A variety of welding machines are used for various types of work on creating metal structures. One of the most versatile and productive is the semi-automatic. It is distinguished by its high speed of welding, the ability to lay long continuous connections and minimal subsequent processing of the joint for painting. Semi-automatic machines can be large and small, expensive and cheap, but the key parameters regarding their suitability for specific types of work are hidden in their configuration and characteristics. We offer a number of tips from experts on choosing semi-automatic welding machines for various purposes.

What to look for when choosing a semi-automatic welding machine

The main operating characteristics of the semi-automatic welding machine can be found in the description and instructions. They need to be taken into account in full, since each point is equally important. Parameters to be taken into account when choosing:

The maximum current is in combination with the constant switching factor. It determines the areas of application of the semi-automatic device, as well as the so-called safety margin. There are also confusions with welding current. There is simply no such adjustment on semi-automatic machines - only adjustment of the burner voltage is available. The lower the constant switching factor, the more often you will have to pause during operation.

Power and range of operating voltages are important when you plan to power the semi-automatic device from a weak electrical network in the private sector or garage. The lower the power consumed by the device, the less voltage drops will occur during operation. Accordingly, the lower the threshold of the voltage range, the higher the drawdown the semi-automatic device will maintain without failures in operation.

The ability to change polarity is an important point when welding flux-cored wire. The functionality of the device and the list of works that can be performed depend on this moment.

The presence of additional modes – they expand the functionality of the installations, although they increase the price. Typically, semi-automatic machines come with an MMA mode - manual arc welding.

Before making a purchase, decide on the thickness, types of materials to be welded, dimensions of the objects to be welded, and the length of the seams. The intensity of use of a semi-automatic device is also important, as are the capabilities of the electrical network (home, country).

How to use it correctly

It should be noted right away that each equipment comes with instructions, which contain not only general recommendations, but also special notes and instructions for using the inverter.

The first step is to select the desired mode and adjust it correctly. We set the strength of the welding current, select it correctly, relative to the properties of the part being welded.

The filler material is wire, the coil of which is placed in the inverter feed block. If your device is not equipped with it, then you need to order it separately.

Replaceable gears are added to the inverter to control the wire feed speed. Beginners need to know that at first you should not set it to maximum feed, as the seam may become deformed.

There are several manufacturers of semi-automatic machines with different functions created, so for further work, check the instructions.

Some tips for beginners: initially try on a separate piece of metal so that you can adjust the settings.

The best manufacturers of semi-automatic welding machines

The manufacturer's reputation is no less important than the number of functions available. By choosing equipment from trusted brands, you automatically rely on quality. We recommend equipment from the following brands:

- Fubag (Germany) – sells a wide range of welding machines and related accessories. Semi-automatic welding machines from this company have high technical parameters and are moderately expensive.

- Svarog (Russia) is a joint Russian-foreign brand. Large dealer networks guarantee maximum, high-quality customer service.

- RESANTA (Latvia) is a leader in its segment. Inverters are reliable, economical, and durable.

- ELITECH (Russia) – the main production facilities are located in Belarus and China, it has its own quality control system.

- Aurora (Russia) - provides an official guarantee for all equipment; production facilities located in China are used for assembly.

The cost depends not only on the brand, but also on the set of functions. If you want to save money, choose a simple model from a well-known brand.

Semiautomatic inverter or classic?

Complete set of semi-automatic welding machine.

In other words, which is better - a transformer or an inverter? Considering the fact that 90% of welding work in Russia is still carried out on transformer types of equipment, the question is not at all idle and needs clarification.

What are the fundamental differences between a transformer and an inverter? Both are sources of welding current. But they generate it using completely different mechanisms of action. But to choose one or the other, what is more important is not the current conversion mechanism, but the differences in application and, most importantly, the quality of the resulting welds.

Transformer models are bulky, they need to be moved on a trolley, but it is better to use them in stationary conditions, without moving them. Inverter semi-automatic machines are lighter and smaller, and the seams with their help are of better quality. But they also cost significantly more than transformer options.

