Principle of argon arc welding MIG and TIG

Before considering the principle of argon arc welding, it is worth understanding. It is necessary to understand how argon welding works. To connect metal parts, they must be heated at the junction. A welding arc is used to melt the metal. Arc burning and metal melting are impossible without oxidation by oxygen in the air. This element oxidizes alloys, with non-ferrous metals and alloy steels faster than carbon metal. Also, bubbles appear in the melting zone due to saturation with hydrogen and nitrogen; during crystallization in the suture bead, cavities, fistulas and numerous pores are formed. The strength of the connections suffers. The geometry of the welded joint deteriorates. In order to ensure reliable protection of the molten metal, various gases are used in pure form, as well as in the form of mixtures.

What are the TIG welding modes?

Welding in argon is performed in automatic (AMA), mechanized semi-automatic (MIG) and manual (TIG) modes. This method is characterized by the use of both consumable electrode metal (wire) and non-consumable tungsten electrode.

Consumable electrode argon arc welding (MIG) differs from mechanized welding by the presence of arc ignition features. Gas and welding wire are supplied through the torch nozzle when a special key on its body is pressed. Gas is supplied 12-25 seconds before power is supplied to the terminals. For mig, the arc is ignited by touching the wire of the product itself.

Key Features

The features of the argon arc welding process should be considered in detail; the technology has many modes and nuances. A protective atmosphere protects the melt pool. But for this it is necessary to constantly supply gas to the working area under a certain pressure. The essence of argon arc welding is the creation of a special environment that prevents oxidation of the additive and metal when exposed to an electric arc with the required combustion temperature.

Now about the features of argon arc welding with a non-consumable TIG electrode. The working element is a burner with a nozzle through which a gas mixture or pure Ar is supplied. Argon has a higher density than air, as a result of which it ensures the displacement of foreign gases from the process zone. This gas is ionized under the influence of an electric discharge and heating of the metal during ignition. So-called thermionic emission occurs. As a result, the gas forms a plasma in which the arc burns confidently. The ionization potential of noble gases is very high. Only high-frequency currents generated by a special device - an oscillator - can penetrate the protective atmosphere.

Arc ignition methods.

Due to the frequency, an electric arc can be formed without the electrode touching a metal surface (striking). In some cases, the arc is also ignited by swinging (striking) against the surface of the product. This requires a highly qualified welder, since when a short circuit occurs, tungsten particles can get into the metal of the product, thereby forming a defect. The electrode itself will also melt, changing its geometry and worsening the welding process. The arc power will decrease due to the decrease in arc voltage. The pressure of the arc itself will also change. Modern devices use the Lift Tig function to prevent this. With its help, the welding current strength during the arc ignition stage is reduced. As the gap between the product and the electrode increases, the current increases to operating values.

Welding torch device

Let's return to the design of the welding torch. A holder (collet) is installed in the central part, into which an electrode is inserted with a protrusion from the nozzle ranging from 2.0 to 5.0 mm. The burner of the device equipped with an oscillator has a button on the body to start the process. When it is pressed, the gas lines are purged, and with a short delay, current is pulsed to the electrode. TIG welding current is a high-frequency or pulsed electric current with a frequency of 150 to 500 Hz. Its voltage is very reliable and fluctuates between 2500 - 6000V.

The seam is formed by melting welding wire fed into the welding zone from outside and subsequent crystallization of the weld pool. An additive is selected that is similar in chemical composition to the alloy. In some cases, an additive with additional alloying elements is used to impart special properties.

How does TIG welding work?

This type of welding requires three things: high temperature, shielding gas, and filler metal. The high temperature is achieved by electricity passing through the tungsten electrode and creating an arc with the metal. The gas comes from a cylinder and flows to the welding site to protect the seam from exposure to air. Filler metal is a wire that is fed into the arc by the welder and melts. The process occurs in the following sequence: first, the welder opens the gas, then the electrode is brought to the connection of the parts being welded at a sufficient distance so as not to touch the metal, then the pedal is pressed and a welding arc is formed. The metal of the parts being welded begins to melt, and the welder with his second hand begins to push the filler wire into the zone of the welding arc, which melts and fills the welding joint.

TIG welding is similar to stick welding. The TIG welding electrode holder sleeve can be installed on an arc welder and this design will work as TIG.

The welding arc in TIG welding can be formed in the same way as in electric arc welding with electrodes, but more often TIG machines have a “high frequency start” function. This allows you to avoid touching the metal to create the welding arc. As soon as power is applied to the electrode, an arc is formed at a distance of up to 2.5 cm from the metal. This is done due to a short moment of high voltage, which helps to overcome the distance to the metal and create an electric arc. Immediately after the arc is formed, the voltage drops to the value set on the device. Thus, the tungsten electrode does not receive physical impact and does not wear out.

