The 1A62 screw-cutting lathe is one of the successors of the famous DIP-200 family, the first machines of which were manufactured in 1932 at the Moscow Machine Tool Manufacturing Plant. Its predecessor was 1D62, which changed the name DIP-200 to a new alphanumeric designation developed by ENIMS in 1937.

The 1D62 went into production in 1937 and was produced for eleven years. In 1948, it was replaced by the model 1A62 lathe, which had improved performance characteristics, as well as a modernized control system and improved ergonomics. It was produced for eight years - until 1956. It was replaced in the production line by the famous 1K62, which was produced for 18 years.

Purpose and scope

The technical characteristics of the 1A62 screw-cutting lathe will allow you to perform almost the entire traditional range of turning operations: turning and boring surfaces with different generatrices, thread cutting with cutters and threading tools, processing of end surfaces, as well as drilling, countersinking, and reaming.

1A62 is used for semi-finishing and finishing processing of various metals and alloys for single and small-scale production. The main consumers of this machine are tool production and repair departments of energy, metallurgy, automotive, mechanical engineering, mining and agricultural enterprises. In the fifties of the last century, this was one of the most popular lathes of this size, and it is still used in small industries and by individuals.

Overview of the device and its scope of use

When a new model of the 1k62 turning machine appeared in 1956, it was produced until 1971. It has a high-rigidity spindle, which is mounted on special bearings. As a result, it became possible to process products made of hardened steel. Shock loading is allowed. However, it does not at all affect the quality or accuracy of processing. The new equipment has a number of undeniable advantages:

- large speed range;

- powerful engine;

- low level of vibration during operation;

- knot stiffness.

As a result, precision machining of metal parts became available. The new device is a frontal one. It can work with any workpieces that have a large diameter but a short length.

The machine has a transverse adjustment on the rear beam. This allows you to work with shallow cones. When the beam is connected to the bottom of the support, it allows for increased functionality during drilling operations.

Model specifics and technical characteristics

Compared to the previous model, which was produced without significant changes for more than ten years, the 1A62 screw-cutting lathe has had the following technical characteristics improved:

- the spindle speed increased by 300 rpm (up to 1200), and the number of steps increased to 21 for forward rotation and to 12 for reverse rotation;

- a 7 kilowatt electric motor is installed;

- instead of a flat main drive belt, a V-belt drive is used;

- a more powerful friction clutch is used;

- a reverse mechanism is installed to change the feed direction during thread cutting;

- the tailstock design has been strengthened;

- the quill diameter has been increased to 70 mm;

- an electric pump was added to supply coolant from a reservoir located in the rear leg;

- The irrigation lubrication system was replaced with a circulation one.

The controls also underwent significant changes, which significantly increased the convenience of the machine operator:

- To set the spindle speed, three handles are used: one circular (with a dial with divisions) and two positional;

- Below the caliper there is a longitudinal feed dial;

- New quick-acting rotary tool holder allows one-handed positioning to any angle;

- The gearbox has been modernized for ease of control (the number of handles has been reduced).

Options

The 1A62 machine inherited the main dimensional parameters from the previous model, including the maximum turning diameter above the support of 210 mm. The main technical characteristics of the machine are given below.

Processing dimensions (mm):

- maximum turning diameter above the bed - 400;

- the maximum length of the workpiece being processed is 1500;

- spindle bore diameter - 36.

Spindle (rpm):

- spindle speed range - 12÷1200;

- reverse spindle speed - 18÷1520;

- spindle cone - M5.

Caliper (mm):

- maximum longitudinal stroke - 1400;

- maximum transverse stroke - 280;

- The maximum stroke of the cutting slide is 110.

Tailstock quill (mm):

- diameter - 70;

- maximum stroke - 150;

- cone - M4.

The machine is equipped with two electric motors: the coolant system (0.125 kW) and the main drive (7 kW).

Purpose of the equipment

The versatility of the model 1A62 lathe makes it possible to successfully use it in turning operations performed on workpieces of cylindrical, conical and shaped configurations, as well as in cutting threads of various types - metric, inch, modular and pitch.

Many experts will recognize the lathe of the model in question from the photo, but a more complete idea of its characteristics can be formed based on the designation of this unit:

- “1” is a number indicating the group to which lathes belong;

- “A” is a number that indicates the generation of equipment;

- “6” – this number indicates that the unit belongs to the screw-cutting group;

- “2” – using this number you can determine the height of the centers (above the bed), for this model it is 220 mm.

