Oxygen cylinders

Figure 2 - Acetylene cylinder

The maximum acetylene pressure in the cylinder

is 3 MPa. The pressure of acetylene in a fully filled cylinder changes with temperature:

The pressure of filled cylinders should not exceed

at 20°C 1.9 MPa.

When the valve of the cylinder is opened, acetylene is released from the acetone and enters in the form of a gas through the reducer and hose into the burner or cutter. Acetone remains in the pores of the porous mass and dissolves new portions of acetylene during subsequent fillings of the cylinder with gas. To reduce acetone losses during operation, it is necessary to keep acetylene cylinders in a vertical position. At normal atmospheric pressure and 20°C, 28 kg (l) of acetylene are dissolved in 1 kg (l) of acetone. The solubility of acetylene in acetone increases approximately in direct proportion with increasing pressure and decreases with decreasing temperature.

To fully utilize the cylinder capacity, it is recommended to store empty acetylene cylinders in a horizontal position

, as this promotes uniform distribution of acetone throughout the entire volume, and with tightly closed valves. When acetylene is removed from the cylinder, it carries away some of the acetone in the form of vapor. This reduces the amount of acetylene in the cylinder during subsequent fillings. To reduce the loss of acetone from the cylinder, acetylene must be withdrawn at a rate of no more than 1700 dm 3 /h.

To determine the amount of acetylene

the cylinder is weighed before and after filling with gas and the amount of acetylene in the cylinder in kg is determined from the difference.

Weight of empty acetylene cylinder

consists of the mass of the cylinder itself, the porous mass and acetone. When taking acetylene from a cylinder, 30-40 g of acetone per 1 m 3 of acetylene is consumed along with the gas. When removing acetylene from a cylinder, it is necessary to ensure that the residual pressure in the cylinder is at least 0.05-0.1 MPa.

Use of acetylene cylinders

instead of acetylene generators,

it provides a number of advantages

: compactness and ease of maintenance of the welding installation, safety and improved working conditions, increased productivity of gas welders. In addition, dissolved acetylene contains fewer impurities than acetylene obtained from acetylene generators.

The reasons for the explosion of acetylene cylinders can be sudden shocks and impacts, strong heating (over 40°C).

Cylinders for propane-butane are produced

according to -84 welded from sheet carbon steel.

The main application was found in cylinders with a capacity of 40 and 50 dm 3. Propane-butane cylinders are painted

red with the word “propane” written in white.

The propane-butane cylinder is

a cylindrical vessel 1, to the top of which the neck 5 is welded, and to the bottom - the bottom 2 and the shoe 3. A brass valve 6 is screwed into the neck. Backing rings 4 are pressed onto the cylinder body. A cap 7 is used to protect the cylinder valve.

The cylinders are designed for a maximum pressure of 1.6 MPa. Due to the high coefficient of volumetric expansion, cylinders for liquefied gases are filled to 85-90% of the total volume. Cylinder filling rate

for propane - 0.425 kg of liquefied gas per 1 dm3 of cylinder capacity. 24 kg of liquid propane-butane is poured into a cylinder with a capacity of 55 dm3. The maximum gas extraction should not exceed 1.25 m 3 /h.

Standard sizes of a gas cylinder 50l

50-liter gas cylinder - its dimensions are standard. The height is 96, and the width in diameter is 29.9 cm. The thickness of the steel wall is 3 mm, and the weight is 22 kg. For cylinders of similar volume, the working pressure is up to 1.6 MPa (kg/cm2). Well suited for gas transportation, storage, and for work in bulk production.

40 liter gas cylinder and its dimensions

40 liter gas cylinders have the same diameter as 50 liter ones, but their height is different, and can reach 146 cm. It is also used for storage, transportation and large-scale work.

The working pressure in 40 liter cylinders can vary and be, in addition to 1.6 MPa (kg/cm2), also 1.47 MPa (kg/cm2). Gas containers with a volume of 27 liters are considered convenient and are used in everyday life. The height of the container is 59 cm with a diameter of 29.9 cm, which is convenient for location in the kitchen when a gas cylinder is connected to the stove.

