How to distinguish bronze from brass: composition, characteristics, features

It is no coincidence that the question of how to distinguish bronze from brass interests many, because products made from these copper alloys are very similar in appearance. Meanwhile, having decided to use products made from such materials for a specific purpose, one should distinguish between these two metals, since they have serious differences in many respects.

These busts are very similar, but they are made from different copper alloys

What are bronze and brass

Bronze and brass are alloys based on copper. Moreover, individual brands of such alloys are very similar in color, but their characteristics may have significant differences. In order to have a good understanding of the question of in which cases to use brass and in which to use bronze, it is necessary to become more familiar with their properties and chemical composition.

Chemical composition of simple brasses

Chemical composition of tin bronzes (click to enlarge)

A material such as bronze has been used by humanity for several millennia, and its popularity is not decreasing. Initially, man learned to produce bronze alloys, the basis of the chemical composition of which is copper and tin.

Later, with the development of the metallurgical industry, bronzes began to be produced, in which tin was replaced by other chemical elements - aluminum, lead, iron, silicon, beryllium, phosphorus, etc. Bronzes of the first type began to be called tin (they are often called bell bronzes, because they used to made bells), and the second - tinless.

A change in the chemical composition of bronze leads to a change not only in its characteristics, but also in color.

Brass is also a copper alloy, but its main alloying element is zinc. The chemical composition of various brands of brass may contain elements such as nickel, lead, iron, tin, manganese, etc.

, but their content is insignificant and is necessary only to give the finished alloy certain characteristics. It is known that the ancient Romans knew how to produce brass, who obtained it by mixing molten copper and zinc ore.

A more efficient production technology, which involves mixing molten copper and pure zinc, was developed in England, and this happened in 1781.

Physical properties of simple brasses (click to enlarge)

Physical properties of tin bronzes (click to enlarge)

For a long time, brass, which has a beautiful light golden color, was used to make decorative items, including those that were passed off as gold. However, manufacturers could not help but pay attention to other, no less significant characteristics of this alloy, which include high corrosion and abrasion resistance, ductility, combined with fairly high hardness and strength.

That is why brass, which also has good casting properties, began to be actively used not only for decorative purposes, but also for the manufacture of products successfully used in various industries.

Comparative characteristics

The basis of bronze and brass, as mentioned above, is the same metal - copper. The difference between these alloys lies in their chemical composition and, accordingly, in the characteristics that they possess. Naturally, the differences between these copper alloys also determine their areas of application.

Due to the fact that bronze is a stronger and more durable material when compared with brass, bells, sculptural compositions, elements of fencing, landscape and interior structures have been made from this material since ancient times.

It is also important that many grades of this alloy are characterized by good fluidity in the molten state. This makes it possible to cast products of even very complex configurations from them.

By adding various chemical elements to the chemical composition of bronze, you can change its color in a fairly wide range, which is also of great importance in the production of decorative products.

This watch ring, judging by the color, is more likely yellow brass (bronze would be redder). Scratches easily remain on the surface - also a sign of brass

Brass differs from bronze in its higher ductility and, accordingly, lower strength and wear resistance, which limits the use of this alloy in many areas. In addition, brass is less resistant to aggressive environments, in particular salty sea water, which does not allow the use of brass products in shipbuilding, where bronze is used very actively and successfully.

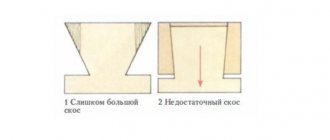

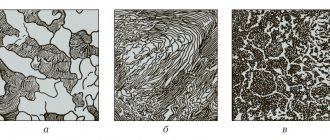

There is also a noticeable difference in the color of these alloys and in their internal structure. Any experienced specialist can tell you how to distinguish brass from bronze: to do this, just look at the fracture of products made from these alloys. Brass has a lighter color when fractured and a distinct fine-grained structure, while bronze is easily identified by its dark brown fracture color and coarse-grained internal structure.

Summarizing all of the above, we can highlight the following differences between brass and bronze.

- The main alloying element in bronze is tin, and in brass it is zinc. Moreover, both alloys are created on the basis of one metal – copper.

- Bronze (even with a classic chemical composition) perfectly resists the effects of aggressive environments, in particular salty sea water. In order to improve the corrosion resistance of brass, additional alloying elements must be introduced into such an alloy.

