Information about the manufacturer of the vertical drilling machine 2Р135Ф2

The manufacturer of drilling machines models 2Р135Ф2, 2Р118Ф2, 2Н125, 2Н135, 2Н150, 2Г175 is the Sterlitamak Machine Tool Plant , founded in 1941.

The history of the Sterlitamak Machine Tool Plant begins on July 3, 1941, when the evacuation of the Odessa Machine Tool Plant to the city of Sterlitamak began.

Already on October 11, 1941, the Sterlitamak Machine Tool Plant began producing special modular machines for the defense industry.

Currently, the plant produces metalworking equipment, including CNC lathes and milling machines, multifunctional machining centers.

Products of the Sterlitamak Machine Tool Plant

- 2135

— universal vertical drilling machine Ø 35 - 2A125

- universal vertical drilling machine Ø 25 - 2A135

- universal vertical drilling machine Ø 35 - 2A150

- universal vertical drilling machine Ø 50 - 2G175

- universal vertical drilling machine Ø 75 - 2N125

- universal vertical drilling machine Ø 25 - 2N135

- universal vertical drilling machine Ø 35 - 2N150

- universal vertical drilling machine Ø 50 - 2R135F2

- CNC vertical drilling machine Ø 35 - 2S125, 2S125-1 (2S125-01), 2S125-04

- universal vertical drilling machine Ø 25 - 2S132, 2S132K

- universal vertical drilling machine Ø 32 - 2С150ПМФ4

- vertical drilling-milling-boring machine with CNC and ASI 500 x 1000 - 2С550А

– radial drilling machine Ø 36 - 400V

- vertical drilling-milling-boring machine with CNC and ASI 400 x 900 - 500V (STC F55)

- vertical milling center 630 x 1200 - SF-16, SF-16-02, SF-16-05

- tabletop milling and drilling machine Ø 16

2Р135Ф2 vertical drilling machine with CNC. Purpose and scope

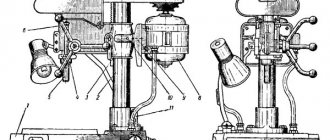

Vertical drilling machine 2Р135Ф2 with a six-spindle turret head, with a cross table and numerical control (CNC) is designed for drilling, reaming, countersinking, reaming, threading and milling in small-scale and mass production of various industries.

2R135F2 drilling machine is used for processing body parts and parts such as “flange”, “cover”, “plate”, “lever”, “bracket”.

The electrical circuit and CNC make it possible to carry out the following technological operations on the machine:

- Drilling;

- End trimming (countering);

- Boring;

- Threading;

- Deep drilling;

- Milling.

Operating principle and design features of the machine

The presence on the machine of a six-spindle turret for automatic tool change, a cross table with program control allows for coordinate processing of parts such as covers, flanges, panels without preliminary marking and the use of jigs.

2R135F2 vertical drilling machine has large ranges of spindle speed and feed rates, which fully ensure the choice of standard cutting modes when processing various structural materials.

2R135F2 machines ensure the accuracy of the center distances of machined holes up to 0.10-0.15 mm and can operate in an automatic cycle (in this mode, multi-operational processing of parts with a large number of holes is performed).

Design of the machine 2Р135Ф2 . A column is mounted on the base of the machine, along the rectangular vertical guides of which the spindle head (support) carrying the turret moves. The gearbox and feed reducer are rigidly mounted on the column. The cross table has a base along which the slides carrying the table itself move in the transverse direction. The latter, in turn, can move in the longitudinal direction along the slide guides. The movement of the slide and table is carried out from the gearboxes.

Numerical control system . The machine model 2Р135Ф2 is equipped with a numerical control device “ Coordinate S70-3 ”, the machine model 2Р135Ф2-1 is equipped with a CNC device 2П32-3 , which ensure simultaneous movement of the table along the X and Y axes when positioning control of movement along the axis (from the coordinate), makes it possible to control by turning the turret, select the value of the working feed and spindle speed. The device has a digital display and allows for input of corrections for tool length.

