Fusion welding

The welding process is a method of joining two or more metal parts by thermally melting the edges of the joined workpieces. Being in a molten state, the metal from which the workpieces are made is mixed and a strong permanent connection is formed at this point. After cooling, a so-called weld seam is formed in place of the molten metal. This process is somewhat similar to casting, but on a limited scale. Nowadays, welding has found wide application for joining two or more workpieces both on an industrial scale and in the artisanal production of metal products. It is also used in the process of repairing various components, since it allows metal to be fused where it has been worn away.

Weld

Depending on which method of heating the workpiece material to the melting point is chosen, there are several types of welding, which we will discuss below.

The essence of welding. Classification of welding methods.

As a rule, complex structures are obtained by combining individual elements (units, assemblies, parts) with each other. These associations are carried out using detachable and permanent connections. Based on GOST 2601-74, the essence of welding is defined as the process of obtaining permanent connections by establishing interatomic bonds between the parts being welded. This occurs due to their local, local, general heating, plastic deformation, or simply the combined action of both.

Rice. 1. Connecting parts by fusion welding:

1 - before welding, b - after welding; 1, 3 - welded parts, 2 - melted edges, 4 - welded seam

The essence of fusion welding

The essence of fusion welding (Fig. 1) is that the liquid metal of one melted edge, formed from heating by an external source, spontaneously combines (mixes to some extent) with the liquid metal of the second melted edge, creating a total volume of liquid metal, which is called the weld pool . After cooling the weld pool metal, weld metal is obtained. Weld metal can only be formed by remelting the metal along the edges or by additional filler metal introduced into the weld pool.

Sources of local heating during fusion welding can be an electric arc, a pelvic flame, a chemical reaction with the release of heat, molten slag, electron radiation energy, plasma, laser radiation energy.

The formation of interatomic bonds in the edges of the parts being joined during fusion welding is achieved due to the fact that the metal along the edges (each separately) is initially melted, and then the newly melted edges are wetted and filled with molten metal from the weld pool.

Rice. 2. Connecting parts by pressure welding without external heating:

a - parts before welding, b - after welding (macrostructure of an aluminum compound), c - optimal relationship between heating temperature and pressure for iron

The essence of pressure welding

The essence of pressure welding (Fig. 2) is plastic deformation of the metal along the edges of the parts being welded. Plastic deformation along the edges of the welded parts is achieved by static or impact load. To speed up the production of a plastically deformed state of the metal along the edges of the parts being welded, pressure welding is usually performed with local heating. Due to plastic deformation, the metal along the edges is subjected to friction with each other, which accelerates the process of establishing interatomic bonds between the connected parts. The zone where interatomic bonds of the joined parts are formed during pressure welding is called the connection zone.

The source of heat in pressure welding with heating is: furnace, electric current, chemical reaction, induction current, rotating electric arc, etc.

The nature of the process of pressure welding with heating may be different. For example, in flash butt welding, the welded edges are initially melted and then plastically deformed. In this case, part of the plastically deformed metal, together with some contaminants, is squeezed out, forming a burr.

The distribution of deformations over the cross section of the welded joint in the welding zone is uneven (Fig. 2, b), as a result of which metal particles slide in the joint zone. All this leads to increased mechanical properties of welded joints. The optimal relationship between heating temperature and pressure for iron is given in Fig. 2, c.

Modern industry has several dozen types and varieties of metal welding methods, for the study, evaluation and determination of rational areas of application of which it is advisable to classify them, dividing them into two main groups: 1) pressure welding (plastic); 2) fusion welding.

In the first group, a very important, dominant role is played by the pressure applied to the welding site, creating plastic deformation and exciting adhesion forces. In this case, heating the metal plays an important, but still subordinate role; in some cases, welding can be carried out without the use of heat.

In the second group, the welding process is based on melting the metal by local heating. Pressure is not applied to the welding site, and if sometimes it is applied, it plays a secondary role.

