Description

These propane cylinders are used for transportation and storage of liquefied hydrocarbon gases. They are made from a range of metals that are resistant to corrosion. The cylinder has the ability to withstand high pressure, but at the same time, during operation, it is necessary to prevent sudden increases in temperature, as this can lead to an increase in pressure.

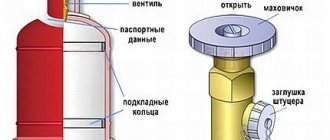

Cylinders with a volume of 50 liters are equipped with valves VB-2, VK-94 (with subsequent connection to it of a pressure regulator RDSG 1-1, 2) or valve KB-2 (using a pressure regulator RDSG 2-1, 2). During work related to gas-flame processing of materials, welding in shielding gases, and plasma cutting, this propane cylinder is used.

How many kilograms of gas are in a 50-liter cylinder?

- According to the norms, a gas cylinder is filled with 30 kilograms of gas, but if you really ask (although they are unlikely to agree to it), they can fill more: 35-40 kilograms, but the responsibility in the event of an emergency will be yours alone.

- The weight of the gas cylinder along with the gas will depend on what kind of gas is pumped into it. If you take a regular 50-kilogram cylinder with propane gas, then its weight will be about 43-45 kg, of which 22.5 kg will weigh the cylinder itself, and the gas can be pumped from 20 to 22 kg, more is simply dangerous for safety reasons.

- If a 50-liter cylinder was filled with propane, then in kilograms it will be exactly 21, if in liters, then the volume is 40 liters. According to other data, a 50-liter cylinder holds 42 liters of propane-butane mixture and exactly 23 in kilograms. The volume of oxygen will be slightly different .

- I don’t know where they fill gas cylinders more than required according to the standard, at our gas stations, and I often fill cylinders for the dacha, even video surveillance has been installed for the gas refuelers, so that God forbid, they don’t pump more. Because there have been cases of explosions, even with fatalities, and now such refueling threatens serious trouble for the owners. They began to demand not only the presence of a plug, but even rubber rings around the body of the cylinder. Now to the essence of the issue. an empty 50-liter propane tank weighs 22.5 kilograms. They fill it with 21.2 kilograms of gas - this is the maximum. The total weight of the full cylinder is 43.7 kilograms.

- I have the following data: a 50-kilogram cylinder contains approximately 20 kg of propane. Well, give or take the uneven filling. But a 27-kilogram cylinder holds 11 kilograms of propane. or are you talking about another gas?

- I thought about this question myself, because I myself want to buy a gas cylinder for my summer house and a gas stove to save on electricity. An empty 50-liter gas cylinder weighs about 22 kilograms. The mass of the gas in nm is approximately the same as the weight of the cylinder itself. That is, one liter of gas weighs a little less than half a kilogram.

- Not so much. A little more than twenty kilograms according to the standards, this is how it should be filled. Considering that the empty cylinder itself weighs 22 kilograms, it turns out that a cylinder filled with gas will weigh around 43-44 kilograms.

Read also: What steel are wrenches made of?

loading.Posted in Your e-mail will not be published.

Required fields are marked *Comment Name * Email * Save my name, email, and website in this browser for the next time I comment.

To avoid problems when working with a cylinder, the following safety measures must be taken into account:

- In the room where the cylinder is used and stored, the air temperature should not exceed 45 °C.

- Filled cylinders are also prohibited from being heated by sunlight or other heat sources.

- Care must be taken to ensure that cylinders are not subject to accidental drops or impacts.

It is necessary to check the gas cylinder for the possibility of gas leakage. If you smell gas in the room, you should immediately stop using the gas cylinder. Next, immediately close the valve on the cylinder and turn off the tap of the gas heater. The next step is to ventilate the room, open a window or door until the smell of gas is completely eliminated; during this time, it is forbidden to light a fire, smoke, or turn on electric lighting in the room.

