This equipment was developed by the Odessa Design Bureau; production was launched at several enterprises of the former USSR in the middle of the last century. Based on the main model, a number of modifications NS-12A, NS-12B, NS-12M were created, with minor differences in characteristics and configuration.

The NS-12 drilling machine performs hole drilling and thread processing in parts made of steel, cast iron, non-ferrous metals and alloys, and non-metallic materials. It belongs to the group of tabletop machines.

Information about the manufacturer of the tabletop drilling machine NS-12

The developer of the tabletop drilling machine model NS-12 is the Special Design Bureau of Special Machine Tools SKB-3, Odessa . SKB-3 was created in 1947 and existed until the mid-90s.

The machine was produced by machine tool factories and several vocational and technical schools of the Soviet Union in the 50s..70s of the last century.

The NS-12 desktop drilling machine has several modifications (NS-12, NS-12A, NS-12B, NS-12M), which differ slightly from each other in design and configuration.

Drilling machines. Photos, Passports, instruction manuals – Drilling machines

Vertical drilling machines

2N118 - Universal vertical drilling machine, Molodechno, 1971. https://www.chipmaker.ru/files/file/69/

excerpt from passport 2N118-1 https://www.chipmaker. iles/file/6314/

2118 — Vertical drilling machine, Novocherkassk. Passport. 1952 https://www.chipmaker.ru/files/file/70/

2118-A , vertical drilling machine, Molodechno. Operating instructions, passport. https://www.chipmaker. iles/file/1408/

S-25 — Vertical drilling machine. Passport. https://www.chipmaker.ru/files/file/71/

2A125 - universal vertical drilling machine. Electrical circuits for 2A125, 2A135, 2A150 https://www.chipmaker. files/file/326/

2A125 - universal vertical drilling machine, Vilnius. RE, Passport, Electrical diagram https://www.chipmaker. iles/file/6987/

2A125 - vertical drilling machine, Sterlitamak. Operating instructions, Passport, Electrical diagram. https://www.chipmaker. files/file/919/

2A135 - universal vertical drilling machine, Sterlitamak, 1960 Description and Service Manual https://www.chipmaker. iles/file/5538/

2A135 - universal vertical drilling machine, Frunze, 1973 Manual for the machine. https://www.chipmaker. iles/file/3837/

2N125, 2N135, 2N150 - vertical drilling machine, Sterlitamak. Materials for spare (wearing) parts. https://www.chipmaker. files/file/833/

2N125, 2N135, 2N150 - universal vertical drilling machine

Album 1 - Mechanics

Album 2 - Acceptance certificate

Album 3 – Electrical equipment

Album 4 - Spare parts catalogue.

2S132K - vertical drilling machine with a floating table Electrical diagram https://www.chipmaker. iles/file/5044/

2054M - vertical thread-cutting machine, Krasnorechensky Machine Tool Plant named after. Frunze, 1976 Passport, instruction manual, drawings of wearing parts. https://www.chipmaker. iles/file/1422/

2054M - vertical thread-cutting machine, Kabanevsky Machine Tool Plant. Operating manual, passport, drawings of wearing parts. https://www.chipmaker. iles/file/1444/

2S132 , 2S132K, 2S132TS, 2S132PF2I - vertical drilling machines Operating manual 1989 https://www.chipmaker. iles/file/5213/

MN-18 Molodechno Passport https://www.chipmaker. iles/file/6858/

MN-18-52 Molodechno Passport https://www.chipmaker. iles/file/6859/

2G125 - vertical drilling machine Operating manual. https://www.chipmaker. iles/file/3967/

Modified on August 29, 2012 by user Kazakh

NS-12 tabletop drilling machine. Purpose and scope

The machine is designed for drilling holes in small parts made of cast iron, steel, non-ferrous alloys and non-metallic materials in industrial enterprises, repair and household workshops.

NS-12 machines allow you to perform the following operations:

- drilling

- countersinking

- deployment

- reaming

- thread cutting

Main parameters of the NS-12 drilling machine:

- Maximum drilling diameter: Ø 12 mm

- Maximum drilling depth: 100 mm

- Maximum height of workpiece: 400 mm

- Distance from spindle axis to column (spindle overhang): 185 mm

- Spindle speed: 450, 710, 1400, 2500, 4500 rpm

- Electric motor power: 0.6 kW

- Machine weight: 121 kg

The drilling depth is measured using a flat scale or stop.

