The data center water cooling technology market is projected to reach $4.55 billion by 2023, according to Stratistics MRC. Below the cut we look into the reasons for the growth in demand for such developments and talk about the technologies themselves that are developing in this area.

/ photo / Immersion cooling system

One of the reasons for the market growth is the increase in the volume of processed data. According to IDC research, by 2025 the amount of data generated by humanity will be 163 zettabytes. As data volumes grow, so does the load on servers in data centers, especially those involved in high-performance computing (HPC). To cool such systems, conventional air units are no longer sufficient.

For example, to cool Google's tensor processors (TPUs), which are designed for TensorFlow, the IT giant had to use water for the first time. Due to the fact that the new generation of processors (TPU 3.0) is distinguished by power and high power consumption, air cooling turned out to be inapplicable for them.

Why is air cooling inferior to water cooling?

Clive Longbottom, director of services at the analytics company Quocirca, notes that air is not so good as a coolant: compared to water, it is 50 to 1000 times worse at removing heat from equipment.

In addition, traditional air cooling units take up more space and consume more energy. And this also affects electricity bills. Therefore, in computer rooms of data centers, where the density of equipment is constantly increasing, it becomes unprofitable to use air for cooling. For this reason, fans in the US National Security Agency data center were replaced with an immersion cooling system (we wrote about other alternative solutions in one of the posts).

Vali Sorell, president of building engineering and engineering company Sorell Engineering, and Mark Hourican, managing partner of the consulting firm Syska Hennessy Group, believe the data center industry is not yet ready to completely abandon from “investing in air” and switching entirely to water cooling. In this case, you will have to completely rebuild the entire data center infrastructure, which is quite expensive.

However, companies that have to work with heavy loads are already developing and using liquid cooling systems.

About data center liquid cooling technologies

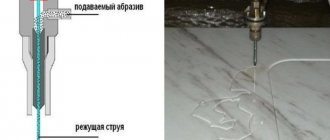

Immersion cooling.

One of the many liquid cooling technologies is immersion cooling (which we have already covered in the blog). The technology involves complete immersion of equipment in a special oil environment. The main advantage of the technology is that oil has higher thermal conductivity compared to air. This helps the system absorb heat more efficiently and remove excess heat.

In 2015, Horizon Computing introduced a system for immersion cooling: the company developed a special box for servers, which is filled with mineral oil. The box design maintains the optimal temperature of the equipment using convection. Such a “container” is capable of operating outdoors without air conditioning, and the low manufacturing costs and simple design of the box allow it to be used without changing the data center infrastructure.

Indirect liquid cooling.

This technology is already being used in Facebook's data centers: in early June, the company demonstrated how a new cooling system made a data center in North Carolina more energy efficient.

Facebook representatives note that in some data centers it is impossible to use free cooling due to harsh natural conditions or high levels of air pollution (for example, they are struggling with this problem in China). Therefore, the company decided to develop an indirect liquid cooling system.

The system is based on evaporative cooling technology. The water for the system is cooled in a special heat exchanger, evaporating through a special membrane layer. Then it cools the air inside the data center, maintaining the optimal temperature of the servers (a diagram of how the technology works can be seen in a post from the Facebook blog).

Testing of the system has shown that it can reduce data center water consumption by 20% (in hot and humid climates) and by 90% (in temperate and cold climates).

/ photo poolie

Heat exchangers on the back of the server rack.

In this case, the cooled water flows directly to the equipment rack, removing excess heat. Lenovo uses this technology in its Neptune project: heat exchangers are already used by 30% of the company's clients for their HPC systems.

In addition to the mentioned heat exchanger, the Neptune project includes a heat exchange module (Thermal Transfer Module) and a direct to Node Cooling system.

The module uses liquid from a heat-absorbing reservoir to move excess heat from the processor through special tubes to an area of thin air. The system is compact in size, which allows it to reduce traditional noise in the server room. And the direct cooling system delivers cold water directly to the unit and “removes” excess heat from key system components.

Cooling systems

Cooling systems in industry

Many industrial processes generate heat that must be used or removed. In economic calculations, water is often considered as a transport medium. Depending on the water content there are:

- flow cooling;

- open cooling systems (evaporative cooling);

- closed cooling systems.

The largest systems are used in power plants, steel production, petroleum refining processes and the chemical industry. In steel and iron production, water is also used in large quantities to purify process gases. In gas scrubbing systems, water treatment also eliminates certain problems.

1.1 Flow cooling

The simplest, and where water is available in sufficient quantities, at the same time the most economical method in terms of technology and costs is direct-flow water cooling, since the efficiency of most thermal processes increases with a decrease in the temperature of the coolant. Water is taken, as a rule, from a water intake (river, canal, lake), passed through heat exchangers, and then returned warm to the water source. In order to save water, warm cooling water can be reused in a further cooling process, which allows for higher temperatures. Since very large quantities of water are required for single use, inexpensive, low-cost water treatment methods are used. Water treatment is usually limited to filtration through sand filters; chemical treatment of water is usually not performed. Related problems in the cooling system such as corrosion, deposit formation or microbiological growth are determined by the properties of the water used.

1.2 Open cooling systems (evaporative cooling)

With this method, evaporative cooling, from the point of view of chemical water treatment, we are talking about the reuse of cooling water. The circulating cooling system can be briefly described as follows: the required amount of cooling water is taken from the cooling tower bowl and is carried through the refrigeration units using water pumps. The cooling water heated there is returned to the cooling tower. There, water losses occur due to evaporation and desalination; these losses must be compensated by make-up water. Heating in the heat exchangers corresponds to cooling in the cooling tower. A significant difference from flow cooling is the need to replenish losses during evaporation, which simultaneously thickens the salts dissolved in water (increases the concentration of salts). As a result, mechanical and/or chemical treatment of make-up water becomes inevitable.

