Brief information about the manufacturer

The machine was manufactured by the Frunzensky Machine-Building Plant named after. Lenin. Now this enterprise has been renamed the Bishkek Machine-Building Plant. This plant began operating in November 1941, at that time it was a plant evacuated to the city of Frunze from Voroshilovgrad.

At the time of its opening, this enterprise specialized in the production of cartridges. Then the possibilities became wider and the plant began to produce: machine tools, injection molding machines, chains for combines and consumer goods.

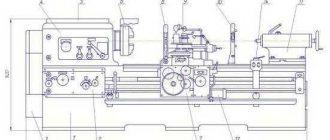

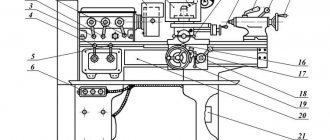

General device

The general characteristics of the FT-11 screw-cutting lathe have some features that expand the functionality. This equipment is capable of cutting threads of non-standard shapes and sizes, and the spindle speed can be changed directly during operation. Other structural elements also have their own characteristics.

bed

Special diagonal ribs add rigidity to this unit. The bed guides are precision ground to ensure smooth movement of the carriage along the front and rear sections of the bed.

Gearbox

Electromagnetic type gearbox clutches. They control the clutch rotation range. The gearbox is fixed on the plate of the left pedestal. There are 9 direct and 3 reverse speed steps.

Spindle box

Changes the balance of the input - output speed of the headstock. It is mounted on roller bearings and also contains a set of gears that facilitate changing speeds.

Tailstock

It is secured using a special clamp through the direction handles. In this case, the degree of clamping can be adjusted using the clamping nut. To ensure significantly less wear on the guides, pneumatic equipment is installed on the tailstock. The support head itself moves along the middle guides.

Gearbox

Using this unit, the operator adjusts the parameters of the thread that the machine will cut. Information about the performance of the support and other functioning elements of the machine comes here.

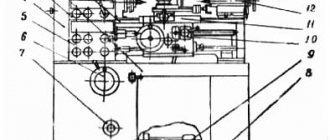

Apron

Contains several sets of couplings that are responsible for longitudinal and transverse transmissions. The blocking device in the element plays an important role. It is not possible to activate the master nut and the longitudinal feed at the same time. The parameters of the maximum axial load can be controlled by the operator himself.

Carriage, upper support

Transverse transmission in this machine is carried out through the upper support, as well as a carriage mechanism. Mechanical transmission is ensured by fixing the screw at the non-working point and extending the button.

At the same time, safety is ensured by the handles, with the help of which the rotation of the spindle is turned on and reversed. In order to prevent carriage shift during end processing, it is secured in a special way.

Tool holder

A tool holder is attached to the teeth of the flat ring of the upper caliper. All opening, turning and securing operations are performed with a special handle.

Electrical system

The machine is connected to a three-phase electrical network with a voltage of 380 W. The required frequency is 50 Hz. All electrical elements are standard, although with some design features.

Main engine

A three-phase unregulated AC motor is used as the main engine.

Engine responsible for calipers

The machine has a separate electric motor to speed up the movement of the support units.

Engine cooling system

A separate engine is equipped with a cooling system. It ensures stable operation of cooling components that prevent the engine from overheating. This prevents wear on the machine and significantly extends its service life.

Electric cabinet

This is a special cabinet in which all electric drives for controlling the machine are located.

KP

The gearbox is controlled by a control panel. In total, the technical characteristics have 24 gear stages.

Design of the FT-11 machine

The basis includes the following components that ensure increased accuracy of work.

Machine bed

It has a solid base, thanks to diagonal ribs, and also includes a pair of guides (flat, prismatic). The first ones are carefully polished and heat-treated, which allows the unit carriage to move perfectly along them. The presence of telescopic shields protects from adverse external factors. The middle guides ensure free movement of the tailstock. Between the pedestals SS there is a container for industrial waste.

Machine speed box

Fixed on the plate of the left cabinet. Equipped with nine direct and three reverse speed stages. Speeds are switched by electromagnetic clutches. From the electric motor to the input shaft of the KS, movement is carried out by a V-belt transmission, and by a flat-toothed belt - from the output to the spindle head.

Headstock

Promotes a change in the balance of the input-output number of revolutions of the unit. The automatic transmission rotates the spindle using the appropriate gear. Mounted on roller and angular contact bearings. A set of gears in the unit contribute to switching speed ranges.

Tailstock

Secures the cam clamp using the handle during light and screw-heavy operations. Adjustment of the degree of pressure is a nut.

What kind of work is it used for?

It is used in finishing and semi-finishing modes. Should not be used for roughing or roughing work. The machine performs all standard turning operations, and it is also possible to carry out non-standard work depending on the length of the kinematic chain.

Threading

The machine has the ability to cut threads. Depending on the set parameters, it is possible to cut metric, inch, modular and pitch threads, as well as several types of non-standard threads.

Metric

Metric threads are cut so that the angle of the triangular profile is 60°. This type of thread is called metric due to the fact that all its geometric parameters are measured in millimeters.

