Adjusting the dispenser

An electronic gearbox, such as Tomasetto, provides for two main gas adjustments on carburetor cars:

- pressure in the second stage (it can be called sensitivity);

- the volume of gases passing through the channel at idle.

The engine must be started on gasoline fuel and warmed up to the nominal temperature level. The idle speed is set to one thousand per minute. The supply is turned off and gasoline is produced. The adjustments are in the following starting position:

- maximum eversion of the dispenser (the gas channel is open to the largest cross-sectional area; with a two-section chamber, each chamber is adjusted separately: for the first - the largest opening, for the second - the minimum);

- the screw that determines the idle speed is screwed to the extreme position and unscrewed five turns;

- the screw adjusting the sensitivity is installed in an intermediate position.

First you need to set the idle speed. To do this, the car starts on gas fuel, using a choke, the speed is set to two thousand per minute. Then the choke is gradually removed, and by rotating the screw that determines the idle speed, the speed is set to the maximum. These operations are repeated until the choke is completely removed and the engine operates stable in idle mode.

The maximum speed is set using the idle speed screw. The screw that determines the sensitivity is gradually tightened. When the speed is lost, they are added by the screw that regulates the idle speed. If this does not work, then the sensitivity adjustment is tightened a couple of turns and the procedure is repeated.

At the end of the adjustment, this screw will be screwed in almost all the way, and the engine speed when idling reaches its maximum value - about 1.2 thousand per minute. After this, this indicator is reduced - slightly below the nominal value, by tightening the idle speed screw, then, unscrewing it slightly, it is set to about a thousand revolutions per minute.

Next, you need to adjust the sensitivity of this unit: the adjustment of the same name is gradually turned away until it affects the engine speed when idling, and it is twisted approximately one turn in the opposite direction. If everything is done correctly, when you press the gas pedal sharply, the power plant should respond responsively.

The third step is to set up the dispenser. With the engine running, the revolutions are set to three and a half thousand per minute, and the screw of the mechanical gas dispenser is tightened until they begin to change. Then this adjustment must be turned back half to three-quarters of a turn.

For a two-section dispenser that provides for separate settings in sections, the above applies to the first of them, the second is placed at a third of the previously configured ones.

If the pressure in your reducer is adjusted in the first stage, then turn off the motor and close the gas flow pipe. Then, using the control hole, which is closed with a bolt, connect a pressure gauge to the cavity of the first stage, allowing you to measure pressure up to one and a half kgf/cm2.

The power plant starts up, and at idle the pressure level is set to about 0.4 kgf/cm2. Then the idle speed and sensitivity of the gearbox are adjusted again. You should take into account the increased gas hazard of these works, therefore, if you are not confident in the reliability of the connection, you need to contact a service center.

The final step is setting up the dispenser. To do this, you need to start the car on gas fuel and set the speed to about three thousand per minute. There is no need to use suction, it is better to involve a partner. Then the screw that regulates the dispenser is tightened until the speed begins to change.

You need to fully verify the presence of this boundary by playing with the screw in one direction or the other. From this threshold, the adjusting screw is unscrewed by half to three-quarters of a turn. After a slight adjustment of the idle speed, the gas injection system for the carburetor can be considered configured.

It is also recommended to check the correct settings of gas equipment for a carburetor engine based on the concentration of oxygen and carbon monoxide in the exhaust. The CO level should not exceed 0.45%. Adjustment is carried out using screws that supply air to the carburetor and regulate the idle speed of the gearbox. If the indicator is underestimated, you need to add it to the second of the specified settings; in the opposite situation, vice versa.

Checking the oxygen content in domestic conditions poses a certain problem. To do this, configure the HBO as follows:

- an oxygen sensor intended for injection modifications of the Lada is installed in the muffler behind the “pants”, this is done using a pre-welded adapter nut;

- contacts for heating are connected in the same way as a gas valve; for signaling, a shielded wire is used, connected to the dashboard and connected to the tester.

As a result, HBO adjustment occurs under your constant control. If the tester shows a voltage level of 0.2-0.8 V, then everything is normal, a lower level means there is not enough oxygen, a higher level means there is too much oxygen. However, depending on the load and operating mode of the engine, these parameters may change, so fine tuning is still necessary.

An even more interesting option is to use a lambda probe emulator, which provides the possibility of color indication. Three LEDs, similar to a traffic light, indicate optimal operation. A microprocessor unit can be connected to this device, which allows you to control the adjustment of the electronic dispenser, but such work cannot be handled independently, and you need to contact a service station. Moreover, this pleasure is not cheap.

