Information about the manufacturer of the horizontal tabletop milling machine NGF-110

The horizontal tabletop milling machine model NGF-110 is produced by the Rostov plant of small-sized machine tools MAGSO, KomTeh-Plus , founded in 1956.

ComTech Financial and Industrial Group , which has existed in the machine tool equipment market for several years and has priority in the production of small-sized metal-cutting machines: lathes, milling, vibrating, sharpening, drilling, which equip schools, vocational schools, colleges, institutes, repair and installation organizations of all regions of Russia.

Machines produced by the Rostov plant of small-sized machine tools MAGSO

- NS-16 - tabletop drilling machine Ø 16

- NGF-110Sh3 - low power milling machine 0.6 kW, table size 100x400 mm

- NGF-110Sh4 - low power milling machine 0.75 kW, table size 100x400 mm

- SNVSH - tabletop drilling machine Ø 16

- SNVSH-2 - tabletop drilling machine Ø 16

- TV-4

- educational screw-cutting lathe Ø 200, RMC 350 mm - TV-6

- educational screw-cutting lathe Ø 200, RMC 350 mm - TV-6M

- educational screw-cutting lathe Ø 200, RMC 350 mm Dubno - TV-7

- educational screw-cutting lathe Ø 220, RMC 330 mm - TV-7M - educational screw-cutting lathe Ø 220 mm, RMC 275 mm

- TV-9 - educational screw-cutting lathe Ø 220 mm, RMC 525 mm

- TV-11 - educational screw-cutting lathe with frequency converter Ø 240, RMC 750 mm

Safety precautions

The instructions require careful study; without them you cannot begin operation. When installing the machine, you must carefully follow the recommendations given by the manufacturer. You must ensure that the table plane remains absolutely level. It is easier to achieve the desired result with the adjustment feet of the equipment. The platform that was used when installing the machine is also suitable.

The basic rules are described as follows:

- The coolant reservoir is filled after the basic settings are set. Lubrication of the gearbox components occurs in the next step.

- Spindle speeds are separately adjustable. To do this, simply turn one of the handles to a suitable position.

It is also important to constantly monitor other parameters. This machine has been produced since 1956 by the Rostov plant of small-sized machines MAGSO, under the leadership of the KomTech Plus company

This enterprise itself is part of an industrial group of companies that consolidated its position in the market for the production of small-sized machine tools more than 10 years ago and maintains it to this day. But what are the technical characteristics of the NGF 110 Sh4 itself and what should you know about it before purchasing?

This machine has been produced since 1956 by the Rostov plant of small-sized machines MAGSO, under the leadership of the ComTech Plus company. This enterprise itself is part of an industrial group of companies that consolidated its position in the market for the production of small-sized machine tools more than 10 years ago and maintains it to this day. But what are the technical characteristics of the NGF 110 Sh4 itself and what should you know about it before purchasing?

NGF-110Sh4 horizontal tabletop milling machine. Purpose and scope

The NGF-110Sh4 milling machine is produced according to TU-79 RSFSR 441-79 and replaced the outdated model of the NGF-110Sh3 milling machine, which was produced according to TU-79 RSFSR 355-72.

horizontal cantilever milling machine NGF-110 is designed to perform milling operations for processing horizontal planes, grooves and other surfaces. Installing a vertical milling head VFG allows you to additionally process vertical planes, as well as planes at a certain angle. Surface processing is carried out using disk, face, end, corner and shaped cutters.

The desktop horizontal milling machine model NGF-110Sh4 is special school equipment and is intended for industrial training in secondary schools for equipping school educational workshops.

Modifications of the desktop horizontal milling machine NGF-110

NGF-110sh1, NGF-110sh2 manufacturer: Plant No. 5 named after. Dzerzhinsky , city of Shchelkovo, Moscow region, village named after Sverdlov.

NGF-110sh2 manufacturer: Sapozhkovsky Mechanical Plant No. 7 , Sapozhok city, Ryazan region.

NGF-110sh3 0.6 kW, table size 100 x 400 mm manufacturer: Rostov plant MAGSO , founded in 1956.

NGF-110sh4 0.75 kW, table size 100 x 400 mm manufacturer: Rostov plant MAGSO , founded in 1956.

Designation of the milling machine NGF-110sh4. Letters and numbers mean:

- N - desktop machine;

- G - horizontal machine;

- F - milling machine;

- 110 — the largest diameter of the cutters used on the machine (mm);

- Ш - school;

- 1, 2, 3, 4 - machine model.