What can be welded with argon TIG welding?

This method has a very wide range of applications. They cook both unpretentious low-carbon steels and alloys of titanium, duralumin, copper, high-alloy heat-resistant and heat-resistant steels, nickel alloys and stainless steel. The modes and methods of the process themselves vary greatly. So, for example, for aluminum, alternating current or pulse mode is used. So we conclude that almost anything can be brewed in argon.

Pros and cons of using Ar and other noble gases

Argon welding is a welding process that takes place in an environment of pure inert gases and mixtures that protect the molten metal from oxidation and saturation with hydrogen and nitrogen.

First, about the advantages of argon arc welding:

- The protective medium is ionized and the arc burns smoothly;

- In fact, maximum protection of both the electrode and the additive from atmospheric gases;

- You can join thin sheet blanks without deformation;

- High performance welding process;

- Wide range of metals and alloys used;

- A seam of uniform structure is formed;

- The risk of lack of penetration, pores, undercuts and other defects is reduced;

- After work, there is no need to clean the seam roller from traces of scale, and this also increases productivity;

- Inert gas is harmless and does not have a harmful effect on the body or the environment.

The disadvantage of this method is that it requires bulky equipment; it is necessary to transport a cylinder and a gas supply system to the work site. Production costs for consumables are increasing.

Advantages and disadvantages

The advantages of argon arc welding include:

- Low heating temperature, which preserves the size and shape of the two products being welded.

- Argon gas is inert, meaning it is heavier and denser than air, which provides maximum protection for the welding area.

- The thermal power of the arc is quite high, which allows the welding process itself to be carried out in a short period of time.

- The process itself is simple, so it is not difficult to learn.

- This welding process allows you to join different types of metals that cannot be joined with other welding forks.

Flaws:

- In drafts and wind, part of the argon protection evaporates, which reduces the quality of the weld. Therefore, it is recommended to carry out the entire process in closed areas with good ventilation.

- Welding equipment is quite complex, and it is also not easy to set up welding modes.

- If a high-ampere arc is required during the joining process, then additional cooling of the metals being joined must be considered.

TIG MIG welding, what is it and what are the differences.

- Tungsten Inert Gas technology is also called RAD - manual argon welding using a tungsten electrode (thin metals are butt welded without additives, workpieces thicker than 2 mm are welded using filler wire); There is an abbreviation wig - indicating that tungsten is used for the electrode;

- Metal inert gas method - manual argon arc with a conventional consumable electrode.

RAD is carried out both on direct current and alternating current. To distinguish between devices that produce alternating and direct current, the designation AC DC argon arc welding has been introduced. TIG equipment that outputs direct current is called DC equipment. When choosing inverters, it is important to consider what argon welding is needed for. AC/DC (direct current/alternating current) welding machines operate in two modes; they can operate on direct and alternating current.

Alternating current - AC

Alternating current (AC) argon arc welding is used for metals with a refractory oxide film such as aluminum. The penetration depth on alternating current is significantly lower than on direct current, about 14-22%.

Pulsed argon arc welding is ensured by the supply of short-term pulses and is used when working with consumable and non-consumable electrodes. With pulse-arc technology, the electric arc is conventionally divided into standby, maintained in idle mode, and working, which occurs when a pulsed current is supplied.

Technology and operating principle

Argon arc welding works on the same principle as manual arc welding with a consumable electrode, but has a number of specific features. The arc is ignited between a non-consumable tungsten electrode and the metal being welded in a protective gas environment, which is supplied through the torch body. If necessary, filler material is manually supplied to the welding zone.

When using automatic argon-arc welding mode, it is necessary to connect an additional device - an oscillator. This need arises due to the poor conditions for arc ignition in an argon environment. In automatic mode, it is difficult to ensure that the electrode touches the metal, as in manual welding, and the arc has to be ignited at a certain distance of the electrode from the metal.

The physical property of argon (high ionization potential) does not allow ignition of the arc gap with low voltage. The oscillator generates a voltage of several tens of thousands of volts, which makes it possible to “break through” the gap between the non-consumable electrode and the product and create conditions for the ignition of a low-voltage arc. Ignition of the arc without physically touching the metal electrodes eliminates such harmful phenomena as melting and contamination of the tungsten electrode.