The operating gas pressure in a 27-liter cylinder, as in a 50-liter cylinder, is 1.6 MPa (kg/cm2), which is standard for all household gas vessels.

The weight of an empty cylinder of 14.5 kg will not be an obstacle to its movement, but it is important to remember that it is better to immediately give the empty cylinder to a gas station than to store it at home.

Dimensions of household gas cylinders

Household gas cylinders vary in gas volume capacity and can be: 2, 12, 27 and 50 liters. The diameter of 5 and 12 liter cylinders is 22.2 cm. The height varies and depends on the capacity: 5 liter - 28.5 cm, and 12 liter - 48.5 cm. And since the gas cylinder has different dimensions, the weight of the empty container will be different. A 5 liter vessel weighs 4 kg, and a 12 liter vessel weighs 6 kg. Such small containers are very convenient for summer residents. They do not need to heat the house all year round, and for the cooking season these are quite suitable volumes.

Dimensions of gas cylinders for cars

One of the requirements for a car gas cylinder was initially that it be compact and that it could easily fit into the trunk. The developers took this requirement into account, and as a result, they produced gas tanks for cars with a length of 66.5 to 121.5 cm, and a diameter of 35.6 cm. The displacement of automobile gas vessels ranges from 50 to 100 liters, which allows you to drive without refueling not one day.

Dimensions of toroidal gas cylinders - new items on our market

There are also toroidal gas cylinders on the Ukrainian market, which are used to equip cars, and their shape fits very well into the spare wheel compartment, saving space in the trunk of a car. Their capacity ranges from 40 to 42 liters, and their dimensions are on average 60x20 cm.

Dimensions of new 40 liter gas cylinders sold by our company

- cylinder diameter, mm 232;

- capacity, l 40;

- height, mm 1350.

Source: https://ballony.com.ua/razlichnye-razmery-gazovyx-i-bytovyx-ballonov-i-oblast-ix-primeneniya.html

DIY valve replacement guide

Before installing the valve, it is necessary to thoroughly degrease the connecting surfaces using rags treated with dishwashing detergent or solvent. Next, the surface is washed with clean water and allowed to dry.

Unscrewing the valve from the gas cylinder

Valve replacement algorithm:

- The connection is sealed by winding the tape with tension in 4-5 layers; it is better to tighten it than to make a loose connection.

- The old tap is removed again, and the cylinder is purged again. Before changing the valve, a special sealant or fum tape is applied to the threads. The thickness of its layer for gas connections differs from plumbing and is 0.1 - 0.25 mm, and its coil is yellow.

- Reinstall the old faucet, remove the old paint and give it a fresh coat of paint.

- The vessel is thoroughly purged with compressed air and inspected from the inside with a flaw detector.

- Drain the remaining condensate away from people, as it has an unpleasant odor.

- The vessel is laid on the ground, one master holds the body so that it does not rotate, and the other, using a gas wrench with an extension pipe, holding the square edges of the gas cylinder valve, unscrews it. It will be difficult to make only the first 1-2 turns, then it twists easily “by hand”.

- The valve warms up to 65 with a construction hair dryer to remove old paint, on the screw thread of the cylinder.

- With the old valve closed, check for leaks.

- Before replacing, check the vessel for corrosion or mechanical damage.

- The valve is closed with a torque wrench. The indicator for fittings made of brass is 250 Nm, and for steel – 480 Nm.

- Allow the sealant to cure for 3 days.

- The cylinder is taken to a specialized organization for testing, for example, in Moscow. The company must be included in the certification bodies in the unified state register of organizations that have the right to carry out this type of work.

Gas cylinder with valve turned off

Mandatory Precautions

Before replacing the gas cylinder valve, precautions must be taken. Work must be carried out in such a way as to protect people from potential hazards and keep the equipment in working condition.

The following precautions are used when preparing to replace a gas valve:

- The remaining contents of the cylinder can only be vented in an open space. An exception can be made only for nitrogen, air and argon.

