Often, for production purposes, it becomes necessary to change the parameters of steel; one of the ways to do this is heat treatment. By their principle, most heat treatment technologies involve changing the structure of steels through heating, holding and cooling.

Despite the fact that all these technologies have the same goals and operating principles, they all differ in temperature and time conditions. Heat treatment can be either an intermediate or a final process during production. In the first case, the material is prepared for subsequent processing, and in the second, new properties are given to it.

One such technology is steel normalization. This is the name for heat treatment, in which the material is heated to a temperature 30-50 degrees above Ast or Ac3, and then it is cooled in still air.

Other heat treatment methods

In addition to normalization, heat treatment of steel includes the following processes:

- annealing;

- hardening;

- vacation;

- cryogenic treatment;

- dispersion hardening.

The principle of implementation and goals of each technology are the same, however, each has its own distinctive features:

- annealing - thanks to it, the structure of pearlite will be as thin as possible, since cooling occurs in the furnace. Annealing can reduce structural heterogeneity, as well as stress after processing by casting or injection, give the structure a fine grain or improve cutting;

- hardening - the technology principle is the same, but the temperatures are higher compared to normalization and the cooling rate is also higher. The process occurs in liquids. Thanks to hardening, the strength and hardness of the material increases, and the parts will eventually have low impact strength and fragility;

- Tempering - Tempering done after hardening reduces stress and brittleness. For this purpose, the material is heated to a low temperature and cooled outside. As the temperature rises, tensile strength and hardness fall, and impact strength increases;

- cryogenic treatment - thanks to it the material will have a uniform structure and hardness; this technology is most suitable for hardened carbon steel;

- dispersion hardening is a final treatment during which dispersed particles are released in a solid solution after hardening at low heat to impart strength to the material.

To perform heat treatment you will need the following:

- tanks with water and oil;

- sanding paper;

- metallographic microscope;

- furnace with thermoelectric pyrometer;

- Rockwell hardness testers;

- sets of microsections (sorbitol, martensite, ferrite-martensite, etc.).

Selecting a heat treatment method for steel

Normalization or another method of heat treatment of steel is chosen depending on the concentration of carbon in it. If the material contains it in amounts up to 0.2%, then the most acceptable method is normalization. If 0.3−0.4% carbon is present, then both normalization and annealing will do.

The choice of one or another processing method should also depend on the required properties. For example, normalization will give the product a fine-grained structure, and, compared to annealing, greater hardness and strength.

In many cases, normalization is the most preferred method of processing materials, since it has many advantages over others. In many industries, in particular mechanical engineering, it is most often used for heat treatment .

Annealing

The operation is carried out to obtain the required equilibrium structure with minimal hardness, for the purpose of further metal processing of the resulting products by cutting. The video will introduce you to the features:

General definition and types

During casting or other primary processing processes, in addition to stress, defects appear. You can remove these changes and achieve a homogeneous structure of the crystal lattice using the following algorithm of actions:

- heating - it is necessary to slightly exceed the critical level for this type of steel;

- a certain period is required to maintain a stable temperature;

- The workpiece should be cooled slowly along with the oven.

Annealing has the following varieties.

Homogenization

Refers to the first kind, when changes are considered minor. The purpose of such manipulation is to remove the heterogeneity of the structure and bring it to uniformity. In this case, the product should be heated at a temperature range of 1000 to 1150 degrees, then held for about 8-15 hours and gradually reduced heating, cooling the workpiece with oxygen.

Recrystallization

Also a type of annealing phase 1. The purpose of the procedure is to bring all the crystals into a single form, as well as relieve the internal stress of the metal. There are two subspecies:

- softening - usually used as a final treatment, implies an improvement in plastic characteristics;

- strengthening – increases elasticity, especially important for hardening springs.

The temperature is selected depending on the alloy, usually 100-200 degrees higher than the recrystallization point. It is necessary to maintain the temperature for an hour or two, then allow it to cool slowly.