Five-speed drive pulleys allow five spindle rotation speeds, which provides free choice of cutting speeds.

The original design of the belt drive tension allows you to quickly change the position of the belt on the pulleys to obtain the desired cutting speed.

The spindle assembly of the NS-12 drilling machine is the most complex and precise assembly in the machine. The spindle assembly is mounted in the spindle head. Main parts of the spindle assembly:

- Spindle - a shaft that rotates on 2 angular contact bearings inside the spindle sleeve;

- The spindle sleeve (quill) is a cylinder that is mounted in the spindle head and has the ability to move axially within 100 mm.

The upper part of the spindle has splines to receive rotation from the take-up pulley, the lower part has a Morse taper for attaching the drill chuck.

The spindle of the NS-12 machine receives five rotation speeds from five-stage drive pulleys, which provides free choice of cutting speeds of 450, 800, 1410, 2490, 4430 rpm.

The quill, inside which the spindle rotates, has a stroke of 100 mm and is balanced by a spiral spring, which returns the quill to the upper (original) position. The quill is raised and lowered by a rack and pinion. The maximum cutting force allowed by the mechanism is 70 kg.

The end of the spindle of the NS-12 drilling machine is an internal Morse cone No. 1, D = 12.065 mm according to GOST 25557 (Tool cones). To install a standard drill chuck with a shortened cone on the machine, you need to install a mandrel in accordance with GOST 2682 (Mandrels with a Morse taper for drill chucks).

On the NS-12 machine you can install one of 4 mandrels in accordance with GOST 2682:

- Mandrel 6039·0002 - version 2, shortened Morse taper B10

- Mandrel 6039·0005 - version 2, shortened Morse taper B12

- Mandrel 6039·0007 - version 2, shortened Morse taper B16

- Mandrel 6039·0011 - version 2, shortened Morse taper B18

So, using one of the 4 mandrels, you can install a drill chuck of one of 6 standard sizes in accordance with GOST 8522 (Three-jaw drill chucks).

- Chuck 4 - shortened Morse taper B10 , clamping range - 0.5..4 mm

- Chuck 6 - shortened Morse taper B12 , clamping range - 0.5..6 mm

- Chuck 8 - shortened Morse taper B12 , clamping range - 1.0..8 mm

- Chuck 10 - shortened Morse taper B16 , clamping range - 1.0..10 mm

- Chuck 13 - shortened Morse taper B16 , clamping range - 1.0..13 mm

- Chuck 16 - shortened Morse taper B18 , clamping range - 3.0..16 mm

An example of a symbol for a 3-jaw drill chuck, size 16, with a connecting conical hole B18:

Cartridge 16-B18 GOST 8522-79

Morse cone instrumental shortened

Tool taper - Morse taper is one of the most widely used tool mounts.

It was proposed by Stephen A. Morse around 1864. The Morse taper is divided into eight sizes - from KM0 to KM7 (in English: MT0-MT7, in German: MK0-MK7).

Morse taper standards: GOST 25557 (Tool cones. Main dimensions), ISO 296, DIN 228. Cones made according to inch and metric standards are interchangeable in everything except the shank thread.

For many applications, the length of the Morse cone turned out to be excessive. Therefore, a standard was introduced for nine standard sizes of shortened Morse cones (B7, B10, B12, B16, B18, B22, B24, B32, B45), these dimensions were obtained by removing the thicker part of the cone. The number in the designation of a short cone is the diameter of the thick part of the cone in mm.

Russian standard for shortened cones GOST 9953

Tool cones are shortened.

Russian standard for drill chucks GOST 8522

Three-jaw drill chucks.

