04/14/2020 Author: VT-METALL

Issues discussed in the material:

- What are the different grades of aluminum?

- Primary aluminum grades

- Brands of technical aluminum

- Grades of deformable aluminum

- Cast aluminum grades

- Aluminum grades for deoxidation

- Grades of aluminum and its alloys

- Main grades of aluminum and its alloys (in table)

- Aluminum sheet grades

It is difficult to imagine modern industry without aluminum and its alloys. And therefore it is so important to know which grades of this metal are used for certain purposes. For example, the types used for the construction of the fuselage of a spacecraft are not suitable for the production of food utensils, etc.

Aluminum marking is used to indicate the percentage of various impurities, as well as the production or enrichment technology. Let's figure out what physical and chemical properties certain grades of this metal have and where they are used.

What are the different grades of aluminum?

Giving a metal certain properties and enhancing its characteristics is possible by alloying it with various chemical elements, such as magnesium, copper, zinc, silicon, and manganese.

There are different grades of aluminum that meet certain standards, for example, “AD0” according to GOST 4784-97. To avoid confusion, the classification includes high-frequency metals.

Aluminum can be of the following grades:

- Primary (“A5”, “A95”, “A7E”).

- Technical (“AD1”, “AD000”, “ADS”).

- Deformable (“AMg2”, “D1”).

- Foundry (“VAL10M”, “AK12pch”).

- For deoxidation of steel (“AV86”, “AV97F”).

In addition to the listed grades of aluminum, its compounds are distinguished separately, with the help of which they create alloys with gold, silver, platinum, and other precious metals. Such compounds are called ligatures.

Chemical composition of aluminum alloys

| Aluminum alloys | |||||||||||||

| Brand | Mass fraction of elements, % | Density, kg/dm³ | |||||||||||

| GOST | ISO209-1-89 | Silicon (Si) | Iron (Fe) | Copper (Cu) | Manganese (Mn) | Magnesium (Mg) | Chromium (Cr) | Zinc (Zn) | Titanium (Ti) | Other | Aluminum no less | ||

| Every | Sum | ||||||||||||

| AD000 | A199.8 1080A | 0,15 | 0,15 | 0,03 | 0,02 | 0,02 | 0,06 | 0,02 | 0,02 | 99,8 | 2,7 | ||

| AD00 1010 | A199.7 1070A | 0,2 | 0,25 | 0,03 | 0,03 | 0,03 | 0,07 | 0,03 | 0,03 | 99,7 | 2,7 | ||

| AD00E 1010E | EA199.7 1370 | 0,1 | 0,25 | 0,02 | 0,01 | 0,02 | 0,01 | 0,04 | Boron:0.02 Vanadium+titanium:0.02 | 0,1 | 99,7 | 2,7 | |

Primary aluminum grades

An example of this group is primary aluminum grade “A5”. To obtain it, enriched alumina is used. It is impossible to find the metal in its pure form in nature, since it has high chemical activity.

When interacting with other elements, the metal forms bauxite, nepheline and alunite. Subsequently, these ores are used to produce alumina, and then, through certain chemical and physical reactions, pure aluminum.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

The requirements that grades of primary aluminum must meet are established in GOST 11069. Marks indicating that a metal belongs to a certain class are vertical and horizontal stripes applied to the workpieces with indelible paint of certain colors. Primary aluminum is used in leading industrial fields, mostly in those where increased technical characteristics of the raw material are required.

Advantages and disadvantages of aluminum cookware

Crockery and cutlery made from this material are present in any modern kitchen. Main advantages of kitchen items:

- good thermal conductivity – pots and pans heat up faster;

- uniform heating of prepared dishes;

- light weight of various kitchen accessories;

- absolute harmlessness to food due to the formation of a special oxide film on their surface;

- Convenient placement of items on shelves in the kitchen.

You can talk about the dangers of dishes made of this metal if they are used incorrectly. For example, if there is no non-stick coating, you cannot cook acidic dishes in it, as this leads to the release of metal into the dishes and to poisoning. See the video below for other shortcomings.

Brands of technical aluminum

In grades of technical (unalloyed) aluminum, the content of foreign impurities is no more than 1%.

