Over the past decades, the rapid development of the electronics industry has led to a decrease in the use of precious metals in the production of components and semiconductors.

However, during the existence of the USSR, precious metals were one of the main and extremely important components of manufactured radio electronics.

There is a specialized reference book for the content of precious metals, from which you can find out the list of precious elements that make up a particular electronics component.

The most common noble metal in radio components is technical silver. It is pure metal with minor impurities or no impurities at all.

Thus, technical silver is almost always a high-grade metal of 999 purity. In this article we will tell you where it is found and how to remove this metal from the contacts and separate it from the copper at home.

Where is this precious metal found?

For precious elements in electronics, properties such as thermal and electrical conductivity, as well as light reflection, play an important role.

Thus, noble metals are used in the following radio components:

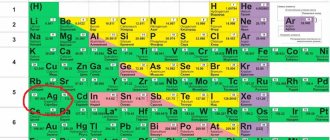

- Microcircuits . The most promising options for metal mining are Soviet-made microcircuits. It is preferable to disassemble microcircuits of the 564, 530, 133, 134, 142, 155 and 1533 series.

- Capacitors . In addition to silver, palladium, platinum and gold can also be found here. The volume of certain metals depends on the type of case (ceramic, yellow, silver and tantalum), as well as on the year of manufacture of the devices. These components were used in various computers, electronic devices and automatic telephone exchanges, as well as in tube televisions and tape recorders.

- Resistors . The basis of these radio-electronic elements is silver. The most cost-effective components are resistors of the PTP, PPBL, PPML and 5K series. It is recommended to collect Soviet resistors produced before 1982. The key difference between this component is the diamond-shaped marking.

- Connectors . These devices, both Soviet and foreign made, are suitable for extracting silver, technical gold and other precious metals. However, the content of precious metals in foreign-made components will be approximately five times lower.

- Transistors . Another electronics component containing a relatively large number of noble elements. The most preferred for silver mining are transistors with the index 2T935A, 2T944A, 2T945A and 2T998A.

In addition to the above radio-electronic components, technical silver may be contained in:

- generator lamps;

- LEDs;

- switches;

- buttons.

Use of silver in electronics. Technical silver in the USSR

Silver conducts electricity and heat better than other metals. It is inert to water, air, and some gases. It is used in a wide variety of industries, the list of which is constantly expanding.

The precious metal is used to create jewelry, in the production of contacts for various electrical products, for minting coins, as a means of investment, in the production of mirrors, clothing, batteries, in the chemical industry, and photography. The volumes of lunar metal attributable to the industrial sector exceed 70% of global production.

Silver alloy wire

During the Soviet era, they did not skimp on silver in the production of radio components. The metal used in this area is called technical. This is a special alloy containing copper, nickel, tin, aluminum, cadmium as impurities. The number of additives is not large, usually does not exceed 0.2% of the total composition. The bulk of it is pure silver.

The exception is magnetic and non-magnetic samples of technical precious metals. Here the silver content varies from 60 to 80%.

If jewelry metal performs a decorative function, then technical metal must provide electrical conductivity and reflection of light.

How to obtain silver from radio components at home?

Silver is a highly inert metal, which means that this element has weak reaction-chemical properties. In other words, it is not easily dissolved.

Under normal conditions, silver does not dissolve in hydrochloric and sulfuric acids, as well as in aqua regia , like gold.

However, this metal has good solubility in oxygen-containing nitric acid.

The answers to the questions of how to isolate, smelt or otherwise extract technical silver from radio components come down to three main methods :

- Mechanical processing is the simplest method, suitable for some types of contacts that can be easily separated using pliers and wire cutters.

- Heat treatment - in cases where it is not possible to extract silver mechanically, there is an option to resort to using a gas blowtorch. When the heat is high, the silver elements can be easily separated from the holder using available means.

- Treatment with nitric acid - this method is used to extract precious metals from massive parts of radio-electronic parts. The method requires high care and accuracy at each stage of processing.

Heat treatment

Smelting is suitable for extracting precious metal from silver contacts where the silver is soldered onto the contact holder.

The tools you need to use are a gas torch or cutter, as well as a knife with a wooden handle .

The principle of operation is to heat the silver contact and then remove it using a knife blade.

When the temperature is sufficient, the contacts can be easily removed from the holder.

Nitric acid treatment

This method is used to extract silver from massive parts of radio-electronic parts, for example, contacts of starters or automatic machines.

For processing you will need:

- quartz stick;

- glass container;

- 8% nitric acid solution;

- copper.

When working with any acids, the following rules must be observed :

- It is important to ensure constant ventilation; the best option is to carry out work in the fresh air;

- eyes should be protected with special glasses, and the skin of hands with rubber gloves;

- you need to pour acid into water, and not vice versa.