Isothermal annealing

The goal is to achieve high-temperature face-centered modification of iron (decomposition of austenite) to soften it. This results in a more uniform structure of the product. More often, this type of metalworking is used for small stampings, because they can be subjected to rapid cooling without problems. Process:

- heating is 20-30 degrees more than the material limit;

- short aging;

- rapid cooling is an advantage over other subspecies.

To eliminate stress

This is an operation of removing, removing the negative internal state of excessive hardness, due to which the metal becomes brittle and short-lived. It quickly deforms from external physical influences. The process involves temperatures from 700 to 750, then a slight cooling to 600 and holding for up to 20 hours, then slowly cooling under the influence of air.

Complete annealing

Used to create a plastic, uniform fine-grained structure. The most typical method of intermediate impact on rolled metal is after casting, forging, stamping and before cutting by any method. Stages:

- heating is 30-50 more than the steel limit;

- holding;

- very slow cooling with the oven - no more than 50-150 degrees in 60 minutes.

Incomplete

There are no significant transformations at the level of the crystal lattice, but hardness is imparted to previously plastic materials. This is especially necessary for structures formed by welded joints, as well as tools that require special strength. The method involves a temperature of about 700, and after 20 hours gradual cooling.

Normalization based on URL lists

Some normalization rules can be developed for specific websites by examining lists of URLs obtained from previous log scans or server logs. For example, if the URL

appears in the log log several times along with

it can be assumed that these two URLs are equivalent and can be normalized into one of the forms.

Skohnfeld et al. in 2006 introduced a heuristic system called DustBuster, which detects DUST (different URLs with similar text), rules that can be applied to URL lists. They showed that once the right DUST rules were found and applied to the normalization algorithms, they were able to find up to 68% of redundant URLs in URL lists.

Equipment and materials

Furnaces for hardening and annealing steel are used as equipment for normalization. Gas heating can be used in furnace equipment. Such systems contain:

- Camera. This is a special, hermetically sealed box where the workpieces are placed.

- Heating elements in the form of burners. Designed to increase the temperature in the oven chamber. Burners can be of the flat-torch type and operate on the principle of indirect or direct heating.

- Devices that perform shut-off and control functions.

- Power control modules. They can be of a combined type, proportional or pulse.

- Thermal insulation material.

The principle of heating the inner chamber of the furnace from gas can be realized through the air space, then the burner is located in the center. Regeneration and recovery burner designs can also be used.

In resistance furnaces, where an indirect heating method is used, the heating system can be made according to different principles. Most often, thyristor circuits are used here to control power, which in turn are controlled using microprocessor circuits.

Searching for records using a filter:

Holding at normalization temperature

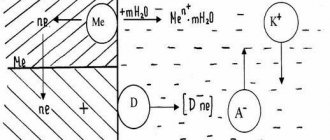

The role of the duration of exposure at the normalization temperature is only to ensure homogenization of the austenitic structure before cooling begins. One hour of exposure for every 25 mm of section thickness is the norm.

The cooling rate during normalization significantly affects the amount of perlite, its size and the thickness of the pearlite plates. The higher the cooling rate, the more perlite is formed, and its plates become thinner and closer to each other. Increasing the proportion of pearlite in the structure and its grinding increases the strength and hardness of steel. Lower cooling rates mean less strong and harder steel.

After the products have cooled uniformly across their cross-section below the lower critical point Ar1, they can be cooled in water or oil to reduce the overall cooling time.

How to Normalize Data for Machine Learning and Data Mining

To perform data normalization, you need to know exactly the limits of change in feature values: the minimum and maximum theoretically possible values.

These indicators will correspond to the boundaries of the normalization interval. When it is impossible to accurately establish the limits of change in variables, they are set taking into account the minimum and maximum values in the available data sample. In practice, a data scientist normalizes data using ready-made functions of integrated environments for statistical analysis, for example, IBM SPSS, SAS or special libraries: Scikit-learn, Auto-sklearn, pandas, etc. Additionally, a data analyst can write custom R or Python code for almost any Data Preparation operation.

The sample needs to be prepared for the simulation to run smoothly.

Learn more about how to normalize data and other aspects of Data Preparation in our new educational course for Big Data analysts in Moscow: preparing data for Data Mining. Join us!