According to GOST 4784-97, grades of technical aluminum must have increased anti-corrosion resistance. However, their strength is not very high. The absence of alloying elements in the metal leads to the formation of a stable protective oxide film on its surface.

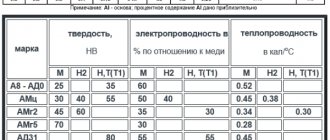

Distinctive features of grades of technical aluminum are high thermal and electrical conductivity. The molecular lattice is distinguished by the almost complete absence of impurities that scatter the flow of electrons. Such properties allow the metal to be used in such areas as instrument making, the manufacture of equipment for heating and heat transfer, and lighting.

Is this aluminum accepted for scrap and at what price?

The raw material is not the most expensive type of aluminum scrap, but not the cheapest either. Food-grade aluminum in Moscow is accepted for scrap metal at different prices per 1 kilogram. Our company “VtorBaza” sets the following cost per kilogram for the following types of scrap:

- Aluminum cans - 30-51 rubles;

- Foil - 45-76 rubles;

- Aluminum containers and utensils - 60-93 rubles.

The final cost of such products is influenced by:

- the degree of purity of the alloy and the presence of impurities present in it;

- volume of collected delivery lot;

- quality and characteristics of the alloy.

The scrap is melted down and reused to make kitchen items, accessories and equipment.

Grades of deformable aluminum

Various grades of aluminum are processed hot and cold by rolling, pressing, drawing, etc. Plastic deformations make it possible to obtain workpieces with different longitudinal profiles: aluminum rods, sheets, strips, plates, profiles, etc.

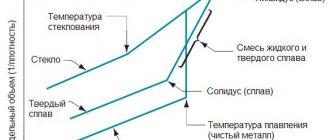

The requirements for deformable grades of aluminum are set out in GOST 4784, OCT1 92014-90, OCT1 90048 and OCT1 90026. A distinctive feature of the metal is the solid structure of the solution, which contains a large percentage of eutectic - a liquid phase in equilibrium with two or more solid states of matter.

Thermal properties

Temperature expansion

Data on the coefficient of thermal expansion (CTE) for aluminum with a purity of 99.99% at various temperatures are shown in Table 4.

Table 4 - Coefficient of thermal expansion (CTE) of pure aluminum 99.99%

Melting temperature

The melting point of pure aluminum is very sensitive to the degree of purity - the content of impurities. It has been experimentally established that the melting point of 99.996% aluminum is 933.4 K or 660.25 ºC.

The solidification temperature of aluminum 660.323 ºС is one of the control points of the 1990 International Practical Temperature Scale, which is used to calibrate thermometers and thermocouples.

Other thermal properties of pure aluminum:

- Boiling point: 2494 ºС

- Specific heat capacity: 0.900 kJ/kg·K at 25 ºС; 1.18 kJ/kg K at 660.40 ºС (liquid state)

- Latent heat of fusion: 397 kJ/kg

- Latent heat of steam formation: 10.78 MJ/kg

- Heat of ignition: 31.05 MJ/kg

Coefficient of thermal conductivity

At moderate to high temperatures, such as above 100 K, the thermal conductivity coefficient k of annealed high purity (99.99+%) is relatively independent of the degree of purity. Below 100 K, aluminum becomes very sensitive to purity. The thermal conductivity coefficient of pure aluminum in the temperature range from 100 to 933 K (from -173 to 660 ºC) smoothly decreases from 3.02 to 2.08 W cm-1 K-1 [1].

Cast aluminum grades

Shaped products are made from casting grades of aluminum, the characteristic properties of which are high specific strength combined with low density. Thanks to these features, it is possible to manufacture (cast) parts of various configurations without the appearance of cracks.

There is a division of foundry metal grades into groups according to their purpose. They are:

- highly hermetic (“AL2”, “AL9”, “AL4M”);

- high-strength and heat-resistant (“AL19”, “AL5”, “AL33”);

- corrosion-resistant.

To improve the properties of parts made from these types of aluminum, various heat treatment methods are used.

Use of aluminum for food packaging

Foil and special forms are produced from sheet material, which are increasingly used and used in the form of packaging. This allows you to maintain the temperature and excellent taste of dishes, as well as reheat or freeze them without losing quality or beautiful appearance.