A 50 liter cylinder is widely used as an excellent fuel for heating. For example, many residents of private homes use propane cylinders to heat residential and commercial buildings. This is due to a number of advantages in use, since propane is economical in price, and you can buy propane cylinders in any locality.

Weight of a filled gas cylinder with propane 50 l

Here you can also find out how much a propane cylinder weighs for 5, 12, 27, 50 liters. Most household cylinders for a propane-butane mixture are equipped with VB-2 type valves.

The device provides protection against unqualified repairs by persons who have not undergone appropriate training.

The reliability of the locking device contributes to long-term and safe operation

How many liters of gas are in a 50 liter cylinder? How many cubic meters of gas are in a 50-liter cylinder?

They act a little differently when supplying gas to high-rise buildings.

Well, how many liters of gas can a 50-liter cylinder hold? And change cylinders with 42 liters of gas (that’s how much is stored in the cylinder) plus the weight of the cylinder itself on all floors and apartments... Therefore, in such cases, a grounded storage facility is usually installed in the courtyard of the house , into which the gas mixture is delivered by special gas carriers.

Read also: Control of color LED strip

In a special device it is converted into a gaseous phase and in this form enters the household pipeline. So how many cubic meters of gas are in a 50-liter cylinder?

Density of liquefied gases: propane – 0.528 kg/l, butane – 601 kg/l. In order to find out how many liters of gas are in a 50-liter cylinder, let’s make small calculations. Propane Density of liquid

A 50 liter propane cylinder has the following technical characteristics.

• working pressure, MPa 1.6; • test pressure, MPa 2.5; • overall dimensions: Shell diameter, mm 292; • height, mm 1015; • wall thickness, mm 3; • material: steel B Art. 3 sp. Empty cylinder weight, kg 19; • mass of liquefied gas, kg 23.

Size chart of composite (lightweight, type 3, CNG-3) gas cylinders for methane (natural gas).

| The cost of cylinders (type 3) including installation* is 550 rubles/liter according to the price list |

CNG-3 methane cylinders, the average coefficient of perfection (mass to volume ratio) = 0.65 , i.e. a 100 liter cylinder will weigh approximately 65 kg.

| Volume, l | Gas capacity, m3 | Outer diameter, mm | Length, mm | Weight, kg | Max. working pressure, MPa | Test pressure, MPa |

| 47 | 11,75 | 326 | 860 | 33,6 | 20 | 30 |

| 50 | 12,5 | 326 | 900 | 35,2 | 20 | 30 |

| 67 | 16,75 | 326 | 1140 | 44,6 | 20 | 30 |

| 80 | 20 | 326 | 1360 | 53,2 | 20 | 30 |

| 100 | 25 | 326 | 1660 | 65 | 20 | 30 |

| 123 | 30,75 | 326 | 2000 | 78,4 | 20 | 30 |

| 67 | 16,75 | 398 | 840 | 45,6 | 20 | 30 |

| 80 | 20 | 398 | 965 | 52,3 | 20 | 30 |

| 85 | 21,25 | 398 | 1015 | 55 | 20 | 30 |

| 96 | 24 | 398 | 1125 | 61,1 | 20 | 30 |

| 100 | 25 | 398 | 1165 | 63,5 | 20 | 30 |

| 132 | 33 | 398 | 1485 | 80,5 | 20 | 30 |

| 160 | 40 | 398 | 1765 | 99,5 | 20 | 30 |

| 185 | 46,25 | 398 | 2005 | 108,5 | 20 | 30 |

Read also: Palladium in radio components of the USSR

see also

Characteristics of a propane cylinder

Propane cylinders come in various sizes. They contain from five to fifty liters. They are intended for gas storage and transportation. They are used in gas welding work and for domestic heating.

Cylinders may differ in the maximum operating pressure of liquefied gases. For propane it is a maximum of 1.6 MPa. Liquefied gas has a high coefficient of volumetric expansion. For this reason, cylinders are filled so that there is enough air left in them to absorb liquid, which will expand during heating.