- The strength and anti-friction characteristics of bronze are also better than those of brass. Such qualities significantly expand the scope of application of bronze alloys, from which not only strong and durable decorative elements are made, but also critical parts for use in various industries. Brass is more often used for the production of bimetallic elements (“steel - brass”), which demonstrate high resistance to the formation and development of corrosion processes.

- Bronze products have a dark brown color and coarse grain when broken, while brass products have a yellow-golden color and a fine-grained structure. This difference in color and internal structure makes it easy to determine what alloy the product is made from.

- Bronze, like brass, although they are based on a metal such as copper, are divided into completely different categories. Thus, bronze can be tin or tin-free, while brass can be two- or multi-component.

Comparison of properties of brass and bronze

Bronze and brass, which have a lower melting point than copper, can be used to make various products at home. However, for this, naturally, it is necessary to stock up on the appropriate equipment and thoroughly study the technology and rules for performing such a technological operation as casting.

What is more expensive: bronze or brass

As practice shows, the price of alloys is approximately at the same level - within 200 rubles / kg. The cost primarily depends on the copper content in the composition. In addition, it is worth considering that bronze is heavier than brass, so with an equal volume of scrap metal, bronze will be more profitable. However, it is important to remember the pricing policy of collection points and the general situation on the metals market.

Which is better, bronze or brass? There is no definite answer to this question, since each of the alloys has its own characteristics and technical characteristics. And the scope of their application is different. Find out more about which scrap metal is more profitable to hand over from the specialists of our company.

Differences between brass and bronze, copper and silumin

The most ancient alloys used by people are bronze and brass. They differ significantly in their composition, but their scope of application is similar. Modern alloys differ significantly from those used by our ancestors. The colors and composition of current metal compounds have undergone significant changes over time.

Archaeologists have found samples of bronze objects made about 25 centuries ago. These are sculptures, various decorations, armor, weapons, numerous household utensils, dishes, and coins. Along with them, brass products were also actively used, which are sometimes very difficult to distinguish from things made of bronze. You can see the appearance of the materials in the corresponding photos. To understand how to distinguish bronze from brass or other materials, you need to familiarize yourself with their parameters.

Characteristics of brass

Brass alloy is produced by combining zinc with copper, to which nickel, iron, manganese, tin, and lead are sometimes added. Typically the material consists of 70% copper component, with 30% zinc component. Almost half of the produced alloy consists of recycled zinc. Technical metal contains about 50% zinc part with 4% lead.

There is also a special type of brass connection called “tompak”. The copper component in it reaches 97%, and the zinc component ranges from 10 to 30%. This compound makes excellent jewelry, various artistic products, insignia, and fittings.

A couple of centuries ago, brass alloys were often used as fake gold, which was achieved by using pure zinc rather than ore. This connection was very difficult for inexperienced users to recognize. It has become actively used in various industrial fields due to its unique properties. These alloys have high ductility, abrasion resistance and good corrosion resistance.

The difference between copper and brass

Copper has features that make it popular in the manufacture of various decorative elements. In addition, it has good electrical parameters, as a result of which it is used in the manufacture of electrical devices. At home, you can distinguish copper elements from brass by several criteria:

- color;

- hardness;

- marking;

- area of use.

Color

To determine the metal, it must be cleaned. The metal surface is freed from contamination using a solution of ordinary water and vinegar. This removes not only dirt, but also oxidative film. The product being tested is carefully examined under a white light source.

A brass item differs from copper by simple visual observation. A copper item will have a brownish-red color with a uniform appearance, while brass will appear lighter, with multi-colored shimmers. This heterogeneity indicates the presence of several metals in the composition, which determine the color shade.

It is practically impossible to detect copper under a yellow lamp or in daylight.

Hardness

To understand how to distinguish copper from brass, you should lightly tap them. When a copper product hits a hard surface, it produces a muffled sound. This is due to the special softness of the metal. Brass objects are characterized by a sharp, ringing sound of impact. This check is used for large items.

Marking

Some items have special markings on their surface. For brass products, the letter “L” is used. Copper elements are practically not marked. Some parts may be marked with the letter "M" with a numerical addition. In this case, special reference books are used to determine the specific composition of the material.

Application area

These materials are also distinguished by area of use. Brass alloys are often used for the manufacture of various components and parts. Copper is an ideal element for the production of electrical wires and other electrical parts. This is due to its excellent electrical parameters.