Technological modes for this type of welding vary depending on the type of welding current used: alternating or direct. There are also differences in the modes for welding different metals. When welding with direct current, the oscillator is turned off after the arc is ignited at the beginning of the process. If welding is carried out using alternating current, then the oscillator remains turned on and delivers pulses with each polarity change, ionizing the arc gap again and again. Aluminum is cooked in this mode. Changing the direction of the current prevents the formation of an oxide film on the metal surface.

When welding with direct current, it is necessary to take into account the heat distribution between the electrode and the workpiece. Two thirds on the anode and one third on the cathode - this is the heat distribution with straight polarity of the connection. This is the connection that is used when welding products made of all types of steel and titanium. In this case, two-thirds of the heat allows you to better warm up the material being welded.

Among the technological features, we can also note the conditions that require the addition of oxygen to the protective gas. Add 3-5% oxygen if it is necessary to avoid the slightest porosity in the weld. Argon mixed with oxygen provides more reliable protection of the weld seam from moisture and harmful inclusions. All random impurities and inclusions simply burn in an oxygen environment.

How to connect terminals

When connecting a welding machine that produces direct current, the polarity of argon arc welding is taken into account.

Straight polarity

With direct polarity, the minus is on the torch body, the positive terminal is connected to the workpiece being welded. The thermal center of the electric arc shifts towards the metal, it quickly melts. This connection method is often used, being in the majority of cases a difference from instant welding in argon.

Reverse polarity

When using reverse polarity, the diameter of the electrode must be thick, it will become very hot, and the melt zone will be wide and shallow. Reverse polarity is used when welding alloys that form film oxides or nitrides that prevent destruction under the influence of external factors (duralumin, titanium).

Due to the flow of positive particles, cathode sputtering of oxide and nitride films occurs, and the quality of the weld improves. Note that reverse polarity is relatively rarely used for this method. Its use accelerates the wear of the electrode, also leaving a high risk of particles getting into the weld metal. It should be taken into account that at reverse polarity Ar goes into the plasma state.

It is better to use special gas mixtures. When argon-arc welding with alternating current, the location of the terminals is arbitrary. Plus and minus change with the frequency of the operating current.

The influence of gases on the welding process

It is difficult to answer unequivocally the question of what is needed for welding with argon and what gas is used for welding with a non-consumable electrode. The inert cloud affects the intensity of seam formation, the depth of penetration and the shape of the seam bead. Pure Ar has low thermal conductivity, due to this the arc column is narrow, the penetration profile is V-shaped, and the seam is welded deeply.

Pure He is much lighter, a wide arc is formed, and the penetration profile is shallow. The use of argon arc welding in an environment is not practiced only when processing dissimilar and heat-resistant stainless metals due to the high cost of the substance.

For non-ferrous and stainless steels, special mixtures based on Ar and He are often purchased. Mixtures of these gases in different ratios provide high-level protection, improve arc performance, for example, using a He+Ar mixture in a ratio of 22-25% to 75-78% will increase heat transfer and increase arc voltage.

A mixture of argon and oxygen with the latter content of 1-3% is also used. This improves overall arc stability. Gas mixtures containing three components each have a wide range of applications.

Argon TIG welding

TIG welding

The abbreviation TIG stands for Tungsten (tungsten) Inert (inert) Gas (gas). That is, TIG welding means welding with tungsten electrodes in an inert gas environment. In this case, the metal (in the form of a rod) to fill the seam (if necessary) is fed with the second hand. Argon is most often used as an inert gas; it protects the metal, heated by the arc to a high temperature, from air gases - oxygen, nitrogen, water vapor. Inert gas is continuously supplied to the arc combustion zone. It looks like this:

TIG welding

TIG welding torch design

Helium is used less frequently due to its high cost and higher consumption (due to lower density). However, at the same current value, an arc in helium releases 1.5-2 times more energy than in argon. This promotes deeper penetration of the metal and significantly increases the welding speed. Therefore, when welding refractory metals, helium is preferred. A mixture of argon and helium (the optimal composition contains 35-40% argon and 60-65% helium) has the advantages of both gases: argon ensures arc stability, helium provides a high degree of penetration.

Advantages

- TIG welding produces a clean, neat and precise weld.

- TIG welding can weld more metals than any other welding method. Corrosion-resistant steel, aluminum, magnesium, copper, bronze, etc. are welded with high quality.

- TIG welding allows you to better control the weld pool and the entire process, which allows you to make neat and precise seams. There are no sparks or splashes during the welding process (if everything is done correctly), because filler metal is supplied without excess. There is no slag on the seam, and the air does not smoke, as when welding with coated electrodes.