A 50 liter propane cylinder is equipped with a valve, as well as protective rings and a safety cap. The outside of each container is painted with weather-resistant paint. It is always red.

Technical characteristics of propane cylinders:

container capacity is 50 l; the operating pressure indicator does not exceed 1.6 MPa; cylinders must withstand test pressure within 2.5 MPa; the container is destroyed at a pressure of more than 5 MPa; excluding protective rings, the diameter of the cylinder is 299 mm; the walls are 3 mm thick; the cylinder has a height of 980 mm; empty container weighs 22 kg; The mass of liquefied gas is 23 kg.

We recommend: Electrics and wire colors in electrical diagrams

Interesting! Propane is a hydrocarbon gas that contains between 75%!p(MISSING)propane and propylene.

Propane is a fossil fuel. This substance is odorless and colorless. Propane is found in associated and natural petroleum gases. It is also obtained from oil refining. Thanks to its chemical and physical properties, it has gained wide popularity in production and everyday life. It is also used during construction work.

If you use liquefied gas for the heating system, the best choice would be to purchase 50 liter cylinders. They are fueled with a mixture of propane and butane. It becomes liquid under high pressure. The following fuel combinations can be used:

summer mixture of butane and propane - SPBTL; winter - SPBTZ.

Cylinders require careful care in winter. Even during frosts, gas does not freeze. However, a situation often arises when the fuel supply stops. This is due to the difference in boiling points of butane and propane.

At a temperature of -10 degrees, the mixture in the cylinder boils. Propane starts to evaporate first. Once butane begins to turn into gas, propane's volatility decreases. In this case, the gas pressure drops below the required value needed to operate the boiler.

In this situation, the cylinder must be heated to zero temperature. To do this, you will need to connect a sleeve made of corrugated pipe to the box with cylinders. Warm air will be supplied through it from the room. Another option is to heat propane tanks with warm water pipes.

Types of gas cylinders for methane

Today there are 4 types of natural gas tanks, these are:

- Type I.

All metal construction. It is cast in specialized tanks and has no seams. Robust and reliable design, proven over the years. The cylinder has a cylinder-shaped neck for a valve on one side, and a rounded bottom on the other. During the manufacturing process, all tanks are subjected to overpressure testing and ultrasonic testing to identify hidden defects. Despite more modern manufacturing technology for other types, many consider Type 1 to be the most reliable design. - Type II.

Cylinders of the second type are made of metal-plastic construction. They are made of alloyed structural steel. The main part of the structure is covered with a reinforcing shell. It is stated that the steel used in this design does not change its physical properties at low ambient temperatures.

- Type III.

The design of the third type of derailment is similar to the previous one. A distinctive feature is the presence of an aluminum liner, which is reinforced with carbon fiber braid. The breaking force is about 140 kgf/mm2. The braid is impregnated with a specially developed composition based on epoxy resin. The advantage of this type of construction is its resistance to corrosion throughout the entire period of operation. - Type IV.

The fourth type is similar in design to the previous two. A special feature of the design is the material of the liner. In this type, it is polymer, reinforced with a reinforcing shell made of carbon fiber or composite material. The main advantage of this type of cylinder is its low weight, due to the use of modern production technologies. The disadvantages include the high price of the product, rarity on the market, as well as the fragility of the product when exposed to mechanical damage.

Rules for the safe use of gas cylinders

When operating compressed gas containers, certain safety rules must be observed.

Moving a gas cylinder

In particular, the following must not be allowed:

- Gas leaks through joints and threaded connections and the formation of an explosive mixture with air.

- Thermal effects on containers, which can lead to an increase in gas volume and pressure inside the container.

- Impact-type mechanical influences that can damage the walls of the container.

Safety regulations require that containers be transported with protective caps installed on them.

Vessels containing gas can be transported from place to place in a horizontal or vertical position. But at the same time, it is necessary to ensure protection against spontaneous movement of containers inside the body.

It is unacceptable to throw gas containers and hit them against hard objects.

