Unit design

The design of most devices is similar. The main elements of air-arc and other cutters are:

- injector/ejector - mixing of elements occurs in it;

- inlets and nipples - for connecting oxygen and preheater gas;

- mixing chamber;

- valves - to regulate the flow of mixture elements;

- nozzle (nozzle) - tube tip, one or more.

The design of a gas cutter is the same for all types of products, but may undergo minor changes. More about this in the following sections.

The work of a gas cutter is not so difficult as it is dangerous. An ordinary cutter works like this:

- the user connects the device with oxygen and flammable gas cylinders, opens the valves (valves) to the desired pressure;

- oxygen and propane/acetylene/hydrogen are mixed into a single stream;

- the flow of the mixture simultaneously burns the metal and blows away the molten oxidized particles.

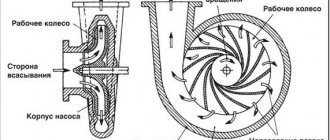

Gas cutter device

The scheme is similar for most devices for gas cutting or gas welding; differences are found only in ejector representatives. A technical data sheet or instructions for use are the best source of information on how best to operate a cutting tool. Now - about the types of equipment.

Product classification

Modern devices work by mixing oxygen and flammable gases. Fuel type is the first criterion for dividing into groups. The most common gas cutters are:

- Propane. It is very common because it is safe and has high efficiency. Used for cutting non-ferrous or ferrous metals, popular among amateurs and professionals. An example of a popular model is the Kord-05P-L340 propane cutter. It cuts metal from 3 to 500 mm thick, weighs only 0.9 kg, and costs about 1,500 rubles.

- Oxygen. It is an injection cutter, the working mixture of which is 85% oxygen and 15% flame. The first is supplied under high pressure, so the mixture ignites. The low cost of the oxygen gas cutter has allowed it to become popular among hobbyists. The cost is slightly lower than the propane analogue, since the considered device cuts not such thick metal (up to 300 mm).

- Acetylenic. This fuel is used when working with thick workpieces, as it gets very hot. The pipe through which acetylene is supplied has a valve that allows you to regulate the flow rate. The acetylene cutter is one of the few that has portable analogues. They become more popular every year because they are not inferior in quality to large products. An example is Redius P2A-01M, which costs about 1,600 rubles.

- Kerosene. Used for cutting carbon steels with a maximum thickness of 200 mm. It is not considered in demand, since it is more often found in the mining, coal industry, and mines. This is a kind of advantage of a kerosene cutter over propane and acetylene (they are not recommended for use underground).

- Petrol. The scope of application is the same as that of kerosene. It is considered a hand cutter, and the fuel is A-80, A-92, A-95 gasoline.

- Hydrogen. A mixture of oxygen and hydrogen has the highest combustion temperature among gases - 2800 degrees. Therefore, a hydrogen cutter is good for work that needs to be done quickly. The main advantage is that it is obtained by electrolysis from water, which is possible at home. Often used in jewelry making. There are larger and smaller specimens, with the latter being more popular. Adding water is the only maintenance requirement.

An interesting video about this was prepared by the Welding Center company:

Also, a gas cutter for metal has a different design; this is the second classification criterion. This includes dimensions, number of tubes, method of ignition of the mixture, and more. Highlight:

- industrial cutters (for large volumes of work; also known as gas metal cutting machines);

- compact, portable, mini-cutters (conventional names, since the product is no larger in size than a blowtorch; used, for example, when lighting a fire);

- tourist (similar to the previously named one, but has a preheating function and works properly at any angle of inclination);

- cutter with piezo ignition (does not contain valves; the mixture is ignited by pressing one button).

Some products for cutting metal with gas are divided into separate groups. Below are more details about them.

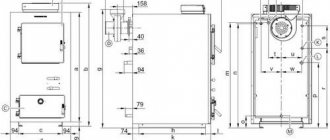

- Air arc cutters. Purpose: cutting non-ferrous or ferrous metals in production conditions. They are small-sized (for example, the domestic air-arc cutter RVDm-315 weighs 500 g and is 315 mm long), highly productive, but only works with a power source and a compressor. Buying it for household needs will be a waste of money. In addition, to operate an air-arc cutter you will need electrodes, cathodes and nozzles, which will have to be purchased regularly.