The group of pressure welding methods can, in turn, be divided into three subgroups, depending on the degree of heating of the welding site. The first is cold pressure welding, in which the metal in the welding zone remains cold all the time, for example welding at normal room temperature. The second is pressure welding without fusion, in which the metal is not brought to melting, but is only heated to the temperature of the so-called welding heat, while the mechanical strength and elastic properties are somewhat reduced and ductility increases. The pressure welding process at this temperature proceeds successfully and gives good results. The concept of welding heat has been developed by practice and is rather vague. Generally speaking, any metal or any pair of dissimilar metals under suitable conditions (sufficient specific pressure, etc.) can be welded at room temperature without any heating.

Moving from the fundamental possibility of welding to fairly convenient pressure welding processes suitable for industrial use, it should be noted that heating the metal greatly facilitates the pressure welding process and in most cases is practically necessary. In this case, the higher the preheating temperature, the better the welding process proceeds, however, the increase in temperature is limited by various additional considerations.

Typically, the metal is heated to so-called welding temperatures, i.e., temperatures lying only slightly below the melting point of the metal. A further increase in temperature is not allowed, since the beginning of melting of the metal can disrupt the normal welding process, deteriorate the structure of the metal, etc. Sometimes the heating temperature is limited by the impossibility of further increasing it when heated in different forges, furnaces, etc.

In many cases, it turns out to be advisable to increase the heating of the metal in the welding zone before melting. In this case, the molten metal during the upsetting process can be completely squeezed out of the welding zone, and layers of metal heated only to the point of transition to a plastic state will come into contact and be welded. In this case, subsequent metallographic examination does not reveal cast metal in the welded joint. Sometimes the molten metal is not completely removed from the welding zone or not removed at all, for example, during spot resistance electric welding. In this case, metallographic examination of the welded joint reveals cast metal.

If, when heated, the metal is brought to melting, then the welding process is called pressure welding with flashing. The group of fusion welding methods, in turn, can be divided into two subgroups: 1) fusion welding, characterized by melting of the base metal and 2) soldering, the main feature of which is consists in the absence of melting of the base metal. The connection is carried out by melting a low-melting filler metal, which has a melting point lower than the melting point of the base metal. This low-melting metal is called solder, and the process itself is called soldering, which can be considered a type of fusion welding. However, it is not always possible to draw a sharp line between fusion welding and soldering, especially for non-ferrous metals.

Based on the above definitions, we can give a brief description of the processes of pressure welding and fusion welding and note some of their features.

The process of pressure welding with heating consists of two operations:

- heating the parts to be joined in the welding zone with an appropriate heat source to the required temperature so that the welding heat temperature is reached on the joint surfaces;

- precipitation, which consists in the fact that pressure is applied to the parts being connected, causing significant plastic deformation of the heated metal, the flow of which along the interface surface excites adhesion forces and produces fusion of the connected parts into one whole. The heated metal that is squeezed out forms a thickening in the welding zone.

Performing pressure welding without fusion does not require particularly high temperatures, so the products being welded can be heated by a variety of heat sources. The metal in the welding zone does not melt, therefore its chemical composition and structure remain practically unchanged or change relatively little, as a result of which the original mechanical properties of the base metal are more or less preserved in the welded joint. In favorable cases, pressure welding can produce completely homogeneous metal in the zone of the welded joint and the welding site cannot be detected by metallographic examination; the metal of the welding zone does not differ from the base metal in chemical composition, structure and mechanical properties.

The surfaces to be joined must be thoroughly cleaned before welding, since the lack of melting of the metal makes it difficult to remove contaminants from the welding zone, as a result of which, during the upsetting process, some of the contaminants remain in the welded joint and reduce its mechanical properties. Sometimes it is advisable to use fluxes that convert refractory oxides on the surface of the metals being welded into low-melting slags, which are more easily removed in liquid form from the welding zone during the upsetting process.