If the money issue is acute, transformers can be chosen for domestic work in the country or in a private house. They are also suitable in a personal garage. If you plan to weld critical areas such as heating, plumbing, containers or stainless steel pipes, you should choose inverters.

The best inexpensive semi-automatic welding machines

Budget equipment is quite reliable, functional and at the same time has an affordable price. Cost savings are achieved through a reduced set of options. If you need a simple unit, we present to your attention 3 inexpensive semi-automatic welding machines.

RESANTA SAIPA-135 (MIG/MAG, MMA)

The semi-automatic welding machine from the RESANTA company is well suited for welding using wire in a gas environment and working with piece electrode elements. When processing non-ferrous metals, inert gases are used - helium, argon. If you plan to work with alloy and low-alloy steels, pay attention to the active gas.

The welding device allows you to regulate the current automatically and change the wire feed speed. The optimal diameter of the working part is 0.6-0.8 mm; the pulling mechanism is suitable for placing a reel within 5 kg.

To switch the semi-automatic welding machine to the MMA welding mode, turn on the switch on the panel, then connect the cable with the electric holder (it is included in the kit). The presence of reliable protection guarantees the absence of sheer drops of rain and large particles from falling on the body. Overheating is excluded.

PROS:

- unpretentiousness in maintenance;

- stable power parameters;

- possibility of using MMA welding;

- polarity settings;

- compactness;

- place for installing the coil;

- low price.

MINUSES:

- modest functionality.

Wester MIG 140i (MIG/MAG, MMA)

Semi-automatic welding machine of inverter type for welding and depositing metal using electrode consumable wire. Shielding gases or flux-cored wire are used as the working medium. The semi-automatic machine allows for electric arc welding.

The adjustments are smooth and the settings are flexible, which makes operating the device as comfortable as possible. This will allow you to solve problems of any complexity. The current at maximum voltage reaches 60%, this is enough to solve professional problems and quietly implement complex projects. The dimensions are compact, the weight is small, the efficiency is high - due to the use of IGBT inverter technology. Built-in thermal protection will keep the inverter operational in case the maximum permissible temperature values are exceeded. There are convenient light indicators, and there are covers on the case to protect against external factors. Transportation is simple, largely due to the comfortable handle.

PROS:

- optimal configuration;

- reliable protection;

- presence of light indicators;

- carrying handle;

- Possibility of professional use.

MINUSES:

Wert MIG 160 (MIG/MAG, MMA)

The semi-automatic welding machine from the Wert company is well suited for novice craftsmen and simple tasks. A good choice for servicing your car yourself. One of the most affordable solutions in its category. It is possible to install coils up to 5 kg, which is generally the norm for the group under consideration.

The quality of the manufacturer's equipment is high, the price is reasonable. The wire feed is regulated with current. Jamming is minimal and usually starts when the hose is bent. Overall, the installation is trouble-free. Soft self-defense is suitable for welding. There are no restrictions on the size of parts. If there is a poor power supply or dead wiring, arc ignition may be weak - it is better to use wire. A worthy solution for your money.

PROS:

- good functionality;

- good reliability;

- availability;

- 5 kg spools.

MINUSES:

- there is no adjustment of wire feed separately from current.

SPECIAL MAG-170 INVERTOR (MIG/MAG)

High-quality welding inverter, welds everything without problems. Suitable for use at home, in the country, in the garage. An ideal alternative to conventional arc welding. You can work on thin metal and wire. The semi-automatic machine will appeal to novice craftsmen and those looking for a high-quality tool at a good price.

Wire feeding is simple and straightforward, you will understand it the first time. Read the instructions carefully; all the operating features of the device are described there. The wires are copper, although in some respects they are more similar to copper-plated ones. There are no restrictions on operating conditions; the solution is suitable for any environment.

PROS:

- price quality;

- good reliability;

- unpretentiousness;

- thoughtful functionality;

- compactness;

- wide range of functions.