View schedule Sign up for a course

Sources

- https://docs.microsoft.com/ru-ru/azure/machine-learning/team-data-science-process/prepare-data

- https://neuronus.com/theory/nn/925-sposoby-normalizatsii-peremennykh.html

- https://www.bigdataschool.ru/bigdata/data-preparation-operations.html

Correction of damaged structure of metals and alloys

Two-stage cooling of steels allows the pearlite plates to be converted into grains. Heating occurs to a temperature above point Ac1. Then it is reduced to 700 and maintained at 500 degrees. Then the metal cools down in air for a long time. This normalization is called spheroidizing. As a result, the product can be easily cut. This is how metals containing 0.65% carbon are processed.

On the topic: Signs of burnt valves. Low compression in the cylinder. Replacing valves

Hardening is the formation of stronger areas of metal after cold stamping or drawing. Recrystallization annealing removes this defect - the brittleness of steels is eliminated by heating to 700 degrees (below Ac1). At this moment, the crystallization lattice of metals is restored. The structure becomes fine-grained and homogeneous. Bright annealing can also be carried out to restore the properties of steels after sheet rolling in order to maintain a shiny surface.

Normalization based on URL lists

Some normalization rules can be developed for specific websites by examining lists of URLs obtained from previous log scans or server logs. For example, if the URL

appears in the log log several times along with

it can be assumed that these two URLs are equivalent and can be normalized into one of the forms.

Skohnfeld et al. in 2006 introduced a heuristic system called DustBuster, which detects DUST (different URLs with similar text), rules that can be applied to URL lists. They showed that once the right DUST rules were found and applied to the normalization algorithms, they were able to find up to 68% of redundant URLs in URL lists.

Hardening of steel and alloys

Hardening (martensitic transformation) is the main method of imparting greater hardness to steels. In this process, the product is heated to such a temperature that the iron changes its crystal lattice and can be additionally saturated with carbon. After holding for a certain time, the steel is cooled. This must be done at high speed to prevent the formation of intermediate forms of iron. As a result of rapid transformation, a solid solution supersaturated with carbon with a distorted crystal structure is obtained. Both of these factors are responsible for its high hardness (up to HRC 65) and brittleness. When hardening, most carbon and tool steels are heated to a temperature of 800 to 900C, but high-speed steels P9 and P18 are heated at 1200-1300C.

Microstructure of high-speed steel R6M5: a) cast state; b) after forging and annealing; c) after hardening; d) after vacation. ×500.

Quenching modes

Quenching in one environment

The heated product is lowered into a cooling medium, where it remains until it cools completely. This is the simplest hardening method, but it can only be used for steels with a low carbon content (up to 0.8%) or for parts of simple shape. These limitations are associated with thermal stresses that arise during rapid cooling - parts of complex shapes can warp or even crack.

Step hardening

With this method of hardening, the product is cooled to 250-300C in a saline solution for 2-3 minutes to relieve thermal stress, and then cooling is completed in air. This helps prevent cracks or warping of parts. The disadvantage of this method is the relatively low cooling rate, so it is used for small (up to 10 mm in diameter) parts made of carbon or larger ones made of alloy steels, for which the hardening rate is not so critical.

Hardening in two environments

It begins with rapid cooling in water and ends with slow cooling in oil. Typically, such hardening is used for products made of tool steels. The main difficulty lies in calculating the cooling time in the first environment.

Surface hardening (laser, high frequency currents)

Used for parts that must be hard on the surface, but have a viscous core, for example, gear teeth. During surface hardening, the outer layer of the metal is heated to supercritical values, and then cooled either during the heat removal process (with laser hardening) or by liquid circulating in a special inductor circuit (with high-frequency current hardening)

Vacation

Hardened steel becomes excessively brittle, which is the main disadvantage of this hardening method. To normalize the structural properties, tempering is carried out - heating to a temperature below the phase transformation, holding and slow cooling. During tempering, a partial “cancellation” of hardening occurs, the steel becomes slightly less hard, but more ductile. There are low (150-200C, for tools and parts with increased wear resistance), medium (300-400C, for springs) and high (550-650, for highly loaded parts) tempering.