Rules for the safe use of gas cylinders

It is unacceptable to store a gas container in a residential area. Ideally, the gas container should be stored in a separate iron box.

Methane cylinders for passenger cars

The first thing I would like to note is that you should not save on a methane cylinder. If you are going to convert your car to methane fuel, be sure to buy a new cylinder .

Remember! methane is stored and operates under high pressure, which means the tank under it must be durable and free of visible damage and signs of corrosion.

It is mandatory to have the cylinder inspected once every 3-5 years.

For a passenger car, you can choose any of the existing types of gas storage. The author of the article, for his personal car, would prefer type 1. Although it is somewhat heavier, it has a decent service life and technical characteristics that exceed other modern types. The new tank will last at least 10 years without visible corrosion processes.

Read also: Soldering station board heater

We would also like to draw your attention to the fact that after 55 explosions of composite gas cylinders of type 2-4 in Uzbekistan, these types were prohibited for use. Currently, the only one allowed in the country is type 1.

In Russia, such bans on use have not yet been introduced. But it is worth noting that the vast majority of cars that suffered from a natural gas explosion were equipped with composite gas cylinders.

Reducer for propane cylinders

Bottled gas is used for welding work. However, it is worth considering that the pressure in the cylinder is quite high. For various jobs it should be reduced. To adjust this value, use a gas reducer:

Direct and reverse acting gearboxes are separated. When using the former, the pressure in the cylinder and the operating indicator decrease. Reverse-acting gearboxes operate on a different principle. When using them, the fuel pressure in the cylinder first decreases, and then the working pressure. Depending on the installation features and location, gearboxes are divided into network, balloon and ramp gearboxes. The latter are used to reduce and maintain gas pressure from one source at the required level. If you need to perform a large amount of welding work, you should choose a ramp reducer. They are capable of reducing the pressure of gas coming from several sources at the same time. Depending on the type of gas, there are gearboxes that work with different types of fuel - oxygen, acetylene, metal, propane-butane. Acetylene should be fixed with a clamp at the stop screw. To connect other types, a union nut is used. Be sure to take into account that the thread of the nut must match the thread of the fitting at the valve. Based on the color of the housing, gearboxes are divided into groups depending on the type of gas to which they belong. Gearboxes with a red housing are designed for propane. Based on the type of gearbox, devices for working with non-flammable and flammable gases are distinguished.

We recommend: Which LED lamps are better: how to choose

Before purchasing a gearbox, it is important to understand the above characteristics.

Price and sizes of methane cylinders of the first type

The most common are still the first type of methane cylinders. Their price depends on the size and capacity and, at the current time, is:

Volume (liters)

Size(mm)

Price ($)

- The second type can be purchased for approximately $7 per liter;

- Third type $8-8.50 per liter;

- The fourth, the most expensive at the moment, costs about $18 per 1 liter.

Rules for using gas cylinders

The gas tank can be connected to different models of cookers, gas smokers, barbecues and grills. The cylinder is often used as a power source for gas generators. Often, summer residents who live on their plots all year round build a heating system using gas, connecting a container with propane-butane to the boiler using a special reducer.

• before connecting, you should check the serviceability of the devices;

• after 3-5 years, cylinders must undergo maintenance (the period may be reduced if signs of progressive corrosion appear);

• when using, check the tightness of the connections and the absence of leaks (not with an open flame, but with a soap solution);

• the tank can be installed in a dry room, moisture will reduce the service life of the metal casing;

• when replacing a cylinder, you need to make sure that all devices are turned off and there is no fire nearby;

• the container must always be in a vertical position.

It is necessary to store a full tank only in compliance with safety precautions. A utility room with moderate humidity is suitable for this. A metal cabinet should be installed in it, in which the gas installation will be stored. Keeping a “time bomb” in the house is strictly prohibited.

The cylinder needs to be refilled only at specialized points. Gas at gas stations is technical and unsuitable for domestic use. In addition, when filling, an inexperienced operator can damage the structure of the container, which will cause it to depressurize.