Briefly about the power of the burners and stove

The total power of the working surface depends on the number of burners and their direct power, indicated in the equipment passport. The average for one burner is 2-2.5 kW. With decent gas quality and normal pressure in the line, this value is quite enough for comfortable and relatively quick heat treatment of products. In this case, the maximum power of the burner is determined when the regulator is turned to the maximum and gas is fully supplied.

Manufacturers often offer household hobs, the burners of which have different power ratings:

- on small ones - 0.7-1.2 kW;

- on average - 1.3-1.8 kW;

- on large ones - up to 4 kW and more.

Such a technological solution is quite logical and convenient: it makes no sense to brew coffee in a Turk on a powerful WOK burner or try to boil a large volume of water on a small one. Choosing different capacities allows you to save gas, and if the room temperature is maintained using an air conditioner, you can also save electricity.

Thus, the acceptable parameters for the calorific value of the gas used by a hob from the middle price segment, consisting of 4 burners, is 8-10 kW. More budget models usually have a total power of 5-7 kW.

Cooking surfaces with a high calorific value for normal safe operation may require the installation of a separate chimney or the installation of a heavy-duty hood. However, for home use, purchasing such models is not always advisable.

Gas stoves with two- and three-circuit burners are especially popular. The so-called double or triple “crown” is a powerful burner in which the flame is produced not in one row, but in several circles. This device allows you to cook faster and heat dishes more evenly.

How to set up and adjust HBO on an engine with a carburetor

Let's start with the fact that when it comes to gas equipment on a carburetor engine, the main manipulations come down to the settings of the evaporator reducer. The specified gearbox allows you to do the following:

- adjust the gas pressure in relation to the second stage (adjust sensitivity);

- set the amount of gas that passes through the XX valve;

So, the general setup procedure is as follows:

- First, the engine starts, and the start must be done on gasoline.

- Next, the gasoline-powered power unit must reach operating temperatures.

- After warming up, you need to set the idle speed on the carburetor to 950-1000 rpm.

- Next, you need to turn off the gasoline supply and wait until the remaining gas is used up.

Now let's move on to setting up the HBO. At the initial stage of adjustments you should:

- Unscrew the dispenser completely (the cross-section of the gas supply channel is open as much as possible).

- If the dispenser has separate sections, allowing for separate adjustments for each chamber, then the first chamber is set to full channel opening, and the second channel is set to a minimum.

- The adjusting screw, which allows you to adjust XX, is first fully tightened, after which it should be released 5 turns;

- As for the sensitivity screw, it should be set to the middle position.

Next you need to start setting the idle mode. After all the manipulations described above have been completed, the car engine needs to be started, and the start-up is already done on gas. It is also necessary to pull out the “suction”.

Then you should raise the speed to 1750-1950 rpm, then, turning the idle screw several turns, the choke is removed in parallel. The operation often has to be done several times. The main task is to find an idle speed such that, with the choke completely removed, the engine runs stably at idle.

After the required speed has been selected (the internal combustion engine operates smoothly and stably with the choke removed), you should begin to turn the screw responsible for sensitivity. The screw must be tightened slowly and in stages.

In the case when the idle speed begins to fluctuate greatly, then the idle speed screw is unscrewed to the maximum. If stable operation of the motor cannot be achieved, then the sensitivity screw is tightened back a couple of turns, after which the entire adjustment procedure is repeated again.

As you can see, it is necessary to find the right balance between the gas “amount” screw and the idle speed screw. A successful result can be considered when the sensitivity screw is fully tightened, and the idle speed is about 1150-1200 rpm, while the motor runs smoothly.

The final stage can be considered an additional adjustment of the idle speed using the appropriate screw. The specified screw is tightened a little more, the speed drops to the minimum possible, then the screw is unscrewed a little, and the XX speed should reach around 1 thousand rpm.

zavernutiy › Blog › theory of gas adjustment

1 check spark plugs, wires, etc.

To begin with, I will divide all gearboxes of the 2nd (2+) generation into 3 groups. 1. Old “Dutch” models from the late 80s, early-mid 90s, VIALLE type. Very reliable devices (resource under 200 thousand). We have few of them and, as a rule, they are already dead. 2. Gearboxes made in Italy, Poland or Turkey. For example, “LONGAS, BRC, VOLTRAN. In general, they are similar to each other and have 2 adjusting screws. 3. Gearboxes made in Italy or licensed with one adjusting screw. For example LOVATO.