Selection and sharpening of tungsten electrodes

Tungsten electrodes

As the name implies, tungsten electrodes are made from tungsten, of which they contain 97-99.5%. In this case, depending on the conditions of use, various additives are used. Tungsten has a very high melting point (3380°C), the highest of the metals. Therefore, electrodes made from it are able to withstand the high arc temperature relatively successfully.

Tungsten at least 99.5%, the rest impurities

* - the number in the marking indicates the concentration of the oxide, and there are electrodes with lower concentrations, for example WL-15 (golden), containing about 1.5% lanthanum oxide. They also have a different color code.

Even if two electrodes are of the same type and have the same dopant concentration, but are manufactured by different companies, they may differ noticeably in performance. The grain size, structure and distribution of the oxide are of great importance. Therefore, choose the manufacturer more carefully.

Selecting the electrode diameter:

The sharpening of the electrode is of great importance; over time, the electrodes become deformed and the sharpening needs to be renewed. When welding with direct current, a cone-shaped sharpening is used; when welding with alternating current, a rounded tip is made.

The length of the sharpening affects the depth and width of the seam during welding; its size is about 2-0.5 of the diameter of the electrode. The width of the penetration zone decreases with increasing sharpening length, and with a short sharpening length, the penetration depth noticeably decreases. The stability of the arc is also affected by the risks formed during sharpening. For stable arc burning, the marks must be located strictly along the axis of the electrode, and their size must be minimal. The best option is to polish the electrode after sharpening it. Bluntness at the tip also affects arc burning. The diameter of the blunting is selected depending on the diameter of the electrode and the magnitude of the welding current.

Sharpening a tungsten electrode

Modes

The current load is determined based on the type of metal and the thickness of the workpiece, taking into account the diameter of the consumable electrode or filler wire. Main operating parameters:

- Current parameters (alternating, direct, direct or reverse polarity is determined only for direct);

- The diameter of the tungsten electrode used;

- Free-burning welding arc voltage;

- How fast is the process going?

Secondary parameters include:

- Electrode position;

- The position of the part being welded;

Welding current - the higher its value, the greater the penetration. Its parameters range from 10 to 1000 A.

The consumption of protective gases varies on average from 3 to 20 l/min. In some cases it can reach values of 50 l/min.

Welding speed from 23 to 123* m/h (*for automatic methods). In most cases, the values are in the range of 23 – 61 m/h.

Arc voltage ranges from 5 to 32V, mostly within 9-14V. The amperage is set using special tables.

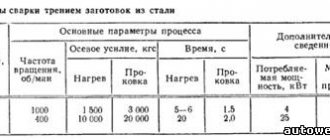

General data on steel welding modes

The welding current can be selected taking into account the diameter of the electrode, the properties of the metal being welded, and the dimensions of the product.

Correct starting and welding with a TIG torch

The parameters are set and it's time to start. Owners of this welding machine model have two options:

Use contact ignition

Use the high frequency ignition function

The latter will prevent metal burning in case of incorrectly set parameters when setting up the argon arc welding machine. It will protect the metal from tungsten inclusions and allow you to independently control the distance to the part from the moment you start working.

And now the most important thing is how to operate the burner correctly? Most experienced welders weld from right to left. During the process without filler material, the electrode should be positioned almost perpendicular to the surface to be welded. If filler material is present, then it is enough to maintain a small angle (15-20 degrees).

Attention! To prevent the weld metal from oxidizing, it is necessary to ensure that the end of the filler rod is constantly in the protective gas zone.

The welding process is completed by filling the crater. Crater welding is the final section of the weld seam, the length of which is reduced to zero. From the point of view of the quality of the welded joint, it is necessary to exclude the formation of a crater in the final part of the weld. For this purpose, the device provides a smooth current reduction mode.

To illustrate all of the above, experts have prepared a special video:

Source

Basic parameters of TIG welding

The arc voltage directly affects the geometric dimensions of the weld. The higher the voltage, the higher the welding speed and the smaller the width of the seam.

The arc size range is from 1.5 to 2.9 mm; to increase the penetration depth, the required length is required. For welding rolled thin metal, a short arc is used to reduce heat input;

An extremely important point is the sharpening angle of the tungsten electrode. The sharper the angle, the wider the arc column and the lower the load. Hence the lower service life.

A blunt sharpening angle has the opposite effect of a narrow weld pool but a longer service life.

The optimal sharpening angle is from 25-45 degrees. It is not recommended to use a sharpening angle greater than 90 degrees.

The speed of the welding process depends on the shape and size of the bead, the geometry of the joint, the strength of the welding current, and the physical properties of the base and filler metals.

