In those regions where there is no main gasification, blue fuel is supplied through gas tanks and cylinders. Inside them, the gas is in liquefied form: to supply it to the equipment, it is converted into a vapor state. An important part in this chain is a special device - a gearbox.

Classification depending on the scope of application

Depending on the scope of application, reducers for gas cylinders are divided into several types:

- Household unregulated.

- Universal adjustable

- Professional.

Household unregulated

This type includes the simplest gearboxes used in domestic gas supply to households and in camping conditions. RDSG reducers are installed together with household gas cylinders. They have the simplest design, allowing the use of gas only in household stoves and are inexpensive and reliable. The frog reducer for a gas cylinder, or RDSG-1, is used in conjunction with containers from 12 to -50 liters.

Household unregulated

For five-liter gas cylinders, popular among summer residents, tourists and hunters, the RDSG-2 Baltika model is used. The Baltika reducer is put on the nipple of the gas cylinder from above and fixed in the rubber seal with a special clamp. The gearboxes are configured for a working pressure of 0.3 MPa and a throughput of 1.2 m3/hour

Universal adjustable

This class of gearboxes has a more complex design and wider capabilities. They can already be used both for domestic gas supply and for work in a home workshop. These reducers have a mandatory threaded connection to the gas cylinder, which securely locks the device.

Universal adjustable for propane with pressure gauge

They are also equipped with a pressure gauge and an adjusting screw that allows you to change the operating pressure from 0 to 0.3 MPa, depending on the needs of the gas consumer device connected to them. These devices also have a greater throughput than household ones - up to 5 m3/hour

Professional

This class is characterized by the use of more wear-resistant materials and better build quality and adjustment. The operating pressure adjustment parameters are also wider – from 0.4 to 1.6 MPa.

Professional gearbox with two pressure gauges

Some models are equipped with two pressure gauges - for inlet and operating pressure, respectively.

Varieties

Currently, the most common types of gearboxes for gas tanks are:

- Household, without adjustment function. The most primitive models, which are often equipped with cylinders for household and mobile use. Devices of this type are marked “RDSG”. Their advantages are reliability and low cost. Scope of application: LPG cylinders with a capacity of 12-50 liters. Household gearboxes are placed on the nipple of the container and fixed with a simple clamp on a rubber gasket.

- Universal. The presence of more complex configurations expands the scope of application of these devices. Along with cylinders for household needs, universal adapters can be found in small production workshops. Reliability of the connection is ensured by high-quality threads and a reliable lock. The device also includes an adjusting nut and a pressure gauge, which allows you to supply gas with the required parameters. Gearboxes of this type are capable of passing up to 5 m3 of blue fuel per hour.

- Professional. They are distinguished by high resistance to operational loads and more precise regulation of fuel supply to the consumer. Professional adapters are designed for pressure conditions of 0.4 - 1.6 MPa. Some varieties are equipped with not one, but two pressure gauges.

Along with this, another principle of classification of reducing devices is applied: for flammable and non-flammable gases. Containers for flammable mixtures are traditionally equipped with a left-hand thread, while oxygen cylinders and vessels for inert gases are equipped with a right-hand thread. This eliminates the possibility of mistakenly switching the wrong adapter.

The operation of any gas equipment is subject to fairly high safety requirements. If the pressure in the system increases, an emergency situation occurs, with the risk of subsequent explosion and fire. To minimize the risk of an emergency, leading manufacturers of gas adapters equip their products with additional valves for releasing excess gas. As a rule, the fuse operates in cases where the pressure exceeds the norm by 2.5-3 times.

Features of using composite gas cylinders

Composite gas cylinders have recently become increasingly popular. This is due to their advantages over their steel counterparts.

- Weight. Almost twice as light as steel.

- Ease of handling. There are comfortable handles.

- Transparency. The fill level can be easily seen.

- Convenient storage. Can be placed one on top of the other and stacked.

- Life time. The service life is practically unlimited.

- Operational safety. It is caused by the absence of sparking and a safety valve and fusible link built into the gas cylinder.