NGF-110Sh4 Dimensions of the working space of the milling machine

Dimensions of the working space of the NGF-110sh4 milling machine

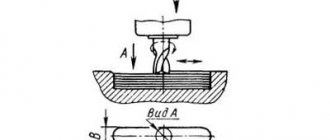

Sketch of a trunk with an earring of a horizontal milling machine NGF-110

- trunk

- earring

- screw

- earring sleeve

- screw

The stand in the upper part has dovetail-type guides in which trunk 1 is installed. The trunk can be moved along the guides manually. The trunk is clamped to the guides using a wedge, which, when the screw is tightened, is tightened and secures the trunk to the stand.

An earring 2 is installed at the front end of the trunk. The earring on the trunk is tightened with a nut 5. Rearranging the earring from one machine to another due to individual adjustment is not allowed.

The bronze bearing-sleeve of the earring 4 has a conical outer surface and two longitudinal cuts, due to which the clearance in the bearing is adjusted with a nut 3.

Before starting work, it is necessary to lubricate the inner cavity of the earring bushing with I-30A oil.

The gap adjustment is determined by the heating of the shackle bushing (when running for one hour at maximum spindle speed, the heating of the bushing should not exceed 50-60 ° C, with sufficient lubrication).

The mandrel is designed for fastening cylindrical disk and other cutters.

The cutters are mounted on the mandrel using mounting rings and a nut.

To ensure the rigidity of the cutting tool, the free end of the mandrel is installed in the support of the shackle. The earring is attached to the trunk.

Device

To install the router trunk, there is a “Swallow Tail”, this is the upper section in the unit rack, and a special shaft clamps the entire structure. The fastening force can be adjusted by tightening the screw, which allows for reliable fixation and safe milling; the shaft in this case acts as an additional fastener. The trunk must be moved manually in three planes. The front part includes a fixed shackle, which is adjusted to the specific machine and its dimensions, and it cannot be moved to another unit. Thus, this element remains the only one indispensable when repairing equipment, unlike the VFG for NGF 110. The drawing of the device also says this.

Read also: Aluminum its physical and chemical properties

The school milling machine NGF 110 is still a universal training device for young professionals learning milling. Due to the fact that the NGF 110 technical characteristics are inferior to more powerful devices, it is ideal for training and at the same time for creating simple parts at a professional level. The drawing NGF 110 includes:

- console for controlling the machine;

- a table with a slide installed on it and a mounting shaft;

- gearbox on a special stand;

- clamps for the part, which allows you to conveniently manufacture it according to the drawing;

- trunk, spindle and earring;

- several protective screens for the safety of students and workers;

- a stove on which a variety of electrical equipment is installed;

- lamp for ease of work at night;

Design of the NGF 110 Sh4 machine and its kinematic diagram

Automatic feeding is carried out on the NGF 110 using a special push-button station, which is as safe as possible and simplified for inexperienced users. A special shaft secures the entire structure. The horizontal milling machine NGF 110 Ш4 is also equipped with several levers for selecting the rotation speed of the spindle units and three different handwheels. Depending on the configuration, the price for the NGF 110 training milling machine may vary; the basic version costs an average of 20 thousand rubles. The NGF 110 shaft, as the drawing indicates, is capable of moving in three directions:

- Vertically along with the console, rack guides are used for this.

- Also, the NGF 110 spindle moves longitudinally thanks to the guide slide.

- And transversely along the console guides, due to the fact that the dimensions of the NGF 110 described above allow the working surface to move along with the slide.

School milling machines NGF 110 also have 3 screws for clamping the working surface and console, as well as feeding workpieces in the longitudinal plane. Also, a pair of nuts, which are used for longitudinal and transverse movement of workpieces, helps with the automatic feeding of the NGF 110. Horizontal milling machines NGF 110 Ш4 are equipped with a mandrel, which is used to attach the milling tool required in a particular case to it. The tools are connected to the frame using several nuts and mounting rings, and their other end is attached to the shank of the wide-universal milling machine NGF 110 Sh4 VFG, thus achieving optimal rigidity for the operation of the cutters.