Technical characteristics of the machine 1A62

Unlike previous models, this screw-cutting lathe has expanded functionality and improved characteristics. Among these improvements, the following should be noted.

- The spindle rotation speed has been increased to 1200 rpm. In this case, you can choose one of 21 speeds of forward rotation of the spindle assembly and 12 – reverse.

- The 1A62 has a higher power engine - 7 kW.

- The main drive of the unit uses more reliable V-belts.

- The design of the machine's friction clutch has been strengthened.

- A reliable double-row roller bearing is installed in the front support of the spindle assembly.

- To prevent spontaneous detachment of the chuck from the spindle, which can occur when the engine of the 1A62 lathe stops rotating, the design of the latter includes a special groove for placing fuses.

- The feed box provides direct engagement of the lead screw, which is necessary when making precise threads.

- The longitudinal feed of the caliper can be set using a dial located on the front part of the apron of the unit.

- The tailstock has been strengthened.

- Thanks to its improved design, the tool holder can be rotated to any angle without the help of a second hand.

- The cooling system for the processing area has been improved, including an electric pump and a reservoir located in the rear cabinet.

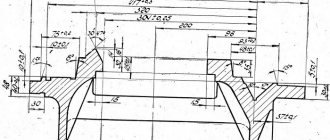

Kinematic diagram 1A62 (click to enlarge)

To ensure the required rigidity when working with long parts, a rest rest can be installed on the model 1A62 lathe.

Organization of machine control

The control of the 1A62 machine is completely manual, so all processing controls are located directly on its main components and assemblies. On the front part of the headstock at the top there are handles for switching operating modes of the gearbox, and just below there are handles for the feed box. Under the gearbox there are three buttons for turning on and off the lighting of the working area, the general power supply of the machine and the electric pump of the coolant system. To the right of the feed box is a push-button block for turning the main engine on and off.

Below the caliper on the apron there are control handles and a handwheel for manual movement of the caliper. On the support itself there are handles for moving and fixing the tool holder. The tailstock is equipped with a handwheel for moving the quill and a handle for fixing it.

Caliper and cutting slide

The support serves for longitudinal and transverse feeding of the cutting tool; a turning tool is attached to its upper part. The main assembly units in its composition are:

- lower slide;

- Bottom part;

- turning part;

- cutter slide with tool holder.

The movement of the lower slide is carried out parallel to the axis of the machine and is done either manually or from the lead screw through the apron drive. The lower part is located on the upper guides of the lower slide. Its lateral movement is carried out either manually or from the apron drive. The rotating part of the caliper can rotate left and right at an angle of 45°. The cutting slide moves manually along the longitudinal guides of the middle part.

To control the mechanical movements of the caliper components, four rotary handles located on the apron are used. These controls enable and disable the following types of movements:

- caliper reverse;

- mechanical movement;

- longitudinal or transverse feed;

- lead screw nut.

For manual control of the support mechanisms, use the handwheel for manual movement of the carriage, located on the apron of the machine, as well as three handles on the support itself, which perform the following functions:

- transverse positioning of the caliper;

- fixing the tool holder;

- movement of the cutting slide.

The types of threads and feeds transmitted to the apron mechanism are adjusted by the controls located on the feed box.

Machine spindle assembly

The spindle assembly of the 1A62 machine is located in the headstock and includes, in addition to the spindle itself, a gearbox, which is used to change its speed and direction, as well as a gearbox that supplies the required type of feed and a given rotation speed to the machine support. The gearbox receives rotation from the main electric motor of the machine via a belt drive.

Machine spindle assembly

The spindle assembly of the 1A62 lathe is responsible for fixing the workpiece during its processing, as well as for transmitting rotational motion to it from the main drive of the device.

We list the characteristics of this unit:

- through hole diameter – 38 mm;

- the maximum diameter of the rod inserted into the spindle assembly is 36 mm;

- rotation speed: forward – 11.5–1200 rpm, reverse – 18–1520 rpm;

- number of settable rotation speeds: forward – 21, reverse – 12.

The internal Morse seat cone in the spindle assembly of the 1A62 lathe has an M5 category.