MINUSES:

- short wires.

Main characteristics of semi-automatic machines

Welding machines reached their epic level in the mid-twentieth century, but their development did not stop there. Already now you can find a wide range on the market, different types of equipment with the latest technologies are appearing.

One of these was the semi-automatic welding inverter.

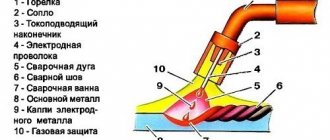

Its main difference is the use of filler wire rather than an electrode. The feed speed is fixed by the master on the machine itself, and the stability of the speed of movement of the seam torch depends on the device.

In addition, welding allows you to ensure high quality seams, facilitates ignition of the arc, and simplifies the work of the working person, since he does not need to change electrodes. The process of such welding is considered mechanical.

The best semi-automatic welding machines price-quality

The good price-quality ratio makes the unit the optimal choice for solving a wide range of problems. The cost is average or a little higher, but it is worth every penny. Let's talk in more detail about such semi-automatic welding machines.

Aurora OVERMAN 200 (MIG/MAG)

OVERMAN 200 welding inverters are used for semi-automatic welding. The working medium is MIG-MAG protective gas, you can use a semi-automatic wire cutter. Thanks to the positive operating mode with maximum currents, the device is well suited for solving household and professional problems. It proves to be a reliable assistant and is effective for working with aluminum.

You can use the model for semi-professional, household metal welding. The controls are simple, thought out to the smallest detail. Settings are available from the front side of the panel. Large drops in supply voltage are acceptable. There are adjustments for voltage, welding current, inductance, and a confident welding function. Detailed speed settings for wire drawing are provided. Arc burning is consistently high.

PROS:

- maximum possibilities;

- versatility;

- good reliability;

- high current;

- comprehensive protection.

MINUSES:

- you need to tinker with the settings.

Svarog REAL MIG 200 (N24002N) BLACK (MIG/MAG, MMA)

The semi-automatic welding machine REAL MIG 200 from the Svarog company has expanded equipment compared to its predecessors and an improved design. The grille on the front panel is made of plastic; an additional induction regulator is provided. The regulator is comfortable, rubberized. At a network voltage of 160 Volts, operation is stable. Welding using flux-cored wire is available, and you can work with aluminum.

The runs are idle, you can do afterburning of the welding wire. There is an MMA mode. For convenient wire feeding, a durable metal feeding mechanism is provided. The model is reliable, ergonomic, and has an average price. It is used for everyday tasks, but the equipment can also be used for professional purposes.

PROS:

- high reliability;

- good functionality;

- wide range of settings;

- versatility.

MINUSES:

- breaks from work are needed.

Aurora OVERMAN 160 (MIG/MAG)

The OVERMAN 160 welding machine is a semi-automatic device; the working areas are represented by gaseous media. It is well suited for self-shielding flux-cored wire. It is possible to solve a wide range of problems with virtually no restrictions. Use semi-automatic devices in factories, garages, and car service centers. Optimal results will be obtained when processing aluminum. The semi-automatic welding machine is well suited for household and semi-professional use.

The controls are clear, understandable and simple. Reliable protection systems are integrated; even a novice technician can perform the settings without any problems. The service life of the installations is impressive. The cost is above average, but it pays for itself during use.

PROS:

- a wide range of adjustments;

- settings for penetration depth, roller shape, arc rigidity;

- confident metal welding;

- connecting the inductor heating;

- fast or slow wire drawing at the operator's discretion.

MINUSES:

- the price is above average.

Solaris MULTIMIG-228 (MIG-MAG-TIG)

Inverter welding semi-automatic model for working with wire and electrode elements, well suited for non-consumable tungsten parts. It is based on IGBT transistor elements. The semi-automatic machine has no restrictions in terms of operating conditions. The control panel is intuitive. A transparent plastic cover is used for protection. The Antistick function reduces the welding current in case the electrodes stick. There is protection against overheating.