The positional rectangular CNC system is closed; code converters are used as measuring devices. The positioning accuracy of the table and support is 0.05 mm, the discreteness of programming and digital display is 0.05 mm. Number of controlled coordinates: total - three; simultaneously - two.

The design organization is the Experimental Research Institute of Metal-Cutting Machine Tools (ENIMS) and the Sterlitamak Machine Tool Plant named after. V.I. Lenin.

2R135F2 machine was accepted for serial production in 1979.

The accuracy class of the machine is N according to GOST 8-77. The quality category is the highest.

Where is the 2r135f2 CNC drilling machine used?

The machine in question is used to regulate the process of rectangular machining and positioning. The program carrier is a punched paper tape with eight tracks. The machine is equipped with a digital display; up to 15 adjustments per tool length can be entered.

The machine has a closed system in which the BS155A selsyn acts as sensors. The table and slide are positioned with an accuracy of up to 0.02 mm, digital display and movement assignments have a resolution of up to 0.01 mm. There are a total of 3 controllable coordinates, 2 of which can be used simultaneously.

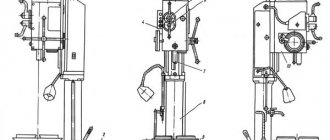

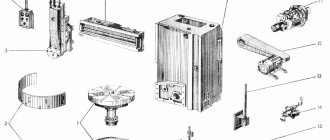

Location of the main parts of the drilling machine 2Р135Ф2

Location of the main components of the 2р135ф2 machine

Designation of the main parts of the drilling machine 2Р135Ф2

- Machine base

- Table slide

- Turret

- Spindle head (caliper)

- Gearbox

- Feed reducer

- Control pendant

- Cabinet with electrical control equipment

- Cabinet with CNC equipment

- Column

- Cross table

On the base (bed) 1 of the machine there are slides 2 of the cross table, which has telescopic protection for the guides. A spindle head moves along the vertical guides of the column, on which a six-spindle turret head is mounted, allowing automatic tool change according to a control program. To speed up manual tool replacement, a special pressing device is provided in the turret. The machine can be controlled from a pendant control panel.

Movements in the machine

- The main movement is the rotation of the spindle with the tool

- Movement along the machine axes:

- X-axis - longitudinal feed - longitudinal movement of the table along the slide guides

- Y axis - transverse feed - transverse movement of the slide along the bed guides

- Z axis - vertical feed - vertical movement of the spindle head (support) along the rack guides

To control table movements (X and Y coordinates) from a program recorded on punched tape, machines are equipped with various CNC devices (one of the most common is the CNC “Coordinate S-70”). Feed along the Z coordinate is carried out in cyclic control mode. For coordinate movements of the table, manual data input on the CNC console can also be used. The presence of a digital display allows you to visually monitor the position of the table, as well as monitor the correctness of the program recording on punched tape.

The machines provide feedback on the position of the working bodies on each of the two movements controlled by the punched tape. Circular electrical contact code converters are used as feedback sensors. Movements of the turret head during fast and working strokes in both directions are limited by adjustable cams acting on switches (electric stops).

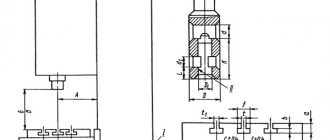

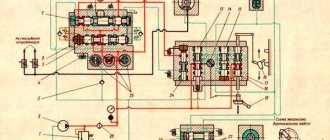

Kinematic diagram of the drilling machine 2Р135Ф2-1

Kinematic diagram of the drilling machine 2р135ф2-1 with CNC 2П32-3

The kinematic diagram of the machine (Fig. 4.6) consists of the following independent kinematic chains: main movement drive (rotation of the turret spindles); cross table feed drive; caliper drive with turret head; turning the turret head; pressing tools out of spindles.