I will give the adjustment method for the second group (with two screws).

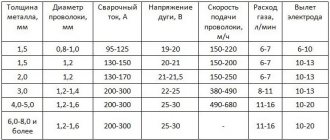

There are two main adjustments on the gearbox: the pressure in the second stage (hereinafter I will call it “sensitivity” - this is closer to the truth) and the amount of gas passing through the idle channel - the idle screw. The engine must be started on gasoline and warmed up to operating temperature. Initial position of the adjustments: - the dispenser is turned to the maximum (maximum cross-section of the gas supply channel, - screw the idle speed screw to the end and then unscrew it by 3-5 turns, - set the sensitivity screw to the middle position.

Idle speed setting. Start the car on gas. If it doesn’t work, then start it on gasoline and switch to gas and keep the speed around 2000. Now you need to reduce the speed to idle and turn the idle screw to find its position when the engine does not stall. If the engine stalls, repeat the operation until operation at idle is stable. Then, turning the idle speed screw, you need to find the maximum speed. Next, you need to gradually tighten the sensitivity screw; if the speed changes, then you need to adjust it with the idle speed screw to maximum. If that doesn’t work, turn the sensitivity screw 2 turns and repeat again. As a result, the sensitivity screw is turned almost all the way, the engine idles at maximum - somewhere around 1100-1200 rpm. Using the idle screw, turn it in to lower the speed slightly below the nominal speed and then turn it back, set it to 950-1000 rpm.

Setting the sensitivity of the gearbox. Gradually unscrew the sensitivity screw until it begins to affect the engine speed at idle, then turn it back 0.75-1.25 turns. We try to accelerate sharply - the engine should respond well to the gas pedal. If it responds poorly – it’s dull, repeat the operation.

Setting up the dispenser. On a gas-powered engine, set 3000-3500 rpm, and tighten the metering screw until the threshold for changing the speed is found. It can be heard by the sound of the engine running. You can turn the dispenser screw more or less to make sure of this. Unscrew the dispenser screw 0.5-0.75 turns from the found threshold.

Final adjustment. This is also done in several steps. Sharply press the throttle, then turn the sensitivity screw 0.25 turns until you feel a dip in the speed gain. After this, unscrew the sensitivity screw 0.5 turns. It is better to carry out the last operation not by ear, but by “starting” the car from a stop at low throttle. After this, repeat the procedure for setting up the dispenser.

Actually, the gearbox is configured. You can drive safely. The only problem that may arise is high CO levels. A characteristic sign is a strong specific smell of unburned gas from the exhaust at idle. In this case, you need to tighten the screw xx a little. To pass a technical inspection, it’s a good idea to go to a service station with a gas analyzer and check the CO level in the exhaust.

Methodology for the 3rd group. These gearboxes have one adjustment screw. The so-called combined idle/sensitivity regulator. How to configure such a gearbox. As in the previous method, start the car on gas (or on gasoline with subsequent transfer) and adjust the idle speed. Set the adjustment screw to the maximum speed - 1000-1100 rpm. Then, turning the screw, reduce the speed a little less than the nominal one and then, turning it back, set it to 950-1000 rpm.

Adjust the dispenser as in the previous method.

I'll add. You can tighten the dispenser screw 0.5 turns and ride. If the car hasn’t started to “stupid”, you can press it another 0.5 turns. As soon as the machine starts to become dull, unscrew the screw until the dullness disappears. This will be the most efficient mode without damaging the engine due to a lean mixture.

Source

Setting up the vacuum reducer

There are two types of vacuum reducers:

- providing separate adjustment at idle speed, as well as sensitivity;

- having a combined regulator of these two settings.

In the first case, the adjustment is carried out similarly to the adjustment of the electronic gear described above. If the regulator is combined, as in the 2nd generation Lovato LPG for cars with a carburetor, the adjustment is as follows:

- the car starts using gas, the speed is adjusted by suction, up to two thousand per minute;

- the choke is gradually removed, the speed is set to maximum by tightening the screw that adjusts the idle speed;

- The same adjustment adjusts the number of revolutions, about a thousand per minute or a little more;

- With a similar setting, the speed is further reduced below the nominal value, and then again rises to a thousand per minute.

This is how the 2nd generation Lovato LPG is configured for the carburetor.