- B7 - Morse cone KM0 , D = 7.067 mm;

- B10 - Morse cone KM1 , D = 10.094 mm. Cartridge 4-B10 (0.5÷4 mm);

- B12 - Morse cone KM1 , D = 12.065 mm. Cartridge 6-B12 (0.5÷6 mm), Cartridge 8-B12 (1÷8 mm);

- B16 - Morse cone KM2 , D = 15.733 mm. Cartridge 10-B16 (1÷10 mm), Cartridge 13-B16 (1÷13 mm);

- B18 - Morse cone KM2 , D = 17.780 mm. Cartridge 16-B18 (3÷16 mm);

- B22 - Morse cone KM3 , D = 21.793 mm. Cartridge 20-B22 (5÷20 mm);

- B24 - Morse cone KM3 , D = 23.825 mm;

- B32 - Morse cone KM4 , D = 31.267 mm;

- B45 - Morse cone KM5 , D = 44.399 mm.

Where D is the diameter of the cone in the main plane.

Analogues of the desktop drilling machine NS-12

2M112 - Ø12 - Kirov Machine Tool Plant, Kirov

NS-12A - Ø12 - Vilnius Machine Tool Plant

NS-12B, NS-12M - Ø12 - Barnaul Machine Tool Plant

ENS12 - Ø12 - Yeysk machine tool plant ESZ, Yeysk

OD71 - Ø12 - Orenburg Machine Tool Plant, Orenburg

NS-12B, NS-12-M - Ø12 - Barnaul Machine Tool Plant

SHUNSS-12 - Ø12 - Mukachevo Machine Tool Plant, village. Kolchino

GS2112 – Ø12 – Gomel Machine Unit Plant

ZIM1330.00.00.001 - Ø12 - Maslennikov Plant, ZIM-Machine Tool Builder, Samara

MP8-1655 - Ø12 - Machine Tool Plant named after. Kirov, Minsk

BS-01 - Ø12 - Bevers, Berdichev

VS3-5016 - Ø12 - Voronezh Machine Tool Plant

R175M - Ø12 - Chistopol AutoSpetsEquipment plant, Chistopol

Р175, Р175М – Ø13 – AutoSpetsEquipment

VI 2-7 - Ø14 - Volgograd Tool Plant

MD-23 – Ø14 – Kaunas Machine Tool Plant

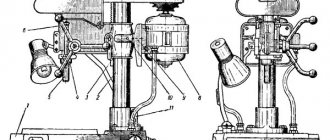

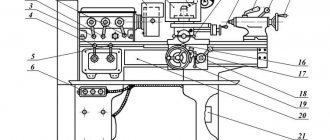

General view of the drilling machine NS-12

Photo of drilling machine NS-12

Photo of drilling machine NS-12

Photo of drilling machine NS-12

Design Features

The NS 12A drilling machine consists of the following structural elements: a plate, a trunk with a spindle, a column and electrical equipment. The plate is needed to fix the shoe in which the column is mounted. There is a special outlet chute on the plate designed to collect coolant. A step-down transformer is installed in the plate itself, and outside there is a special push-button module designed to control the operation of the machine. The column of the unit is necessary for fixing the rack, to which the gear installed in the trunk clings. A spindle assembly, an electric motor and a tensioning mechanism are fixed on the trunk.

The design of the NS 12A drilling machine is quite simple, which allows for easy replacement of a failed unit or part. This is considered a plus of this series in particular and Soviet technology in general.

Location of components of the drilling machine NS-12

Location of components of the drilling machine NS-12

Specification of components of the drilling machine NS-12

- Plate

- Column

- Trunk (spindle head)

- Spindle sleeve (quill)

- Spindle

- Spindle quill feed handle

- Rack

- Electric motor

- Electric motor plate (sub-motor plate)

- Belt tensioner stopper

- Shoe (bracket for fastening the column to the plate)

Brief description of the design and operation of the NS-12 desktop drilling machine

The machine consists of the following main parts: plate 1; column 2; trunk with spindle group 3; electrical equipment 8.

to the plate , in the hole of which a column 2 is installed. The column is secured by tightening the shoe.

Along the perimeter of the plate there is a trench for collecting coolant. At the bottom of the chute there is a drain hole with a plug. When connecting the machine to a centralized supply of emulsion, instead of a plug, a nipple with a rubber hose can be wrapped.