Main movement chain

Main movement chain: two-speed asynchronous electric motor M1 (N = 4/4.5 kW; n = 1470/990 rpm) - 29/41 gear transmission - shaft I - shaft II (through gears 24/48 and 36/36 at engaged couplings M1 and M2 or through gear 14/36 with engaged coupling M3) - shaft III (via gears 14/36 and 48/24 with engaged couplings M4 and M5) - shaft V through bevel gear 21/21 - to one of turret spindles through 35/42 gears; 31/49; 49/47; 47/35.

Cross table feed drive chain

The feed drive chain of the cross table has two gearboxes, one of which moves the table along the slide (X-axis), and the second drives the movement of the slide along the frame (Y-axis).

Kinematic chain of the slide drive

The kinematic chain of the slide drive ensures their fast, medium and slow movements. Fast movement (at a speed of 7000 mm/min): M4 electric motor (N=0.6 kW; p=1380 rpm) - 16/40 gears; 34/22; 22/52; 52/34 - ball screw.

Moving at medium speed (200 mm/min): M4 electric motor - 16/64 gears; 25/55; 25/55; 38/42; 22/52; 52/34 - ball screw. Slow movement (at a speed of 50 mm/min): M4 electric motor - 16/64 gears; 25/55; 25/55; 16/64; 22/52; 52/34 - ball screw. A feedback sensor is mounted on the ball screw.

The table moves along the slide from the M5 electric motor (N = 0.6 kW; n = 1380 rpm); the kinematic chain of the drive of this movement is similar to the kinematic chain of the drive of the slide movement.

Turret Caliper Drive Chain

Caliper drive chain with turret head: DC electric motor M2 (N = l.3 kW; n = 50..2600 rpm) - 13/86 gear (or 37/37 gear - 4/25 worm gear - lead screw, equipped with a brake clutch (preventing arbitrary lowering of the caliper when the electric motor is turned off) and a remote control feedback sensor.

Turret rotation drive chain

Turret head rotation drive chain: M3 electric motor (N=0.7/0.9 kW; n= 1400..2700 rpm) - 23/57 gear - 1/28 worm gear - 16/58 gear - turret body .

Pressing tools out of spindles

Pressing tools out of spindles: M3 electric motor - 18/52 gear (with the clutch engaged) - 1/28 worm gear - 21/21 gear - eccentric mounted in the groove of the turret head rotation axis and pressing tool.

Lubricating the turret support

Lubrication of the turret head support is carried out forcibly according to the following scheme: MZ electric motor - 18/52 gears; 52/75 - EZ eccentric, driving the plunger pump.

Gearbox lubrication

The gearbox is lubricated by a gear pump driven by the gearbox electric motor through a V-belt. The oil supplied by the pump enters the distribution chamber, where it is distributed to lubricate all moving parts of the gearbox and electromagnetic clutches, and then drained into the reservoir. The oil level is controlled by an oil indicator.

Lubrication of caliper feed gearboxes and cross table

Lubrication of the caliper feed gearboxes and the cross table is carried out by spraying oil onto the gears. The oil level is monitored visually using oil indicators.

Lubricating the guides and screw pairs of the cross table

The guides and screw pairs of the cross table are lubricated manually using a lubricator. The bearings of the turret spindles are lubricated with grease.

Coolant supply

The coolant is supplied from a centrifugal pump. To cool the tool in the cutting zone, an individual drive is provided, which allows you to direct a stream of coolant to the desired location. The supply of coolant in the automatic cycle begins when the caliper moves down (the beginning of the working feed) and stops when the caliper begins to return to its original position (in this case, the corresponding toggle switch must be turned on on the control panel).

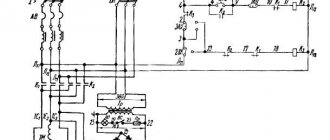

Electrical equipment of the machine

The electrical equipment of the machine consists of a separate cabinet of relay automation and CNC, as well as elements installed directly on the machine. Electrical connections between the machine components and the CNC are made by harnesses in metal hoses ending with connectors.

The electrical circuit of the machine provides the following operating modes:

- commissioning;

- semi-automatic with task input from CNC switches;

- semi-automatic with task input from punched tape;

- automatic with task input from punched tape.