The difference between bronze and brass

Bronze, like brass, has a copper component at its core. Some brands of these alloys are similar in color, but have completely different properties. The bronze item has a coarse-grained structure with a dark brown or reddish tint, in contrast to the yellowish brass with a fine-grained shape.

It should be taken into account that the presence of tin in large quantities in the bronze alloy gives it an almost white color. Modern compositions contain an alloying component of tin or any other (beryllium, lead, aluminum, silicon with zinc).

Numerous things made of brass and bronze have differences, which can be determined by knowing their technical parameters.

Metal objects made of brass and bronze are distinguished by weight. A bronze item is heavier than a brass item, however, before determining the alloy, it is necessary to take items of approximately the same size for comparison. To determine what material a thing is made of, you need to try to bend it. A brass object may give in slightly, but a bronze object may break. You can try to make a small cut with a hacksaw, in which the bronze part will produce small shavings. It will not change its characteristics when heated.

To understand how to distinguish brass from bronze, you can use the chemical method. A small amount of shavings of both alloys is placed in various glass containers with dilute nitric acid (parts 1 to 1). It is necessary to wait some time so that the bulk of the metal has time to dissolve in the chemical composition. The liquid, which does not reach a boil, is kept on low heat for half an hour. When combined with bronze shavings, a whitish tin precipitate is formed.

Bronze is used to make large items, as it is more resistant to abrasion. In addition, a variety of marine accessories are also made from this alloy, which is not affected by salt water, is not susceptible to oxidation and does not rust.

The difference between silumin and brass

Silumin material consists of an aluminum base with the addition of silicon, as well as a small amount of copper, iron, and manganese. It has good wear resistance and strength compared to aluminum things. The difference between silumin and brass is the fragility of this material and the features of its application.

They are used for casting many products used in a variety of fields, including household goods, as well as for the manufacture of costume jewelry. A silumin object is characterized by high porosity and low strength. During processing, silumin begins to crumble, which clearly distinguishes it from brass things.

Source: https://oxmetall.ru/metalli/latun/otlichiya-ot-bronzy-medi-i-silumina

Difference between metal and alloy

There are several methods to distinguish non-ferrous metal from its alloys.

This can be done both without the use of special means and with the help of chemical reactions and tools. The best experts in metals are the people who work with them, as well as those who are well aware of their properties. So, a person who knows the difference between copper and brass is a foundry worker, a chemistry teacher, a scrap metal acceptor with extensive experience, a pawn shop worker, or a jeweler. All of them, to one degree or another, work with metals and know a lot about them.

Definition of color and sound

The main difference between a metal and its alloys is color. To determine what a product is made of, you need to:

- Clean it from the layer of dirt and patina.

- Examine carefully under daylight or under a white fluorescent lamp. Under no circumstances should the product be examined under the light emanating from an incandescent lamp.

- The best option would be to compare a brass or bronze product with a copper one. A piece of wire, which is always made of non-ferrous metal, is suitable as such an example.

Copper always has a reddish tint, brass is yellow or golden , and the color of bronze can be from yellow-pink to brown.

The main thing in this method is to take your time and carefully examine the sample. But if brass contains more than 80% bronze, then the color of the alloy will not differ much from the color of the metal.

A characteristic feature that allows you to distinguish brass from bronze is the sound heard when a metal object hits the sample under study. The difference will be fairly easy to hear. A copper object has a muffled and low sound, while a brass object, on the contrary, has a ringing and high-pitched sound. This is a very effective method, but is only used when testing large samples.

We recommend: Types of trash cans in the cabinet under the sink

Application of chemical solutions

To check whether the person in front of you is copper or brass, you can use a small amount of hydrochloric acid solution.

This chemical is dropped onto the test sample and the reaction is monitored. Nothing will happen to pure metal, but a white substance will be released on the surface of the brass - zinc oxide. But a salt solution helps to distinguish copper from bronze. It needs to be heated and poured over the sample being studied. The metal will darken when exposed to a hot saline solution, unlike bronze, which will not change at all.

Drill Usage and Marking

Using a drill you can easily identify brass. But it is important to remember that the tool will damage the metal object. The fact is that during operation of the drill, chips come out from under the drill, which for copper are quite long and ornate, while for brass they are, on the contrary, short and needle-shaped. After all, the metal is much softer than its alloy.

Sometimes on a piece of the material being examined you can see markings that can easily tell you what is in front of a person. So, the mark on copper begins with the letter “M”, and on brass - with “L”. But in other countries, product labeling is somewhat different from Russian:

- In the USA you can see C2, C3, C4 badges on brass alloy.

