What the article is about:

What is MIG-MAG welding and how does it stand for?

There are different types of welding, much depends on the technology and consumables. MMA is manual arc welding using coated electrodes. TIG - argon arc welding with a non-consumable electrode, most often tungsten.

MIG and MAG - semi-automatic welding in a protective gas environment. Unlike arc welding, there are two designations here. MIG welding is semi-automatic welding using inert gas, and MAG welding is also semi-automatic welding, where active gases, such as carbon dioxide or nitrogen, act as a protective medium.

What does TIG, MIG, MAG stand for?

TIG welding - stands for: Tungsten Inert Gas , welding in an inert gas environment with a non-consumable electrode.

MIG and MAG welding - stands for: Metal Inert/Active Gas , that is, arc welding in a protective environment of active or inert gases.

The semi-automatic method of welding metals is recognized as the most effective and versatile. It is most widely used for industrial purposes, but this type of welding is often used for domestic use.

This is all thanks to the fact that mobile inverter semi-automatic machines have appeared on the market, which, in addition to the MIG and MAG modes, are also capable of supporting MMA welding.

Progress of welding machines

Modern welding technologies with the index MIG, MAG, TIG are among the most modern methods of arc welding and at this stage of development of the world industry are used literally everywhere. A novice welder does not always know what MIG/MAG welding is. The definition of this process is as follows: this is the process of joining parts of metals, in which a special protective gas is supplied to the burning zone of an electric arc, pushing atmospheric gases out of the zone of the metals being welded. This is the protective function of gas. In MIG welding, the weld pool is completely protected from oxygen and nitrogen.

What is semi-automatic MIG/MAG welding?

Unlike a conventional MMA inverter, which welds exclusively with a coated consumable electrode, the operating principle of semi-automatic welding is somewhat different. The main consumables here are shielding gas and wire, which is wound on a reel and fed automatically when the semi-automatic machine is operating.

During welding, the wire passes through a gas gun. At the moment the arc appears, it melts and fills the weld pool with molten metal. The gas, which is also supplied along with the wire, protects the molten metal from the negative effects of the environment.

Due to the fact that the entire welding process is practically automated, this welding received such a consonant name - semi-automatic. Unlike manual arc welding, there is no need to change the electrode every time. There are also no many other operations, without which the process of welding parts with an electrode cannot take place.

Peculiarities

Semi-automatic MIG MAG welding is effective only if all rules are followed and all features are taken into account. We will talk about some of them further.

Selecting a device

First, a little about the equipment. MIG MAG welding machines perform specific tasks, so you need to choose a welder with special attention. First of all, pay attention to what current the device operates on: direct or alternating. We recommend purchasing a DC device and installing reverse polarity when performing work.

A semi-automatic welding machine using alternating current or direct current and straight polarity is not capable of generating a stable welding arc. Under such conditions, it is difficult to form a weld because the filler wire melts too quickly and the metal spatters.

Also pay attention to additional functionality. Many MIG/MAG welding machines can also perform MMA or MMA and TIG welding. Such welders are universal and significantly increase your capabilities when carrying out work. You don't need to have several different devices when all the functions are in one.

Selecting consumables

Now about consumables. First about the wire. Its diameter is selected based on the thickness of the metal you are going to weld. The composition of the wire must be identical to the composition of the base metal. Copper wire cannot be used for welding stainless steel. This is a grave mistake.

As for the shielding gas, everything is not as complicated as it might seem at first glance. You can use inert, active gas or gas mixtures. We will give several recommendations regarding the choice of shielding gas when welding various metals.

For welding non-ferrous metal and its alloys, as well as non-ferrous metal-based materials, it is best to use inert gas. This can be helium, argon or gas mixtures of argon and helium in various proportions. If you are boiling copper and cobalt, use nitrogen gas. When working with various types, it has become better to use carbon dioxide (carbon dioxide). But keep in mind that in this case the wire must contain an increased amount of silicon and manganese.

Experienced welders also use mixtures of inert and active gases to improve arc stability and reduce metal spatter. This is a very specific topic that comes with experience. So in this article we will not touch on the topic of a mixture of inert and active gas.

Seam formation

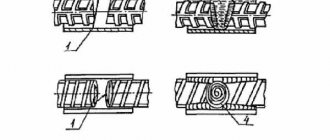

When MIG/MAG welding, it's not just the welding machine and consumables that are important, but also how you form the weld. As we already wrote above, with this welding method, the seam is formed thanks to molten metal and molten wire. Therefore, the shape of the finished weld bead depends on how you transfer the molten wire into the weld pool.