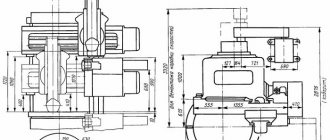

Schematic and wiring diagrams of the 1A62 machine (click to enlarge)

Operating rules

Compliance with operating rules and routine maintenance guarantee the operability and stability of the performance characteristics of the 1A62 screw-cutting lathe during periods between scheduled repairs. Caring for equipment includes both maintaining cleanliness and order directly on the machine and in the working area of the machine operator, as well as monitoring the condition of its components and assemblies. In addition, it is necessary to carry out the regulated checks and activities provided for in the “Care and Maintenance Manual” of this machine.

After the end of the work shift, the machine operator must disconnect it from the power supply, remove tools, fixtures and equipment from the machine, clean its shavings and conduct an external visual inspection of the mechanisms to determine their serviceability. It is also necessary to check the condition of grounding and protective elements: fences, casings and screens.

Before starting a work shift, visual inspection is carried out in the same order. After which it is necessary to check the oil levels in all mechanisms of the machine and only then check the machine at idle speed.

The lubrication system of moving parts of the machine requires special control. The Manual lists control and technical measures that must be performed at the beginning of each shift to ensure that all moving mechanisms of the machine are lubricated. The lubrication system of the 1A62 screw-cutting lathe uses one type of industrial lubricant - machine oil “L” (according to modern classification - industrial oil I-30A).

Oil check

Checking and filling oil into the main components and units of the machine is carried out in the following order:

- Gearbox. The oil level is checked using the indicator on the neck (the norm is the upper level). Before starting work, it is necessary to clean the plate filter by turning the special handle located on the box body. The timing of oil changes is regulated. After starting the machine, it should be changed the first time after ten days, the second time after 20. Then the oil is changed every 35-40 days.

- Gearbox. Oil is poured to the upper level of the oil indicator. The frequency of oil changes is the same as for the gearbox.

- Apron. To lubricate the worm gear, oil must be poured through the hole in the flange to its bottom edge.

- Caliper. There are nine oil nipples on the bottom and top of the caliper that lubricate all moving parts of the caliper. Oil must be added to them every shift. In addition, each shift it is necessary to lubricate the guides of the upper part.

- Tailstock. Lubrication of the quill, screw and bearing is carried out by two oil nipples, which must be filled with oil every shift.

- Guitar. The body of the guitar has a reservoir for oil, which is poured into it up to the level of the oil indicator. The oil change intervals are the same as for the gearbox.

- Lead screw. Before starting a work shift, it must be lubricated with machine oil along its entire length. To lubricate the lead screw supports, as well as the roller supports, three oil nipples are provided, which must be filled with oil every shift. The vertical roller bearing receives lubrication through a separate oiler, to which oil is added once a week.

Location of controls

The mechanism has the following handles responsible for control:

- For moving the slide and carriage in mechanical mode.

- To move the slide.

- Connections to the frame at the tailstock.

- Clamping the quill, moving it.

- Lead screw control.

- Rotation of the indexable cutting head and its fastening.

- Friction part clutch.

- The thread pitch and position are at normal or maximum level.

- To control the gear.

- Selecting the type of thread.

- For left-hand thread, feed.

- Indicator of thread pitch, feed.

- Spindle operating frequencies.

Each handle has several positions to ensure functional control.

Headstock

A general passport with technical parameters will confirm that the part ensures that a certain frequency is transmitted to the spindle during rotation. The number of operations the masters perform is the same frequency that is set. The headstock is designed in such a way that it provides the following capabilities:

- Multi-start thread.

- Right-hand thread or reverse left-hand thread.

- Increased gear ratio to 8.32.

- Thread increased by 16 with a pitch 4 times larger than the standard one.

Tailstock

Guide elements move the tailstocks forward. Be sure to attach it to the frame. A certain fastening of this unit will allow you to perform certain specific works. Additional clamps are the handle eccentric along with a simple lever system. The quill is additionally secured with a handle. The rotational movements of the lever are caused by the displacement of the handle.

Characteristic is the active use of transverse displacements of the tailstocks. Flat cones should not cause problems. This makes it easy to process parts whose dimensions are small. Metric threads are made with a minimum depth.

Caliper

The main purpose is to move the cutter fixed in the tool holder. This movement is carried out along the axis of the spindle, across this part, or at a certain angle. The cross design is always characteristic of this part. In total, it has three main moving units:

- Carriage.

- Cross slides.

- Cutting slides.