The fusion welding process is carried out as follows. The parts to be connected are assembled in the desired position, and a sufficiently powerful heat source with a high temperature is supplied to the connection point, melting the metal of both parts being connected. The molten metal of the welded parts spontaneously, without external mechanical influences, merges into a common weld pool. Once the heat source is removed, the weld pool, cooling, quickly solidifies, and the deposited metal firmly connects both parts into one. The molten metal of the weld pool very intensively transfers heat into the mass of the product due to the high thermal conductivity of metals, therefore, to form a weld pool of the required size, a heat source of not only sufficient power, but also a very high temperature is required. Experience shows that for fusion welding of metals such as steel, copper, medium-thick cast iron, the heat source must have a temperature of at least 3000°; at lower temperatures, welding, if possible, gives mediocre results and is not economically viable due to low productivity.

They learned to obtain such high temperatures on an industrial scale relatively recently (about 70 years ago), so all types and varieties of fusion welding are relatively new.

In a molten bath, various contaminants that were on the surface of the metal (oxides, dirt, etc.) have the opportunity to float to the surface of the bath and turn into slag, therefore, when fusion welding, the requirements for the cleanliness of the metal surface may be less than when pressure welding.

The process of melting the metal and the exposure of the bath to a very high temperature of the heating source causes a sharp change in the chemical composition, structure and mechanical properties of the weld metal, compared to the base metal. The original properties of the metal of the welded joint, which are preserved during pressure welding, are not preserved in this case. The constituent parts of the metal evaporate and burn out, gases from the surrounding atmosphere are absorbed by the bath, as a result of which the solidified metal of the bath receives a completely different composition and structure. A change in mechanical properties often manifests itself in a sharp decrease in the ductility of the metal.

To eliminate the adverse effects of metal melting and exposure to high temperatures, they often resort to improving the weld metal by introducing various additives into the bath.

After the discovery of fusion welding methods at the end of the last century, special attention of technicians of that time was attracted by the fact that fusion welding was performed in one operation - heating; the application of pressure, i.e., the upsetting operation, was not required. The conventional old methods of pressure welding required two separate operations - heating and then applying pressure during the upsetting process. The main significance in this case was rightly attributed to sediment.

To emphasize the main distinctive feature of fusion welding, it was called autogenous welding. The word autogenous is derived from the Greek roots auto and gene and can be translated as self-generating. Subsequently, this word in colloquial speech began to be predominantly used to refer to only one type of fusion welding, namely gas welding, and from this a kind of technically illiterate colloquial jargon gradually emerged with expressions like “he cooks with an autogenous gas,” “autogenous cutting,” etc. Therefore, Currently, the term “autogenous welding” is not recommended for use in the technical literature.

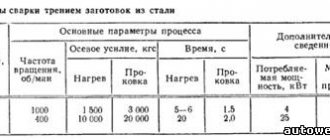

Shown in FIG. 1 classification of welding methods is not convenient enough for further development and detailing. For practical purposes, another classification system is much more convenient, based on the method of heating metal during welding. The classification by heating method can be greatly detailed, covering all types and varieties of welding that are of industrial importance, if, along with heating methods, some other characteristics are taken into account when classifying.

The basic scheme for classifying types of welding according to the method of heating the metal is shown in Fig. 2. The classification is based on the type of energy used to heat the metal during the welding process.

Accordingly, all types of welding are divided into four groups:

- chemical - heating is produced due to chemical reactions:

- electric - heating is produced by electrical energy;

- mechanical - heating is produced due to mechanical work, for example the work of friction forces;

- cold - no heating is produced at all.

If other types of energy, for example radiant or light, find application in the future, then new groups of welding methods can be identified accordingly.

In the group of chemical methods, the most important reaction will be the combustion of solid, liquid or gaseous fuel in air or technically pure oxygen. Forge welding can be classified as a group of chemical methods, when the welding site is heated in various types of furnaces and forges. This also includes a subgroup of numerous methods and varieties of gas welding, where heating is produced by burning flammable gas in special welding torches. Thermite welding, with all its varieties, belongs to the group of chemical methods, in which the heat source is a hot powder mixture - thermite, consisting of metal particles, such as aluminum or magnesium, with a high calorific value and metal oxides with a lower calorific value, such as iron scale.

The use of electrical energy for heating has created a very large and diverse group of electrical welding processes or electric welding, which is the most important type of metal welding in modern industry.