Composite cylinders supplied to the Russian market are produced in the Czech Republic, Norway and India. When purchasing such a cylinder, it is necessary to clarify the connection standard. If the gas cylinder is equipped according to the Russian standard, you can use a regular reducer for the gas cylinder. If the gas cylinder comes with a European connector, then you will need to either order an adapter or purchase an imported reducer. Please note that each additional connection increases the risk of gas leakage.

Specifics of servicing imported gas cylinders

Recently, the domestic market has been flooded with composite gas tanks made in the Czech Republic, Norway, India, etc. Before purchasing such a container, it is important to familiarize yourself with its switching standards. As a rule, a regular gearbox is not suitable for such devices: you have to use additional adapters or imported adapters. The last option is more preferable, because the presence of unnecessary connections in the supply chain reduces its reliability.

Similar articles

- How and why is propane-butane produced?

- Cylinder installations: application

- How to transport helium cylinders

What is a propane reducer?

The design of all propane reducers is very similar. They all have:

- Sealed housing made of aluminum, brass or plastic.

- Inlet pipe for connection to the cylinder.

- Outlet pipe for connection to the consumer.

- High and low pressure chambers.

- Flexible membrane.

- Valve and stem.

- Return spring.

- Working spring.

In professional gas reducers, a pressure gauge, an adjusting screw or flywheel, and a threaded connection of the supply pipe are added to the design. The gearbox housing has a cylindrical shape, which is due to the use of a round membrane that bends inside the operating pressure chamber. The inlet and outlet pipes protrude from the housing.

How to choose a household propane reducer

The choice of a device for supplying a propane-butane mixture to gas-using equipment is based on two key parameters:

The operating mode of most household propane appliances is 30 mbar, 37 mbar or 50 mbar. Based on this indicator, the appropriate gearbox is selected. If its output pressure differs from the operating parameter of a gas stove, boiler or, for example, a grill, this may lead to improper operation of the equipment and even create an explosive situation.

For stable and safe operation of the gas consumer, it is also important that its consumption does not exceed the performance of the gas reducer. In this case, the upper level of gearbox consumption is not standardized. That is, for a boiler with a power of 24 kW with a mass flow of 2 - 2.5 kg/h, it is permissible to install a gearbox with a capacity of 3 kg/h and higher - the automatic boiler or stove will still not allow “extra” gas to pass through.

0.45 m3 (for propane - butane)

1000 Pa - 1 kPa - 10 mbar

30 mbar - 0.03 bar

Some owners of autonomous gas supply systems make the mistake of purchasing industrial gearboxes instead of household ones, considering them more reliable. Firstly, such devices are an order of magnitude more expensive, and secondly, they are designed to work with more powerful gas equipment, so they are not always compatible with household appliances.

You should also pay attention to the type of thread of the device. Gearboxes designed to work with non-flammable gases are equipped with a right-hand thread, and with flammable gases they have a left-hand thread and a mark on the nut.

Rules for installation and operation of a gas reducer

To connect a propane reducer to gas-using equipment, two methods are used: using a herringbone fitting or using a threaded connection. The first option is considered the simplest and is often used to connect the cylinder to a gas stove. The second method is more reliable and aesthetic, in addition, it allows you to connect one propane tank to several consumers at once.

Whatever option is chosen, during the process of connecting the gas reducer and starting the system, you must adhere to the following instructions:

- Make sure there are no cracks or depressions on the housing, check the integrity of the pressure gauge (if equipped).

- Connect the device to the cylinder (gas holder). For better tightness of the threaded connection, you should additionally use flax or FUM tape.

- Connect the gas line to the outlet pipe of the reducer. When using a herringbone fitting, secure the pipe at the mounting location with a clamp.

- Slowly open the cylinder valve, then turn the tap on the gas consumer.

It is worth noting that the device is intended for use in temperate climates, so its use is permissible at temperatures from -15 to 45 degrees Celsius.

A high-quality household propane stabilizer can last for more than one year without major repairs.