- The work area should be well ventilated, although it is advisable to carry out work outside.

- There should only be one closed gas cylinder within the workplace.

- The flywheel must be unscrewed slowly to prevent electrification.

- You can begin replacing the valve only after the pressure in the cylinder and outside has been completely equalized.

When screwing the valve into the cylinder, fum tape or special lubricants are used, which provide increased tightness and strength of the connection. When replacing a faucet, such seals greatly complicate the process of dismantling it. To solve this problem, you can heat the valve with a hairdryer.

You can heat the shut-off valves only after bleeding the gas from the cylinder and closing the tap. In this case, the procedure is safe and will not lead to unpredictable situations.

An alternative to a hairdryer is to wrap a cloth around the valve and then pour boiling water over it. With this heating method, any suitable plug should be screwed onto the outlet fitting to prevent water from entering there.

After taking all precautions and warming up the shut-off valves, you can begin to unscrew the valve, which can be a difficult task at home. If, in addition to replacing the cylinder shut-off device, you also need to replace the valve installed on the gas pipeline, we advise you to study the procedure and rules for performing this work

If, in addition to replacing the cylinder shut-off device, you also need to replace the valve installed on the gas pipeline, we advise you to study the procedure and rules for performing this work.

Reducer for propane cylinders

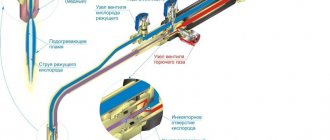

Bottled gas is used for welding work. However, it is worth considering that the pressure in the cylinder is quite high. For various jobs it should be reduced. To adjust this value, use a gas reducer:

- Direct and reverse acting gearboxes are separated. When using the former, the pressure in the cylinder and the operating indicator decrease. Reverse-acting gearboxes operate on a different principle. When using them, the fuel pressure in the cylinder first decreases, and then the working pressure.

- Depending on the installation features and location, gearboxes are divided into network, balloon and ramp gearboxes. The latter are used to reduce and maintain gas pressure from one source at the required level. If you need to perform a large amount of welding work, you should choose a ramp reducer. They are capable of reducing the pressure of gas coming from several sources at the same time.

- Depending on the type of gas, there are gearboxes that work with different types of fuel - oxygen, acetylene, metal, propane-butane. Acetylene should be fixed with a clamp at the stop screw. To connect other types, a union nut is used. Be sure to take into account that the thread of the nut must match the thread of the fitting at the valve.

- Based on the color of the housing, gearboxes are divided into groups depending on the type of gas to which they belong. Gearboxes with a red housing are designed for propane.

- Based on the type of gearbox, devices for working with non-flammable and flammable gases are distinguished.

Before purchasing a gearbox, it is important to understand the above characteristics.

How many cubic meters of gas are in a standard household propane tank?

Here you can also find out how much a 5, 12, 27, 50 liter propane cylinder weighs.

| Volume | 5 liters | 12 liters | 27 liters | 50 liters |

| Empty cylinder weight, kg | 4 | 5,5 | 14,5 | 22,0 |

| Propane tank weight, kg | 6 | 11 | 25,9 | 43,2 |

| Mass of stored gas, kg | 2 | 5,5 | 11,4 | 21,2 |

| Cylinder height, mm | 290 | 500 | 600 | 930 |

| Cylinder diameter, mm | 200 | 230 | 299 | 299 |

What is the thread on a propane tank?

Valves of the VB-2 type are installed on most household cylinders for propane-butane mixture. These shut-off devices are manufactured in accordance with GOST 21804-94 and are designed for pressures up to 1.6 MPa. The tap has a left-hand thread SP21.8-1 (6 turns), which allows you to connect any gearboxes with a union nut and a similar thread.

The valve provides a strong connection to the neck, complete tightness, has clear markings and a modern design. Threaded surfaces are lubricated with a special lubricant that reduces friction during operation. The screw plug with rubber gasket prevents gas leakage during transportation or storage. The device provides protection against unqualified repairs by persons who have not undergone appropriate training. The reliability of the locking device contributes to long-term and safe operation of the gas cylinder structure.