Electric welding is divided into two large subgroups: 1) electric arc welding, in which heating is produced by an electric arc discharge, and 2) contact electric welding, when heating is produced by the Joule heat of the current flowing through the metal.

The scope of application and industrial significance of individual welding methods vary. Of the chemical methods, gas welding is of greatest practical importance, and of the types of gas welding - oxygen-acetylene welding, which is used in almost all industries. Forge or forge welding, which is the oldest method known since time immemorial, is currently being replaced in many industries by more productive and advanced welding methods. Thermite welding has a relatively limited range of applications. In our practice, until recently, this method was used almost exclusively for welding rail joints, mainly tram joints. With the advent of the new magnesium thermite, a new, rather significant area of application for thermite welding appeared - the connection of steel wires of telegraph and telephone communication lines.

The most important type of welding for most industries is electric arc welding. This method, based on the melting of metal by an electric arc discharge, currently ranks first in our industry in terms of the number of operating installations, employed workers, volume and cost of products. This method has recently been largely mechanized and automated, and automatic electric arc welding is beginning to gain increasing importance. The electric arc welding method is very universal and is applicable to products of a wide variety of shapes and sizes, but it is especially beneficial for large-sized products. The larger the dimensions of the product and the greater the thickness of the metal, the greater the advantages of electric arc welding over other possible welding methods.

Electric resistance welding, after arc and gas, in its industrial significance is currently the third welding method, rapidly progressing and developing. The development of resistance welding, which requires significant electrical power, is closely related to the increased electrification of industry and the transition to mass production, so this welding method is essentially the most suitable for mass production of similar products. The resistance welding process is significantly mechanized and can easily be fully automated. A characteristic feature of resistance welding is the use of relatively complex specialized machines designed to perform a specific operation.

cyberpedia.su

Classification of types of fusion welding

Depending on the source of thermal energy, which is capable of heating the edges of parts to the melting temperature, fusion welding is divided into electric, gas and other types of welding. Electrical technology can again be divided into electric arc and induction. Let's consider the types most used both in everyday life and in industry. The most widely used types of welding are electric arc and gas welding. In the case of electric arc, metal melting occurs due to the high temperature of the electric arc (about 5000 degrees), which occurs between the workpiece and the electrode. When using gas welding, the heat source capable of bringing steel to the melting point is a burning gas or a mixture of gases (for example, propane and oxygen with a combustion temperature of up to 2050 degrees). The filler material for the seam in this type of welding is most often either a separate special filler, or its role is played by metal from the body of the workpiece.

And also, depending on the type of electrode used, the following types of welding can be distinguished:

- Using a consumable electrode. The seam is formed during the melting process of an electrode coated with a special coating. It is selected individually, depending on the types of steels being connected. Not used when joining thin sheet metals due to excessive overheating and frequent burns.

- Using a non-consumable electrode. It is made of a refractory metal, most often a tungsten alloy, and is intended only for igniting and maintaining the arc. Welding is often carried out in an inert gas shielding environment, which isolates the seam from the nitrogen contained in the surrounding air. Most often used in the case of sheet products.

Gas welding

Other types of fusion welding, such as induction, laser, plasma, etc., have not yet found widespread use due to the high cost of the equipment, so they will not be considered.

Thermal welding of materials

Thermal processes are based on the melting of connected parts due to thermal energy. There are several types of thermal welding:

- electric arc (in a protective gas environment, submerged arc and others);

- electroslag;

- electron beam and beam (laser);

- plasma;

- gas;

- termite.

Electric arc welding is the most widely used. But other types are also in demand in various modern areas of production and in everyday life.

Electric arc melting

Electric arc welding works by releasing energy in the arc due to the fact that the resistance of the arc is significantly greater than the resistance of the entire electrical circuit forming a closed loop.

Therefore, almost all the thermal energy is released in the arc, heating it to 4.5-6 thousand degrees and causing the melting of any metal. The arc occurs in the gap between the electrode and the metal being welded, causing them to melt.