A reducer for a household gas cylinder performs a function comparable to that of a stabilizer in the operation of an electrical system; this device is a stabilizer, but for gas equipment. Its main goal is to reduce the gas pressure coming from a gas pipe or from a gas cylinder to the required value of the equipment to which the blue fuel is supplied.

Read also: Concrete mixer for 120 liters, how much to fill

The next most important function of the gearbox is to automatically maintain the operating pressure at the proper level. Reducers for gas cylinders differ in shape, size, weight capacity, etc. But according to the principle of operation, these devices can be divided into only two types: direct and reverse gearboxes.

The principle of operation of a gas reducer for a cylinder

Direct type gearboxes are designed in such a way that the gas passing through the fitting opens the valve and presses it to the seat using a spring, and high-pressure gas stops entering the chamber. Next, the membrane pushes the valve away from the seat, the pressure gradually decreases, reaching the operating pressure level of the gas appliance to which the reducer is connected.

As a result, the spring straightens, the valve moves away from the seat and ceases to prevent the flow of new volumes of gas fuel. If the pressure begins to increase again, then this spring is again pressed down by the valve and gas does not enter the device.

In reverse-action gearboxes, when gas enters, the valve compresses and prevents it from entering the device. With the help of a special adjusting screw, the pressure spring begins to compress, the membrane bends, the transfer disk presses the return spring, the valve rises, and the gas again moves into the chamber of the device. In the working chamber, the gas pressure increases along with the pressure in the gas pipe or in the cylinder, the membrane is straightened with the help of a spring, the transfer disk moves down, presses on the return spring and, under its influence, the valve is again pressed against the seat. It should be noted that gearboxes of the second type of action, i.e. reverse gearboxes are more popular than direct-acting gearboxes, as they are considered safer.

Features of using gas reducers in everyday life

We know that gases are divided into flammable and non-flammable. At the same time, I would like to remind you that gearboxes for different types of gases do not differ in appearance from each other, and in order to distinguish them, it was customary in the manufacture of devices to make threads for gases with flammable properties - “left”, and for non-flammable gases - “right” .

Gearboxes operating on various types of gas are used in a variety of areas of industry, agriculture, construction, and medicine. For example, oxygen reducers are used in gas welding, cutting, and in the work of medical institutions, and acetylene reducers are used in body work at car service and repair stations.

Propane reducers are used in construction, especially in roofing work, but the main purpose of such reducers is to supply and regulate gas from gas cylinders to gas stoves.

More recently, outdated gas containers have been replaced by new, so-called composite cylinders, which differ from their predecessors in lighter weight and a higher level of safety. New technologies have advanced so much that even if, God forbid, of course, something happens to such a cylinder, then when it explodes you will not even find fragments. Composite cylinders do not rust inside, but their use, of course, places higher-level demands on us. The regulator must ensure constant pressure at the outlet of the composite cylinder and keep it at the operating level. To work with new types of cylinders, regulators that meet European standards are used.

These gearboxes include the A300i-A310i gearbox, which differ from the gearboxes we are used to in the following characteristics:

— the presence of an easily tightened nut; — increased gasket service life to 10 years; - a type of construction that ensures more reliable tightness of connections.

Household reducers for gas cylinders most often have a very affordable price, and considering the role these devices play in ensuring the safety of not only our homes, but sometimes our lives, their cost can be called absolutely acceptable.

When choosing a reducer, it is necessary to take into account all the details: what gas the device will be intended for, what type of gas cylinder will be used, what diameter of the gas hose is needed, etc. For example, it is recommended to purchase a reducer from the same manufacturer as the device itself to which gas is supplied.

Types of gas reducers for gas cylinders and prices

Let's look at some types of regulators for gas cylinders, which are in good demand in the gas equipment market. The RDSG-1-1.2 “frog” device with thread and RDSG-2 “Baltika” without thread have a very simple design and, apparently for this reason, a fairly low price.

Differs in the following characteristics:

— inlet pressure — 0.07-1.5 MPa; - outlet pressure - 2950-3300 mPa; — weight 310 g; — ability to withstand temperatures from -30 to +45 degrees Celsius; — throughput 1.2 m3 of gas per hour.

