2N112 tabletop drilling machine. Purpose and scope

2N112 desktop drilling machine is designed for drilling holes and cutting threads in small parts made of cast iron, steel, non-ferrous alloys and non-metallic materials in industrial enterprises, repair shops and household workshops.

The drilling depth is measured using a flat scale or stop.

The original design of the belt drive tension allows you to quickly change the position of the belt on the pulleys to obtain the desired cutting speed.

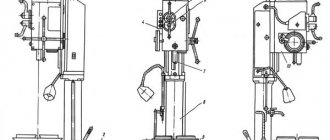

Using a stand to install the 2N112 makes it possible to drill the ends of long parts, such as shafts. The shaft diameter is up to one hundred and twenty millimeters, the length is up to a thousand millimeters.

2N112 drilling machine allows you to perform the following operations:

- drilling

- countersinking

- deployment

- reaming

- thread cutting

The spindle of the 2N112 receives 7 rotation speeds from 4-speed drive pulleys, which provides a choice of cutting speeds in the range from 500 to 4000 rpm.

The end of the spindle is an external shortened Morse taper KM2, designation B18 according to GOST 9953 (Shortened tool tapers) - shortened cone: D = 17.780 mm, cone length 37.0 mm.

The shortened cone B18 corresponds to a three-jaw drill chuck of the 16th standard size in accordance with GOST 8522 (Three-jaw drill chucks) with a clamping range from 3 to 16 mm.

An example of a symbol for a 3-jaw drill chuck, size 16, with a connecting conical hole B18:

Cartridge 16-B18 GOST 8522-79

Main technical characteristics of the tabletop drilling machine 2N112

Developer: Molodechno Machine Tool Plant MSZ.

Manufacturer - Training and production workshops of the Perm Mechanical College named after N.G. Slavyanova.

The machine parameters correspond to TU2-024-734 dated March 2, 1967 and GOST 8-53.

- Maximum drilling diameter: Ø 12 mm

- Maximum drilling depth: 100 mm

- Maximum height of the workpiece installed on the work table: 420 mm

- Spindle speed limits per minute - (7 steps) 500..4000 rpm

- Spindle end - B18 external shortened Morse taper 2 according to GOST 9953

- Standard drill chuck - Chuck 16-B18 GOST 8522-79, clamping range 3..16 mm

- Electric motor power: 0.6 kW

- Machine weight: 120 kg

Morse cone instrumental shortened

Tool taper - Morse taper is one of the most widely used tool mounts.

It was proposed by Stephen A. Morse around 1864. The Morse taper is divided into eight sizes - from KM0 to KM7 (in English: MT0-MT7, in German: MK0-MK7).

Morse taper standards: GOST 25557 (Tool cones. Main dimensions), ISO 296, DIN 228. Cones made according to inch and metric standards are interchangeable in everything except the shank thread.

For many applications, the length of the Morse cone turned out to be excessive. Therefore, a standard was introduced for nine standard sizes of shortened Morse cones (B7, B10, B12, B16, B18, B22, B24, B32, B45), these dimensions were obtained by removing the thicker part of the cone. The number in the designation of a short cone is the diameter of the thick part of the cone in mm.

Russian standard for shortened cones GOST 9953

Tool cones are shortened.

Russian standard for drill chucks GOST 8522

Three-jaw drill chucks.

- B7 - Morse cone KM0 , D = 7.067 mm;

- B10 - Morse cone KM1 , D = 10.094 mm. Cartridge 4-B10 (0.5÷4 mm);

- B12 - Morse cone KM1 , D = 12.065 mm. Cartridge 6-B12 (0.5÷6 mm), Cartridge 8-B12 (1÷8 mm);

- B16 - Morse cone KM2 , D = 15.733 mm. Cartridge 10-B16 (1÷10 mm), Cartridge 13-B16 (1÷13 mm);

- B18 - Morse cone KM2 , D = 17.780 mm. Cartridge 16-B18 (3÷16 mm);

- B22 - Morse cone KM3 , D = 21.793 mm. Cartridge 20-B22 (5÷20 mm);

- B24 - Morse cone KM3 , D = 23.825 mm;

- B32 - Morse cone KM4 , D = 31.267 mm;

- B45 - Morse cone KM5 , D = 44.399 mm.