- Three-pipe devices. Also known as in-nozzle mixing cutters. Unlike most gas welding cutters, they have not two channels (tubes), but three. The first carries cutting gas - oxygen, the second - flammable gas (propane, acetylene, etc.), the third - heating gas. For normal operation of a three-pipe device, increased working gas pressure (minimum 20 kPa) is required.

Three-pipe gas cutter

The design allows you to use any flammable gas; you just need to select suitable mouthpieces for the cutter. They are among the safest products, since the mixing of elements occurs not at the base of the product, but at the head. However, this increases the price of a three-pipe cutter by 1.5-2 times.

Equipment for gas cutting is divided into injection and ejector. The latter have two separated channels - for heating and combustible gases. In injection systems they are combined. An ordinary cutter, which is used to work in factories, most often an injection one; This type also includes devices for manual oxygen cutting, compact and mini-products. Ejector equipment for oxygen cutting is a three-pipe apparatus.

Next - a few words about regular investments in work.

Types of units

If you are planning to make a repair and are choosing a device, then the following information will definitely interest you.

There are quite a few types of cutters. They all have different devices and characteristics.

Let's study the most popular of them:

The oxygen apparatus is an ejector unit in which the burning jet is formed by oxygen supplied under pressure. The oxygen autogen is considered one of the most budget-friendly devices and is quite suitable for DIY cutting;

A kerosene cutter, as the name suggests, operates using kerosene vapor. As a rule, it is used when cutting carbon steel no more than 20 cm thick. It is almost never used for cutting with your own hands, since it has a complex structure and is used mainly in industrial work (the characteristics of the burner allow it to be used in the coal or mining industry, underground , while it is undesirable to use a propane or acetylene cutter there);

A propane machine is used when cutting products that contain non-ferrous and ferrous metals of different compositions (most often, a propane autogen is used when cutting cast iron - batteries or pipes). Professionals pay attention to the safety and reliability that a propane device provides compared to the use of other units. Therefore, it is propane autogen that is most often used when doing DIY work. In addition, if you use the propane method of metal cutting, you can be sure that efficiency and productivity are guaranteed;

An acetylene gas torch is used to process parts and sheets that are thick. All such burners have separate valves, with the help of which you can set a higher speed and power of gas supply during operation. There are even portable cutters that require an acetylene mixture to cut metal. Since acetylene allows the flame to reach the highest temperature, despite the compact size of the device, it can cut even very thick metal. This portable cutter is extremely convenient for DIY use and is therefore in great demand.

But still, universal ejector devices are the most popular. Universal autogens can cut metal in any direction and at any angle.

IMPORTANT TO KNOW: How to choose a miter saw for metal?

At the same time, they are extremely easy to use and are lightweight. One of the latest developments by manufacturers is a gas cutter with piezo ignition.

Video:

It is extremely convenient for do-it-yourself use, since such a device is turned on with one press of a button.

But such an autogen is quite expensive, so if you need a device for a short period of time and for a small volume of metal cutting, then purchasing such a torch will be inappropriate and wasteful. It is much better to buy a mini cutter.

Consumables for cutters

The mouthpieces and nozzles of products are most susceptible to wear. To make oxyfuel cutting torches work longer, you can go in two ways:

- regularly buy new consumables;

- take care of existing ones.

Which option to choose is up to you, but a professional chooses the second one. Care consists of:

- cleaning the nozzle channels with a metal rod made of soft material (copper, aluminum);

- selection of the optimal ratio of metal thickness and pressure level of the combustible mixture.

Air arc cutters require much more investment in stable operation, because they require electrodes of different diameters, nozzles, cathodes, power sources and a compressor. Therefore, for periodic work they should not be considered as an option.

Now - briefly about how metal is cut with a cutter.

Disadvantages of processing

Low carbon steel is most suitable for gas cutting, but medium and high carbon steel is not a very suitable material for cutting. Due to the high carbon content, the ignition temperature increases and the melting point decreases. And this condition complicates the cutting process.

It is difficult to cut metal using a gas mixture if it has low thermal conductivity. Therefore, these types of material are not suitable for processing.

Gas cutting of metal should only be performed by a qualified and experienced professional. It is important to observe all the key factors of proper processing: oxygen pressure and speed of the procedure. It is necessary to take into account the thickness of the product and the diameter of the cutter nozzle. If the rate of oxidation and metal cutting do not match each other, then the result will be poor-quality processing.