The mode is selected using switches located on the control panels of the machine and the CNC.

Vertical drilling machine mod. 2р135ф2

This Computer Numerical Control (CNC) machine is designed for drilling, countersinking, reaming, threading, face trimming, etc. in low to mid-volume production. The presence on the machine of a six-position turret for automatic change of cutting tools and a cross table with program control will create the ability to carry out coordinate processing of parts such as covers, flanges, panels and other parts without preliminary marking and without the use of jigs, machine accuracy class N.

Numerical control system. Machine mod. 2Р135Ф2 is equipped with a numerical control device “Coordinate S70-3”, which ensures simultaneous movement of the table along the X and Y axes when positioning the movement control along the axis (from the coordinate), makes it possible to control the rotation of the turret, select the value of the working feed and spindle speed. The device has a digital display and allows for input of corrections for tool length.

The positional rectangular CNC system is closed; code converters are used as measuring devices. The positioning accuracy of the table and support is 0.05 mm, the discreteness of programming and digital display is 0.05 mm. Number of controlled coordinates: total - three; simultaneously - two.

A column is mounted on the base of the machine, along the rectangular vertical guides of which a support carrying a turret head moves. The gearbox and feed reducer are rigidly mounted on the column. The cross table has a base along which the slides carrying the table itself move in the transverse direction. The latter, in turn, can move in the longitudinal direction along the slide guides. The movement of the slide and table is carried out from the gearboxes.

Rotate the turret head. The head rotates using the following kinematic chain. From the MZ electric motor (0.7/09 kW, 1400/2700 rpm) through the shaft transmission to the shaft, from which the worm gear transmits the movement to the shaft and transmission, which rotates the turret head. The clutch must be engaged. Before turning the turret, it must be unlocked, since it is secured by spring-loaded caliper rods located in the grooves of the turret. When the shaft on which the worm sits rotates, it has the ability to move axially, so it turns out of the worm wheel and, moving down through the rack and pinion gear with the wheel and the module, turns the shaft with an eccentric, which will release the turret with a system of levers; at the same time, the second rack wheel moves the rack on the shaft and thereby disengages the wheel on the shaft. Thus, the turret head is released and the kinematic chain connecting the rotation drive to the turret spindle is broken. After this, the worm reaches a hard stop and begins to rotate the turret by means of a transmission, changing the tool (direct rotation).

Simultaneously with the rotation of the turret head through the transmission, the shaft and gear rotates a positional command device on the shaft, which stops the direct rotation of the turret head by reversing the electric motor, having previously reduced its rotation frequency to 1400 rpm. During reverse rotation, the turret reaches the hard stop of the caliper and stops; at the same time, the worm, turning out of the worm wheel, moves upward. The shaft rotates in the opposite direction, the gear engages with the turret spindle wheel. The head is fixed and the spindle begins to rotate. The choice of the operating sequence of the turret spindles is set on the console. There are six processing cycles in total.

The table moves from the M4 engine (0.6 kW, 1380 rpm). The table gearbox does not differ from the sled gearbox, therefore, its kinematic diagram does not indicate shafts and wheels.

Thread cutting. For cutting threads with a machine tap, chucks are used that can be installed in any position of the turret. When cutting threads, use a copier, a screw-nut in steps of 1.0; 1.25; 1.5; 1.75; 2.0; 3.0 mm, set of replaceable collets for fastening taps, adapter squares. The threading head has a mechanism for adjusting the operation of the head in the cycle forward (threading) - reverse (unscrewing the tap after cutting the thread). The full cycle of work with the support is provided by the electrical circuit of the machine. Rotation from the spindle is transmitted through a liner inserted into the spindle of the turret head, through a gear coupling to the driver, spline shaft and collet.

www.4ne.ru

Setting up the machine

Regardless of the position of the operating mode switch on the CNC console, the adjustment mode is turned on by switch 23 located on the machine control panel (Fig. 4.7). In the adjustment mode, carried out by means of controls located on the machine console, the following is performed: turning the turret to a given position; pressing out the tool; turning spindle rotation on and off; moving the table along the X and Y axes in accordance with the selected speed and direction; moving the turret support along the Z axis in accordance with the task.