Temperature table for quenching and tempering steels

| No. | steel grade | Hardness (HRCe) | Temperature hardening, degrees C | Temperature holidays, degrees C | Temperature zak. HDTV, deg.C | Temperature cement., deg. C | Temperature annealing, degrees C | Temper. Wednesday | Note |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 1 | Steel 20 | 57…63 | 790…820 | 160…200 | 920…950 | Water | |||

| 2 | Steel 35 | 30…34 | 830…840 | 490…510 | Water | ||||

| 33…35 | 450…500 | ||||||||

| 42…48 | 180…200 | 860…880 | |||||||

| 3 | Steel 45 | 20…25 | 820…840 | 550…600 | Water | ||||

| 20…28 | 550…580 | ||||||||

| 24…28 | 500…550 | ||||||||

| 30…34 | 490…520 | ||||||||

| 42…51 | 180…220 | Sech. up to 40 mm | |||||||

| 49…57 | 200…220 | 840…880 | |||||||

| 670 | Nitriding | ||||||||

| 10 | Steel 7KhG2VM | = 57 | 840…860 | 460…520 | Oil | Sech. up to 100 mm | |||

| 42…46 | Sech. 100..200 mm | ||||||||

| 39…43 | Sech. 200..300 mm | ||||||||

| 37…42 | Sech. 300..500 mm | ||||||||

| НV >= 450 | Nitriding. Sech. St. 70 mm | ||||||||

| 25 | Steel 30HGSA | 19…27 | 890…910 | 660…680 | Oil | ||||

| 27…34 | 580…600 | ||||||||

| 34…39 | 500…540 | ||||||||

| «— | 770…790 | With oven up to 650 | |||||||

| 26 | Steel 12Х18Н9Т | 6 mm water | |||||||

| 29 | Steel 20Х13 | 27…35 | 1050 | 550…600 | Air | ||||

| 43,5…50,5 | 200 | ||||||||

| 30 | Steel 40Х13 | 49,5…56 | 1000…1050 | 200…300 | Oil |

Demormalization in the database: “star” and “snowflake”

As can be understood from the above examples, the main goals of normalization are:

- elimination of redundancy in data storage, leading to an increase in the size of the database;

- eliminating the need to modify data in linked tables to minimize time and operations carried out in one transaction. Or, as experts put it, reduce the thickness of the transaction, because thick transactions interfere with multi-user work due to mutual blocking and increased system response time. This will be discussed in a separate chapter.

But the list of stated goals concerns transactional applications.

In interactive analytical processing applications, the priority changes: system response time comes to the fore, to the detriment of which data may be redundant.

Heat treatment of non-ferrous metals

Alloys based on other metals do not respond to hardening as well as steel, but their hardness can also be increased by heat treatment. Typically a combination of hardening and pre-annealing (heating above the phase transformation point with slow cooling) is used.

- Bronzes (copper alloys) are annealed at a temperature just below the melting point, and then quenched with water cooling. Quenching temperature from 750 to 950C depending on the composition of the alloy. Tempering at 200-400C is carried out for 2-4 hours. The highest hardness values, up to HV300 (about HRC 34), can be obtained for products made of beryllium bronze.

- The hardness of silver can be increased by annealing to a temperature close to the melting point (dull red color) and then quenching.

- Various nickel alloys are annealed at 700-1185C, such a wide range is determined by the variety of their compositions. For cooling, salt solutions are used, particles of which are then removed with water or protective gases that prevent oxidation (dry nitrogen, dry hydrogen).

| Metal | Annealing temperature, C° | Cooling medium |

| Copper Brass L96 Brass L90-L62 Cupronickel Nickel silver Silver Aluminum Duralumin | 500 — 600 540 — 600 600 — 700 650 — 700 700 — 750 650 — 700 300 — 350 360 — 380 | Water Outdoor Outdoor Water Water Water Outdoor Oven Cooling |

Description of steel 65G. Material for the production of knives

65G steel, which is actively used for the manufacture of knives, is a material created based on an alloy of elements such as carbon and iron

It is important to note here that the proportions of these two substances can differ significantly, depending on what qualities are required from the steel, and also why it will be used in the future

General Product Information

A significant point included in the characteristics of 65G steel is its low cost. It is because of this that all products made from this alloy are in great demand.