First, you need to dilute the nitric acid by mixing deionized water and acid in a 1:1 ratio.

The resulting liquid must be mixed with a quartz rod. The amount of diluted acid must be taken into account based on the calculation of 50 grams of silver per 1 liter of liquid.

After that, dissolve the silver in acid mixed with water. The dissolution process is quite long and will take from 8 to 10 hours .

When the process of dissolving silver is completed, it is necessary to obtain the metal so-called “silver cement”.

This is done by adding copper to the solution.

By adding copper, the silver displacement reaction will be accelerated, and silver cement .

To prevent the reaction rate from decreasing, it is necessary to periodically shake off the cement from the tubes.

The completion of the process will be indicated by a cooled solution without signs of a displacement reaction, as well as the presence of clean liquid on top and a layer of silver cement below. The next step is to separate the elements by filtering the resulting cement . To do this you will need a funnel, container and coffee filters.

To remove residual copper nitrate from the powder, the filtration procedure must be carried out several times.

The resulting filtered liquid must be evaporated and fused in dry form with a gas burner or cutter.

Comments

K1 When removing solder in hot alkali, I never use either quartz or glassware - it’s a shame. Only stainless steel, however, it loses its presentation, but can serve almost forever.

The silver recovered from desoldering products is what has been dissolved in the solder. The same thing happens with gold, but I don’t know the technology for extracting them, I haven’t tried it.

K2 Galvanic deposition (and dissolution) of copper and silver occurs at very low voltages across the bath. From personal experience: galvanic copper coating of brass products; standard sulfuric acid copper plating electrolyte; the current density at the cathode is about 4 A/dm2, at the copper anode - approximately twice as much; distance between electrodes 7…10 cm; the temperature is close to 20°C. Under these conditions, the voltage across the bath was only 0.28-0.31 V! To carry out selective dissolution or precipitation (purification) of silver, the voltage applied to the bath can be even lower. And even if the electrolyte (in this case, ammonium nitrate solution) has lower electrical conductivity than acid solutions, and the anode is a bunch of small parts piled up with a small contact area with each other, it is unlikely that you will need to have more than 1.5...2 V on the bath to get at the anode the required current density. Excessive voltage will simply uselessly heat the solution, wires and power source. This is what happened in the experiment described. Here it would be very desirable to use a low-voltage current source, designed for a current of at least 10 A. It is impossible to make it yourself “from improvised means,” but this is not necessary. A wide range of sources of this type are available in Chinese stores. For example, here is this module: https://ru.aliexpress.com/item/200W-10A-CC-CV-DC-DC-7-32V-12v-TO-1-28V-5v-power-Buck-Converter/ 32703689125.html?spm=a2g0s.8937460.0.0.595c2e0ejvfTSf converts input DC voltage 7...32 V to output 1.25...28 V, maximum current 10 A, has protection against short circuit at the output and against overheating. It also has a very high efficiency, that is, the primary source is loaded with current in inverse proportion to the ratio of the input and output voltages. What is very important, both the output voltage stabilization mode and the load current stabilization mode are implemented, and there are also corresponding adjustment controls. With minimal adjustment adjustments, it was successfully used as a current source for galvanic work. Actually, such modules are designed to power LED emitters with a stable current and to charge batteries. And of course, you should not skimp on the thickness of the supply wires and the quality of the connections.

K3 At first glance, the need for preliminary removal of solder is not obvious. How can it interfere with the galvanic removal of silver coating in an ammonium nitrate solution? Logically, it is lead and tin that should dissolve first. And only then - silver and copper. Yes, the sludge will contain hydrated oxides of tin and lead. But how much can this interfere with the release of silver? Passivation of the solder surface with the formation of a film of lead dioxide is also possible. But, apparently, the authors of this recommendation have practical experience.

K4 It is quite possible that it is not pure copper, but a copper-silver alloy. Copper and silver form a continuous series of solid solutions, and the deposition potentials of these metals are close. Electrochemical separation of copper and silver is a challenging task even in industrial settings. Therefore, it may be useful to check the cathode deposit for its silver content.

K5 If metallic silver is to be smelted into a compact metal, then reducing the silver chloride to the metal may be unnecessary. In the classical method, silver chloride is fused with soda or a more fusible carbonate flux. Sodium carbonate reacts with silver chloride to produce sodium chloride, oxygen, carbon dioxide and metallic silver, which collects at the bottom of the vessel in the form of a compact bead. The flux also protects the molten silver from dissolving excess oxygen and spattering during crystallization.