The price of such a gearbox ranges from 150 to 200 rubles.

The M714 gearbox is made in Italy and costs only 50 rubles more, having:

— inlet pressure 20 bar; — outlet pressure 30 m bar; — has an elastic gasket with a long service life.

— inlet pressure — 18 bar; — ability to adjust pressure from 20 to 60 bar; — the ability to operate the device at temperatures from -20 to +50 degrees.

The cost of the gearbox is about 1000 rubles.

Gearbox BPO-5 (miniature).

— inlet pressure 2.5 Pa; - outlet pressure - 0.3 Pa; — weight only 650 g.

— inlet pressure -20 mPa; — working pressure - 0.8; — weight 2 kg; — throughput capacity 25 m3 of gas per hour. Gearbox BKO-50:

— inlet pressure 20; — working pressure 1.25; — weight 2.1 kg; — throughput capacity 50 m3 of gas per hour.

— inlet pressure 20 MPa; — working pressure 1.25; — weight 2.1 kg; — throughput capacity 80 m3 of gas per hour.

— inlet pressure — 20 MPa; — working pressure — 1.6; — weight 13 kg; — throughput capacity 250 m3 of gas per hour.

— inlet pressure 20 MPa; — working pressure 1.6; — weight 13 kg; — throughput capacity 500 m3 of gas per hour.

Do not forget that each type of household gas cylinder reducer is designed not only for a specific purpose, but also for a specific gas. If the documents for the device indicate the word “propane”, then this reducer cannot operate on methane. Following these simple rules will ensure not only an uninterrupted supply of gas from the cylinder to the gas appliance, but will also preserve your health, and maybe even your life.

How to choose a reducer for a household propane cylinder

To select a propane reducer for a gas cylinder, it is necessary to study and compare their characteristics. The most significant are:

- Purpose.

- Maximum inlet pressure, kg/cm3.

- Working pressure, kg/cm3.

- Maximum gas consumption, m3/hour.

- Connection standard.

- Planned service life.

- Price.

Depending on the planned application and the planned type of cylinder, one or another model may be the best choice. So, for example, if you plan to connect a tabletop gas stove in a garden house that you visit on weekends (or take it on a boat trip) and estimate your monthly gas consumption to be five liters, a five-liter cylinder and a Baltika RDSG-2 gas reducer are best suited.

Gearbox Baltika RDSG-2

For a stationary stove with an oven, you will already need a cylinder with a capacity of 27 or 50 liters and, accordingly, a Frog RDSG-2 gearbox.

If you want to connect a composite cylinder to a thermal umbrella, and both the cylinder and the umbrella have European connectors, then it makes sense to consider imported gas reducers with a KLF connector, for example, produced by the German company GOK.

If you plan to carry out gas welding in a home workshop, then a professional gas reducer BPO 5-3 Krass would be a good choice. It provides a maximum flow rate of up to 5 m3 per hour and the ability to regulate operating pressure up to 0.4 MPa. To do this, it is equipped with an adjusting flywheel and a pressure gauge, which allows you to more accurately set the operating pressure in accordance with the needs of the gas welding torch or cutter.

Types of gas reducers

From the school course, the concept of non-flammable – inert gas – comes to mind. This broad group includes nitrogen, argon, helium, neon, etc. they do not support combustion and do not burn. It is widely used as a shielding gas during welding. On the other hand, there are flammable gases (butane, hydrogen, methane, propane, propylene, etc.), which either liquefy or compress and then move their cylinders. So, in order to prevent confusion, engineers, even at the production stage, suggested cutting versatile threads.

Thus, a gas reducer intended for use in the group of flammable gases is manufactured with a left-hand thread. The opposite thread turning to the right provides a gas reducer for inert gases. Among other things, manufacturers use color dyeing to promote brighter highlighting.

Before buying a gas reducer for a cylinder, we advise you to pay attention to the throughput of the device. The optimal solution would be to buy a 2nd generation gas reducer. Before making a purchase, you must make sure that the selected model meets the gas flow parameters sufficient for the consuming device.