How many m3 of propane are in 1 5, 12, 27, 50 liter cylinder?

We have made special calculations that conditionally transform propane-butane into a gaseous state. Under standard conditions (100 kPa, 288 K), 0.526 m³ of propane or 0.392 m³ of butane is formed from 1 kg of liquefied gas. Taking into account the percentage of the mixture (60% prop.), the volume of combustible gas is calculated using the formula M*(0.526*0.6+0.392*0.4). How many cubic meters are in a propane tank can be seen in the table below. The last line shows the number of liters of propane-butane mixture (in the liquid phase).

| Cylinder capacity (l) | 5 | 12 | 27 | 50 |

| Capacity (cubic meters of flammable gas) | 0,95 | 2,59 | 5,38 | 10,01 |

| Liquid propane volume (liters) | 4,3 | 10,2 | 22,9 | 42,5 |

It should be borne in mind that the calorific value of the propane-butane mixture is three times higher than that of natural gas (methane).

How much does a 5, 12, 27, 50 liter propane cylinder cost?

The price depends on the specific area in which the customer lives. How much an empty propane cylinder costs in our region, as well as the cost of refilling, is shown in the following table:

| Cylinder volume (liters) | 5 | 12 | 27 | 50 |

| Estimated cost of an empty new cylinder | 1080 | 1380 | 1500 | 2250 |

| Cost of refilled propane | 1155 | 1560 | 1905 | 3000 |

*prices are indicative depending on the manufacturer

The price of a cylinder is sometimes several times higher than the cost of the contents. But repeated refilling allows the tanks to be used for many years and even decades.

Jets for bottled gas

One important point must be taken into account: the stoves, originally designed to operate on mains natural gas, have jets (nozzles) that are not suitable for operation on bottled propane.

The jet is like a bolt with a hole in the top through which fuel flows to the burner. Bottled gas injectors have a smaller hole diameter because the pressure of liquefied propane is higher than that of natural fuel. Consequently, to connect such a stove to a liquefied gas cylinder, you will need to purchase and replace the entire set of nozzles.

USEFUL INFORMATION: Replacing a gas stove in an apartment with an electric one: approval and installation

A new set will cost an average of 200 rubles. (the cost depends on the brand of the stove), it can be bought at a gas equipment spare parts store or ordered from the manufacturer.

If the jets need to be replaced, do the following:

- The burners and the burner table cover are removed.

- Using a hex wrench, the old injectors are removed and the new ones are screwed in.

You can understand all the nuances of the process of replacing jets by watching the video.

Advantages and disadvantages of gas heating

The main disadvantage of heating a house with bottled gas is its high cost. Money will have to be spent not only on the fuel itself. It also takes some time to fill the cylinders. To do this, you will have to go to the gas station once a week.

However, this heating method also has some advantages:

- High efficiency with low labor intensity in installing the system, when compared with heating with wood.

- Possibility of converting the heat exchanger to mains gas.

- Autonomous operation of the system.

- Durability of equipment operation.

In general, when considering gas heating as the only option, the financial side of the decision comes up. This is not economically viable. It is better to use propane cylinders as a temporary measure, followed by re-equipment of the boiler.

Installation and replacement of valve on a gas cylinder

When starting to install a shut-off unit for a liquefied gas cylinder, you must remember that this element will operate under high pressure conditions. Therefore, all work on installing or replacing such a unit should be carried out in strict accordance with the instructions.

Technically, changing the valve on a gas cylinder is quite easy - the outdated unit is simply unscrewed from the inlet hole in the container, like a regular fitting, and a new shut-off element is screwed into its place

However, special precautions must be taken

After all, we repeat, this unit is under pressure (for example, as much as 30 atmospheres of pressure are applied to the valve of an acetylene cylinder), therefore, the process of dismantling and installation itself should be organized according to the following scheme:

- At the very beginning, the valve shut-off unit should be moved to the “open” position. That is, unscrew it all the way to the uppermost position. As a result, the remaining contents of the cylinder will go either into the atmosphere or into some container.