A step-down transformer and a package switch housing (for local lighting) are mounted inside the plate, and a push-button station is installed outside (for the machine’s electric motor).

to the column (Fig. 4) (m = 2), in mesh with which there is a gear mounted in the trunk, rigidly fixed to the handle 4 (see diagram of the location of the controls). When turning handles 3, 4 (Fig. 6), the trunk moves along the column. After installing the trunk to the required height, handle 3 clamps the trunk.

A spindle group 5, an electric motor 8 with a plate and a tensioner 10 for the V-belt are attached to the trunk

The spindle , unloaded from the pulley, is installed in sleeve 4 (quills) on precision angular contact bearings.

The sleeve moves when handle 6 is turned (Fig. 1).

The transmission of rotation from the pulley to the spindle is carried out using two parallel keys.

The five-speed spindle pulley is secured by a bushing on two radial bearings.

The electric motor is mounted on a sub-motor plate, the guides of which freely fit into the corresponding bores in the trunk. After the belt is thrown onto the corresponding pulley stage, this plate is pulled away from the trunk to the normal belt tension and in this position is fixed with clamping screws.

Machine design

Appearance

This model is designed for forming holes in small workpieces made of various materials: steel, wood, polymers. If you have a tap, the thread can be cut. It has found application in repair shops and is widely popular among home craftsmen.

The design consists of a work table, which serves as a base. On its surface there are polished T-shaped grooves for fixing the workpiece. A vertical column is installed on the frame, in the upper part of which electrical equipment, a spindle head and shafts for switching the number of revolutions are mounted.

The passport describes in detail the design features of the NS-12 desktop machine. They are as follows:

- use of cast iron bodies. This ensures long term maintenance-free operation of the equipment;

- convenient system for changing the spindle speed. For this purpose, pulleys of various diameters are installed on the headstock and electric motor shafts. The drive is carried out using a belt drive;

- Precision processing provides a report of the drilling depth on a stop or on a flat scale.

The original belt tension system makes it possible to change gears. But to do this you need to wait until the electric motor stops completely. To drive the spindle head on the NS-12A machine, you can install flat and toothed belts.

When working on the equipment, it is mandatory to install a protective casing on the shaft with spindle pulleys. This will prevent dangerous situations from occurring.

This is interesting: Screw-cutting lathe 1V62G - technical characteristics and design

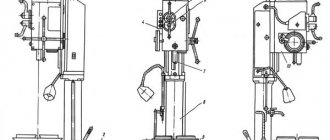

Location of controls for the NS-12 drilling machine

Location of controls for the NS-12 drilling machine

Specification of controls of the NS-12 machine

- Stop button

- Electric motor start button

- Handle for clamping the trunk (spindle head) on the column

- Handle for raising and lowering the trunk (spindle head) along the column

- Quill lifting handle for manual spindle feed

- Tensioner Clamp Screws

- Local lighting switch

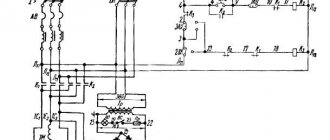

What does the electrical diagram of the device include?

This characteristic of the machine of this model, such as ease of use and repair, is determined, among other things, by the simplicity of the electrical circuit. The elements of the electrical circuit of the NS-12 drilling machine, which are responsible for controlling the equipment, are the “Start” button, when pressed, the drive motor is started, and the “Stop” button, with which the electric motor is turned off.

The characteristics of the drilling machine include the presence of local lighting, which is turned on when the handle of the corresponding batch switch is turned. The operation of the local lighting system requires the use of a step-down transformer, which is mounted in close proximity to the machine.

This is interesting: Tools for a hand router: what you can do it yourself or buy

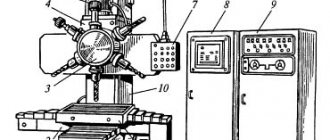

Kinematic diagram of the drilling machine NS-12

Kinematic diagram of the drilling machine NS-12

- Rack on spindle sleeve

- Gear for moving the spindle sleeve

- Gear rack on column

- Gear for moving the trunk (spindle head) along the column

Description of the kinematic scheme

From the electric motor, using a V-belt drive through a five-speed pulley, the machine spindle connected to it by means of keys (and sliding along them) is driven into rotation.