The consumption of the gas protecting the weld pool depends on where the welding takes place, indoors, where there is no air movement, or outdoors.

If there is wind or draft, it is necessary to increase the gas supply as it will be partially blown away. If the wind in the welding area is strong, then it is necessary to additionally use special mesh nozzles. They are also called confusing ones.

Consumption also depends on the speed of welding and electrode wire feeding. The higher the speed, the higher the gas consumption.

Preparatory activities before welding

- The equipment must be in good working order and have a valid NAKS certification certificate;

- Connect the gas cylinder to the welding machine via a hose. Connect the burner to the connector respectively to positive if reverse polarity is selected or to negative if reverse polarity is used;

- Connect the grounding cable to the body of the welding equipment;

- Repair the power cable to the electrical network. Turn on the device;

- Check the gas supply and operation of the oscillator. Perform a test ignition of the welding arc.

Nuances of welded joints of different metals

Now let’s talk about what can be welded using argon-arc tig welding and what features need to be taken into account.

Aluminum

The melting point of the oxide is much higher than that of aluminum itself. Its temperature varies between 20000-20500 °C.

To remove oxides, reverse polarity is required, and, accordingly, a thick refractory or graphite rod approximately equal to the thickness of the part being welded. Use alternating current.

Welding requires a current strength significantly higher than for other metals, even at a higher melting point than its melting point. Linear expansion of aluminum is one of the difficulties in welding. Large shrinkage of the metal occurs and, as a result, weld defects in the form of sink marks and undercuts.

Aluminum has high fluidity, which also leads to the formation of various types of defects. To reduce the fluidity of aluminum, it is necessary to use linings with high heat-dissipating properties.

Products containing copper

Copper is actively saturated with hydrogen and is characterized by fluidity. Because of this, welding copper is extremely difficult in a vertical and overhead position. Before welding, it is necessary to thoroughly clean and degrease the surface.

TIG, MIG technologies are used using pure Ar and graphite electrodes. Like aluminum, copper has high thermal conductivity, which makes it weldable at high currents.

Copper welding is carried out with preheating of the product to a temperature of about 600 – 650 °C. To reduce welding deformations.

Stages of manual argon arc welding

To carry out welding in an argon environment, non-consumable electrodes are used. To work you will need:

- power supply;

- torch with tungsten electrode;

- gas cylinder with argon;

- filler wire.

The diagram for performing welding work using a non-consumable tungsten electrode in a shielding gas environment is shown in the figure:

The electrode is located in the torch holder and protrudes 2-5 mm forward.

Its diameter is selected based on the nature of the weld and the thickness of the metal parts being connected. Around the electrode holder there is a nozzle for supplying argon to the welding area at the time of work.

Welding with argon injection should be carried out in the following sequence:

- cleaning the surface of the welding zone;

- bringing the burner into working position: supplying argon to create a protective layer and igniting the arc;

- welding process.

Thorough cleaning of the edge surface of the parts to be joined from dirt and oxide film must be carried out before starting the welding process. To do this, use mechanical or chemical cleaning followed by degreasing the surfaces.

Then the equipment is brought into working condition: the power source is connected to the electrical network, the part to be welded is connected to the part to be welded, shielding gas is supplied using the control buttons on the torch, and the part itself is connected to ground. An arc is ignited using a high-frequency pulse. It will close the circuit between the electrode and the metal of the welded product. Moreover, the gas is supplied 20 seconds in advance before the current is applied to provide a protective layer.

Important! The tungsten electrode must not be allowed to touch the surface being welded; it must be located at a minimum distance of 2 mm from it to create a small welding arc. In this case, it ensures maximum penetration of the metal thickness.

Immediately after igniting the arc, the welder begins to create a weld in an area protected by argon. Argon welding is carried out as follows:

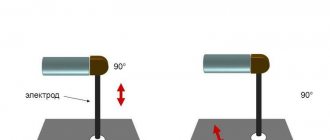

With the torch in his right hand, the welder slowly draws the arc strictly along the seam line, and with his left hand, in line with the movement of the torch, he feeds the filler wire into the welding zone. The wire should always be positioned in front of the torch at a slight angle of 15o to 30o degrees to the surface to be welded, and the torch electrode should make an angle of about 90o with it.

Important! Do not allow the filler wire to be fed sharply when performing manual welding work, as this will lead to the formation of splashes of molten metal and a sloppy weld line.

After finishing work, the supply of argon should not be stopped immediately to prevent oxidation of the weld metal that has not yet cooled down.