Machine control panel 2р135ф2-1

Setting the working parts of the machine to the zero position

The working parts of the machine are set to the zero position automatically before the “Program Entry” command. When button 15 is pressed, the turret support quickly rises until the limit switch is activated along the Z coordinate. The table moves until the limit switches are activated along the X and Y coordinates, and at the same time commands are sent to the CNC about the initial position of the working parts. The installation cycle is complete.

Rotating the turret

To select the position of the turret head, switch 24 is set to the desired position. By pressing button 6, the cycle of turning the turret head to the position specified by switch 24 begins. When you press button 6 and there is no task, the head moves non-stop.

Turning on the spindle in the “Setup” mode

The spindle is turned on in the “Adjustment” mode for all operations (except for thread cutting) with button 21, and turned off with button 22 (when threading, buttons 21 and 22 do not work). The spindle rotation speed is set by switch 27.

Movement of working bodies along the X, Y, Z axes

Movement of working bodies along the X, Y, Z axes. The selection of the working axis is made by switch 4.

The selection of fast, medium or slow movement is made by switch 7, and the selection of the direction of movement is made by switch 5.

Setting the program start in the XY plane

To adjust the start of the program in the XY plane, catchers or center finders are used. In manual mode, the spindle axis is aligned with the beginning of the program, and the zero offset values along the X and Y axes are entered on the CNC control panel, which give zero readings on the digital display.

The machine is adjusted along the Z axis after installing the cutting tool in the turret spindle. In the initial position of the caliper, check that the turret head does not touch the device with the workpiece clamped in it when rotating.

Technical characteristics of the machine 2Р135Ф2

| Parameter name | 2Р135Ф2 |

| Basic machine parameters | |

| The largest drilling diameter in steel is 45, mm | 35 |

| The largest diameter of cut threads in steel is 45, mm | M24 |

| The smallest and largest distance from the end of the spindle to the table surface, mm | 40..600 |

| Distance from the axis of the vertical spindle to the rack guides (overhang), mm | 450 |

| Largest cutter diameter, mm | 100 |

| Maximum milling depth, mm | 2 |

| Maximum milling width, mm | 60 |

| Longitudinal movement of the table along the slide guides (X-Axis), mm | 630 |

| Transverse movement of the slide along the bed guides according to the program (Y-Axis), mm | 360 |

| Maximum movement of the spindle head according to the program (Z axis), mm | 560 |

| Caliper. Spindle head. Spindle | |

| Spindle speed, rpm | 45..2000 31..1400 |

| Number of spindle speeds | 12 |

| Speed of rapid movement of the support (spindle head), m/min | 4 |

| Number of caliper feeds along the Z axis, mm | 18 |

| Caliper feed, mm | 10..500 |

| Maximum permissible torque, Nm | 200 |

| Spindle taper | |

| Desktop | |

| Dimensions of the working surface of the table, mm | 400 x 710 |

| Maximum load on the table (center), kg | |

| Number of T-slots Dimensions of T-slots | 3 |

| Speed of rapid movement of the table and slide, m/min | 7 |

| Feed speed of table and slide during milling, m/min | 0,22 |

| Minimum table movement speed, m/min | 0,05 |

| Positioning accuracy of the table and slide along the stroke length, mm | 0,05 |

| CNC system 2P32-3 | |

| Number of controlled coordinates | 3 |

| Number of simultaneously controlled coordinates | 2 |

| Discreteness of setting the movement of the table, slide and support, mm | 0,01 |

| Electrical equipment, drive | |

| Main motion drive electric motor, kW | 3,7 |

| Electric motor for driving the spindle head (support), kW | 1,3 |

| Electric motor for moving the slide and table, kW | 1,1 |

| Electric motor for driving the turret head, kW | 0,75 |

| Electric coolant pump X14-22M, kW | 0,125 |

| Machine dimensions | |

| Machine dimensions, mm | 1800 x 2170 x 2700 |

| Machine weight, kg | 5390 |

- Vertical drilling machine with numerical control 2Р135Ф2-1. Operating manual 2Р135Ф2-1.00.000 РЭ, 1983