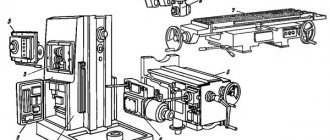

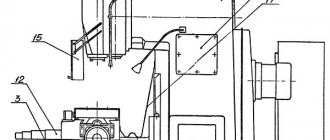

NGF-110 Location of components on the machine

Location of components on the NGF-110sh4 machine

List of components of a milling machine

- rack with gearbox

- console

- table with sled

- trunk with earring

- mandrel

- stove with electrical equipment

- protective screen

- vice

- local lighting lamp

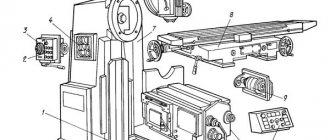

NGF-110 Location of machine controls

Location of machine controls NGF-110

List of controls for the milling machine NGF-110

- handle, spindle speed switching

- handle, spindle speed switching

- longitudinal feed handwheel

- cross feed handwheel

- vertical feed handwheel

- push-button control station

Location of machine controls NGF-110

General view and controls of a school metal cutting machine

NGF-110 is a single-column milling machine with a cast base in the form of a shaped plate. In the corners it has holes in the ears for fastening to the table, and horizontal adjustments during installation. In the front part there is a console with a table and sled. On top there is a round trunk with an earring. On the sides, a lamp with lighting and a protective screen are attached to the body.

The engine is located at the rear and is connected to the gearbox by a belt drive. It is turned on by buttons at the bottom of the machine. The spindle speed switching handle is on the side of the stand. On the slide and the end of the table there are flywheels with movement control handles. The table is raised vertically by a handwheel at the very bottom of the screw.

Reference! The trunk extends to a given size manually and is held motionless by a handle located at the top left.

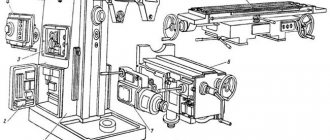

NGF-110 Kinematic diagram of a milling machine

Kinematic diagram of the NGF-110sh4 milling machine

Kinematic diagram of the NGF-110sh4 milling machine

Kinematic diagram of the NGF-110sh4 milling machine

Rotation from electric motor I is transmitted by a V-belt transmission to gearbox shaft II (Fig. 7). Next from shaft II. rotation is transmitted to shaft III and then to spindle IV through gears 4, 5, 6, fixedly mounted on shaft II, movable triple and double gear blocks sitting on shaft III and gears 12, 13 fixedly mounted on spindle IV.

Movable gear blocks allow six different spindle speeds to be achieved (see spindle speed graph).

Description of the main components of the NGF-110 milling machine

Machine stand NGF-110 with gearbox

The stand is the basic unit on which all other components and mechanisms of the machine are mounted.

The rigidity of the rack structure is achieved due to the developed base and the trapezoidal cross-section of the rack in height.

The rack is divided into two compartments. The gearbox is mounted in the upper compartment, and the electric motor is mounted in the lower compartment.

Gearbox of milling machine NGF-110

Photo of gearbox of milling machine NGF-110sh4

Diagram of the gearbox of the NGF-110sh4 milling machine

A three-shaft six-speed gearbox is mounted in the upper part of the rack housing and provides spindle speed control from 125 to 1250 rpm. The required rotation speed is selected using the switch levers located on the left side of the machine.

To inspect the gearbox, you must remove the side cover.

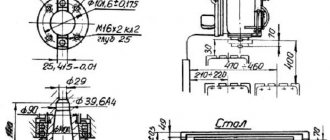

The spindle is a double-bearing hollow shaft. The short span between the supports and the significant diameter of the sections provide the necessary vibration resistance and rigidity of the spindle.

The front journal of the spindle is supported by two angular contact bearings 8 (Fig. 2), and the rear journal is supported by radial bearing 9. To eliminate the axial clearance of the front bearings, two nuts 10 are installed on the spindle. Spacer rings 11 and 12 are installed between the bearings. When the bearings wear out the gap in them is eliminated by grinding the ends of the internal spacer ring 12. The compensation ring 13 is used to eliminate the axial play of the spindle.

The main bearings that determine the geometric accuracy of the spindle are angular contact single row ball bearings No. 46 208 of the front support and radial ball bearing No. 206 of the rear support. In the axial direction, the spindle is fixed by the stand collar and the front cover.

The clearance in the front bearing is adjusted by tightening the nut located in the front part of the spindle.

To access this nut, it is recommended to remove the side cover on the rack.