Once the idle speed has been set, it is necessary to ensure that the engine responds quickly and picks up speed when you press the gas. To do this, you need to gradually unscrew the sensitivity adjusting screw until the idle speed begins to change. As soon as a change in idle speed has been noticed, the specified screw must be screwed back 2/3 of 1 full turn or one and a quarter turns (depending on the particular internal combustion engine, etc.).

When finished, you need to press the gas pedal, first smoothly, then you can press it sharply. The main thing is that if the setting is done correctly, there should be no failures, the engine should quickly exit the idle mode, respond adequately to pedaling, rev up well and respond quickly to any pressing of the gas pedal.

- After the settings have been completed and the response to the gas pedal is satisfactory, you need to move on to the settings of the dispenser itself. To do this, you should raise the speed, on average, to 3 or 3.5 thousand rpm without suction. For these purposes, it is better to invite an assistant who will press the gas.

Next, tighten the screw on the dispenser until the speed begins to change. To make sure that the revolutions really change, it is recommended to loosen and tighten the screw half a turn or more at the approximate “point” of the speed change.

So, when the position of the screw leading to a change in speed has been found, the screw should be unscrewed from this position by half or 3/4 of a quarter of a turn. Please note that if a dispenser is installed that has two sections, then all the manipulations described above are carried out with the first chamber.

Instructions for adjusting HBO 2nd generation

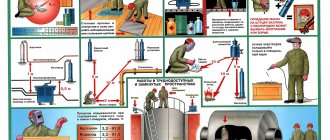

The first step is to check the engine for air leaks. In order to determine whether it is there or not, you need to buy a can of liquid for cleaning carburetors, and spray this liquid on the areas where there may be suction. Typically, such areas are in the place where the gaskets are located between the carburetor and the manifold, between the intake manifold and the cylinder head, between the air filter housing and the carburetor, as well as at the vacuum connections. If air leaks are detected in this way, then CORRECT ADJUSTMENT OF THE 2nd GENERATION IS IMPOSSIBLE. Fix the problem first, and only then can you make adjustments.

Second phase:

Check the air filter for clogging. It is advisable to replace the air filter before tuning.

Third stage:

You need to check whether the gas is completely shut off when you switch the car to gas. How to check you ask? Yes, it’s easy, you need to move the switch button to position 0, and use up the remaining gasoline from the line and carburetor. After the car has stalled, switch the button to the “Gas” position, and after starting, remove the hose that is located at the output of the gasoline shutoff solenoid valve.

If gasoline does not flow, then everything is fine, and we can start tuning.

Fourth stage:

On a working car, at idle speed, tighten the bypass screw, which is usually gold in color, to the maximum. In the photo it is indicated as “Screw 1”.

If, when tightening it, the idle speed disappears, then add idle speed with screw number 2 until, with screw 1 tightened to the maximum, the machine will idle stably.

After adjusting the idle speed, it is necessary to adjust the gas supply at high speeds.

Fifth stage:

Adjusting the gas supply at high speeds using the greed screw.

First, unscrew it 3 turns, then raise the speed to 3000, and hold it there. We tighten the greed screw until the engine begins to choke. As soon as the engine starts to choke, slowly unscrew the screw until the engine starts to run “easy”, usually 2-3 turns.

Ways to increase the power of a burner

Based on the design features of the burner, several methods of increasing the power of the stove are popular. But is it appropriate to test them on your own experience?

It is worth recalling that even independent repair of gas appliances is prohibited, and even modifying equipment at home is an undertaking bordering on dangerous and even deadly sabotage.

Unfortunately, explosions and carbon monoxide poisoning are tragedies that shock the public with the frequency and number of victims. Therefore, it is definitely not worth altering the design of the burner for the sake of your own convenience. And the methods described below are more useful for understanding theory than for practical application.

Method #1 - boring or replacing the jet

The nozzle through hole is one of the main regulators of the gas volume, which gradually enters the burner. To increase the power of the burner, you need to carefully bore the nozzle or replace it with a part with a wider feed hole.

For boring, you can use a sharp knitting needle with a diameter of up to 3 mm. But you shouldn’t get too carried away - uncontrolled enlargement of the hole or replacement of the nozzle is fraught with extremely unpleasant consequences.

It is impossible to increase the gas flow without miscalculations, since the burner itself must be able to process it. Excess gas will cause the flame to pull away from the burner. The fire will change color to red, soot will appear, which is almost impossible to remove from the dishes. The problem can be solved by installing a larger diameter burner.

However, replacing the burner is not always possible due to the design of the stove body itself. Even if you actually replace the burner, the new volume of gas transmitted through the nozzle may not be enough. This threatens even bigger problems: the flame can jump down and burn out near the nozzle itself.

