800 | 10 | 2400x2000x4500 |

| IV2146 | 40 | 3,5 | 4000 | 250 | 180 | 100 | 100 | 800 | 9280 | 10 | 2400x2000x5300 |

We draw your attention to the fact that all information provided on the site regarding configuration, technical characteristics, color combinations, as well as prices is for informational purposes only and under no circumstances constitutes a public offer as defined by the provisions of Article 437(2) of the Civil Code of the Russian Federation. For detailed information, please contact our sales department.

www.gidropress.ru

Technical characteristics of sheet bending machine IV2144

| Parameter name | IV2142 | IV2143 | IV2144 | IV2146 |

| Main parameters of the machine | ||||

| Maximum thickness of bent sheet (h) at bt = 500 MPa (50 kgf/mm²), mm | 6 | 5 | 4,5 | 3,5 |

| Maximum width of bent sheet, mm | 1600 | 2000 | 2500 | 4000 |

| Maximum angle of rotation of the bending beam, degrees | 180° | 180° | 180° | 180° |

| Maximum stroke of the pressure beam, mm | 250 | 250 | 250 | 250 |

| Amount of vertical table adjustment, mm | 100 | 100 | 100 | 100 |

| Amount of vertical adjustment of the bending beam, mm | 100 | 100 | 100 | 100 |

| Rotation speed of bending beam, deg/s | 38 | 38 | 38 | 38 |

| Smallest internal bending radius (h - sheet thickness), mm | 1.25*h | 1.25*h | 1.25*h | 1.25*h |

| The smallest value of the folded edge (h - sheet thickness), mm | 8*h | 8*h | 8*h | 8*h |

| Maximum movement of the back stop, mm | 800 | 800 | 800 | 800 |

| Electrical equipment and machine drive | ||||

| Electric motor drive pumps 1, 2 (M1), kW | 7,5 | 7,5 | 7,5 | 7,5 |

| Electric motor drive pump 3 (M2), kW | 2,2 | 2,2 | 2,2 | 2,2 |

| Back stop electric motor (M3), kW | 0,37 | 0,37 | 0,37 | 0,37 |

| Total power of electric motors, kW | 10,07 | 10,07 | 10,07 | 10,07 |

| Dimensions and weight of the machine | ||||

| Dimensions of scissors (length x width x height), mm | 2900 x 2000 x 2000 | 3300 x 2000 x 2000 | 3790 x 2000 x 2000 | 5300 x 2000 x 2000 |

| Weight, kg | 5230 | 5580 | 6350 | 9820 |

- Sheet bending machines with a rotary bending beam IV2142, IV2143, IV2144, IV2145, IV2146. Operating manual IV2144-00-001 RE, 1981

- Banquetov A.N., Bocharov Yu.A., Dobrinsky N.S. and others. Press-forging equipment, 1970

- Bocharov Yu.A., Prokofiev V, N. Hydraulic drive of forging and pressing machines, 1969

- Belov A.F., Rozanov B.V., Linz V.P. Volumetric stamping on hydraulic presses, 1971

- Zhivov L.I. Forging and stamping equipment, 2006

- Kuzmintsev V.N. Forging with hammers and presses, 1979

- Rozanov B.V. Hydraulic presses, 1959

- Titov Yu.A. Equipment for forging and pressing shops, 2001

- Shcheglov V.F. Forging and pressing machines, 1989

- Berlet Development of forging drawings, 2001

- Rudman L.I. Sheet Forming Equipment Handbook, 1989

- Romanovsky V.P. Handbook of Cold Forging, 1965

- Okhrimenko Ya.M. Technology of forging and stamping production, 1966

- Kuzmintsev V.N. Forging with hammers and presses, 1979

- Meshcherin V.T. Sheet stamping. Atlas of circuits, 1975

Bibliography:

Related Links. Additional Information

- Directory of enterprises producing forging and pressing equipment in Russia

- Classification and designation of hydraulic and crank presses

- Mechanical presses

- Hydraulic presses

- Automatic forging and pressing machines

- Bending and straightening machines

- Guillotine shears, press shears

- Hammers

- Repair of hydraulic systems of metal-cutting machines

- Designations of hydraulic circuits of metal-cutting machines

- Repair of gear hydraulic pumps

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Listogib IV2144: technical characteristics, principle of operation

IV2144 belongs to the category of hydraulic sheet bending machines. A distinctive feature of the equipment of this model is that its design contains a rotating beam.

Appearance of sheet bending machine model IV2144

The main purpose of the machine model IV2144, which can be equally successfully used in various fields of industry and in construction, is the manufacture of products using cold bending technology from sheet metal. Rolled sheets that can be processed on such a machine are usually made of steel that has not been subjected to heat treatment, as well as ductile non-ferrous metals.