- Grachev L.N. Design and adjustment of computer-controlled machines and robotic complexes, 1986, p. 122

- Panov F.S. Working on CNC machines, 1984, p.163

- Barun V.A. Working on drilling machines, 1963

- Vinnikov I.Z., Frenkel M.I. Driller, 1971

- Vinnikov I.Z. Drilling machines and work on them, 1988

- Loskutov V.V Drilling and boring machines, 1981

- Panov F.S. Working on CNC machines, 1984

- Popov V.M., Gladilina I.I. Driller, 1958

- Sysoev V.I. Handbook for a Young Driller, 1962

- Tepinkichiev V.K. Metal cutting machines, 1973

Bibliography

Related Links. Additional Information

- Classification and main characteristics of drilling-milling-boring group of machines

- Selecting the right metalworking machine

- Machine repair technology

- Methodology for checking and testing drilling machines for accuracy and rigidity

- Directory of drilling machines

- Manufacturers of drilling machines in Russia

- Generations of CNC systems. Terms and concepts of CNC systems

- Russian manufacturers of modern CNC systems

- Review of Russian-made CNC systems

- Recommendations for choosing CNC devices

- Problems with modernized CNC machines: tips and tricks from professionals

- Requirements for ensuring stability and safety of machine control systems

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

§ 2. VERTICAL DRILLING MACHINE 2Р135Ф2-1 WITH CNC. Technical specifications.

Section: LIBRARY OF TECHNICAL LITERATURE Short path https://bibt.ru<<Previous page Book table of contents Next page>>

The 2R135F2-1 vertical drilling machine is designed for drilling, countersinking, reaming, threading, light straight milling of parts made of steel, cast iron and non-ferrous metals in small-scale and mass production. A turret head with automatic tool change and a cross table with program control allow coordinate processing of parts such as covers, flanges, panels, etc. without preliminary marking and the use of jigs. Machine accuracy class P.

Technical characteristics of the machine 2Р135Ф2-1. The largest diameter of the workpiece is 35 mm; the largest diameter of the cut thread is M24; maximum milling width 60 mm; number of tools 6; number of spindle rotation speeds (total/per program) 12/12; spindle speed limits 35.5-1600 min-1; number of feeds along the Z axis 18; limits of working feeds along the Z axis 10-500 mm/min; speed of rapid movement of the table and slide 7000 mm/min, and when milling 2200 mm/min; speed of rapid movement of the caliper 4000 mm/min; table working surface size 400x710 mm; overall dimensions of the machine 1800x2400x2700 mm.

The CNC device type 2P32-3 is designed to control the process of positioning and rectangular processing (parallel to the coordinate axes). The software carrier is an eight-track punched tape, a method for specifying movements in absolute coordinate values. There is a digital display and 15 corrections for tool length can be entered. The CNC system is closed; BS155A selsyn is used as feedback sensors. The positioning accuracy of the table and slide is 0.05 mm, the discreteness of specifying movements and digital display is 0.01 mm. The number of controlled coordinates of all/of them simultaneously is 3/2.

Basic mechanisms and movements of the 2R135F2-1 vertical drilling machine. On base A (Fig. 68) a column B is installed, along the vertical guides of which the caliper G with turret D moves (feed along the Z axis). A gearbox, which transmits the main movement to the spindle, and a caliper feed box G are attached to the column. Cross table B, consisting of a table and a slide, makes two mutually perpendicular feed movements along the X', Y' axes from the gearboxes E.

Rice. 68. Kinematic diagram of a vertical drilling machine 2Р135Ф2-1 with CNC

Skip to navigation