When cooled, an unbreakable seam is created, the properties of which are related to the current, the composition of the additive and many other factors.

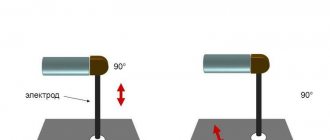

Arc welding is carried out using consumable and non-consumable rods (electrodes). The equipment uses inverter technology, which makes it possible to create compact, productive devices.

When welding workpieces using an electrode, an arc is ignited between it and the joint surface. This is created due to a short circuit when the rod touches the metal, and its subsequent tearing off at a distance of 3-5 mm.

The arc melts the end of the electrode and the edges of the work being welded. At the arc formation point, a weld pool is created.

To obtain a weld, it is necessary to move the electrode along the joint at a speed sufficient to melt the edges and the electrode, but not sufficient to burn through the parts.

After cooling the metal, a weld is obtained that is comparable in strength to the base. The electrode can be in the form of a separate rod in the coating or a filler wire on the wire feed mechanism.

When welding with a non-consumable rod, an electric arc occurs between it and the edges of the workpieces. The edges and, if necessary, the filler wire melt in the resulting weld pool. The rod can be carbon or tungsten. Non-consumable electrodes are usually used for welding copper, copper alloys (brass, bronze, cupronickel) and refractory metals.

Flux and gas protection

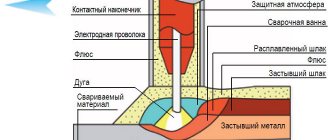

Welding metal under a layer of flux is usually performed automatically or using a semi-automatic process (semi-automatic). In the first case, all processes are automated; in the second, the electrode supply process is carried out automatically, and the movement of the torch is carried out by the welder.

The melt in the weld pool is protected by molten slag from exposure to atmospheric air. Slag is obtained by melting the flux entering the bath. The type of welding using fluxes is very productive, and it also produces a high-quality weld without pores or other defects.

Gas welding protects the welding area from the harmful effects of water vapor, atmospheric oxygen and nitrogen.

This is achieved by supplying a jet of shielding gas through the torch nozzle into the welding zone, which allows atmospheric air to be displaced. Used when using non-consumable and consumable electrodes. The result is a high-quality seam with high labor productivity.

Electroslag

The electroslag type of welding is carried out by fusing the vertical edges of the product with the electrode. When an electric current passes through the varnish, heat is generated. The arc is present only at the initial stage. Subsequently, the metal is melted due to the heat generated by the slag.

Copper sliders are installed on both sides of the gap. They are cooled by supplying water. A tray with flux is installed at the bottom. An arc is ignited between it and the electrode and the wire is fed there.

An electric arc melts the wire and flux, forming a weld pool over which a light liquid slag floats. As the edges and welding wire melt, the sliders move up the joint. The result is a high-quality seam. Thanks to this process, thick metals can be welded in one pass.

Radial

In industry, especially instrument making and electronics, it is necessary to weld very small parts that have special requirements for the welding process. The choice of welding method in this case is small. They can only be dealt with by a powerful light beam, a stream of electrons or plasma.

To obtain an excellent quality seam, a high-energy source is required. This could be a laser or other similar energy source capable of concentrating enormous thermal energy in a small area and for a short time. Electron beam welding uses the energy of electrons accelerated to high speed. In the case of a laser, heating is carried out due to the energy of photons.

Plasma, gas, thermal reaction

The essence of the type of welding using plasma is the formation of a jet of ionized gas, which is a current conductor.

The plasma temperature reaches 30,000 °C, which allows you to melt any metals in the shortest possible time. Plasma energy depends on the welding current, operating voltage, and gas flow. Welding seams are of high quality, thin, without internal stress.

Gas welding is carried out by burning a flammable gas in oxygen and releasing a large amount of heat. This is one of the oldest types of welding.

The temperature of the gas flame is three thousand degrees. Thanks to this, the joints of the welded product melt. The melting process takes a long time, which causes heating of large areas of the surface of the joined products. When cooled, it causes high stress in the seam and the part itself.

Thermite welding uses the heat generated by burning a mixture of aluminum and iron oxides.