The material itself belongs to the group of spring steels. The substance lends itself best to operations such as bluing and blackening. Due to the special qualities of steel, the material is most often used for the production of various throwing knives; rarely, but nevertheless, it is used as a base when assembling cutting-type knives. The rare use of the alloy is due to the fact that it quickly becomes covered with rust and oxidizes.

It is worth noting that hardening 65G steel is one of the main procedures, since the alloy is practically not afraid of high temperatures. The only negative that can occur if overheating is too strong is a decrease in impact strength.

Main product advantages

Among the main advantages of 65G steel are the following:

- Huge margin of safety. This suggests that even under high mechanical loads the knives will not break or deform.

- High resistance to shock and deformation loads. It is because of this quality that the material is more often used to create throwing knives or swords, and somewhat less often for medical-type scalpels.

- Sharpening the material is quite simple.

- The tear resistance is also at a high level.

As for the marking of steel, the number 65 indicates the percentage of a substance such as carbon in hundredths of a percent, that is, 0.65%. The letter “G” indicates that manganese has become the main alloying substance.

Negative qualities of the alloy

It is known that 65G steel also has a number of negative qualities that create certain restrictions in the use of the alloy.

- One of the most noticeable disadvantages is the strong susceptibility to corrosion due to the fact that the steel belongs to the carbon-containing group.

- Despite the fact that steel of this grade is sharpened quite simply, it also easily loses this sharpening. For this reason, you have to constantly monitor the sharpness of the cutting edge and sharpen it as necessary.

- There are quite a lot of restrictions in the scope of application.

It is worth noting here that both advantages and disadvantages are relative properties. It is impractical to classify them as absolutely any product made from this alloy. This can easily be explained by the fact that every steel manufacturer uses production technology with some modifications. Sometimes the composition is not very different, and sometimes the difference is almost everything. Naturally, the products in this case will be different.

Features of the composition

Certain properties of 65G steel have made it completely unsuitable for a procedure such as welding. However, even despite this, the scope of application remains quite wide, if you do not take into account the use as a bladed weapon. From such an alloy it is possible to successfully manufacture such parts as springs, leaf springs, metal structures, various components, etc. Steel is used in the assembly of trucks as a spring for the rear axle. In order to avoid such a defect as rust for as long as possible, it is necessary to store products only in a dry place, and also periodically coat them with an oil composition.

It is worth highlighting that the absence of a large number of elements for alloying the composition makes it quite cheap. In addition, hardening of 65G steel improves parameters such as wear resistance, high impact strength and some others. Hardening occurs at a temperature of 800-830 degrees Celsius, followed by tempering at a temperature of 160-200 degrees Celsius.

Purpose of isothermal annealing and normalization

Isothermal annealing is used for high-alloy and high-chromium steels. Its peculiarity lies in heating the metal 30-50 degrees above the critical point Ac3 and in accelerated cooling to a holding temperature below the critical point A1, and then in natural cooling in the open air.

This type provides several visible advantages, the first of which is time, that is, the entire process - from heating, holding to cooling - takes much less time than the stage of cooling the part together with the furnace. The second advantage is that with isothermal holding and sudden cooling, a smoother and more uniform structure across the cross-section of the part is achieved.

- Normalization. The normalization process is carried out as an intermediate before processing and hardening in order to eliminate work hardening and internal stress. Hypoeutectoid steel is heated to the critical point Ac3 30–50 degrees higher, and is gradually cooled in the open air. Moreover, in contrast to annealing, during normalization, supercooling occurs, due to which a more uniform, fine and fine-grained structure is achieved.

- Consequences of normalization. The strength and toughness of steel is significantly increased. Normalization is much faster than annealing, and its performance is much higher. Therefore, it is recommended to normalize steels containing carbon rather than anneal them.