Inch

The parameters of this thread are specified in inches. This option is most often needed to create connections.

Modular

This is a separate variety that is used in the manufacture of worm gear elements.

Pitchovaya

Pitch threads have different sizes and pitch parameters. It is necessary to multiply the size number by the number pi, known from school.

Non-standard

If you turn on the lead screw without the feed box, thereby shortening the kinematic chain, you will be able to cut non-standard threads according to the existing parameters.

Turning operations in finishing and semi-finishing modes

In addition to thread cutting, the FT-11 lathe also performs other operations:

- performing drilling and countersinking;

- turning cones;

- opening holes;

- processing and trimming of ends.

Each operation has its own minor nuances that help an experienced operator complete the job with maximum speed and high accuracy parameters.

Taper turning

Turning cones on this machine, thanks to some of its design features, is possible without the use of a cone ruler. This can be done by moving the upper support.

Features and Benefits

The FT 11 model is a universal screw-cutting lathe, which, despite its significant obsolescence, boasts decent accuracy and the presence of an automatic gearbox. The unit is designed to perform a wide range of work tasks and performs well in both finishing and semi-finishing of various workpieces. At the same time, practice shows that using the unit for roughing and grinding work is extremely undesirable, which is also described in the operating instructions.

The FT 11 lathe is excellent for operation in high-speed modes. It can be used to cut pitch, inch and modular threads. In addition, if the master sets up the working guitar accordingly, it becomes possible to cut non-standard threads, which is a plus in the versatility column. Also, with the help of FT 11, you can turn cone-shaped workpieces without using a special ruler. To do this, just move the upper support.

This model of equipment is characterized by a special frame design, which eliminates the possibility of waste getting into the grooves of the guides. Due to this, the service life of the machine is extended. In addition, it becomes possible to work with products made from special materials that have undergone special processing.

Working with the FT 11 machine will be as productive as possible due to the automation of gear control. The master does not waste extra time changing the processing mode of the part, changing it, literally, right on the fly. Thanks to the introduction of an automatic transmission, it is possible to make stepwise regulation of the intensity of spindle rotation, as well as reverse and stop the spindle without disconnecting the unit from the network. In addition, the automatic transmission makes it possible to operate the spindle in jog mode.

If the master needs to cut a thread with a non-standard pitch, he can turn off the gearbox and connect the rotation element directly to the lead screw. This is also a significant advantage of the machine.

We also note that the FT 11 lathe is equipped with special magnetic starters that protect it from spontaneous starting. This can happen if the electricity supply is unexpectedly turned off and then turned back on.

Design features

There are several specific advantages that have been noted with the FT-11 machine. They arose due to the special design of the unit and make it popular compared to similar equipment.

Impossibility of metal shavings getting into the grooves

The special design of the frame allows the guide grooves to be free of dust and chips. This greatly simplifies the work and increases the safety of turning operations.

Automatic transmission

The automatic transmission is designed to switch spindle speeds at idle, as well as during the cutting process. The design consists of 6 electromagnetic clutches, which allow you to switch 9 speeds and slow down the spindle itself.

The gearbox is made as an independent unit and consists of a housing with borings for the shafts. The automatic transmission dramatically increases the performance parameters of the equipment.

Application of semiconductor and relay elements and circuits to control operation

Controlling the operation of the machine using relay circuits, as well as semiconductors, is an obvious advantage, since it speeds up the processing of the workpiece. True, this complicates the repair process in case of equipment malfunctions.

Accelerated spindle return

Another design feature of the FT-11 machine is the accelerated reverse motion of the spindle. This significantly speeds up the processing of individual parts.

Optional gearbox disabling option

The gearbox uses electromagnetic clutches with magnetically conductive disks and contactless conductors. A fuel oil pump is used for cooling.

Magnetic starters

These elements are necessary for safety and they prevent the unit from starting unintentionally if the power supply is restored.

Main nodes

All units of type 11f1 have a standard design - the main operating units are similar, but may have different designs.

The electrical part is represented by the following components:

- main electric motor;

- electric motor for quickly moving the caliper assembly;

- engine for cooling system operation;

- cabinet for all electric drives;

- Transmission.

Component electricians of a lathe

The machine can operate from a mains voltage of up to 380 V at a frequency of 50 Hz.

The main engine operates using alternating current. A separate control point is provided for selecting gearbox adjustments.

To select the main operating characteristics, the unit has a feed box. It records the performance indicators of the main components, including the machine support. This allows the operator to navigate when cutting threads, relying on special information tables.

The designers compiled all the relevant information regarding the equipment settings for implementing the function of cutting threads on the machine casing in the form of specialized tables.

Table for cutting threads on the casing of a FT 11 lathe

The frame is equipped with special diagonal stiffeners. During its manufacture, high-quality grinding of its guides is carried out, which is necessary for the smooth movement of the carriage during operation of the equipment.

Other important components of the machine include:

- an apron to ensure longitudinal and transverse feeds when the machine is operating in a formed or normal mode;

- spindle head, designed to change the ratio between the output and input revolutions of the unit;

- to switch spindle rotation speeds, special sets of gears are provided;

- rear grandma.