These nodes sometimes have different names in various technical literature. The rotating plate is fixed at literally any angle in relation to the base. The main thing is that the caliper supply does not turn on simultaneously from several parts at once. A special locking mechanism is provided for this.

Gearbox

Certain types of threads are created thanks to the feed module. A lead screw with a fixed pitch of 12 millimeters becomes the main assistant during all kinds of manipulations. There is no need for special links, even when the current pitch needs to be increased. According to the passport, the mechanism facilitates the creation of the following types of threads:

- Pitchevaya 1-96.

- Modular – 0.5-3.

- Inch - from 2 to 34 threads.

- Metric. The minimum step is 0.5 millimeters. The maximum step limit is 12.

It is enough to use the appropriate parts so that the thread eventually increases the pitch. Despite the versatility of the unit, it also has certain operating limits.

Workspace dimensions

The processing space of metal-cutting equipment depends on the type, layout and geometric dimensions of the machine. Its dimensions limit the maximum dimensions of the workpiece that can be placed in the working area of the machine. In addition to the technical parameters of the equipment, these limitations also depend on the shape of the part and the location of the machined surfaces on it. For horizontal lathes, the workspace is usually divided into two types: for shaft-type parts and for disk-type parts.

The 1A62 lathe has a traditional layout and is classified as universal. For it, the maximum dimensions of a “shaft” type part are 220 mm in diameter and 1400 mm in length. A disc type part can have the following dimensions: 400 mm in diameter and 100 mm in height. Overall dimensions are not the only limitations when performing turning operations and are directly related to the weight of the workpiece. Thus, the maximum weight of the product when turning in the chuck of a lathe is 500 kg, and between centers - 1500 kg.

Recommendations for operating the equipment

In order for the unit to work efficiently, and for the produced parts to be of high quality and meet the parameters, the machine must be configured correctly.

The installation takes place on a specially prepared platform that can dampen vibrations from the load and withstand the weight of the machine.

The final setup of operating modes and rules of use are specified in the instructions included with the machine. Based on the experience of workers with these types of equipment, the accompanying documentation provides a clear procedure and instructions for operating the unit.

Manufacturer information

The 1A62 screw-cutting lathe was produced from 1948 to 1956 at the Moscow Machine Tool Plant named after. A.I. Efremova. Before the revolution, this enterprise belonged to the Bromley brothers and was engaged in the production of various metal products. The plant was nationalized in 1918, and four years later, at the request of the labor collective, it was renamed “Red Proletarian”. Along with the new name, the company received a new specialization: the production of machines for metal and woodworking. The plant began reconstruction and construction of new production facilities. And in 1923, the first turning equipment was produced - machines of the TN series of three standard sizes.

The key year for the “Red Proletary” was 1930, when the design of a more powerful standardized machine called DIP (“Let's catch up and overtake”) began. Just two years later the first machine was manufactured and tested, and by the end of 1932 the company produced the first 25 DIP-200. The next year, the company was already producing 300 machines per month, and in 1934 it began producing larger-sized DIPs with indices 300, 400, 500. At the end of the thirties, DIP-200, in accordance with the newly adopted ENIMS classification, received a new designation - 1D62. During the war, “Red Proletary” produced machine tools (including those specialized for the needs of the defense industry) and produced artillery shells.

After the war, “Red Proletary” not only produced new types of lathes, but also designed them for other factories, thus becoming the leading enterprise in the industry for turning equipment. In 1948, the plant began production of the 1A62 machine, which replaced the legendary DIP-200, and the following year mastered their mass production. In 1951 the enterprise was named after A.I. Efremov - Minister of Machine Tool Industry of the USSR in 1941-1949. In 1951, a prototype of the now famous 1K62 was created. Two years later, this model went into production and was produced until 1971. In total, more than two hundred thousand of these machines were produced during this period. In the sixties, the company mastered the production of specialized machines and CNC turning equipment.

Since 1971, “Red Proletary” began producing 16K20 machines, and two years later began mass production of them, and in various configurations: with copiers, indication, CNC, etc. In the seventies, the plant had the largest production volumes in its entire history and supplied machine tools not only to the CMEA countries, but also to foreign countries. Since 1983, the company began mass production of CNC machines. At the same time, the plant stopped production of 16K20 machines and switched to production of the MK6056 screw-cutting lathe.

In the early 90s, the company faced difficult times. First, the demand for CNC machines fell almost to zero, then for universal machines, and by the mid-90s, “Red Proletary” produces only a few hundred machines a year. 1999 - the plant moved to a new production site, but with only part of the previous equipment.