- In the European Union, the letter C is placed on copper and brass, but after it on the metal you can see A, B, C, D, and on the alloy - L, M, N, P, R.

This method makes it quite easy to distinguish pure copper from brass. If markings are present, then you should not resort to other recognition methods.

Sample hardness and weight difference

If the sample is small and thin-walled, then you can try to bend it.

The metal is soft and easily deformed, while its alloy is much harder and less susceptible to external influences. We recommend: Precious metals in old tube TVs of the USSR

If the inspector has two pieces of the same shape and volume in front of him, then determining whether it is a metal or an alloy will not be difficult . The fact is that copper and bronze are much heavier than brass. When comparing samples of different weights and shapes, the use of this method becomes much more difficult.

These methods make it possible to fairly accurately distinguish pure metal from its alloys without the use of expensive special means. The main thing is to follow the recommendations. And then, when selling scrap metal, expensive copper will not be mistaken for cheaper brass and bronze.

The difference between bronze and brass: characteristics of the alloys, their comparison and differences

Bronze and brass are very similar in appearance. However, they differ significantly in their chemical composition and characteristics. The metallurgical industry clearly distinguishes one alloy from another. But in everyday life it can be very difficult for a buyer to figure this out, especially when purchasing a rather expensive bronze item. Therefore, it is extremely important to know how to distinguish bronze from brass.

Characteristics of metals

Bronze is an alloy of copper and tin, silicon, beryllium, aluminum, lead and other elements. However, only tin is often used to obtain high-quality bronze. There are also alloys that use nickel and/or zinc. They are called spiater and are a cheap analogue of bronze.

Depending on what metal is present in the alloy, bronze is distinguished:

- tin;

- beryllium;

- aluminum;

- silicon

Properties and characteristics of copper

When interacting with atmospheric oxygen, a yellow-red oxide film is formed on the surface. In its pure form, the metal is characterized by sufficient ductility and softness. The hardness of the material increases with the addition of tin impurities, resulting in bronze, the oldest alloy created by ancient man. Lead and zinc added to bronze make it more fluid and soft. Ship propellers, sculptures, and medals are produced from this type of metal by casting.

Unlike iron, it does not have magnetic properties, but has high electrical and thermal conductivity, which explains its wide range of applications. With the addition of impurities, these properties decrease. A refractory but not very hard metal is characterized by a high boiling point, melting point, and density.

It exhibits high resistance to corrosion processes. For example, when interacting with water, iron oxidizes faster. The chemical activity of the metal is low; oxidation does not occur in dry air conditions. Amphotericity or duality is expressed in the ability to exhibit the characteristics, depending on conditions, of the parameters of a base or an acid. The metal is easily rolled into sheets and strips, and pulled into thin wire thousandths of a millimeter thick.

Differences between bronze and brass

Brass and bronze have different chemical compositions and properties, but the appearance of these alloys is almost identical. It is very difficult for an ordinary person not involved in the industrial production of alloys to distinguish bronze from brass. Therefore, it is worth understanding what properties are characteristic of these alloys, what are their differences, and how to determine what alloy the item being purchased is made of.

Differences between bronze and brass

Properties of bronze and brass

Bronze and brass are metal alloys that are made from copper. The difference between them lies in the main alloying material. This affects the physical and chemical properties of these alloys. Accordingly, the composition of bronze and brass directly affects the areas of application of these materials.

Bronze is a copper-based alloy with the addition of alloying materials such as tin, beryllium, silicon, aluminum and lead. Other components, such as zinc or nickel, may also be used. In this case, the alloy is called spiatr; it is much cheaper, but also inferior in physical characteristics.

Bronze appearance

There are several types of bronze alloys, which differ depending on the main alloying component. Today there are:

- tin;

- beryllium;

- silicon;

- aluminum

There is also a classification depending on the presence of tin in the composition. Based on this, tin bronze is distinguished - an alloy of copper and tin, and tin-free bronze. There is also an arsenic type, but today it is not used in production.

Brass is an alloy of copper and zinc, with possible content of other components: nickel, lead, tin, iron, manganese and others. This alloy has been known since ancient times. It was most likely developed by the Romans, who smelted copper with zinc ore. Zinc in its pure form began to be used only at the end of the 17th century in England.

Brass is similar to gold, which is why it was often used to counterfeit gold coins.