Application

Gas reducers are widely used in households and private households. They are operated on all types of gas and are used in a wide variety of industries. Gas reducers can be found in agriculture, in the construction industry, in medical institutions, and simply in a country house.

For example, an oxygen reducer is used both in welding work and in providing medical care. As for acetylene gas reducers, you can find them in any mechanic shop.

Propane reducers are indispensable during construction work; you cannot do without them in activities related to laying roofing and bitumen materials. A gas reducer for a propane cylinder has become not a luxury, but a necessity; with its help, millions of housewives regulate the pressure coming from the cylinders to the gas stoves. A propane reducer often has a funny name, and if you ask in a store whether you can buy a frog reducer for a gas cylinder, then rest assured, the seller will perfectly understand your request.

Precautionary measures

Household gas is very dangerous. The main threats posed by propane are:

Reminder about domestic gas

- Fire hazard.

- Unsuitable for breathing.

- Explosion hazard when the maximum concentration of propane in the air is reached, as well as when the temperature in a closed volume rises sharply.

- During a gas leak, the temperature drops sharply and frostbite is possible.

To preserve the life and health of people and their property, precautions should be taken:

Rules for using gas

- Avoid proximity to open flames and heat sources.

- Avoid the presence of other flammable materials in the work area.

- Eliminate the presence of nitrates and perchlorates near gas equipment due to their chemical activity.

- Do not use the reducer for a propane cylinder if it is damaged or leaking.

Design features and maintenance

According to their design, gearboxes differ into direct and reverse acting devices. The differences between them are in the design details, the performance characteristics are identical.

Design of gearboxes for a gas cylinder

In addition, gas reducers are used in single-stage and two-stage types. In single-stage, the pressure is reduced in one stage. In a two-stage reduction, the reduction is carried out in two steps. Balloon single-stage reducers are most widely used due to their reliable design and ease of use.

Diagram of direct and reverse acting devices

Direct-type devices have the following operating scheme: propane entering the high-pressure zone presses the valve away from its seat. Propane enters the working chamber, filling it and increasing the pressure in it. It acts on the membrane, compressing the main spring. The membrane goes down, pulls the stem and closes the valve when the operating pressure value is reached. During the use of propane, the pressure in the working chamber drops, high-pressure propane opens the valve again and gas enters the working area again.

Direct action gearbox diagram

In reverse type devices, the valve is opened by the main spring, overcoming the force of the high pressure gas. After the working area is filled and the pressure reaches the set value, the rod moves down, closing the valve. As propane is used, the pressure in the working area decreases and the spring opens the valve again.

Reverse gearbox diagram

Reverse-acting devices are considered more reliable and safe. They have gained popularity in household and professional applications.

How does a cylinder reducer work:

1 Direct gearbox

An ordinary simple gas pressure reducing device consists of two chambers with an area of high and low pressure, separated by a rubber membrane. In addition, the “reducer” is equipped with an inlet and outlet fitting. Modern devices are designed in such a way that the bellows connection is screwed directly into the gearbox. Increasingly, you can find a gas reducer with a third fitting intended for mounting the monomer.

Read also: The meaning of the transition from copper to bronze

After gas is supplied through the hose and then through the fitting, it enters the chamber. The created gas pressure tends to open the valve. On the reverse side, a shut-off spring presses on the valve, returning it back to a special seat, popularly called a “saddle.” Returning to its place, the valve prevents the uncontrolled flow of high-pressure gas from the cylinder.

Membrane

The second acting force inside the gearbox is a rubber membrane that divides the device into high and low pressure areas. The membrane acts as an “assistant” to high pressure and, in turn, tends to lift the valve from the seat, opening the passage. Thus, the membrane is between two opposing forces. One surface is pressed by a pressure spring (not to be confused with the return spring of the valve), which wants to open the valve, on the other hand, the gas that has already passed into the low pressure zone presses on it.