Gearbox lubrication

Gear wheels and gearbox bearings are lubricated by splash lubrication.

I-30A oil is poured into the oil reservoir to a level controlled by the oil indicator.

Change the oil for the first time after 15 days of operation, then every 3 months.

The console is the basic unit of the feed mechanism. A table with a slide is installed on the console guides. Cross feed of the table is carried out from the cross feed screw 2. Vertical feed of the console along the guides of the rack is carried out from the vertical feed screw 3.

Milling machine work table and console

Table and console of the milling machine NGF-110sh4

Console of milling machine NGF-110sh4

Console of milling machine NGF-110sh4

The console is the basic unit of the feed mechanism. A table with a slide is installed on the console guides. Cross feed of the table is carried out from the cross feed screw 2. Vertical feed of the console along the guides of the rack is carried out from the vertical feed screw 3.

Work table of the milling machine NGF-110sh4

Milling machine table NGF-110sh4

- Table

- Sled

- Cross feed nut

- Longitudinal feed nut

- Longitudinal feed screw

- Table clamp screw on slide

The work table of the machine is the last element in the feed chain and has the ability to move in three directions: along the slide guides - longitudinally, together with the slide along the console guides - in the transverse direction, and together with the console along the rack guides - in the vertical direction.

Protective screen

A protective screen is installed on the machine to protect the worker from flying chips in the cutting zone.

Frequently asked questions about NGF-110

Before purchasing the machine, I had several questions. I asked them on this forum, they answered me promptly. After reading almost this entire section of the forum, I realized that the same questions were asked several times before and after me. Therefore, I decided to combine the most frequently asked questions along with the answers into one message, which, I hope, the moderators will attach to the section header and which will be useful to other beginners. Or maybe not for beginners. I also added here (disguised as questions/answers) several links to topics and messages that seemed useful to me, which “I thought I saw somewhere, but finding again would take half a day.”

I wrote some answers based on my own experience, some based on other people’s posts on this forum. I understand that I could well have missed some points or made inaccuracies. Therefore, I ask you to write additions to this topic. But at the same time, I would not like this topic to turn into a long sheet of uninformative messages, so I ask you to refrain from messages that are not related to adding/correcting this FAQ . I will move the additions from your messages to this title (with attribution, of course), and then delete the moved messages and thus keep the size of this thread to a minimum (in a long thread, they usually read the first and respond to the last message :fool: ).

So, I lay it out for your consideration:

—————————————————————————————-

Q: What modifications of the NGF-110 are there, how can you distinguish them visually?

A: There are four known modifications: NGF-110Sh1, NGF-110Sh2, NGF-110Sh3 and NGF-110Sh4.

- NGF-110Sh1 Distinctive features - round trunk, metal gear shift lever, vertical feed with a steering wheel at the base of the feed screw.

Photos from this topic.

- NGF-110Sh2. Google gives the only mention of such a modification - a topic on this forum. More often it is referred to on the forum simply as “round-nosed.” It differs from the NGF-110Sh1 in that it has a gear shift knob instead of a lever and gears (thanks to Retrorest for clarifying this issue), but there are still some doubts (if anyone has information, please share).

Photos from this thread and from this thread and from Mar1lynManson

- NGF-110Sh3. Rectangular “humpbacked” trunk, thin (~30 mm) base, speed shift knobs with balls at the ends, engine start buttons on the column under the speed switches, the engine is hidden in the column, vertical feed handwheel on the console, a plate with the type and year of manufacture is located nearby with buttons.

Photos by the author

- Transitional model from NGF-110Sh3 to NGF-110Sh4. The base is still from NGF-110Sh3, everything else is from NGF-110Sh4. On the nameplate it is designated as NGF-110Sh3.

Photos from this topic and the author. The author's plate was completely painted over, so the machine was initially mistaken for a homemade hybrid.

- NGF-110Sh4. A completely rectangular trunk, a thick (~100 mm) base, in which there are buttons for turning on the motor and a transformer for local 36-volt lighting. Local lighting. All-plastic gear shift knobs. The plate with the type and year of manufacture is located on the trunk.

Photos from this thread and from this thread

- NGF-110Sh4, modern version. Thin base, electrics in overhead box.

Photos from this topic.

—————————————————————————————-

Q: Is there a fundamental difference between NGF-110Sh3 and NGF-110Sh4? Which one is preferable?