Due to its fine-grained structure, it is widely used in industry. Today, the production of steel-brass bimetal has become popular. The finished material has increased resistance to corrosion and physical wear. Moreover, such an alloy is quite ductile and can be easily cast and physically bent.

Appearance of brass

There is a variety called tombak, which is used in artistic casting, making accessories and insignia.

The main differences between the alloys

Despite their similar appearance due to the use of copper as a base, bronze and brass have certain differences due to the addition of tin and zinc. Thanks to this, the scope of application of both materials is quite wide and varied.

Bronze is used quite often by sculptors. It is excellent for the production of monuments, sculptures, busts, fences and other artistic products. It can stand for hundreds of years without changing its shape or structure. Brass is used quite rarely for such purposes, which is due to the high ductility of this alloy, which negatively affects the durability and wear resistance of sculptures.

Brass and bronze

Due to its properties, one of which is resistance to salty sea water, bronze was previously widely used in maritime affairs. In order for brass to achieve the same properties, it is necessary to add alloying components such as aluminum, tin or lead.

Despite the external similarity, there are small differences between bronze and brass that can be seen with the naked eye. The main thing that should be highlighted is the difference between bronze and brass in color. Bronze has a dark brown tint, while brass is lighter, reminiscent of gold due to its yellowish tint.

Copper and bronze differences - Metals, equipment, instructions

Bronze and brass are very similar in appearance. However, they differ significantly in their chemical composition and characteristics.

The metallurgical industry clearly distinguishes one alloy from another.

But in everyday life it can be very difficult for a buyer to figure this out, especially when purchasing a rather expensive bronze item. Therefore, it is extremely important to know how to distinguish bronze from brass.

How to determine what we have in front of us: brass or copper, their main differences

Anyone who searches for and sells non-ferrous metal sometimes has doubts about the type of scrap and, accordingly, its true value upon delivery.

Copper is a non-ferrous metal, and brass is an alloy that is typically 70% copper, so it often resembles it.

A mistake can be quite costly. For copper at collection points they give 285-300 rubles, for brass - about 150 . There are many ways to find out what kind of metal we see - copper or brass, and we will tell you how to distinguish them from each other in this article.

What is copper and brass

Copper is a non-ferrous metal. Its color is reddish-pink, it is pliable when working, soft and malleable. It has high thermal and electrical conductivity, so copper is often used to produce:

- parts of electrical appliances;

- cables;

- radiators.

Copper is not hardened because it becomes hard even after cold forging. It tends to become covered with patina - a green coating that occurs when the ambient humidity is high.

To increase strength, improve a number of other indicators and reduce the cost of the material, impurities are added and an alloy is obtained.

One such alloy is brass .

In the classic version it contains a third of zinc.

Brass is golden yellow, stronger and harder. It does not oxidize so intensively , and is not so plastic.

Sometimes, depending on the purpose of the alloy, they add:

- tin;

- silicon;

- lead;

- manganese.

What is the difference between copper and bronze: basic testing methods

There are several ways to distinguish bronze from copper:

- Sound. When hitting a copper object, a muffled sound will be heard. Bronze is more “sonorous”, so this is a very common way to check.

- Bronze is characterized by less ductility. However, it weighs a little more.

- Saline test. To prepare it, you will need 1 liter of water, in which you need to dissolve 200 grams of salt. Heat the solution to 50 degrees. We lower the object there for 15 minutes - if after this time it darkens, then this is a copper product, because the color of bronze remains unchanged.

- Bronze products are very difficult to bend, which cannot be said about copper ones.

- If a copper object is in contact with air for a long time, its surface will turn a little green - this is a natural patination effect.

- By type of chips. When drilling a copper product, long ornate chips appear, resembling a spiral. As a rule, the shavings from bronze products are small and crumbly.

The melting points of copper and bronze are also different. Pure copper melts at a temperature of about 1100 degrees Celsius. Bronze already melts at 900 degrees, but it all depends on the exact composition of the alloy (the more tin, the lower the melting point).

Copper and bronze are similar in appearance, but they are different types of non-ferrous metal, which is expressed not only in their physical and chemical properties, but also in price. Pure copper will always be more expensive, but its cost also depends on the type of scrap being delivered (shavings, mix, 1st grade, etc.). If you have copper or bronze scrap metal in stock, you can hand it over at collection points on very favorable terms. Weighing of non-ferrous metal is carried out on precise electronic scales, which are regularly checked for serviceability.