Welding principle

As mentioned above, the principle of fusion welding is based on the process of mixing molten metal in the welding zone, forming a strong, permanent joint. The thermal energy source, which has a fairly large power, concentrates thermal energy on a small area of the weld pool. It is in this bath that the alloy brought to the melting point is located, which is fed there either using an electrode or with a special wire (in the case of welding with a fireproof electrode). By moving the source of thermal energy along the edge of the parts being joined, the weld pool is also moved, gradually adding filler material to it. After cooling, the bath material crystallizes, which leads to the formation of a strong weld.

The process of igniting a high-temperature arc consists of three sequential steps. First, the electrode touches the workpiece, resulting in a short circuit that causes the tip to heat up. Next, the tip is moved a short distance from the part; this distance is selected experimentally. It should be such that the arc is most stable. Heating the electrode is necessary for stable exo-emission of electrons, which also guarantees a stable electric arc.

Fusion welding principle

When the electrode melts, the filler material is transferred into the weld pool, and the parts are joined. On some welding machines designed for welding with a fireproof electrode, arc ignition is non-contact. It is performed by a special device called an oscillator.

Thermo-mechanical welding of materials

Thermo-mechanical welding includes forge, contact and similar types. These methods of welding metal simultaneously use thermal and mechanical energy. This type of technology includes the following:

- blacksmith's;

- contact;

- diffusion;

Forge welding is a method in which the products to be welded are first heated to the required temperature in a forge, and then connected to each other with a hammer. If a press is used instead of a hammer, then this method is called a pressing method.

The contact type has this name due to the fact that welding is carried out at the point of contact of the parts being connected. They are pressed tightly against each other using special electrodes, and then a powerful current is passed through the compression point.

At the point of contact, the greatest resistance is obtained, which causes the main heat to be released at this point. Accordingly, this leads to melting of the metal at the point of contact. Using contact welding, spot or seam welding is obtained.

Resistance welding has become widespread in mechanical engineering, especially in the automotive industry. This is due to the high productivity and cost-effectiveness of this type of welding. It is the easiest to automate and is widely used in robotic systems.

It is impossible not to mention the diffusion type of welding. Its essence lies in the preheating of the workpieces and their subsequent connection using deformation that occurs from mechanical pressure. In this process, atoms diffuse from one part being connected to another and an inextricable connection is obtained.

Types of electrodes used

A high-quality weld can only be obtained with the correct selection of filler material, so it is worth paying attention to their varieties. The welding electrode is a steel rod coated with a special coating that melts during the welding process and protects the seam from exposure to nitrogen from the air. In the case of welding with a fireproof electrode or gas, no coating is required; the seam is protected by inert gas or flame from the torch. Therefore, in principle, the electrode, wire and other filler material are practically the same.

The filler material from which the wire is entirely composed plays a primary role in the strength of the weld. During the heating and melting process, alloying elements burn out from the alloys, thereby deteriorating the quality of the connection. In order to avoid this, steel rods are selected whose degree of alloying is equal to or even higher than the grades being joined. If the alloy grades are different, the degree of alloying is estimated based on the maximum alloyed alloy. An excess of alloying elements compensates for their burnout.

If the steel grades are unknown and there is no way to determine them, then a special transition (also called a buffer) electrode or a special filler wire is used. It allows you to weld even dissimilar steels, for example, such as stainless steel and simple black low-alloy steel, playing the role of a transition material.

Requirements for welding seams

The requirements that may be placed on welding seams largely depend on the final purpose of the finished structure. Nevertheless, several general requirements can be identified that connections of this type must satisfy. The hardness and tensile strength of the welded joint must have the same indicators (or similar) as those of the base metal. Tests are carried out on special equipment with a sample of the finished product.

Visually check the quality of the seam as follows. After completing the welding work, the seams are cleaned of slag and oxides, and all auxiliary devices are also removed. The seam should be uniform, fine-scaled and have a uniform width. There should be no sagging, burns, narrowing or breaks. The metal that is deposited must be homogeneous and not have pores or surface cracks.