The compression spring has manual adjustment of the pressure applied to the valve. We advise you to buy a gas reducer with a seat for a pressure gauge, this way it will be easier for you to adjust the spring pressure to the desired output pressure values.

As the gas leaves the reducer to the source of consumption, the pressure in the working space chamber decreases, allowing the pressure spring to straighten. She then begins to push the valve out of the seat, again allowing the device to be filled with gas. Accordingly, the pressure creeps up, pressing on the membrane and reducing the size of the pressure spring. The valve moves back into the seat, narrowing the gap, reducing the gas filling of the reducer. The process is then repeated until the pressure equalizes to the set value.

It should be recognized that gearboxes for direct type gas cylinders, due to their complex design, are not in high demand; reverse type gearboxes are much more widespread; by the way, they are considered devices with a high degree of safety.

2 Reverse gearbox

The operation of the device consists of the opposite action described above. Liquefied blue fuel is supplied to a chamber where high pressure is created. The bottled gas accumulates and prevents the valve from opening. To ensure gas flow into the household appliance, you need to turn the regulator in the direction of the right-hand thread.

On the back of the regulator handle there is a long screw, which, when screwed, presses on the pressure spring. As it contracts, it begins to bend the elastic membrane to the upper position. Thus, the transfer disk, through the rod, exerts pressure on the return spring. The valve begins to move and begins to open slightly, increasing the gap. Blue fuel rushes into the gap and fills the working chamber with low pressure.

In the working chamber, in the gas hose and in the cylinder, the pressure begins to increase. Under the influence of pressure, the membrane is straightened, assisted in this by a constantly compressed spring. As a result of mechanical interactions, the transfer disk lowers, weakening the return spring, which tends to return the valve to its seat. By closing the gap, the flow of gas from the cylinder into the working chamber is naturally limited. Then, with a decrease in pressure in the bellows liner, the reverse process starts.

In a word, as a result of checks and balances, the swing can be balanced and the gas reducer automatically maintains balanced pressure, without sudden jumps and drops.

Periodic inspection and service work

Inspections and service work are divided into daily and periodic.

Leak test

Daily inspections are required before starting work. Periodic checks are usually carried out in specialized workshops. For gearboxes equipped with a filter, the work includes cleaning or replacing it

Typical faults and their repair

Deviation of the operating pressure from the specified one can be caused by the following reasons:

- Spring breakage or displacement.

- Depressurization of the housing.

Gas leakage is caused by:

- Membrane damage.

- Depressurization of the housing.

- Valve failure.

Some gearboxes are made collapsible. They are, in principle, available for self-repair. Non-separable gas reducers, of course, in the event of a malfunction must be replaced entirely.

Important! Remember that when disassembling the gearbox, you accept full responsibility for the consequences of its use.

So, for example, a home craftsman who has basic plumbing skills is quite capable of replacing a spring or membrane in an unregulated “Frog” gas reducer. A housing with a damaged seal cannot be repaired. In this case, the entire device will have to be replaced.

After replacing damaged parts with new ones from the repair kit and assembling the gas reducer, it is necessary to check its tightness using a soap solution.

System connection standards

Devices that support two standards for connecting the reducer to a gas cylinder are widespread:

- GOST - common in the CIS countries, used on locally produced steel cylinders.

- GLK is a European standard, used primarily on composite cylinders.

Connecting the reducer to the gas cylinder

To connect the working pipe:

- Threaded connection.

- Nipples 6.3 or 9 mm.

- Universal nipple.

- GLK.

Some gas reducers, for example, RGDS, are equipped at the factory with a 9 mm nipple pressed into the housing.

Reducers with adjustable operating pressure are equipped with a threaded half-inch outlet, which can optionally be secured with a union nut and a universal nipple.

It is safer to use devices that match the standard. Each adapter is an additional connection that increases the risk of gas leakage.

Installation and startup procedure

In order to ensure fire safety, the following procedure for installing and starting up the equipment should be observed:

- Carry out a thorough external inspection of the container, gas reducer and pipelines and ensure that there are no visible defects or excessive heat.