A socket is provided to connect the heated gearbox. The connectors are enlarged and designed for a current of 315 V. They increase the service life of the cable-device connection in comparison with standard conditions. The semi-automatic machine is well suited for short and long seams. Microprocessor control.

PROS:

- price quality;

- durability;

- versatility of settings;

- reliability, regardless of operating conditions;

- microprocessor.

MINUSES:

- skills are needed.

Advantages and disadvantages of working with semi-automatic machines

Let's consider the advantages of the equipment; this is a good quality of welding seams even for a person who has picked up an inverter for the first time.

The arc is ignited without difficulty, it is easy to direct and maintain constant combustion. The seams can be obtained strong and neat.

The advantages of inverters also include performance. Despite the fact that manual arc welding is a little simpler, a welder working with semi-automatic machines can boast of the efficiency and fruitfulness of his work.

An inverter with a mechanical welding method is widely used not only at home, but also in workshops and enterprises.

The semi-automatic machine is good for working with capricious metals that are difficult to process. For example, with something like aluminum, which is very difficult to work with. Since an oxide film forms on it, which significantly complicates welding.

The equipment is suitable for working with small and thin parts. The semi-automatic machine allows you to apply neat seams without damaging the original material or burning it.

The best professional semi-automatic welding machines

Professional devices are suitable for continuous operation over a long period of time. Let's look at popular models and tell you about their features.

Aurora SPEEDWAY 250 (MIG/MAG, MMA)

Professional three-phase model for semi-automatic wire welding (steel). Working medium – active or inert protective gas MIG-MAG, MMA piece electrode technology is suitable. The sarking machine is used in production and professional services. The control interface is convenient, the semi-automatic machine can be configured to solve a wide range of tasks. IGBT technology guarantees reliability for many years of operation.

The inductance is adjusted to optimize melting depth, arc stiffness and bead shape. Combustion stability is excellent, with minimal splashing. The wire spool can be installed up to D300. Feeding mechanism is open type. All accessories necessary for operation are included. The power unit is designed on the basis of IGBT.

PROS:

- user-friendly interface;

- attractive design;

- maximum performance;

- high durability.

MINUSES:

- the price is above average.

BLUEWELD Starmig 215 Dual Synergic (TIG, MIG/MAG, MMA)

The professional machine is suitable for all types of welding. It is used in small industries and car services. Maximum quality of seams is guaranteed. It is possible to work with any materials, and the most accurate integration of a set of 17 synergetic programs is guaranteed.

The model is in demand in the field of body repair. Functionality, reliability, and the ability to obtain high-quality and beautiful welds are important. LCD display, large. There is a Euro connector for connecting burners. After changing the polarity, you can work with flux-cored or solid wires.

PROS:

- extensive settings;

- the ability to solve problems of increased complexity;

- high durability;

- overheat protection.

MINUSES:

Aurora ULTIMATE 350 (MIG/MAG, MMA)

Productive inverters that belong to the professional category. The design type of the device is the so-called decompact. There is a take-out mechanism and a set of 4 rollers. The standard delivery includes a package with cables to the feeding mechanism - that is, 5 in length. As a result, the welding working area expands.

The control panel is extremely simple in terms of settings; it implements a full range of necessary functions. Crater filling and gas purge are available. The operating mode of the burner element is four-stroke. There is a switch for changing poles. IGBT guarantees maximum durability of the solution.

PROS:

- stable long-term work;

- convenient settings panel;

- the presence of a pair of digital displays;

- efficient air cooling;

- advanced modular control.

MINUSES:

- high price.

Svarog PRO MIG 200 (N229) (TIG, MIG/MAG, MMA)

Professional unit with a wide range of settings. It allows you to adjust welding parameters and quickly perform all basic settings. It is enough to select one parameter, and the rest will be set automatically.

There is a function for quick ignition of the arc, and protection against sticking is provided. The manufacturer has integrated the option of uniform penetration into the device. The device can be used in unstable networks, during voltage sags. Preparation for work is extremely simple; before starting work, it is recommended to do a dry run. There is a built-in test purge. The security level is high.