- Once the cylinder is free of hazardous contents, you can begin to remove the valve body from the threaded hole in the top of the cylinder. For these purposes, you can use either a special tool or a regular adjustable wrench. It is necessary to understand that the valve was screwed in very tightly and, possibly, using a liquid sealant, therefore, before dismantling, the body of the shut-off element must be heated with a hair dryer.

- Having removed the old valve from the cylinder, you need to prepare a new shut-off unit for installation. That is, you just need to apply a gel or polymer seal to the conical fitting at the bottom of the body. As the latter, most often, ordinary FUP tape is used.

- After preparation, the valve is screwed into the hole on the cylinder body, first by hand, and then with a key. Moreover, as a key, it is best to use a special tool - a torque wrench, which allows you to adjust the tightening force. After all, for steel cases you need to create a torque of 480 Nm, and for brass - 250 Nm.

After completing the installation of the valve, you should put information about the date of the operation on the cylinder passport - a special plate mounted in the container body.

Safety precautions and installation quality control methods

Upon completion of the valve installation process, it is necessary to check the quality of the work performed.

To do this you need to do the following:

- A hose from the supercharger (compressor) is connected to the side fitting of the housing.

- The valve is moved to the “open” position and a portion of compressed air is pumped into the cylinder. After this, the cylinder valve is moved to the “closed” position.

- Next, a pressure gauge valve with a screwed-in measuring device (pressure gauge) is connected to the side fitting of the housing.

Of course, a hermetically mounted valve must maintain the pressure at the same level for a sufficiently long time.

Simplified control method

This technique is practiced in the field or in the absence of measuring instruments at hand.

To implement it you need to do the following:

- Compressed air is pumped into the cylinder and the valve is closed.

- Whipped soap foam is applied over the valve with a shaving brush.

- The tightness of the balloon-valve assembly is controlled by the absence of “bubbles” in the soap “cap” on the valve.

Despite its simplicity, this method is considered quite effective and is used by most pressure pipeline specialists.

Weight of an empty propane cylinder liters GOST – Theory of law

Made of high-alloy steel that can withstand external and internal loads without disturbing the original properties of the contents of the cylinder. It should be remembered that as the temperature increases, the pressure increases, so during storage and transportation, do not allow the temperature to rise sharply.

This is especially important in winter at low negative temperatures! Download the certificate Delivery in Moscow and Moscow Region Our store delivers using its own courier service, so orders are delivered on any day convenient for the buyer from Monday to Saturday between 13:00 and 18:00 or 18:00 and 22:00.

Free delivery within the Moscow Ring Road applies to some groups of products!

How much does a gas cylinder weigh?

The included accessories have a significant mass that must be taken into account. Average weight of the set: shoe - 5.2 kg metal cap - 1.8 kg ring - 0.3 kg The weight of a 40 liter oxygen cylinder is indicated in the table: Cylinder volume, litersWork.

Cylinder volume, litersWork. The weight of a gas cylinder is 50 liters without gas. The mass of gas in it is approximately the same as the cylinder itself weighs. That is, one liter of gas weighs a little less than half a kilogram.

There is a gas stove at the dacha, and every summer we have to replace the empty cylinder with a full one.

Important: A cylinder filled with gas weighs about 43 kilograms. This means that about kg of gas is filled into it. A liter gas cylinder contains a little more than 20 kilograms. If we assume that a propane-butane mixture is used for domestic needs and the content of How many kilograms of gas are in a liter cylinder?

Because there have been cases of explosions, even with fatalities, and now such refueling threatens serious trouble for the owners. They began to demand not only the presence of a plug, but even rubber rings around the body of the cylinder. Now to the essence of the issue.

Gas is filled into it. The total weight of the full cylinder is. I have these data: a kilogram cylinder contains approximately 20 kg of propane. Well, give or take the uneven filling. But a kilogram cylinder holds 11 kilograms of propane.