- Connect the reducer to the gas cylinder.

- Connect the consumer device to the gearbox

- Open the cylinder valve slightly and listen.

- Open the gearbox valve (if present).

- Open the valve of the consumer device and start using it.

If there is a whistling or clicking noise, immediately close the gas cylinder valve.

Required pressure and volume

The key characteristics of a gas reducer are inlet pressure, operating pressure and flow rate, or the maximum volume of gas passing through the device in an hour.

The inlet pressure is determined by the standard pressure in the cylinders and is usually 20 MPa.

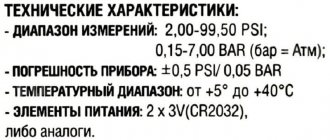

Technical characteristics of gearboxes

The operating pressure for household unregulated gas reducers is set at 0.3 MPa ±5%

For adjustable semi-professional and professional adapters, the operating pressure is set by the user in the range of 0-0.4 MPa, and for certain high-performance models - up to 1.6 MPa

The consumption volume must exceed the volume consumed by the device (or group of devices) per hour.

Reducers for household gas cylinders

The stabilization function implies maintaining gas pressure within the range of operating values for the safe operation of gas stoves. They can be classified according to the following criteria:

- along the gas mixture - forward, reverse;

- if possible, regulation – regulated, unregulated;

- according to the regulation range - input - 2-3 MPa, output - 0.3-1.5 MPa;

- by connection method - fitting, nipple;

- by capacity;

- according to the presence of indication - with a pressure gauge, without a pressure gauge.

Also, due to design features, they have a variety of shapes, materials from which they are made, weight, and color.

Adjustable reducer for gas cylinder

Adjustable gas reducers operate on the same physical principles as non-adjustable ones and have a similar design. The difference is that the compression force of the reducing spring supporting the membrane can be changed using an adjusting screw coaxial with the spring in the simplest models, or using a flywheel and a more complex mechanical transmission.

Adjustable reducer for gas cylinder

The principle of operation is that by changing the pre-compression force of the reduction spring, the user changes the threshold gas pressure in the working chamber required to operate and close the intake valve. A pressure gauge is also added to the parts, installed on the working pipe and allowing you to visually monitor the result of the adjustment.

Reducer for gas cylinder

Since we are choosing a reducer for a gas cylinder, we consider it necessary to touch upon the topic of the container itself. The technological process and widespread introduction of new innovative materials are bearing fruit. You can increasingly find new composite cylinders on the market, replacing the old generation. Modern models, unlike outdated predecessors, have less weight and offer a greater level of safety. The latest manufacturing technologies undergo multi-level testing; at testing sites, the composite cylinder is subjected to an explosion, but even after such tests you will not find small fragments.

Composite cylinders are not subject to internal corrosion, are lightweight and comfortable. However, they do not know how to supply gas evenly on their own. A filled cylinder, of course, produces more powerful pressure than a half-empty one. A gas regulator will come to the rescue; its task is to regulate the pressure at the outlet of the composite cylinder and maintain it at the required level throughout the entire period of use.

Gas pressure reducers that have passed European certification demonstrate good collaboration with composite cylinders. Let's highlight one of these devices: the household gas reducer A300i-A310i IGT. The positive aspects include the following characteristics of the product:

- the presence of a nut that can be tightened by hand;

- service life of the control membrane increased to 10 years;

- the design ensures maximum sealing of the connecting elements;

- the gas hose on a fitting without a thread is clamped with a clamp.

Despite the fact that the importance of the device in creating conditions for the safe operation of a stove or other device is difficult to overestimate, household reducers for gas cylinders are usually sold at an acceptable cost. Despite the fact that the price rarely exceeds 300-400 rubles, these devices can protect not only your home, but also your life from dangerous situations.

Choosing a gas pressure reducing device is not a complicated process, but you should know and take into account such details as:

- The name of the gas passing through the device;

- Characteristics of the cylinder;

- Dimensions, type of flexible gas supply;

- Required flow and outlet pressure;

- Connection method.