When handle 5 (Fig. 6) is turned, gear 2 (Fig. 4) rotates, which moves rack 1 and the sleeve associated with it up and down.

The sleeve, moving in the cavity of the trunk, moves up and down the spindle, connected to the sleeve by angular contact ball bearings.

The vertical movement of the trunk is carried out by the action of gear 4 (Fig. 4), driven into rotation by handle 4 (Fig. 6), on rack 3 (Fig. 4), mounted on the column.

If necessary, it is possible to rotate the column together with the trunk around its axis after loosening the clamp of the shoe in which the column is secured.

The belt guard casing is either cast or welded (extended).

Spindle bearings for drilling machine NS-12

The spindle of the NS-12 machine is mounted in a sleeve on 2 ball angular contact bearings:

- Bearing No. 36203 GOST 831-41 angular contact ball, accuracy class P, size 17x40x12 mm

- Lower bearing No. 36203 GOST 831-41 angular contact ball, accuracy class B, size 17x40x12 mm

The take-up pulley is mounted on two radial ball bearings:

- Bearing No. 205 OST 6121-39 single-row radial ball, size 25x52x15 mm

Electrical equipment and electrical circuit of the drilling machine NS-12

Electrical diagram of the drilling machine NS-12

Electrical equipment of the drilling machine NS-12

The electrical equipment of the machine consists of:

- electric motor 0.6 kW

- push-button starter with “Stop” and “Start” buttons

- local lighting with step-down transformer and package switch

Control of the NS-12 machine

1. By pressing the “Start” button of the push-button starter, the electric motor is turned on. By pressing the “Stop” button of the gearbox push-button starter, the electric motor is turned off.

2. By turning the handle of the packet switch VO, the local lighting of the LO is turned on. The machine must be grounded.

Drive of the machine NS-12

The electric motor is attached to the spindle head by means of a submotor plate. On the axis of the electric motor there is a stepped pulley, which is connected to the spindle pulley by a V-belt.

Local lighting of the NS-12 machine

The machine is equipped with equipment for local lighting. Due to the fact that the tabletop drilling machine, model NS-12, is most often installed on workbenches or tables, therefore, the fittings (bracket) and the apparatus (transformer) for local lighting, when installing the machine, must be attached near the machine, and if the machine is installed near walls - then to the last one.

Machine control principle

Before putting the machine into operation, you need to make sure that grounding is present.

Operating the machine is quite simple:

- to turn it on, you must press the “Start” button on the push-button starter panel;

- switching on is accompanied by the start of the electric motor;

- the machine is ready for work, and to stop work, press the “Stop” button. The power will turn off and the engine will stop. If necessary, local lighting is turned on by turning the toggle switch of the package switch.

Technical characteristics of the NS-12 machine

| Parameter name | NS-12 | NS-12B | NS-12M |

| Basic machine parameters | |||

| Largest drilling diameter, mm | 12 | 12 | 12 |

| The greatest distance from the end of the spindle to the table | 20..420 | 100..400 | 300 |

| Distance from the axis of the vertical spindle to the rack guides (overhang), mm | 185 | 200 | 200 |

| Desktop | |||

| Width of the working surface of the table, mm | 360 x 360 | 300 x 350 | 300 |

| Number of T-slots Dimensions of T-slots | 3 | 3 | |

| Spindle | |||

| Maximum movement of the spindle head, mm | 300 | 200 | |

| Spindle sleeve stroke, mm | 100 | 100 | 100 |

| Spindle speed, rpm | 450, 710, 1400, 2500, 4500 | 450, 800, 1410, 2490, 4430 | 880, 1500, 2880 |

| Number of spindle speeds | 5 | 5 | 3 |

| Spindle taper | Morse 2 | Morse 1 | B18 |

| Drive unit | |||

| Main motion drive electric motor, kW | 0,65 | 0,6 | 0,37 |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 770 x 465 x 700 | 760 x 470 x 955 | 810 x 450 x 910 |

| Machine weight, kg | 121 | 130 | 140 |