O (skripka) : There is no fundamental difference. Sh3 was produced earlier and its quality seems to be better. Sh4 has somewhere to put electrics. They have the same rigidity - it is contained not in the platform, but in the column. The main thing is to look at wear and tear.

—————————————————————————————-

Q: Where can I get documentation for the machine?

A: Here on the website, go to the “files” section, enter “NGF*” (without quotes, but with an asterisk) in the search bar at the top right, and you can also find educational posters in this topic

—————————————————————————————-

Q: How much does the machine weigh?

A: The weight of NGF-110Sh1, NGF-110Sh2 is unknown to the author of these “FAQs” (if you have this information, contact me to add it here), NGF-110Sh3 - 200 kg, NGF-110Sh4 - 240 kg.

The heaviest structural element is the column, weighing about 70 kg.

—————————————————————————————-

Q: How can I transport NGF-110 with minimal effort?

A: When disassembled, the machine is transported in a passenger car. Loading the column requires two people; everything else is loaded and unloaded by one person. You can look at the links in detail and with pictures: one and two. Disassembly takes 20-40 minutes.

Briefly “at your fingertips”:

- Remove the earring.

- Loosen and pull out the wedge of the trunk, remove the trunk.

- Remove the horizontal mandrel (see below) or, if you are very lucky and the machine is equipped with a VFG, remove the VFG and its flange.

- Release the table clamp (the bolt above the cross-feed handle), loosen and pull out the wedge, unscrew the rear shelf of the table, move the table towards the top using the longitudinal feed until the screw comes out of the nut and then move it to remove the table (do not lose the insert between the clamp and the wedge in the hole latch).

- Release the console lock (the curved handle with a thread near the guides on the right side of the console), loosen and pull out the wedge, push the console up with a vertical feed until the vertical feed screw comes out of the glass, then remove the console from the guides upwards (do not lose the insert between the lock and the wedge in the hole latch).

- Unscrew the glass (do not lose the two pins).

- Remove the rear cover of the column.

- To make the column lighter, you can remove the motor.

- From inside the column, unscrew the six bolts securing the column to the base, separate the column, without losing the two pins.

The minimum set of tools is wrenches 19, 17, 14, 13, 8 (for releasing the feed fixing bolt), a 6 mm hexagon, straight and Phillips screwdrivers, tools and devices for pressing out the horizontal mandrel.

—————————————————————————————-

Q: How to press out a mandrel?

A: To press out a horizontal mandrel, you need a piece of pipe with an internal diameter of 40-45 mm, a length of 50..180 mm, a thick washer with a 22 mm hole (a disk cutter is suitable), and a 27 key.

If there are no spacer bushings on the mandrel, you will need a pipe 200...250 mm long; if there is no nut on the mandrel, a VAZ classic hub nut is suitable.

Unscrew the cleaning rod, put the pipe on the mandrel, put on the washer (cutter), the pipe will be spread between the spindle in the column and the cutter, put on the required number of bushings up to the thread of the mandrel and tighten the nut on the mandrel to pull out the mandrel.

If the mandrel is very stuck, you can try to heat the pipe. Expanding from heat, the pipe will additionally stress the mandrel.

—————————————————————————————-

Q: What is the seat size of the cutting tool for NHF?

A: NGF-110Sh1 were produced in two versions - with an ISO-30 taper and with a Morse 3 taper in the spindle. Ш3, Ш4 have Morse taper 3 in the spindle. The VFG spindle has a hole with a Morse taper 2.

—————————————————————————————-

Q: What size are the horizontal mandrel bushings?

A: Internal diameter 22.2, external 35, bushing width - 2 pcs. 40, one - 35, one - 25, two - 15 and one - 10.

—————————————————————————————-

Q: Can I use an earring from another machine?

A: The hole for the split mandrel sleeve in the shackle is bored individually on each machine. When using an earring from another machine, the hole will have to be rebored in place. You will also have to make a new bronze split or adapter bushing for the increased hole diameter. Here is a link to a post describing the boring process.

—————————————————————————————-

Q: How tall should I make a bedside table for the machine?

A: Depends on your height and machine model. The bedside table for NGF-110Sh4 should be 100mm lower than the bedside table for NGF-110Sh3 due to the greater thickness of the base. “On average for the forum,” the height ranges from 480 mm for NGF-110Sh4 to 800 mm for NGF-110Sh3. When predominantly using the native VFG, it is advisable to make the height 50 mm higher than when used in the horizontal version.