1.2.1 Cooling tower

The heated cooling water is irrigated in the cooling tower using special built-in elements. The water is cooled through close contact with air in two stages: 1. Heat removal through direct contact of cooling water with colder air is approximately 15-25% of the total heat exchange; 2. By evaporating some of the water, most of the heat is removed. The most commonly used cooling towers differ depending on the type of air injection - cooling towers with natural and forced draft, and depending on the type of direction of air and water flow - counterflow and cross-flow cooling towers. In natural draft cooling towers, the air moves from bottom to top inside the tower only due to temperature and pressure differences, while in forced draft cooling towers the flow is carried out by a fan. Power plants typically use high-rise natural draft cooling towers, which are the most economical type of cooling tower for very large cooling water needs. Industrial plants, on the other hand, operate primarily with forced-draft sectional cooling towers of low design, with numerous cells connected together, often into larger units. To maintain a constant volume of water in the cooling circuit, the water evaporated in the cooling tower must be replenished. Since when water evaporates, its constituent parts do not evaporate, the remaining amount of water is saturated with these substances. This increase in concentration cannot continue arbitrarily, since the dissolved set of salts will inevitably increase their solubility. To avoid high salt concentrations, some of the water must be drained from the system continuously or intermittently. These activities are called salt removal or shalak removal.

1.3 Closed and semi-open cooling systems

Unlike open systems, recooling of heated water in closed systems is carried out not by irrigation in a cooling tower, but by means of a heat exchanger. The heat exchanger can be cooled either through a second open cooling system (secondary system) or using air in an air cooler (air cooler). A typical example of closed circulation is the cooling of chill molds during continuous casting. Due to high temperatures, and the associated danger of hardness deposits with catastrophic consequences (fracture of the chill mold), the chill mold in a closed system is cooled with demineralized or softened water. Recooling is often done using a plate heat exchanger and a secondary open cooling system. Water losses in closed cooling systems are naturally much lower. Replenishment is carried out mainly with softened or completely demineralized water. Regarding water treatment, these systems require little maintenance since the concentration of chemicals used remains more or less constant. Since softened or completely demineralized water behaves aggressively towards substances usually processed in such systems, care should be taken, first of all, about good corrosion protection.

Semi-open cooling systems are used where high process temperatures occur for a short time, but the amount of heat removed is relatively small. Therefore, for cooling with recycled water, you can use a fairly large container that has a lid. This container is designed in such a way that, through the heat radiation of the container into the environment and the contact time of the water, the required temperature of the cooling water is achieved. Water losses are relatively insignificant and are limited mainly by leaks in case of significant evaporation. Replenishment is carried out, as in closed systems, most often with completely demineralized or softened water. A typical example of semi-open cooling systems is the cooling of electrical units, as well as the quenching medium in induction hardening machines. Unlike closed systems, in which only galvanic corrosion after the absorption of oxygen caused by the use of various precious materials must be prevented, in semi-open systems oxygen is constantly introduced, which leads to increased corrosiveness of the water. When cooling electrical units, such as in induction hardening machines, the dissolution of metals due to energy from an external source (stray currents) must be taken into account.

1.4 Converter gases

In steel production, huge quantities of converter gases saturated with dust are generated. Environmental requirements require thorough cleaning of converter gases, which is usually done using wet dust collectors. Wet dust collectors using recycled water can experience significant problems due to calcium carbonate and iron oxide deposits in the water spray area, discharge piping, and fan. Iron oxyhydrate deposits, characterized by a loose porous structure, are easily removed mechanically. In contrast, sintered slags, the basis of which consists of crystalline, tightly intergrown calcium carbonate, are strongly adherent products that are mechanically very difficult to remove. Mechanical removal of these caked slags results in short converter run times, which significantly increases production costs.

1.4.1 Scale formation when cleaning converter gases

Part of the necessary fillers containing lime during the conversion of iron into steel is captured by the exhaust gases during the oxygen blast phase and is supplied to the treatment system. This trapped amount of lime, based on relatively short successive filling times, is so large that the wash water becomes saturated with lime. The relatively small amount of make-up water is not enough to make the water capable of accepting calcium ions again. At pH values between 10 and 12.5, calcium appears predominantly in the form of calcium hydroxide. Deposits can be expected wherever calcium carbonate deposits arise from aqueous solutions or dispersions of soluble calcium salts upon contact with carbon dioxide (or, in other words, an aqueous carbon(IV) monoxide complex).

1.5 Heat transfer in heat exchangers

Industrial heat exchangers consist of a number of tubes (tubular heat exchangers) or plates (plate heat exchangers) that are covered by a casing. The coolant transfers the heat of a hot stream through a heat-conducting contact surface to a cold stream of substance, such as cooling water. In this case, the hot stream cools along its path, while the cold stream heats up. To calculate the temperature characteristics of both streams, the energy balance of the system must be calculated. During operation of the heat exchanger, under the influence of cooling water, deposits can form that interfere with heat transfer. The heat transfer coefficient becomes lower. The degree of contamination of the heat exchanger for units in operating mode is shown by the Fouling factor. It indicates the extent to which deposits interfere with heat transfer. In this case, the Fouling factor itself is the difference between the inverse heat transfer coefficient observed in the installation and the theoretical inverse heat transfer coefficient for a clean heat exchanger.