General provisions

The principle of most heat treatment technologies involves heating and holding steels and cooling, which changes their structure. Despite the same principle and similar goals, each of them has certain temperature and time regimes. Heat treatment can serve both as an intermediate step and as a final technological process. In the first case, such methods are used to prepare the material for subsequent processing, and in the second, new properties are imparted using this method.

Steel normalization is the process of heating, holding the material, and then cooling it in air.

As a result, a normalized structure is formed. This explains the name of this processing method.

Normalization is used for different steels, as well as castings. In addition, welded seams are subjected to this operation to refine the structure of the material.

Purpose of the process

Normalization is designed to change the microstructure of steel; it does the following:

- reduces internal stress;

- through recrystallization, it refines the coarse-grained structure of welds, castings or forgings.

The goals of normalization can be completely different. Using this process, the hardness of steel can be increased or decreased, the same applies to the strength of the material and its toughness. It all depends on the mechanical and thermal characteristics of the steel. Using this technology, it is possible to both reduce residual stresses and improve the degree of machinability of steel using one or another method.

Steel castings are subjected to this treatment for the following purposes:

- to homogenize their structure;

- to increase susceptibility to heat hardening;

- to reduce residual stresses.

Products obtained by forming are subjected to normalization after forging and rolling in order to reduce the heterogeneity of the structure and its banding.

Normalization together with tempering is needed to replace the hardening of products with complex shapes or with sharp changes in cross-section. This will prevent defects.

This technology is also used to improve the structure of the product before hardening, increase its machinability through cutting, eliminate the secondary cement network in hypereutectoid steel, and also prepare the steel for final heat treatment.

Application

The choice of any of the considered processing methods is determined by the carbon concentration in the steel. For materials with a value of this indicator up to 0.2%, it is preferable to use normalization. Steels with a carbon amount of 0.3 - 0.4% are processed by both normalization and annealing. In such cases, the choice of method is based on the required properties of the material. Thus, normalization of steel gives it a fine-grained structure, greater strength and hardness compared to annealing. In addition, this technology is a more productive process. Therefore, other things being equal, it is more preferable. It is preferred to hardening due to the fragility of the products obtained in this way and when processing objects with differences in cross-section in order to avoid defects.

Thus, normalization can be considered an intermediate technology in relation to them: it produces a material that is harder than annealing, but less brittle than quenching, improving the structure and reducing stress. In view of this, normalization has become more widespread in mechanical engineering.

If you find an error, please select a piece of text and press Ctrl+Enter.

Using Normalization

This form of heat treatment is used to achieve different purposes. Thus, the use of normalization can increase or decrease the hardness of a steel alloy, toughness and strength characteristics. This method of heat treatment is used when it is necessary to improve the machinability of steel using different methods - cutting, stamping, etc.

Parts produced by casting undergo normalization in order to obtain a homogenized structure and eliminate internal stresses. The same can be said about parts obtained after forging. That is, normalization serves to obtain a homogeneous metal structure and eliminate internal stresses. In addition, this process can be used as a replacement for hardening products with complex profiles. In addition to the mentioned results of the normalization process, you can add such results as minimizing grains in the alloy structure, removing secondary cementite, and increasing the machinability of steel.

Essentially similar heat treatment processes

In addition to normalization, the following operations can be added to the list of heat treatment of steels:

- annealing;

- vacation;

- hardening;

- cryogenic treatment and several others.

The annealing operation provides a high-quality, finer structure of pearlite; this occurs because furnaces are used to cool the parts. The purpose of this operation is to reduce the heterogeneity of the structure, remove stress, and increase machinability.

The principles underlying the hardening operation are identical to those of normalization, but there are some differences. For example, when hardening, much higher temperatures and high cooling rates are used. Hardening leads to improved strength characteristics, hardness, etc. But often workpieces that have undergone hardening are characterized by reduced viscosity and high fragility.

Tempering of parts is used after the hardening operation. Tempering reduces brittleness and internal stress. In this case, the temperature range is lower than that used in normalization. The parts are cooled in air. As the temperature increases, the tensile strength and hardness decrease and at the same time the impact strength increases.

Cryogenic treatment of steel results in a uniform metal structure and increased hardness. This processing technology is used for hardened carbon steel.