—————————————————————————————-

Q: What kind of oil and how much should I pour into the machine? Is it possible to fill a car?

A ( KimIV , VVKV, etc. ): The instructions indicate I-30 oil. Fill up to the marks on the indicator window (the window is located on the right side of the machine and is sometimes painted over). The bearings are lubricated with oil poured into the box; they do not need their own lubricant. No one who has filled in car oil has complained yet.

—————————————————————————————-

Q: What seal should be in the front spindle cover?

A: Normally there is no seal there. Oil from the spindle thickening is sprayed by centrifugal force and enters the annular groove of the cover, from where it flows back into the column through the drain hole in the cover and column. If you have oil leaking through the spindle cover, either the cover is installed incorrectly (it is turned and the drain hole of the cover is not at the bottom), or the drain hole is clogged in the cover or column.

—————————————————————————————-

Q: In which direction should the horizontal spindle rotate?

A: If you look at the horizontal spindle from the shackle side, the direction of rotation should be counterclockwise. Otherwise, when using a horizontal spindle, chips will fly towards the operator, and when using a VFG, the cutter will rotate in the opposite direction.

—————————————————————————————-

Q: Is it permissible to switch the engine to rotate in the opposite direction?

O ( skripka ): Acceptable, but the fastening bolt of the receiving pulley was observed to be unscrewed. The gearbox has no restrictions on the direction of rotation.

O ( kontric ): An oil spreader is installed on the input shaft of the box. Its blades are bent in one direction. When changing the direction of rotation, its efficiency will greatly decrease, kmk. Further. When the cutter rotates clockwise, the console will be pushed by the cutting force to the left (when working with a horizontal spindle) and rest against the right vertical guide of the column with a stopper, which is not good. With the correct direction of rotation, the console will be pressed against the column guide (this time the left one) with the entire length of its guide

O ( O-Witte ): During reverse rotation, when working with thin phrases without a key, when the cutter jams, the nut on the sender unwinds and the cutter turns. But with the correct rotation, you can break the phrase, alas...

—————————————————————————————-

Q: What bearings can be installed in the feed?

A: Of course, persistent. Here are some posts about installing thrust bearings:

- TomaTLAB

- Ferroman

- Alexander_77

- Edison

- Kim IV

—————————————————————————————-

Q: What bearings are used in the machine?

ABOUT:

- On the spindle 2 pcs. 46208 and 1 pc. 206, all three accuracy classes 5.

- On the intermediate shaft 2 pcs. 303 accuracy class 0.

- On the input shaft 1 pc. 303, 1 pc. 204, both accuracy classes 0.

- On the vertical feed screw 1 pc. 8104 accuracy class 0.

—————————————————————————————-

Q: What bearings are used in VFG?

A: According to this message

2 pieces 36206E and 1 piece 205 on the spindle, plus 46205L and 36205L on the secondary shaft and 2 pieces 202 plus 1 piece 8102 on the input shaft.

Of course, for the spindle you need to take bearings of a higher class, no worse than 5th.A 205 at the rear end of the spindle will be enough; it only takes radial loads there.

Addition from the author of the FAQ: it is better to replace the outer 202 on the input shaft with 160202 (6202 RS, closed on one side) or 180202 (6202 2RS, closed on both sides), this will prevent chips from getting into the bearing and squeezing out the lubricant through the bearing. Also, several members of the forum have both bearings on the secondary shaft that cost 46205L from the factory.

—————————————————————————————-

Q: Where can I read about noise reduction and VFG adjustment?

A: A lot of useful information can be found in these topics:

- "The Story of One Head (WFG)",

- “Inside the WFG” (message from Petr2 ),

- "The head of the NHF - getting rid of the noise."

—————————————————————————————-

Q: How can I expand the capabilities of the machine?

ABOUT:

- Increasing the vertical feed stroke (refinement of the cup).

- Slotting head from Elin

- Slotting head from door closer from drakon30

- Automatic feeders from Elin

- Drive of vertical and longitudinal feeds from a gravity apex

- "low profile" clamping device from Anatoly 57

- turntable from starij

- autofeed from hoakinn , also from avtogen

- auto feed from maka13

—————————————————————————————-

Q: What can you come up with if there is no regular WFG?

A: This topic contains links to self-production options published on the forum.