Over the next ten years, the plant made an effort to regain at least part of the domestic market, which during this time was filled with foreign products, but in general its efforts were not crowned with success. In 2011, the company stopped producing machine tools, and its new owners announced the leasing of production and office space as its main activity. In 2016, it was announced that the production of turning equipment (including CNC ones) would be resumed, but the plant has not yet recorded any significant success in this matter.

Caliper and cutting slide 1A62

The 1A62 caliper, like similar units of lathes of other models, is responsible for the movement of the cutting tool relative to the workpiece. The characteristics of this element of the machine directly affect the accuracy of technological operations, as well as the functionality of the equipment.

The 1A62 lathe support has the following technical capabilities:

- the longitudinal carriage moves at 650, 900 and 1400 mm, the transverse carriage moves at a distance of up to 280 mm;

- number of stages of longitudinal and transverse feeds – 35;

- feeds can be made within the following limits: longitudinal – 0.082–1.59 mm/rev, transverse – 0.027–0.522 mm/rev;

- number of thread parameters to be cut: metric – 19 (pitch from 1 to 12 mm), inch – 20 (pitch – 2–24 threads/inch), modular – 10 (pitch – 0.5–3 modules), pitch – 24 (pitch – 7–95).

The cutting slide of the 1A62 lathe, which serves to more accurately move the cutting head, is controlled by several flywheels and control levers. This allows you to achieve the following operating characteristics of this unit:

- maximum movement value – 113 mm;

- in accordance with one division of the dial, the slide moves by 0.05 mm;

- the maximum angle through which this unit can be rotated is 900, while the rotation scale division value is 10;

- maximum cross-section of the cutting tool holder – 25x25 mm;

- the number of turning tools that can be simultaneously installed in the tool holder is 4.

It should be noted that the cutting slide of the 1A62 lathe is mechanically driven.

Machine lubrication system

Technical characteristics of the lathe DIP-500 (1D65)

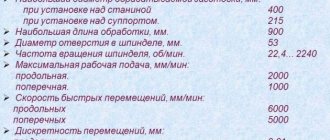

| Parameter name | DIP-500(1d65) | 165 | 1m65 | 1n65 |

| Main settings | ||||

| Accuracy class according to GOST 8-82 | N | N | N, P | N, P |

| The largest diameter of the workpiece being processed above the bed, mm | 1000 | 1000 | 1000 | 1000 |

| The largest diameter of the workpiece above the support, mm | 620 | 600 | 600 | 650 |

| Maximum workpiece length (RMC), mm | 5000 | 2800, 5000 | 3000, 5000, 8000 | 1000, 3000, 5000 |

| Height of installed cutter, mm | 50 x 50 | 45 x 45 | 50 | |

| Distance from the spindle axis to the base of the cutter, mm | 40 | |||

| The largest mass of the workpiece in the centers, kg | 5000 | 5000 | 5000 | |

| Spindle | ||||

| Diameter of through hole in spindle, mm | 100 | 85 | 85 | 128 |

| The largest diameter of the clamped rod, mm | 80 | 80 | 120 | |

| Maximum torque on the spindle, kN/m | 9,5 | |||

| Number of speed steps for direct spindle rotation | 12 | 24 | 24 | 24 |

| Spindle direct rotation frequency, rpm | 4,25..192 | 5…500 | 5…500 | 5…500 |

| Number of spindle reverse rotation frequency steps | 12 | |||

| Spindle direct rotation frequency, rpm | 4,25..192 | |||

| Size of the inner cone in the spindle | KM 6 | 100, 1:20 | 100, 1:20 | 100, 1:20 |

| Spindle end according to GOST 12595-72 | 1-15M | 1-15M | 2-15M | |

| Diameter of standard cartridge, mm | 1000 | |||

| Spindle braking | There is | There is | There is | There is |

| Submissions | ||||

| Maximum longitudinal movement of the caliper RMC=3000, mm | 2520 | 2710 | 700, 2700, 4500 | |

| Maximum lateral movement of the caliper, mm | 600 | 600 | 600 | |

| The cost of dividing the dial during longitudinal movement, mm | No | 0,1 | 0,1 | 0,1 |