The metal is harmless to health and does not adversely affect the properties of dishes. Aluminum packaging, which can take on and retain any shape, is used for transporting semi-finished products, fast food, meat and fish, as well as other products.

Grades of aluminum and its alloys

There is a division of aluminum alloys into:

- deformable (used for forging and rolling);

- foundry (for casting parts).

The requirements for their chemical composition are defined in GOSTs 1131 and 4784-97.

Depending on the type of hardening, alloys can be:

- heat-strengthened;

- hardened by pressure.

More common is another classification, which is based on the characteristics of the alloys. According to it, heat-strengthened alloys are divided into:

- heat-resistant (“AK4”, “AK4-1”, “D20”, “1201”);

- high-strength (“B93” and “B95”);

- highly plastic medium strength, or aviali, alloyed with aluminum, magnesium and silicon (“AD33”, “AD31” and “AD35”);

- welded with normal strength (“1925” and “1915”);

- duralumin with normal strength, alloyed with aluminum, copper and magnesium (“D16”, “D1” and “D18”);

- forging (“AK8” and “AK6”).

Thermally non-hardening steels with increased corrosion resistance and weldability are divided into:

- highly plastic of medium strength, called magnalia (“AMg1”, “AMg6”, “AMg2”, etc.);

- highly plastic, low strength, alloyed with magnesium (“D12” and “AMts”), and unalloyed, or technical aluminum (“AD1” and “AD0”).

When manufacturing sheets, the requirements of GOST 21631–76 must be observed. Products are classified depending on the area of application and properties:

- Acid-resistant grades of aluminum sheet are used to produce fuel tanks, welded containers, aircraft components, rivets, frames and automobile radiators. The metal is characterized by good weldability and corrosion resistance, increased ductility and deformability. For the manufacture of flat acid-resistant sheets, aluminum alloys of the “AMg” grades (2, 3, 5 and 6), alloyed with manganese and magnesium, are used.

- Technical aluminum is used for finishing and insulation work. Its advantages include financial savings due to increased flexibility and low weight of the sheets.

- Smooth perforated aluminum is widely used in construction; it is used for the manufacture of air duct grilles, decorative interior parts, and reinforcing plasterboard corners. Holes in perforated parts can be rectangular, round, or diamond-shaped. They are made on special coordinate-punching presses.

- Grades of food grade aluminum are produced from annealed, semi-cold-worked and cold-worked (cold-worked to harden the material) alloys (“A5M”, “A5N2”, “A5N”), as well as from primary aluminum that has not been subjected to heat treatment (“A7” or “AD0”). The sheets are characterized by high hygiene, absence of impurities and alloying elements.

Finished products can be either sheets, 0.3–2 mm thick, or slabs, up to 10.5 mm thick. The width of the rolled product is 0.5-2 m, length – 2–7.2 m.

Separately, we note corrugated aluminum sheets (profiled) used for roofing work. Their distinctive features are durability and high performance characteristics.

Profiled products are made from grades of aluminum suitable for bending and have the following advantages:

- Due to the light weight of the sheets, they can be used for the reconstruction of old structures. Due to their age, structures may not be able to cope with heavy loads, so lightweight corrugated sheets are an ideal option for them.

- Suitable for roofing work in both multi-story and single-story buildings.

- Due to the flexibility of the metal, it is suitable for work on roofs with complex configurations.

- Due to the ease of installation, basic skills in working with sheets are sufficient, which can be mastered without problems.

In addition, anodized aluminum sheets with a matte, mirror or semi-matte surface are also produced. Household appliances, window blinds, lighting fixtures, decorative elements, solar panels are made from alanode - a sheet of aluminum with a mirror surface. The scope of its use is directly related to reflective abilities.

Rolled and low-grade material

Electrical aluminum obtained during foundry production is accepted separately. Usually these are components for machine tools, automobile, and aircraft components. Piston scrap contains silicon. Rental points in Moscow accept electrical aluminum with nickel if the component content is no more than 2.8%.

Low grade electrical aluminum - crushed, shavings. The material is sorted by alloy type. A separate class is multi-grade shavings.