Oxygen cutting involves the use of explosive substances. If safety rules are not followed, there is a high probability of an explosion of the gas-air mixture; it is necessary to monitor the condition of the gas equipment. To protect against burns, you must use personal protective equipment.

A significant disadvantage is the possibility of metal deformation and low cutting accuracy.

Related video: Cutting metal with a cutter

Instructions for use

The preparatory stage consists of inspecting the equipment.

Check that the hoses are connected correctly, that the fasteners are tightened, and that they are tight. It is recommended to lubricate the valve seals with glycerin and then begin work. Cutting steps:

- open the valve with oxygen, then with flammable gas;

- set fire (with a match, lighter) to the resulting mixture;

- regulate the jet using valves to the desired size and flow rate;

- warm up the cutting area;

- open the cutting oxygen valve and perform the operation;

- close the valve with flammable gas, then with oxygen;

- If necessary, cool the tip in cold water.

Open the valves on the cylinders

Open the valves on the cutter

Set the mixture on fire

It is important to remember about PPE - gloves, covered hands, gas cutting glasses, etc. It is advisable to have comfortable shoes, non-synthetic clothing, and completely degrease the cut area, otherwise an explosion when oxygen comes into contact with oil is inevitable. It is not worth reminding that smoking near cylinders is prohibited.

Portable burners

Compact devices that are an attachment to a small collet cylinder with flammable gas.

The flame temperature in mini-burners does not exceed 1300°C, so when working with them we can talk more about the process of melting, but not cutting. Conditions are not created for the “burning” of metal due to the absence of the main cutting element - an oxygen jet that oxidizes the steel.

Mini-cutters are primarily used for cutting fusible metals and alloys: aluminum, bronze, brass, copper.

Some useful tips

First, about the cutting conditions:

- when adjusting the outgoing jet, remember that the melting temperature of the metal is always higher than the ignition temperature, otherwise the workpiece simply will not burn out;

- the temperature of the oxides (splashes) must be lower than the melting temperature of the metal, otherwise cutting will not take place at all;

- a classic propane cutter will not work on cast iron or high-carbon steel, because... carbon lowers the melting point;

- oxides must be removed immediately, otherwise they will harden and complicate the work;

- the metal must have low thermal conductivity so that the edge does not have time to cool after preheating.

A few more recommendations before starting work:

- when choosing a mouthpiece, pay attention to the markings - they have letters (“A” for acetylene, “P” for propane, etc.);

- the valves have arrows with a direction and a letter indicating the direction of rotation when opening (“O”) and closing (“Z”);

- the fitting nut for oxygen has a right-hand thread, for flammable gas - a left-hand thread;

- never point gas equipment for cutting metal towards the sources of the mixture (cylinders);

- keep an eye on the hoses; a good gas cutter connects them and places them to the side so that they do not interfere with the process.

In short, this is all you need to know about the operating principle and types of gas cutters for metal. Before purchasing, the user decides on the type of equipment, evaluates the amount of work, and estimates how much a gas cutting machine or a compact mini-instance will cost. If you are an experienced user who can make recommendations regarding cutters, please share it in the discussion for this article.

Mini cutter

A mini-cutter is a type of portable autogen for metal work, but with an even smaller size.

Essentially, a mini-cutter is a lighter that has a gas cutter nozzle, which is located on top of the device.

At the same time, the characteristics of the device are quite good: the mini-autogen has a good flame pressure and a sufficient size of the gas tank, which allows you to work with it even in windy weather.

But there is one nuance here: prolonged burning can greatly heat the upper part of the mini cutter, and parts made of plastic can melt, and in most cases it is not possible to repair or replace them.

The mini-burner has the same operating principle as a standard size unit.

But due to the fact that the volume of the gas cylinder is small, it must be refilled periodically (you can use a regular collet cylinder).

Video:

One of the disadvantages of a mini-burner can also be noted that the length of the exiting flame is insignificant, so working with some types of metal is extremely inconvenient.

Mostly, such mini-devices are used by jewelers or craftsmen who repair air conditioners and refrigerators, as they are very convenient for working with small objects with your own hands.

IMPORTANT TO KNOW: How to make a guillotine for cutting metal with your own hands?

In everyday life, a mini-burner is used to light a fireplace in a private home or country house.