Dimensions of methane cylinders of the second type

Model: CNG-2 DIGITRONIC Light

| 27 | 229x855 | 180-200 |

| 38 | 273x850 | 220-240 |

| 55 | 316x910 | 270-300 |

| Volume (liters) | Size(mm) | Weight, kg) |

| 50 | 325 x 780 | 40 |

| 55 | 325 x 830 | 44 |

| 60 | 325 x 880 | 47 |

| 65 | 356 x 800 | 57 |

| 70 | 356 x 880 | 60 |

| 80 | 356 x 980 | 65 |

| 80 | 406 x 800 | 64 |

| 90 | 406 x 890 | 72 |

| 100 | 406 x 980 | 79 |

| 110 | 406 x 1140 | 91 |

| 120 | 406 x 1180 | 98 |

Dimensions of methane cylinders of the third type

Model: CNG-3 STAKO

| Volume, l | Outer diameter, mm | Length, mm | Weight, kg |

| 47 | 326 | 860 | 33,6 |

| 50 | 326 | 900 | 35,2 |

| 67 | 326 | 1140 | 44,6 |

| 80 | 326 | 1360 | 53,2 |

| 100 | 326 | 1660 | 65 |

| 123 | 326 | 2000 | 78,4 |

| 67 | 398 | 840 | 45,6 |

| 80 | 398 | 965 | 52,3 |

| 85 | 398 | 1015 | 55 |

| 96 | 398 | 1125 | 61,1 |

| 100 | 398 | 1165 | 63,5 |

| 132 | 398 | 1485 | 80,5 |

| 160 | 398 | 1765 | 99,5 |

| 185 | 398 | 2005 | 108,5 |

Toroidal gas cylinder HBO

This type of cylinders appeared already in the 2000s. At the moment it is most common for cars and crossovers. The key feature of installing a toroidal LPG cylinder is that it is placed in a niche under the spare wheel. This way the tank is hidden and not visible in the trunk. The driver can also make full use of the cargo area with the seats folded down. Its width and length do not change.

The toroidal HBO cylinder has the shape of a donut and is made of the same steel as its cylindrical counterparts. In the central part of the structure there is a hole for a multivalve.

However, such a tank also has disadvantages. The first point concerns the spare tire. Since the cylinder is placed in its place, the spare tire needs to go somewhere. Also, toroidal HBOT cylinders have a smaller volume than cylindrical ones. But they do not hide free space and are located in the lower part of the car strictly in the middle, without disturbing its stability on the road.

Dimensions of methane cylinders of the fourth type

Model: TK-FUJIKIN (TKF), Korea

| Volume (l) | Outer diameter (mm) | Length (mm) | Weight, kg) |

| 42 | 310 | 810 | 16 |

| 61 | 336 | 1000 | 22 |

| 68 | 392 | 850 | 27,1 |

| 73 | 392 | 900 | 28,5 |

| 101 | 452 | 950 | 37,5 |

| 103 | 452 | 950 | 37,5 |

| 107 | 448 | 940 | 40 |

| 123 | 452 | 1110 | 43 |

| 131 | 460 | 1090 | 40 |

| 138 | 358 | 1830 | 47,8 |

| 145 | 485 | 1090 | 46 |

| 164 | 392 | 1820 | 61 |

| 230 | 458 | 1830 | 63 |

| 35 | 280 | 864 | 16 |

| 91 | 452 | 850 | 39,5 |

| 99 | 462 | 864 | 35 |

| 103 | 452 | 950 | 43 |

| 105 | 408 | 1143 | 38 |

| 132 | 408 | 1397 | 48 |

| 138 | 462 | 1143 | 45 |

| 175 | 408 | 1829 | 65 |

| 187 | 537 | 1143 | 64 |

| 192 | 408 | 2032 | 66 |

| 194 | 462 | 1524 | 59 |

| 198 | 408 | 2108 | 66 |

| 264 | 537 | 1524 | 82 |