Modified on March 17, 2021 by Edison, don’t pay attention, I’m in a hurry

Electrical diagram of the milling machine NGF-110

Electrical diagram of the milling machine NGF-110sh4

Electrical equipment includes: a three-phase squirrel-cage asynchronous electric motor installed in the lower compartment of the rack, and a magnetic starter, transformer, terminal blocks, fuses, switches, push-button control station, thermal relay installed in insulated niches of the machine plate (item 6, Fig. 1).

The machine is equipped with a local lighting lamp

Technical characteristics of machine tools models NGF-110Sh4

| Parameter name | NGF-110sh3 | NGF-110sh4 |

| Basic machine parameters | ||

| Main dimensions GOST, TU | TU-79 RSFSR 355-72 | TU 79 RSFSR 441-79 |

| Accuracy class according to GOST 8-82 | N | N |

| Dimensions of the working surface of the table (length x width), mm | 100 x 400 | 100 x 400 |

| Distance from the axis of the horizontal spindle to the table, mm | 30..200 | 30..200 |

| Distance from the axis of the horizontal spindle to the trunk, mm | 85 | 85 |

| Distance from the end of the spindle to the suspension bearing (earring), mm | 235 | 235 |

| The largest diameter of the cutter installed on the machine, mm | 110 | 110 |

| Desktop | ||

| Maximum table longitudinal movement, mm | 250 | 250 |

| Maximum transverse movement of the table, mm | 85 | 85 |

| Maximum table movement vertical, mm | 170 | 170 |

| Number of T-slots | 1 | 1 |

| Movement of the table by one division of the longitudinal dial (one revolution), mm | 0,05 (4) | 0,05 (4) |

| Movement of the table by one division of the transverse dial (one revolution), mm | 0,05 (4) | 0,05 (4) |

| Movement of the table by one division of the vertical dial (one revolution), mm | 0,025 (2) | 0,025 (2) |

| Rapid table travel longitudinal/transverse/vertical, mm/min | No | No |

| Number of table feed stages | No | No |

| Limits of working mechanical table feeds. Longitudinal, transverse, vertical, mm/min | No | No |

| Table rotation angle (in the extreme forward position), degrees | No | No |

| Spindle | ||

| Horizontal spindle rotation speed, rpm | 100, 160, 250 ,490, 630, 1000 | 125, 200, 310, 500, 800, 1250 |

| Number of horizontal spindle speeds | 6 | 6 |

| Inner taper of horizontal spindle | Morse 3 | Morse 3 |

| Drive and electrical equipment | ||

| Number of electric motors on the machine | 1 | 1 |

| Main motion drive electric motor, kW (rpm) | 0,6 (1410..1440) | 0,55..0,75 (1390..1480) |

| Dimensions and weight of the machine | ||

| Machine dimensions (length x width x height), mm | 685 x 640 x 790 | 685 x 640 x 925 |

| Machine weight, kg | 200 | 340 |

- Tabletop horizontal milling machine NGF110Sh4. Operating manual, 1984

- TU 79 RSFSR 441-79

- Avrutin S.V. Fundamentals of Milling, 1962

- Avrutin S.V. Milling, 1963

- Acherkan N.S. Metal-cutting machines, Volume 1, 1965

- Barbashov F.A. Milling business 1973, p.141

- Barbashov F.A. Milling work (Vocational education), 1986

- Blumberg V.A. Milling machine handbook, 1984

- Grigoriev S.P. Practice of coordinate boring and milling work, 1980

- Kopylov R.B. Working on milling machines, 1971

- Kosovsky V.L. Handbook of a young milling operator, 1992, p. 180

- Kuvshinsky V.V. Milling, 1977

- Nichkov A.G. Milling machines (Machinist's Library), 1977

- Pikus M.Yu. A mechanic's guide to repairing metal-cutting machines, 1987

- Plotitsyn V.G. Calculations of settings and adjustments of milling machines, 1969

- Plotitsyn V.G. Setting up milling machines, 1975

- Ryabov S.A. Modern milling machines and their equipment, 2006

- Skhirtladze A.G., Novikov V.Yu. Technological equipment for machine-building industries, 1980

- Tepinkichiev V.K. Metal cutting machines, 1973

- Chernov N.N. Metal cutting machines, 1988

- Frenkel S.Sh. Handbook of a young milling operator (3rd ed.) (Vocational education), 1978