I thought about this question myself, because I myself want to buy a gas cylinder for my dacha and a gas stove to save on electricity. An empty 50 liter gas cylinder weighs about 22 kilograms.

The mass of the gas in nm is approximately the same as the weight of the cylinder itself.

The permissible mass of liquefied gas max is 5.3 kg 6.8 liters. The mass of the empty cylinder is 6.0 kg. The weight of a full cylinder is 11.3 kg. Propane cylinder 5 l with valve: Volume - 5 l.

The highest working gas pressure is 1.6 MPa. Dimensions - x mm. Wall thickness - 3 mm. The permissible mass of liquefied gas max is 2.2 kg. The weight of the empty cylinder is 3.1 kg. The weight of a full cylinder is 5.3 kg. Reply from 22 replies[guru] Hello!

Here is a selection of topics with answers to your question: How to determine by the weight of a cylinder with liquefied propane-butane how many atmospheres are left there? I have been working with gas since I was 15 years old, I started with my father, and now I have my own company. And please take into account that the density of the gas changes. How can you determine by the weight of a cylinder with liquefied propane-butane how many atmospheres are left there?

Important: the norms for filling cylinders by volume may differ at gas stations; the gas filling volume or weight must be clearly indicated by the gas seller when indicating the cost of filling a cylinder; in this case, the weight can be similarly recalculated according to the specified filling volume of a household gas cylinder. How many kilowatt hours are there in 1 kg of liquefied gas? The bulk of propane consuming devices - gas stoves, titaniums, welding torches, heating boilers - require reduced pressure.

To do this, the most common gearbox, BPO, is installed on the valve. A passport is placed on the upper part of the neck, on which the main technical parameters of the device are stamped.

These include: the name of the manufacturing plant, quality control mark, individual number, month and year of manufacture, inspection date updated every 5 years, volume, weight in empty and filled state. How many kg of propane are in 1 5, 12, 27, 50 liter cylinder? You can find this out in the product quality certificate or in the table below.

Here you can also find out how much a 5, 12, 27, 50 liter propane cylinder weighs. Volume 5 liters 12 liters 27 liters 50 liters Empty cylinder weight, kg Cylinders for technical gases.

Medical oxygen is used for medical purposes for breathing apparatus, oxygen cocktails, etc. Cylinders for technical gases manufactured in accordance with GOST can be designed for different types of gases.

They also differ in volume.

The cylinder must not have mechanical damage, traces of loose rust, or welding. All elements of the cylinder, the shoe and the neck, are attached to the shell using hot crimping.

The cylinder passport must be easy to read.

The service life of a cylinder produced since the beginning of the year, according to the order of Rostechnadzor, from the gas in the cylinder; Oxygen, argon, nitrogen, helium, welding mixtures: a liter cylinder at atm contains - 6 cubic meters.

Carbon dioxide: liter cylinder - 12 cubic meters. Important That is, one liter of gas weighs a little less than half a kilogram. A gas-filled cylinder weighs about 43 kilograms.

Source: https://teoriprava.ru/ves-pustogo-ballona-propana-litrov-gost.html

DIY Gas Valve Troubleshooting Guide

The cylinder itself is solid, and it’s unlikely that anything will break there. Therefore, the majority of malfunctions concern gas valves.

Procedure:

- Repairs are carried out in a well-ventilated area;

- We open the shut-off assembly to allow the remaining gas to escape;

- To turn the valve manually or with a gas wrench, you need to warm up this element. In this case, there is no danger, since the cylinder contains only gas vapors, and not their mixture with air, which is explosive in the first place. The only thing that needs to be monitored is moderate heating of the structure, since overheating can increase the pressure in the cylinder. The point of warming up is that the metal expands and it becomes possible to unscrew the valve even manually, or with a slight lever force in the form of the same gas wrench;

- After removing the element, the conical fitting is sealed - a sealant or fluoroplastic tape is applied to it;

- A new valve is installed, after which the fact and time of repair are entered into the cylinder passport. Installation is carried out with a special torque wrench, which makes it possible to correctly dose the forces and not break the thread. The maximum pressure allowed in this case is 480 Nm for steel and 250 for brass valves;

- Having removed the valve from the cylinder, it is necessary to drain the condensate from it, if we are talking about propane-butane, which we widely use. This procedure is practically never performed by anyone, despite the fact that it is extremely desirable. However, it is necessary to drain it away from residential buildings, since this condensate has an extremely unpleasant odor.