Where D is the diameter of the cone in the main plane.

What is a tabletop drilling machine 2m112

Drilling machines 2M112 are household-grade machines with an electric drive, designed to perform a wide range of vertical drilling operations:

- drilling and reaming round holes in workpieces and parts;

- drilling of cylindrical holes (countersinking and reaming);

- cutting internal threads in parts.

The equipment is universal and can drill holes in parts and workpieces made of steel, iron, cast iron, non-ferrous metal alloys, durable plastic and any type of wood.

The machine is designed for use in small metalworking and woodworking enterprises, repair shops, vocational schools and home workshops. The price for the tabletop drilling machine 2M112 is favorable. The equipment has excellent performance characteristics.

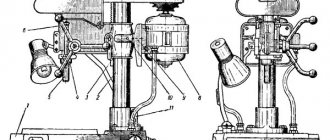

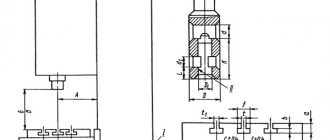

Spindle head of drilling machine 2N112

Spindle head of drilling machine 2n112

Spindle head of drilling machine 2n112

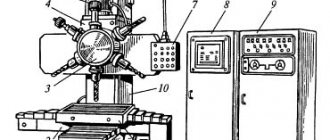

The device of the drilling machine 2M112

The kinematic diagram and general view include the following elements:

- Electrical engine.

- V-belt transmission.

- Vertical bracket.

- A spindle included in the tool head.

- Handle for moving the tool head along the bracket.

- Quill feed handle.

- A base plate with a coordinate table, on the surface of which there are T-shaped grooves.

- Protective casing covering the pulley of the 2M112 drilling machine.

- Clamp with measuring ruler.

Tabletop drilling machine 2M112 without protective casing

Technical characteristics of the machine 2N112

| Parameter name | 2M112 | 2N112 | 2N115pm |

| Basic machine parameters | |||

| Largest nominal drilling diameter, mm | 12 | 12 | 15 |

| The smallest and largest distance from the end of the spindle to the table | 0…400 | 70..420 | 70..520 |

| Distance from the axis of the vertical spindle to the rack guides (overhang), mm | 190 | 160 | 160 |

| Desktop | |||

| Width of the working surface of the table, mm | 250 x 250 | 250 x 250 | 250 x 250 |

| Number of T-slots | 3 | 3 | 3 |

| Spindle | |||

| Maximum movement of the spindle (drilling) head along the column, mm | 250 | 350 | |

| Spindle sleeve stroke, mm | 100 | 100 | 100 |

| Spindle speed, rpm | 450, 800, 1400, 2500, 4500 | 500, 710, 1000, 1400, 2000, 2800, 4000 | 500, 710, 1000, 1400, 2000, 2800, 4000 |

| Number of spindle speeds | 5 | 7 | 7 |

| Spindle taper | Morse B18 | Morse B18 | Morse B18 |

| Drive unit | |||

| Main motion drive electric motor, kW (rpm) | 0,55 | 0,6 (1350) | 0,8 (1350) |

| Dimensions and weight of the machine | |||

| Machine dimensions (length width height), mm | 795 x 370 x 950 | 785 x 465 x 795 | 785 x 465 x 895 |

| Machine weight, kg | 120 | 120 | 130 |

- Barun V.A. Working on drilling machines, 1963

- Vinnikov I.Z., Frenkel M.I. Driller, 1971

- Vinnikov I.Z. Drilling machines and work on them, 1988

- Loskutov V.V Drilling and boring machines, 1981

- Panov F.S. Working on CNC machines, 1984

- Popov V.M., Gladilina I.I. Driller, 1958

- Sysoev V.I. Handbook for a Young Driller, 1962

Bibliography

Related Links. Additional Information

- Classification and main characteristics of drilling-milling-boring group of machines

- Selecting the right metalworking machine

- Machine repair technology

- Methodology for checking and testing drilling machines for accuracy and rigidity

- Directory of drilling machines

- Manufacturers of drilling machines in Russia

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

Technical characteristics of the machine 2M112

The explanation of the name of the machine is as follows. The first number 2 means that the equipment in question is a drilling equipment, and the letter M means that the base model (its symbol 2112) has been modernized. The first of the ones in the designation indicates the type of unit, and the last two digits indicate the largest size of the round hole that can be obtained on this equipment.