General rules for choosing a balloon reducer

Summarizing the rules for choosing a gearbox for a gas cylinder, it should be noted that:

Classification of reducers for gas cylinders

- it is necessary to sketch out a diagram of the planned system from the gas cylinder to the end user;

- clearly formulate the following requirements for the device:

- Purpose.

- Operating pressure.

- Need for adjustment.

- Maximum volume.

- Method of connection to a gas cylinder and to a working device.

- Availability of maintenance and repair.

- Allotted budget.

- From the variety of products on the market, you should choose those that meet the stated requirements.

- Next, you need to enter the models and their characteristics into the comparison table and conduct a price analysis.

If devices that meet the stated requirements do not fit within the allotted budget, then it is necessary to either revise the budget or simplify the requirements for the device.

Gas reducers for gas cylinder, price and types

Let's try to choose a reducer for gas cylinders, from those popular types that are in greatest demand among consumers. Let’s take a look at the gas appliance market and find out what the price for a gas reducer for a cylinder was at the end of 2017.

Household gas reducer RDSG for propane stabilization

The leading position in the market, and among consumers in the country, is occupied by the RDSG-1-1.2 “Frog” device with a threaded fastening. The RDSG-2 Baltika gearbox equipped with a threadless connection is not inferior in popularity. Both leaders represent the simplest design. As a result, they can offer the lowest possible cost. Specifications: — inlet pressure from 0.7 to 15.7 Bar; — the output pressure lies in the adjustment range from 30 to 32 mBar; — device weight 310 g; — permissible operation in the range from -30 to +45 ±3 °C; — gas throughput characteristic — 1.2 m3/hour. You can buy a gearbox RDSG 2-1.2 Baltika or RDSG 1-1.2 Frog for up to 350 rubles.

| Inlet pressure | Outlet pressure | gas throughput m3/hour | Weight gr. | Price, rub. | |

| Gearbox M714 | 0 – 20 Bar | 30 mBar | 0,5 | 250 | up to 500 |

| Gearbox N240 | 20 – 60 Bar | 18 mBar | 0,5 | 400 | up to 2000 |

| Gearbox BPO-5 | 2.5 MPa | 0.3 MPa | 5 | 700 | up to 1000 |

| Gearbox BKO-25 | 20 MPa | 0.8 MPa | 25 | 1200 | up to 1200 |

| Gearbox BKO-50 | 20 MPa | 1.25 MPa | 50 | 1450 | up to 1500 |

| Gearbox BVO-80 | 20 MPa | 1.25 MPa | 80 | 2100 | until 1700 |

| Reducer RKZ-250 | 20 MPa | 1.6 MPa | 250 | 6700 | up to 17,000 |

| Reducer RKZ-500 | 20 MPa | 1.6 MPa | 500 | 8300 | until 23,000 |

It remains to add that the gas reducer is not a universal device. Each model can only run on one specific gas fuel. Before purchasing, carefully check your documents and passport details. Each gearbox has its own purpose and some of them are designed for propane, others for methane, others for argon and so on. They are not interchangeable, so be careful.

Compliance with simple safety rules will preserve your property, health and ensure a stable supply of gas from the cylinder to your device. Due to the low price of household appliances, we advise you to give preference to trusted manufacturers with a reputation as a reliable supplier.

Do not connect your device “directly”; the results of such a connection will most likely turn out to be an unexpected problem for you. Handle with special care cylinders containing compressed gas (pump it under a pressure of 250 bar). The price for the “Frog” is not at all expensive, so you can save money on this. It is much more prudent to acquire it than to spend money later on eliminating the consequences of the disaster.

We offer a video review of the device:

As is known, liquefied hydrocarbon gas (propane-butane) is stored in cylinders or gas tanks under a pressure of several bar. To reach the operating parameters of consumers (30-50 mbar), a special device is used in autonomous gas supply systems for private facilities - a household propane reducer . If we draw an analogy with an electrical network, this device acts as a stabilizer, that is, it reduces the pressure to the required value and automatically maintains it at the same level.