Design Features

The supporting element of the sheet bending machine of this model, on which all other parts of its structure are fixed, is a split-type bed, consisting of two racks and a work table located between them. To give greater rigidity to the IV2144 frame, its side posts are connected with three ties.

The rotary bending beam, which is equipped with a sheet bending machine of this model, has a welded structure and is fixed on the machine in a vertical suspension. Such a beam communicates with the bending cylinder rods through several elements of a kinematic chain (a rack and pinion mechanism connected to the beam rotation shafts, which in turn are connected to the screws on which it is suspended).

Components of sheet bending machine IV-2144

The machine of this model is also equipped with a pressure beam, which also has a welded structure. Such a beam, connected to the cylinder rods responsible for its clamping, moves in a vertical plane along the guides of the bed posts.

Let's consider the technical characteristics of the IV2144 machine, which are especially important for its users.

- The maximum thickness of a steel sheet that can be bent is 4.5 mm.

- The length of the work table, which determines the maximum width of the processed sheet, is 2.5 m.

- The force created by the pressure beam is 40 tons.

- The force created by the rotary bending beam is 30 tons.

- The power of the electrical equipment equipped with the sheet bending machine is 10 kW.

- The maximum adjustment distance for the work table and bending beam in the vertical direction is 10 mm.

- The maximum stroke of the pressure beam is 250 mm.

- The area occupied by the machine is approximately 9 m2.

- The weight of the sheet bender is no more than 9 tons.

Controls of sheet bending machine IV2144

The hydraulic system of the equipment, which includes the following elements, is responsible for the technical characteristics of the pressing and bending beams of the sheet bending machine of this model:

- two main cylinders ensuring the operation of the pressure beam;

- two main cylinders of the bending beam;

- hydroelectric station

The hydraulic drive of the IV2144 machine simultaneously performs several functions: rapid supply of the bending beam to the surface of the sheet being processed, its rapid retraction to its original position and slow movement during the bending process. The position of the pressing and bending beams, depending on the thickness of the sheet being processed, as well as the required bending angle can be adjusted, for which the machine is equipped with manual control mechanisms.

The press is powered by a hydraulic unit model K34007EM

In order to accurately position the position of the sheet being processed and regulate its movement by a given amount, the machine of this model is equipped with a mechanized back stop. Such an emphasis, which is driven by a carriage mounted on it, a lead screw and an electric motor, is attached to the work table of the equipment using a special bracket. In addition, the design of the stop includes hydraulic grips and an indicator of the position of the trailing edge of the workpiece, which allows not only to quickly change, but also to control the position of the sheet being processed.

The back stop of the machine is designed for precise positioning of the sheet during the bending process

To prevent distortions of the presser beam of the machine during its movement between the racks, the design of the sheet bender provides a synchronizer, consisting of a shaft with gears attached to its ends. The synchronizer, together with the pressure beam, moves along rails fixed to the machine racks, the adjustment of the position of which ensures the accuracy of such movement.

The most heavily loaded sheet bending mechanisms are lubricated using a centralized system, and less loaded ones are lubricated using a syringe mechanism. To control the operation of the machine, its design provides two remote controls, one of which is mounted on its right stand, and the second on a hinged control device.

Using the working tools of a sheet bender, which are supplied as standard, you can perform simple bending operations on metal sheets (internal bending angle – 32–180°, bending radius – 7 mm). If such a machine is equipped with additional interchangeable devices, then it can be used to successfully create products of even quite complex configurations from metal sheets - pipes and other closed contours, parts with a U-shaped profile, boxes, etc.

How does the sheet bending machine IV2144 work?

If we briefly describe the operation of this machine, it looks like this: the deformation of a sheet blank is carried out through the influence of a bending beam on it. In this case, the formation of the product of the required profile is ensured through the use of appropriate mandrels, which are fixed on the pressure beam.

The standard bending mandrels of the machine can be replaced with other interchangeable devices for bending closed loops or pipes

The step-by-step operating diagram of the sheet bender of this model is as follows:

- The metal sheet to be processed is placed on the machine's work table, advanced until it comes into contact with the stops and secured using hydraulic clamps.

- A clamping beam with a replaceable mandrel fixed on it is lowered onto the sheet, the configuration and dimensions of which depend on the required bending shape.

- The metal is deformed by a bending beam, which is located under the sheet being processed.

- After processing is completed, the bending beam is lowered to its original position, and the clamping beam releases the finished product.

Article rating:

Share with friends:

met-all.org