Features of supplied aluminum

Electrical aluminum, stripped of insulation, is highly valued at rental points in Moscow. If there are transformers, they must be removed from the bus. The veins are cleaned mechanically, since firing leads to melting and the appearance of streaks on the metal. No paper allowed.

Sell aircraft wire

The most valuable aluminum is shiny and clean. The presence of oil is a reason for a decrease in cost due to clogging. If there is a steel core inside, cutting is necessary. Products with traces of oxidation and paint are not accepted. Before delivery, it is necessary to remove the wire grid, damaged parts, and elements containing impurities.

Sources and examples of scrap metal

Electrical aluminum is widely used. These are thin or thick wires and cables used in wiring in homes and large communication networks. In new systems, aluminum parts are less common than durable copper, but in old systems they are widespread. Since many people are replacing wiring with copper, the amount of electrical aluminum that can be recycled is large.

Table of the main grades of aluminum and its alloys

Below are the grades of aluminum steel according to the classes to which they belong:

| Primary aluminum | |||||

| «» | «» | "A5E" | «» | «» | |

| "A7E" | «» | "A85" | "A95" | "A97" | |

| "A99" | "A995" | "A999" | |||

| Technical aluminum | |||||

| «» | "AD0" | "AD00" | "AD000" | "AD00E" | |

| "AD0E" | "AD1" | "ADoch" | "ADS" | "ADch" | |

| Aluminum for deoxidation | |||||

| "AV86" | "AV86F" | "AV88" | "AV88F" | "AV91" | |

| "AV91F" | "AV92" | "AV92F" | "AV97" | "AV97F" | |

| Cast aluminum | |||||

| "AK21M2.5N2.5" | "AK4M4" | "AK5M2" | "AK5M7" | "AK7" | |

| "AK7M2" | "AK9" | "AL1" | "AL11" | "AL13" | |

| "AL19" | "AL2" | "AL21" | "AL22" | "AL23" | |

| "AL23-1" | "AL24" | "AL25" | "AL26" | "AL27" | |

| "AL27-1" | "AL28" | "AL29" | "AL3" | "AL30" | |

| "AL32" | "AL33" | "AL34" | "AL4" | "AL4-1" | |

| "AL4M" | "AL5" | "AL5-1" | "AL6" | "AL7" | |

| "AL7-4" | "AL8" | "AL9" | "AL9-1" | "B124" | |

| "B2616" | "VAL10" | "VAL10M" | "VAL11" | "VAL12" | |

| "VAL8" | |||||

| Aluminum wrought alloy | |||||

| «1201» | «1420» | «» | "AD31" | "AD33" | |

| "AD35" | "AK4" | "AK4-1" | "AK6" | "AK8" | |

| "AMg1" | "AMg2" | "AMg3" | "AMg3S" | "AMg4" | |

| "AMg4.5" | "AMg5" | "AMg5P" | "AMg6" | "AMts" | |

| "AMtsS" | "ATspl" | "B65" | "B93" | "B94" | |

| "B95" | "V95P" | "B96" | "V96ts" | "V96TS1" | |

| "VD17" | «» | "D12" | "D16" | "D16P" | |

| "D18" | "D19" | "D1P" | "D20" | "D21" | |

| «» | |||||

| Aluminum anti-friction alloy | |||||

| "AMST" | "AN-2.52 | "AO20-1" | "AO3-12 | "AO3-7" | |

| "AO6-1" | "AO9-1" | "AO9-2" | "AO9-2B" | "ASM" | |

According to GOST 4784-97, aluminum is marked with letters and numbers. A breakdown of aluminum grades is given below, using the following designations:

- “A” – technical aluminum;

- “D” – duralumin;

- “AK” – aluminum alloy, malleable;

- “AB” – avial;

- “B” – high-strength aluminum alloy;

- “AL” – cast aluminum alloy;

- “AMg” – aluminum-magnesium alloy;

- “AMts” – aluminum-manganese alloy;

- “SAP” – sintered aluminum powders;

- "SAS" - sintered aluminum alloys.