The 2M112 tabletop drilling machine has technical characteristics characteristic of all devices of drilling machines of this class.

Thus, the universal desktop vertical drilling machine model 2M112 can work with holes no more than 12 mm in diameter, and the material of the conditional workpiece is considered to be non-hardened steel 45 (for less durable materials, for example, aluminum, more is allowed).

Main technical characteristics:

- Spindle overhang – 0.19 m.

- The number of the Morse cone used is B18.

- Vertical movement of the chuck with the working tool is 100 mm.

- The range of adjustment of the clearance between the lower end of the spindle and the upper edge of the grooves on the table is 50...400 mm.

- The table is a coordinate table, working dimensions are 200×250 mm (options with a table increased in width are also available).

- The number of spindle rotation speeds (changes in steps) is 5, from 450 to 4500 min-1.

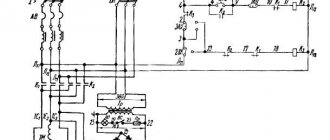

- Drive – electric: motor power – 550 W, supply voltage 3 phases 380 V.

- Overall dimensions of the drilling machine 2M112 (length×width×height) – 770×370×950 mm.

- Weight – 120 kg.

Kinematic diagram of the tabletop drilling machine 2M112

Soviet machines, manufactured both at the Komunaras plant and at the production site in Kirov, were designed for the accuracy of the drilling operation N (normal) according to GOST 8-82.

In addition to drilling, the purpose of the equipment is to cut threads. For this purpose, the design provides for a vertical special thread-cutting chuck.

Technical characteristics of the drilling machine 2m112

| Parameter | Meaning |

| Drilling diameter in steel 45 GOST 1050-88, mm | 12 |

| Spindle overhang (distance from the spindle axis to the generatrix of the column), mm | 190 |

| Outer spindle cone size according to GOST 9953-82 | B18 |

| Maximum spindle movement, mm | 100 |

| Dial division price, mm | 1 |

| Distance from the end of the spindle to the working surface of the table, mm | 50…400 |

| Dimensions of the working surface of the table, mm | 200 x 250 |

| Number of T-slots | 3 |

| Distance between grooves, mm | 50 |

| Groove width, mm | 14 |

| Number of spindle speeds | 5 |

| Speed, rpm | 450…4500 |

| Drilling feed | manual |

| Electric motor power, kW | 0,55 |

| Rotation speed, rpm. | 1500 |

| Supply voltage, V | 380 |

| Overall dimensions, mm | 770x370x950 |

| Machine weight, kg no more | 120 |

The technical characteristics of the machine make it possible to process workpieces with a wide range of characteristics - dimensions 250 x 250 mm (worktable size) and height up to 400 mm (height from the spindle to the working surface). When using a special cabinet for installing large parts, the machine can drill end holes in parts up to 100 cm in length.

In addition, the following should be taken into account:

- machine motor power – 550 W (from three-phase 380 V);

- spindle reach – 19 cm;

- vertical movement of the spindle with drill – 10 cm;

- the three-jaw spindle chuck B-18 rotates in the speed range - 450-4500 rpm (5 speed modes);

- the maximum diameter of a drill that can be fixed in a shortened Morse clamping cone KM-2 is 2-12 mm (for steel workpieces) and 16 mm (for other materials);

- The maximum depth of drilled holes is 10 cm.

All modules and structural elements comply with GOST, the spindle transmission in all planes is manual. The weight of the machine is 120 kg with dimensions 77 x 37 x 95 cm. The measuring flat scale has a division value of 1 mm.

How to buy a drilling machine 2M112?

You can buy a tabletop drilling machine 2M112 in Moscow at an affordable price. JSC Gigant guarantees the shortest possible delivery times.

If you want to leave an order, please contact the managers of our company in the following ways:

- telephone; +7;

- address: Moscow, 1st Institutskiy proezd, 5, building 1 (metro station “Ryazansky Prospekt”);

- Fax ;

Our equipment is reliable, practical, but its main advantage is, undoubtedly, its reasonable cost.