In general, the gearbox, which is non-separable, must be replaced every six years. As for the hoses, they must be reinforced and subject to inspection no earlier than once every six months when replacing the cylinder.

Frequency of draining condensate from the cylinder

But when should condensate be drained? This question is very individual and depends on the quality of the gas being filled and operating conditions.

If you take the cylinders to a specialized gas station, they will inspect them and, if necessary, drain the remainder - you don’t need to do anything

Many users of gas cylinders have not encountered this need at all, while others do this before each refueling. Both of these extremes are normal behavior under certain conditions, and to determine which is closer to you, let’s look at these conditions in more detail.

Option #1 - refueling at a specialized substation

If you fill the cylinder at a specialized substation, you may not encounter condensate at all, for several reasons. Firstly, they fill with the “correct” gas, with a high content of propane, and not just cheap butane, as at car gas stations.

Secondly, their gas quality control is much stricter, so the degree of gas purification is higher, and there are practically no foreign impurities.

Thirdly, at most of these substations, cylinders are exchanged, and before refueling they are inspected and serviced, excessively worn ones are rejected, and after refueling, safety and tightness control is carried out. In particular, substation workers drain condensate if it has accumulated in the cylinder.

Even if you insist on refilling your particular cylinder, it will not be done without first making sure that the unit is in working order and safe. The fact is that specialized substations operate officially, complying with the standards and technical requirements for refilling cylinders, and are responsible for the safety of each client.

Option #2 - refueling at a gas station

Cylinders filled at gas stations, but used for domestic purposes, are much more prone to condensation.

In a car, the gas mixture constantly splashes and mixes in the cylinder without having time to separate into fractions, and modern gas equipment simply sprays condensate into the fuel system along with gas

If a cylinder filled at a gas station is placed at home, all impurities and weakly volatile gases will settle at the bottom and remain there in the form of condensate. Therefore, when refueling with automobile gas, the condensate must be drained at least every 3–4 refuelings, and better before each one.

Separately, we can mention small tourist gas cartridges, up to 1 liter in volume. They have a different outlet, reminiscent of a lighter refill can, and doing anything with it yourself other than using it for its intended purpose is difficult and unsafe. However, many craftsmen refill the cans with their own hands.

Although, in principle, it is more convenient and simpler when such cartridges are filled only at specialized points, with gas of the correct composition and a high degree of purification, so condensation does not form in them. And they are relatively inexpensive, and do not last for decades, like their larger counterparts, so when such a can starts to act up, they usually just buy a new one.

Screwing in new shut-off valves

There is an unspoken ban on carrying out such work, especially at home, but sometimes there is simply no other choice but to carry out the replacement yourself

It is important to remember that replacing a gas cylinder valve with your own hands requires a person to adhere to maximum safety precautions, since the health and lives of other people directly depend on his actions

First of all, it is necessary to monitor fire safety. You should not open the valve suddenly; also, when replacing, you need to make sure that there are no other cylinders in the room. Situations when it is necessary to replace a valve are not uncommon. Despite all the apparent complexity, the replacement procedure is quite simple and accessible.

Replacing the valve on a gas cylinder should be done without haste, since it is necessary to ensure compliance with the technical data of the element. The main indicators are as follows: propane valve - operating pressure up to 1.6 MPa. Replacing the valve on a gas cylinder yourself requires that the pressure does not exceed these values.

Before tightening the valve, all connected parts must be degreased to prevent clogging of the locking mechanism. To do this, you can use a cloth with regular detergent or moistened with white alcohol. After this, rinse the surfaces with plain water and allow them to dry.