Aluminum purity classification

The following conditional classification of aluminum purity levels is usually used [1]:

- 99.50-99.79 – commercial purity aluminum

- 99.80-99.949 – high purity aluminum

- 99.950-99.9959 – super purity aluminum

- 99.9960-99.9990 – extremely pure aluminum (extreme purity)

- more than 99.9990 – ultra-purity aluminum.

Below is an overview of the properties of aluminum with a purity level of 99.50 and above. About the influence of alloying additives and impurities on the properties of aluminum and aluminum alloys, see here.

Aluminum sheet grades

To produce these blanks, aluminum or its alloys are used, deformed hot and then rolled cold.

Sheets are made from:

- technical aluminum grades “A0”, “AD0”, “A5”, “A6”;

- duralumin alloys of grades “D1”, “D12”, “D16”;

- wrought alloys "AD31";

- aluminum-manganese alloys "AMts";

- aluminum-magnesium - “AMg”.

To increase corrosion resistance, the sheets are clad, that is, covered with a film of pure aluminum, which can have a thickness reaching 5% of the total thickness of the sheet.

The surface of standard aluminum sheets (general and special purpose) is usually smooth, with a raised, high or regular finish. The sheets are used to produce stainless steel products used in industries such as fuel, food, chemical, construction and mechanical engineering.

For the production of sheets, aluminum and its alloys of the grades "A5", "1105", "AD", "AMg1", "AMg3", "A6M", "AMg2", "AMg5", "AMts", "AMg6", " AD1", "VD1", "D16", etc.

- Sheet aluminum grade "A5".

The surface of the A5 sheet is matte, the thickness varies from 0.5 to 10 mm, the finish is of normal quality. In terms of its chemical composition, it meets the requirements of GOST 11069-74. Sold in both sheets and rolls.

Characterized by high thermal conductivity and corrosion resistance. Due to its high plastic properties, rolled metal of the “A5” grade is easily formed in different ways and processed. This grade of aluminum is suitable for argon welding.

Depending on the condition of the metal, the sheets can be:

- cold-worked (A5N);

- soft or annealed (“A5M”).

"A5N" refers to durable grades of aluminum. This property is due to its cold processing. At the same time, the impact strength and ductility of the material are reduced.

Industrial structures and equipment are made from A5 grade sheets, including food containers, decorative elements, and cladding coatings.

- Sheet aluminum grade "A6M".

When producing annealed sheets from soft aluminum grades “A6M”, the requirements of GOST 21631-76 are observed. The material is used in the food industry. Aluminum "A6" in composition meets the requirements of GOST 11069-74.

- Sheet aluminum grade "1105".

For the production of rolled products “1105”, duralumin alloyed with magnesium and copper is used. The first two digits (11) are used to designate duralumin, and the last ones are used to designate the alloy serial number.

Aluminum sheets of grade “1105” are used for the manufacture of welded structures and parts operated at low temperatures:

- Aluminum sheet “1105N” is a cold-worked rolled product, plastically deformed to give greater strength. Changes in properties and structure are caused by pressure acting on its surface. As toughness and ductility decrease, properties such as strength and hardness increase.

- Aluminum sheet “1105M” is a rolled metal product annealed at high temperatures, characterized by ductility, malleability and softness.

- Aluminum sheets with a thickening and a cladding layer are designated “1105UM”, without a cladding layer - “1105AM”. A distinctive feature is its high resistance to aggressive operating environments.

- Hardened, naturally aged aluminum sheets used in various industrial fields are marked “1105T”. The range with normal plating is designated “1105AT”.

- Sheet aluminum grade "AD".

High ductility and corrosion resistance are the distinctive features of AD sheets made from technical aluminum with a small amount of impurities. Sheets can be soft (“ADM”) or hard-worked (“ADN”). They are used as workpieces in various industrial fields.

- Sheet aluminum grade "AD1".

The material can be purchased both in sheets and rolls. For the production of sheets, AD1 grade aluminum is used, which meets the requirements of GOST 21631-76 and GOST 4784-74. Distinctive features are ease of molding and machining, corrosion resistance. The purity of the alloy as a percentage is indicated by numbers, the deformable metal is indicated by letters.

- Sheet aluminum grade "AMg1".