But a sluggish flame and soot in this case are the lesser of evils. A falling flame indicates incomplete combustion of the gas, which releases combustion products dangerous to life and health - soot and carbon dioxide.

Method #2 - reducing the jet-mixer length

Fortunately, this method is less popular among tips on how to try to increase the power of a gas stove. This method is more dangerous than the previous one, as it involves even more interference in the design of the burner, is less effective and can also lead to negative consequences.

The size of the area that is emphasized in the description of the burner design also affects the power of the flame produced. If you reduce this zone, gas will flow into the burner faster and the burner power will increase slightly.

However, the portion of air required for normal combustion simply will not have time to be added to the incoming gas. As a result, the modernizer will receive the same red flame with soot, which is likely to come off the burner.

Method #3 - removing the divider

You can try to increase the burner power without affecting the operation of the nozzle. The divider covering the burner evenly divides the flow of the gas-air mixture, distributing the flame into separate bundles. Removing the divider increases the area of contact between the flame and the cookware. The column of fire becomes higher and larger, and the heat treatment itself proceeds faster.

However, this is only a temporary measure and is not suitable for every pan. For this kind of cooking, you need to use tall cauldrons or special WOK pans. Additionally, a fire uncontrolled by a cutter becomes quite dangerous.

Method #4 - increasing gas pressure

The pressurization method is only suitable for stoves connected to gas cylinders. The standard pressure in a cylinder for domestic use is about 1.6 MPa. But this value is not constant: the force of gas pressure on the walls of the vessel can be influenced by both the degree of filling of the cylinder itself and the temperature in the room, the composition of the gas, etc.

The higher the temperature of the gas, the more it expands, pressing on the walls of the container. Therefore, the cylinders are not filled completely, but approximately 85%. And, the less gas remains in the vessel, the weaker its flow flowing to the burner.

You need to try to increase the pressure of the gas entering the stove using a reducer, the so-called “frog”. It is unsafe to damage the design of the unit, and, fortunately, most modern gearboxes are non-separable. However, replacing the part may solve the problem. Supplying gas with increased pressure will provoke more air leaks, due to which the flame on the burner will increase significantly.

But do not forget about safety precautions and monitor the gas supply even when the burner control is closed. Too high a pressure can cause gas leakage even when the burners are not turned on.

Based on all of the above, you can understand that when choosing one of the ways to increase power, you should be extremely careful and not overdo it.

The only safe and affordable way to increase the power of your burners is to buy a new hob or stove. It is necessary to initially select gas equipment that meets the needs of the family. Any attempts to change the passport parameters of burners by an inexperienced technician at home will inevitably lead to serious problems.

Adjusting the flame on the stove burners

It is necessary to debug the normal operation of the burner in cases where the flame loses its efficiency and quality. Setting up a gas stove should also be done by a specialist. But understanding the algorithm of this process will be useful for any user.

First, it’s worth understanding what a properly burning stove flame looks like. The fire should be blue. An intense bright blue glow is a sure sign that the stove is working correctly and does not need debugging. A yellow, orange or red flame indicates an incorrect composition of the combustible mixture. In this case, there is clearly not enough air; its flow must be increased.

To change the gas-air mixture entering the burner, it is necessary to adjust the operation of the air dampers, which are usually located near each burner.

Direct setup goes like this:

- after disconnecting the stove from the gas system, it is necessary to gain access to the adjustment mechanisms under a special partition or in the gas control knob;

- the stove is reconnected to the main line, gas is supplied alternately to each burner;

- the volume of air entering the mixer is adjusted by turning a special screw;

- As soon as the flame in each burner acquires the correct color, you can turn off the stove again, reassemble it and connect it to the main line.

When setting up the stove, you may need to work with the gas control valve and its thermocouple. If the flame regularly goes out at a minimum fuel supply level, perhaps the problem lies in the gas control. The operating principle of this option is based on a special sensor that responds to the energy released during the combustion process. If the flame goes out unexpectedly, the thermocouple sensor cools down, signaling the gas supply to stop.

However, oxidation processes and a decrease in the sensitivity of the sensor due to the ingress of liquids or the formation of deposits from food deposits can provoke incorrect gas shutoff outside of an emergency situation. Therefore, both the stove and this block should be kept clean, and if necessary, call a professional to clean it.

If you are faced with unusually noisy operation of the burner, we recommend that you find out the cause of the noise of the burner and how to eliminate it.