A new valve is never screwed to a cylinder with bare threads. It is imperative to use a sealant: special thread compound or fluoroplastic fum tape. They are applied to the lower fitting and only after that the valve is tightened.

The thickness of the gas fum tape is greater than sanitary tape and is 0.1 - 0.25 mm, and its reel should be yellow. The tape is wound with tension in 3-4 layers. It is better to twist it once again when it breaks than to make the seal loose.

It is advisable to tighten the valve with a torque wrench. Steel shut-off valves are screwed with a maximum force of 480 Nm, and brass valves - 250 Nm. After clamping the valve, you can proceed to subsequent steps to test the tightness of the resulting connection.

According to the rules of safe operation, independent installation of valves on gas cylinders is strictly prohibited. If the situation is hopeless, you can very carefully try to replace the device yourself. Technically, the work itself is not difficult, but breaking the seal of the cylinder is always fraught with risk.

To begin with, it is worth considering the process of replacing the valve by a technician at a specialized enterprise. Removal of the fittings is carried out using a cylinder valve wrench. A dynamic key is used for installation. The tightening force should not exceed 250 N for brass fittings and 480 N for steel fittings. Before delivery of the gas cylinder, the threads are sealed with paint.

In handicraft conditions, you can try to remove and install the valve manually. To increase the tightness, use FUM tape.

The replacement process will look like this:

- the cylinder is completely emptied of gas away from residential premises;

- carefully unscrew the valve;

- smoothly remove the device without damaging the case;

- gas condensate is poured out;

- install a new valve;

- check the tightness of the device.

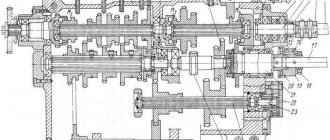

Formulas will help

For oxygen

V = K coefficient × Vb

K=((0.968× D + 1) × 293×10-3)/((273+ T) × Z)

Vb in dm3 ─ capacity, D in kgf/cm2 ─ pressure gauge data, Z ─ oxygen combustion coefficient. The parameter 0.968 kgf/cm2 recalculates the technical indicators of atmospheres.

For propane and butane

Gas mass = Vcylinder m3 × (0.4× Flat prop. + 0.6 × Flat bottle)

Under normal conditions, the density of liquid propane is 510 kg/m3, and butane is 580 kg/m3. The numbers 0.4 and 0.6 indicate the percentage of chemical elements.

Valve problems

If the gas cylinder valve is leaking, it will require strengthening its sealing or even replacing it. One way or another, you will have to unscrew and tighten it.

The security measures here are:

- Remains of gas in the open air are eliminated. Exceptions: nitrogen and argon.

- It is better to carry out work outside.

- The flywheel unscrews smoothly.

- Work with the valve can begin as soon as the pressure indicators are completely equalized: external and external.

To screw in the valve, you need fum tape or special lubricants to improve the sealing properties. When a faucet is replaced, such seals cause a lot of trouble. Need a hair dryer. It heats up the valve.

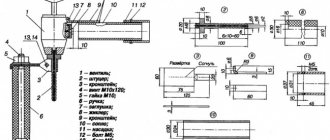

How to unscrew the valve? To work you will need:

- a pair of bolts at least 2 cm long and a pair of nuts for them,

- corner profile made of metal. Its length is at least 1 m.

- pipe wrench.

On the shoe of the container, the distance between a pair of adjacent holes is measured. The same holes are drilled in the profile, on one extreme side. A metal strip is then screwed to the cylinder body. He lies down on his side.

The foot is placed on this profile. Use the hand with the key to unscrew the valve.

How to tighten the tap on a gas cylinder? All parts are first degreased. Fum tape is used. It is permissible to use sealing grease. The lower fitting is covered with a sealant. The tap turns on.

A suitable fum tape has a thickness of more than 0.1-0.25 mm and a yellow reel. Tape tension – 3-4 layers.

A torque wrench is used to clamp the valve. If the crane is made of steel, then the maximum force of its fastening is 480 Nm. If it is brass - 250 Nm.

After clamping, the tightness is tested.