K6 Niobium and tantalum capacitors are (still) produced in full swing due to their small size and specific parameters (https://www.digikey.com/products/en/capacitors/tantalum-capacitors/59, https://www.digikey .com/products/en/capacitors/niobium-oxide-capacitors/67, https://www.digikey.com/products/en/capacitors/tantalum-polymer-capacitors/70).

Sales of the resulting metal raw materials and its average price per gram

For the subsequent sale of precious metal from contacts, you need to know its resulting mass and sample. As mentioned earlier, technical silver used in radio electronics is a pure metal of 999 purity.

Accordingly, metal obtained mechanically or by smelting will be 999 fine. If silver was extracted chemically using nitric acid, the output would be a metal of approximately 980 fineness. This is due to the copper impurities present in silver.

The direct cost will depend on two main factors :

- percentage of pure silver in the resulting alloy;

- places of sale of precious metals.

For 2021, the price for 1 gram of technical silver scrap is as follows :

- sample 999 – from 24 to 35 rubles;

- 980 – from 21 to 27 rubles;

- 960 – from 16 to 22 rubles;

- 925 – from 9 to 11 rubles.

When selling more than 1 kg of precious metal, you can earn 2-4 rubles more for each gram of it.

It is also most likely that on the Internet, using thematic sites and forums, you can find buyers who are ready to offer a higher price for those. silver from contacts than from a pawn shop.

What is the refining procedure?

It has long become popular to extract pure silver from alloys from which various parts and contacts are made. In order to obtain real pure precious metal at the output, you need to use a special separation technique called refining. It is thanks to it that you can separate silver particles from other metals, including copper.

Small silver bars for refining

Ideal for extracting pure silver:

- Scrap old silver jewelry;

- Waste from electrical cleaning of silver;

- Technological scrap, which contains silver;

- Waste from lead production, which is popularly called “silver foam”.

There are several ways to help separate Ag from other metals. The main ones are:

- cupellation;

- electrolytic method;

- chemical method.

The choice of method to be used depends on the volume of material, its composition and condition.

Items containing silver suitable for refining

A lot of silver, which can be used for technical purposes, is contained in Soviet radio equipment and electrical industrial equipment. The contacts of the following devices that had already failed were also covered with metal:

- mine magnetic starters;

- mine substations;

- relay;

- flags (ceramic capacitors);

- temperature sensors;

- communication equipment;

- X-ray, photographic films;

- electrical computer equipment from different periods of production.

Section question - answer

How to dissolve silver?

Expert opinion

Andrey Seleznev

Chemist-technologist, Volgograd

There are several ways to obtain secondary technical metal:

- chemical dissolution;

- electrolytic refining;

- cupellation with lead;

- cleaning silver with copper;

- obtaining silver from film.

How to clean silver from impurities at home?

Expert opinion

Andrey Seleznev

Chemist-technologist, Volgograd

The easiest and fastest home method for producing silver is electrolysis. Refining does not require the use of chemicals. All you need is nitric acid for the electrolyte and electric current.

Electrolysis method

Recently, the method of refining silver by electrolysis has become popular.

It is carried out by creating a double electronic layer: a dirty section of the precious metal is used as an anode, which is placed in a container, and a thin plate of non-corroding steel is used as a cathode. The electrode must be immersed in a nitrate solution, and then nitric acid must be added to it and the device producing an electric current must be started. The anode bags contain undissolved fragments of argentum, as well as all kinds of technical debris. A pure sample in microcrystalline form accumulates in the cathode. In this case, the volumes of released silver increase towards the other pole of the system, which leads to a short circuit. To avoid such consequences, you need to break off the crystals when stirring the solution near the location of the cathode.

Then the resulting composition must be extracted in the form of a sediment and cast into a prepared mold. To successfully complete the procedure, it is necessary to replace the electrolyte in time, because if there is copper in the impurity, upon completion of the refining it will begin to deposit on the cathode, covering the noble metal.

If the silver solution behaves like a galvanic cell, it is better to use electrolytic technology . In the electrolytic refining of silver, the role of the anode can be played by graphite or a non-corrosive alloy, and high-quality stainless steel can be used as the cathode. In this case, the voltage should be kept at a level of no more than two volts, and the process itself should be carried out until all the silver is completely deposited.

Necessary tools and materials for refining

To refining silver chemically you will need:

- special glassware;

- quartz stick;

- nitric and sulfuric acid;

- ammonium chloride;

- sodium sulfide;

- salt;

- paper filter;

- funnel;

- deionized water;

- scales;

- copper scrap or zinc powder;

- special protective equipment - gloves, goggles, gown, respirator.

For cupellation:

- bake;

- crucible;

- lead.

For electrolysis:

- power unit;

- insulation tube;

- brass stick;

- stainless steel fork;

- insulating tape;

- tea filter (bag);

- plastic container (can be from a bottle).