Specifications

All machine parameters are typical for this type of equipment. Technical characteristics are determined by the design features of this equipment.

Main parameters:

The FT-11 machine has a higher accuracy class according to GOST. The largest diameter of the workpieces processed depends on the fixation. Above the support this figure is 26 cm, and above the bed - 50 cm. The maximum permissible distance between centers is 100, 150, 200 cm.

Gearbox, spindle:

The diameter of the through hole when machining in a spindle is a maximum of 6.6 cm. The number of stages of spindle rotation is 21 at direct speeds. The rotation speed parameters are located in the range of 10-2000 rpm.

There are 9 stages for reverse rotation of the spindle, and the rotation speed range is 50-2000 rpm.

Caliper:

The maximum stroke of the cutting slide is 14 cm. The graduation scale of the upper dial of the caliper is 0.05 mm. The maximum cutting force measured in N is 16000.

Gearbox:

The technical characteristics of the feed box are as follows:

- number of longitudinal feed stages – 24;

- cross feeds – 24;

- limits of modular threads – 5–112;

- metric threads – 0.5–112;

- inch threads - 56-0.25.

Caliper movement speed: transverse – 2 m/min, longitudinal – 4 m/min.

Tailstock:

The center of the support head is Morse 5 PT, and the maximum movement of the quill is 20 cm.

Electrical equipment and drives:

The machine has 3 electric motors and a cooling pump. Main drive power – 11 kW.

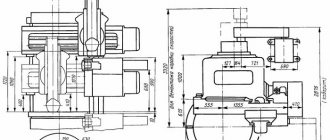

Dimensions and weight:

- width – 137;

- length – 285.6;

- height – 143.5.

The weight of the machine at RMC 100 cm is 3445 kg.

Machine structure

The device has a classic set of working units, many of which were designed according to a type that was innovative at that time.

Electrical equipment. The machine is connected to a three-phase electrical network with a voltage of 380 V and a frequency of 50 Hz. The device is equipped with the following electrical equipment:

- Main electric motor.

- Cooling pump electric motor.

- Electric motor for forced movement of the caliper unit.

- A gearbox with electromagnetic type clutches that control the clutch speed range.

- A cabinet containing electric drives for controlling the machine.

The main engine of the machine is an unregulated three-phase motor operating on alternating current. The operation of the automated gearbox is controlled via the control panel.

Gearbox. Using this unit, the operator configures the parameters of the thread being produced. The feed box receives performance indicators of the caliper and other working components of the machine. The operator can quickly navigate the values of all feeds or thread cutting steps using information tables that are located on the front wall of the spindle head.

On the casing of the machine there is a table with information about the settings for cutting high-quality threads. To create this type of thread, a feed box is not used, but is done directly - by reducing the length of the kinematic chain.

Apron. Thanks to this unit, the carriage and support support feeds in normal and forced modes. Different sets of apron couplings are responsible for longitudinal and transverse feeds. The design of the device provides for the presence of a blocking element that does not allow the longitudinal feed to turn on while the longitudinal feed in the apron is turned off. Simultaneous activation of the uterine nut and the longitudinal feed is not possible.

Using special screws, the operator can control the position of the uterine nut, and when the permissible load level increases, a special locking clutch is activated. It is noteworthy that the maximum load level is set by the operator himself.

Rear grandma. The unit is secured using a special clamp through the control handles, and the clamping force can be adjusted. Special pneumatic equipment installed on the unit prevents accelerated wear of the guides.

The operating principle of this device is based on the use of compressed air supply to the headstock. Before each start of work, the operator must prepare this system by draining moisture from a special filter. Every few months this filter should be removed and thoroughly cleaned.

Bed. The unit has increased rigidity due to the presence of special diagonal ribs. Careful production grinding of the bed guides ensures trouble-free movement of the machine carriage on the front and rear sides of the unit.

These structural elements of the frame are protected using telescopic shields. The tailstock moves along the middle guides. Waste from the production process is collected in a special trough between the pedestals on which the frame is mounted.

The spindle head is a device that allows you to change the ratio of the input and output speeds of the unit. The spindle rotates thanks to an automated gearbox through a special gear. The unit is mounted on two types of bearings: roller and angular contact. Switching the spindle speed ranges is carried out using sets of gears.

Video: FT11 lathe.

Safety precautions

Any lathe requires careful handling. First of all, it is important to follow all safety rules. These include:

- all clothes must be buttoned, sleeves tied up so that the rotating parts of the apparatus cannot grab them;

- hair removed;

- wearing special glasses;

- bring the cutting element to the workpiece as carefully as possible;

- gears cannot be switched while the equipment is running; Do not leave the machine running unattended.

Before starting work, be sure to check the grounding of the machine.

Analogs

Main analogues of FT-11:

- 1K62;

- 16B25 PSp;

- 1624M.

These are all universal screw-cutting lathes that are capable of performing a huge number of turning operations.

FT-11 is a universal screw-cutting lathe with a large number of functions. It is possible to cut several types of threads, including non-standard ones. It is possible to modernize such equipment and increase its productivity. Ideal for finishing and semi-finishing work.