This is a wrought alloy for which magnesium is used for alloying. The number indicates the content of the main alloying element (1% magnesium). Distinctive features of the material are good weldability, ductility, and corrosion resistance. Aluminum grades are used in the production of building structures and parts in the industrial sector.

- Sheet aluminum grade "AMg2".

It has characteristics similar to “AMg1”, but with a two percent magnesium content. Easy to cut. High electrical conductivity is due to the small inclusion of impurities.

- Sheet aluminum grade "AMg3".

Contains 3% alloying substance – magnesium. Available in the form of rolls and sheets. Main characteristics: excellent ductility, corrosion resistance, weldability. Aluminum grades "AMg3" are used to make medium-strength structures, welded tanks, industrial pipelines, hydraulic equipment, frames and skins of railway cars.

- Sheet aluminum grade "AMg5".

Sheets with 5% magnesium content. Aviation aluminum grades are used to make chemical containers used under pressure, pipelines, welded external structures, plating of river and sea vessels, aircraft and trucks.

- Sheet aluminum grade "AMg6".

A wrought alloy, used in the same way as AMg5, but containing 6% magnesium.

- Sheet aluminum of the AMts brand.

Aluminum sheets containing 1–1.6% manganese. The material is characterized by easy welding, ductility, and corrosion resistance. It is used in the production of ship cladding, building structures, radiators, beverage containers, decorative elements, and chemical containers operated under high pressure.

- Sheet aluminum grade "VD1".

For the production of “VD1”, a high-strength duralumin wrought alloy alloyed with magnesium and copper is used. It is characterized by ductility, ease of processing, and corrosion resistance. To enhance corrosion resistance, additional cladding is used, that is, a layer of pure aluminum is applied.

Various grades of aluminum are widely used in all areas of industry. The metal is one of the five most common in the world. Under natural conditions, it is a component of various ores. By adding other components, various grades of aluminum are created that have improved characteristics, for example, higher corrosion resistance, strength, and heat resistance.

Aluminum alloys

The most common elements in aluminum alloys are copper, manganese, magnesium, zinc and silicon. Less common are alloys with titanium, beryllium, zirconium and lithium.

Aluminum alloys are conventionally divided into two groups: cast and wrought.

To make casting alloys, molten aluminum is poured into a mold that matches the configuration of the resulting product. These alloys often contain significant silicon impurities to improve castability.

Wrought alloys are first cast into ingots and then shaped into the desired shape.

This happens in several ways depending on the type of product:

- By rolling, if necessary, to obtain sheets and foil.

- By pressing, if you need to obtain profiles, pipes and rods.

- Molding to obtain complex shapes of semi-finished products.

- Forging, if you need to obtain complex shapes with increased mechanical properties.

Optical properties

Spectral reflectance

The reflectivity of a smooth aluminum surface with respect to light is more than 90% at wavelengths from 0.9 to 12.0 microns; for waves with a length of 0.2 microns, this reflectivity decreases to 70%. For wavelengths below 0.2 µm, reflectivity decreases sharply.

Maximum reflectivity is achieved by vapor deposition of aluminum, which produces very smooth surfaces. To achieve maximum reflectivity, these gas phase films require a thickness of at least 10-5 cm.

The reflectivity of an aluminum surface decreases as its roughness increases. A sandblasted aluminum surface may only reflect 15-25% of the light compared to a polished surface of the same chemical composition. Figure 3 shows the normal reflectance of various pure aluminum surfaces.

Figure 3 – Spectral reflectance of pure aluminum [1]

Electrical resistivity

The accepted value of electrical resistivity of ultrapure aluminum (99.990%) at 20 ºC is 2.2548×10-8 Ohm m or 64.94% of the International Annealed Copper Standard (IACS). The electrical resistance of 99.9% pure aluminum at various temperatures is shown in Table 5.

Table 5 - Electrical resistivity of pure aluminum (99.90%)

The electrical conductivity of pure aluminum is isotropic unless it contains oriented dislocations.

The effect of grain size on electrical resistivity in industrial aluminum is negligible. However, cold-worked aluminum has, in the direction of the resulting cold plastic deformation, a slightly higher – 0.5-1.0% – electrical conductivity.