PROS:

- good performance;

- 100% protection;

- 5 years warranty;

- visual control;

- light indicators;

- shockproof.

MINUSES:

- the cost is above average.

Which semi-automatic machine to choose for car repairs + (Video)

Body work predominates in car repair. The bodies of modern passenger cars are made of thin metal. To weld it, you will need a small current and a welding wire thickness of up to 0.8 mm. It is less common to weld some parts that have a thickness of 1 to 5 mm.

It follows from this that to perform welding work it will be quite enough to purchase a semi-automatic inverter welding machine of medium power. It will not overuse electricity in the garage, will provide sufficient on-time, will not overload, and overload the network.

Such semi-automatic machines have a large base of spare components and types of welding wire. And the price for them is quite affordable. The main thing is that there is current and voltage regulation available. Such semi-automatic machines will not be able to weld large volumes of thick metal, but this is rare in car repairs.

BLUEWELD Starmig 210 Dual Synergic

Compact and ergonomic welding machine is designed for joining stainless steel, aluminum or steel products in MIG/MAG mode in shielding gas or flux-cored wire, as well as for MIG welding. Depending on the thickness of the metal, you can select the optimal operating mode. The semi-automatic welding machine will perform a wide range of various body or installation work, suitable for work at a service station, in a car service, good for a garage or construction work on a summer cottage. Current welding parameters are displayed on a large LCD screen, which is very convenient when setting up the machine. The user can weld with flux-cored wire or with a solid section. The unit is equipped with 17 synergetic programs, adjustment of electronic inductance and wire annealing. Among analogues in its class, the semi-automatic is distinguished by high quality assembly and reliability. It is not surprising that this model is widely used in automotive repair, where, in addition to technical characteristics, it is important to produce smooth, neat welding seams.

Advantages:

- manual shutdown of synergy

- adjustable voltage

- burner mode selection

- synchronization with additional equipment for remote control is available

- good power indicator

- better functionality

- precise control via processor

Flaws:

- high-quality aluminum welding will require skill

- high price

RESANTA SAIPA-165

A good wire household semi-automatic machine compares favorably with analogues in the price segment up to 15,000 rubles. The device is assembled on the IGBT platform - this is a plus. The model is equipped with wire feed adjustment and smooth current adjustment. With minimal CO2 consumption, the device welds thick and thin metal equally well, making it convenient for the garage or periodic work in a car service center. Although the semi-automatic welding machine is budget-friendly, the key technical and operational characteristics are quite attractive: wire thickness up to 0.9 mm, welding with or without gas, duty cycle at 160 A is 70%, a mechanism protection system from overheating is implemented. After some manipulations with the current settings and adjusting the feed speed of the welding wire, the user can easily produce an even and neat seam, which cheap semi-automatic machines can rarely boast of.

Advantages:

- excellent workmanship, good ergonomics

- light weight for a device of this class

- electronic control of automation elements

- good results when welding thin metal

- long service life

Flaws:

- no critical comments identified

Characteristics for equipment selection

Initially, you should rely on power and current indicators. They will show what the equipment's performance, endurance and reliability will be. As for the power potential, it varies from 2.5 to 7.5 kW on average. Moreover, the main range is in the sector up to 4-5 kW. Perhaps in professional environments they use 7.5 kW models, but for domestic repairs you can limit yourself to a 3 kW device. Another question is how to choose the right semi-automatic welding machine for body work based on current strength? In this case, the performance indicator should be compared with specific tasks. The current varies from 55 to 160 A. Models up to 100 A are suitable for welding body sections up to 3 mm thick. But if you plan to make complex butt joints with a thickness of about 8-10 mm, then the minimum indicator for this characteristic should be 140 A. The possibility of welding materials with different dimensional parameters is also affected by the diameter of the wire. It varies from 0.6 to 1 mm on average, and as the thickness increases, the possibilities for welding massive structural elements expand.