Pros and cons of semi-automatic welding

The advantages of semi-automatic welding are obvious, and first of all, it is the high speed of welding work. The length of the welding wire is large, and the volume of gas in the cylinder is also large. Thanks to the automatic supply of wire to the welding site, the speed and scale of welding work increases significantly.

The second plus is associated with a very neat and smooth weld seam. It is impossible to obtain such a seam using manual arc welding, just as it is impossible to effectively weld very thin metal. Semi-automatic welding is the best way to weld thin-walled workpieces, the thickness of which does not exceed 0.5 mm.

The only disadvantage of semi-automatic welding is the need to have shielding gas in a cylinder on hand. It goes without saying that the cylinder needs to be refilled and transported to the welding site, which is not very convenient or simple.

In addition, in some places it is not possible to deliver the cylinder at all. Then semi-automatic welding is carried out using flux-cored wire.

Prospects for welding technologies

In this article, we got acquainted with the main types of welding, which are popular and in demand at the moment in most large industries and in technological chains. Today, MIG welding, TIG technologies, stick electrode welding, etc. are mainly used. However, we have not mentioned the automatic joining methods used in industry.

If we delve into the world of technologies that are at the development stage, we can trace the tendency towards synergetic control schemes, when setting a parameter on automatic systems, for example, the thickness of the metal being welded, sets the corresponding wire feed speed, welding current and other parameters. This greatly increases work comfort and production efficiency. Among other things, now, in the 21st century, welding is an independent type of production and contributes to the creation of fundamentally new structures. Welded parts serve at ultra-high and ultra-low temperatures, at pressures, and are capable of operating even in the vacuum of space.

Modern technologies in the field of welding make it possible to work even with plastics, glass, ceramics and other materials. Recently, welding has even been used to connect soft living tissues. Therefore, this profession will develop, improve and remain as in demand as throughout the history of man and progress. And the work of such specialists will and will remain important and necessary.

Application to non-ferrous metals

The following widely used types of melting wire can be used in semi-automatic MIG welding devices:

- aluminum;

- steel (for welding stainless steel);

- powder type;

- with special copper coating.

The last two varieties are in greatest demand among professional welders because they are very easy to use and have a relatively low price.

In addition, their use guarantees high MIG welding speed without the formation of large amounts of spatter. Particularly popular is the so-called “cored” wire, made in the form of a flexible tube filled with filler powder.

To weld aluminum using MIG technology, a special type of wire is used that contains powdered antioxidant compounds (ferroalloys, mineral additives and other complex compounds). This composition of the melting component makes it possible to do without gas, the role of which is played by the powder mixture melting in the arc.

Its main difference from the coated electrode used in MMA technologies is the absence of harmful fumes, which require special protective equipment to protect against..

Another important point regarding the direct use of flux-cored wire is the need to protect it from severe deformation. The fact is that a broken or damaged wire product is no longer suitable for further use.

Flux-cored wire is also quite suitable for welding using MAG technology, especially since in a carbon dioxide environment it ensures a soft and stable arc. The remaining types of melting components listed above are also intended for use in inert or carbon dioxide environments.

When purchasing this product, you should check with the seller about its compatibility with certain types of metals (alloys), and also decide on the types of tips for this category of products.

Current and voltage

According to most experts, it is more expedient to weld metal workpieces using the MIG method with arc supply voltages of no more than 19-30 volts, the exact value of which is selected depending on the model of the welding unit in question.

On modern semi-automatic machines, the current and voltage are most often not regulated, which is explained by the presence of a built-in system for automatic stabilization of the arc discharge.

For this type of welding, the main emphasis is on a well-chosen proportion of the wire diameter and a fixed value of the welding current.

In practice, universal semi-automatic MIG/MAG units are usually used, designed to work not only with inert gas, but also with carbon dioxide.

Thanks to this, the capabilities of such devices are significantly expanded, which primarily concerns the choice of current adjustment range and the use of various modifications of the welding wire.

Data on the proportions of the main operating parameters of MIG welding can be found in the table.

Advantages and disadvantages

The MIG welder is often criticized for being bulky. You can’t just hang it on your shoulder; you’ll have to carry a huge gas cylinder and other components with you. You will not be able to quickly move from one point to another unless you install the entire set of equipment on a special cart.

But, despite this, instant welding has many advantages that more than offset the disadvantages. For example, during operation no dangerous fumes are emitted, the arc is quite easy to ignite (beginners will appreciate this plus), the wire is consumed very economically, and it is possible to weld almost any metal of any thickness.