Bibliography:

Related Links. Additional Information

- Milling machines: general information, classification, designation

- School lathes. Review

- Comparative characteristics of cantilever milling machines of the 6N, 6M, 6R, 6T

- Feed box for console milling machines of the 6M : 6M12P, 6M13P, 6M82, 6M83, 6M82Sh, 6M83Sh

- Feed box for console milling machines of the 6P : 6P12, 6P13, 6P82, 6P83, 6P82Sh, 6P83Sh

- Feed box for console milling machines 6T : 6T12, 6T13, 6T82, 6T83, 6T82Sh, 6T83Sh

- Milling machine repair technology

- Adjustment of milling machines

- Friction clutch. Friction shaft. Friction clutches in metal-cutting machines

- Automatic cycles of milling machines (6P12)

- Testing and checking metal-cutting machines for accuracy

- Directory of universal milling machines

- Manufacturers of metal-cutting machines in Russia

- Manufacturers of milling machines in Russia

Home About the company News Articles Price list Contacts Reference information Interesting video KPO woodworking machines Manufacturers

How do the trunk and gearbox work together with other components?

To install the trunk on this tabletop machine, “dovetails” are used, which are located in the upper part of the unit rack and are clamped using special wedges to ensure structural rigidity. This, in turn, is tightened tightly by tightening the screw and spindle, which allows you to securely fasten the unit and ensure safe use of the device at school. A special earring, individual for each configuration, is inserted into the front part of the trunk, which is prohibited from being reused. But even taking all this into account, milling on such a machine still cannot be done.

Next, the trunk is tightened with the earring using a nut and the first bearing is located, consisting of an alloy of bronze and several other metals. For the convenience of the router, it has several longitudinal cuts and an outer surface in the form of a cone.

Design of the machine NGF 110 Ш4

The base of any machine is considered to be its stand, on which each mechanism and working unit is mounted. The stand is made from bottom to top using a trapezoidal section, and is placed with a massive base towards the floor. This ensures a rigid structure on any surface. It includes several compartments - upper and lower. The first contains a gearbox (6 in total), a spare spindle and 3 shafts, and the second contains an electric motor, which runs the entire device, allowing it to prepare parts according to the master’s drawings.

Read also: Motorcycle tackle photo

If you find an error, please select a piece of text and press Ctrl+Enter.

NGF 110 milling machines are suitable for teaching high school students the basics of the craft. The equipment has been working stably in factories and workshops for many years.

The equipment represents a class of technology for study. "MASGO" from the city of Rostov-on-Don is a specialized enterprise responsible for the production of the machine.

Small dimensions and modest weight make NGF 110 milling machines easy to install in special classes and help solve various problems.

Before starting work, the responsible person must carefully check whether the unit is installed and configured correctly. Start of work is allowed only after safety instructions have been given.

The Dubof company produces high-quality furniture according to individual measurements and wishes. They work with high-quality modern equipment, which allows them to offer consumers the execution of any ideas and design solutions.

The mass of the machine is equal to 340 kilograms. The final weight of the workpiece along with the occupied area is taken into account separately. The equipment has the following dimensions in millimeters:

The main work is performed on a table mounted separately on the unit. It’s good if you can choose an option with height adjustment.

The characteristics of the technical plan are accompanied by the following description:

- 6-horizontal spindle supports so many speeds.

- The spindle head allows adjustment of rotation speeds. Its limits are 125-1250 rpm.

- The displacement along and across to the bottom of the limb is 0.05 mm. For the vertical, the indicator is 0.25 mm.

- To fix the workpiece, use one T-shaped slot for the table.

- Certain parameters are observed when moving the table. For the vertical it is 17 cm, in the case of the transverse direction - 8.5 cm. Longitudinal movement - 25 cm.

- 11 centimeters is the maximum diameter for a cutter that is installed on the machine.

- 85 millimeters - this is how far the horizontal trunk is from the spindle, which makes fixing easier.

- Desk with dimensions 10 by 40 cm.

The main machine drive begins to move due to the electric motor and its operation. The standard power of modern installations is 0.55 kW. Some standard features are excluded:

- Additional effort applied for each serve.

- Rotating movements.

- Acceleration of the working part.

The machine will not help small-scale, professional production facilities.

Local lighting comes from lamps standing on the machine. During installation, flexible corrugation is used. It allows you to adjust the position in relation to the part being processed.