| Dial division price for transverse movement, mm | 0,12 | 0,05 | 0,05 | 0,05 |

| Maximum longitudinal movement per dial revolution, mm | 10 | 50 | 50 | 50 |

| Maximum lateral movement per dial revolution, mm | 12 | 6 | 6 | 6 |

| Number of longitudinal feed stages | 32 | 32 | 40 | |

| Limits of longitudinal feeds, mm/rev | 0,225..3,15 | 0,20..3,05 | 0,20..3,05 | 0,05..3,05 |

| Transverse feed limits, mm/rev | 0,114..1,6 | 0,07..1,04 | 0,07..1,04 | 0,017..1,04 |

| Maximum longitudinal cutting force Pz, kN | 12 | 12 | 41 | |

| Maximum transverse cutting force Px, kN | 780 | 780 | ||

| Speed of fast movements of the caliper, longitudinal, m/min | No | 2,16 | 3 | 3 |

| Speed of fast movements of the caliper, transverse, m/min | No | 0,735 | 1 | 1 |

| Number of metric threads to be cut | 22 | 44 | ||

| Limits of pitches of cut metric threads, mm | 1..14 | 1…120 | 1…120 | 1…120 |

| Number of inch threads to be cut | 36 | 31 | ||

| Limits of pitches of cut inch threads | 2..28 | 28…¼ | 28…¼ | 28…¼ |

| Number of modular threads to be cut | 13 | 37 | ||

| Limits of pitches of cut modular threads | 0,25..3,5 | 0,5…30 | 1…120 | 0,5…30 |

| Number of cut pitch threads | No | No | No | No |

| Longitudinal switch stops | No | No | ||

| Transverse switching stops | No | No | ||

| Cutting slide (upper slide) | ||||

| Maximum movement of the cutting slide, mm | 240 | 240 | 240 | |

| Price for dividing the tool slide movement dial, mm | 0,05 | 0,05 | 0,05 | 0,05 |

| Number of feed stages | 40 | |||

| Limits of longitudinal feeds, mm/rev | 0,017..1,04 | |||

| Speed of rapid movements, mm/min | 1 | |||

| Maximum rotation angle, degrees | ±90° | |||

| Price of one division of the rotation angle, degrees | 1° | |||

| Tailstock | ||||

| Center in the spindle according to GOST 13214-79 | Morse 6 | Morse 5 | Morse 5 | |

| Maximum movement of the quill, mm | 300 | 300 | 300 | |

| Maximum movement of the quill with the tool installed, mm | 280 | |||

| Quill diameter, mm | 120 | |||

| Maximum movement of the quill in the transverse direction, mm | ±30 | ±15 | ||

| Electrical equipment | ||||

| Number of electric motors on the machine | 1 | 3 | 4 | 3 |

| Main drive electric motor, kW | 17 | 22 | 22 | 22 |

| Electric motor for high speed caliper, kW | No | 1,5 | 1,5 | 1,5 |

| Lubrication pump drive | Built-in | S12-54 | ||

| Cooling pump (pump) | PA-22 | PA-22 | 0,12 | |

| Total power of all electric motors, kW | 23,62 | |||

| Dimensions and weight of the machine | ||||

| Machine dimensions (length width height) RMC=2800.3000, mm | 8000 x 1700 x 1620 | 5825 x 2100 x 1760 | 6140 x 2200 x 1760 | 6140 x 2200 x 1770 |

| Machine weight RMC=3000, kg | 11500 | 12500 | 12800 | 12800 |

Bibliography:

Universal screw-cutting lathe 1D65. Passport, Red Proletary, 1940

Acherkan N.S. Metal-cutting machines, Volume 1, 1965

Batov V.P. Lathes., 1978

Beletsky D.G. Handbook of a universal turner, 1987

Denezhny P.M., Stiskin G.M., Thor I.E. Turning, 1972. (1k62)

Denezhny P.M., Stiskin G.M., Thor I.E. Turning, 1979. (16k20)

Modzelevsky A. A., Muschinkin A. A., Kedrov S. S., Sobol A. M., Zavgorodniy Yu. P., Lathes, 1973

Skhirtladze A.G., Novikov V.Yu. Technological equipment for machine-building industries, 1980

Tepinkichiev V.K. Metal cutting machines, 1973

Chernov N.N. Metal cutting machines, 1988

Pikus M.Yu. A mechanic's guide to machine repair, 1987

Related Links. Additional Information

Home About the company News Articles Price list Contacts Reference information Download passport Interesting video KPO woodworking machines Manufacturers