Steel grade 45 and its features

This steel is an alloy of iron and carbon. Steel grade 45 due to its hardness is traditionally in high demand in various industrial sectors. In this alloy the share of iron is about 45 percent

The properties of a material are directly related to its alloying elements and the amount of carbon, which is very important in the production of rolled metal products. This or that temperature treatment allows you to obtain a durable product

After normalization, the hardness of grade 45 is directly related to the temperature during operation.

This steel is carbon structural steel. Normalization should be carried out outdoors, and not in a special oven, unlike other stages of processing. Grade 45 is easily and quickly amenable to mechanical processing, in particular:

- drilling;

- turning;

- milling.

The following products are produced on the basis of this steel:

- bandages;

- cams;

- cylinders;

- gears;

- crankshafts and camshafts;

- gear shaft;

- spindles.

Principles

The essence of normalization is heating the steel to a temperature exceeding the upper critical temperature values by 30 - 50 ° C, holding and cooling.

The temperature is selected based on the type of material. Thus, hypereutectoid options should be normalized in the temperature range between points Ac1 and Ac3, while for hypoeutectoid steel temperatures above Ac3 are used. As a result, all materials of the first type acquire the same hardness due to the fact that the same amount of carbon passes into the solution and the same amount of austenite is fixed. The result is a structure consisting of martensite and cement.

The second component helps to increase the wear resistance and hardness of the material. Heating high-carbon steel above Ac3 leads to an increase in internal stresses due to the growth of austenite grains and an increase in its quantity due to an increase in the concentration of carbon in it, leading to a decrease in the martensitic transformation temperature. Because of this, hardness and strength are reduced.

As for hypoeutectoid steel, when heated above Ac3 it gains increased viscosity. This is due to the fact that in low-carbon steel, fine-grained austenite is formed, which, after cooling, turns into fine-crystalline martensite. Temperatures between Ac1 and Ac3 are not used for processing such materials, since the structure of hypoeutectoid steel in this case receives ferrite, which reduces its hardness after normalization and mechanical properties after tempering.

Optimal heating temperatures for various types of heat treatment

The holding time determines the degree of homogenization of the structure. The standard indicator is considered to be an hour of exposure per 25 mm of thickness.

So, there is a direct relationship between these quantities. That is, with increasing cooling intensity, more pearlite is formed, the distance between the plates and their thickness are reduced. This increases the hardness and strength of normalized steel. Consequently, low cooling intensity contributes to the formation of a material of lower strength and hardness.

In addition, when processing objects with large differences in cross-section, they strive to reduce thermal stresses in order to avoid warping, both during heating and cooling. So, before starting work, they are heated in a salt bath.

When the temperature of the workpiece decreases to the lower critical point, it is permissible to accelerate the cooling by placing it in oil or water.

Thus, normalization reduces internal stresses and refines the coarse-grained structure of forgings, castings, and welds through recrystallization. That is, the microstructure of steel changes.

Steel cooling rate during normalization

The cooling rate during normalization is usually not a critical value. However, when the product has large differences in cross-sectional dimensions, measures are taken to reduce thermal stresses to avoid warping.

This is interesting: Description of GOST 380-2005 for carbon steels - we cover it on the shelves

Regulatory materials and labor standards applied in state (municipal) institutions

4.1. The institution applies the following basic regulatory materials on labor standards:

- regulations on the organization of labor standards at shipbuilding industry enterprises;

- methodological recommendations for the development of labor standards;

- methodological recommendations for developing a labor standardization system;

- labor standards (norms, time standards, numbers, production standards, service standards).

4.2. At the institution level, intersectoral and sectoral labor standards are used as basic indicators when developing local labor standards, calculating derivative indicators, and for the purposes of organizing and managing personnel. In the absence of intersectoral and sectoral labor standards, enterprises develop local labor standards.

4.3. Regulatory materials for labor standards must meet the following basic requirements:

- comply with the modern level of technology and technology, labor organization;

- take into account to the maximum extent the influence of technical, technological, organizational, economic and psychophysiological factors;

- ensure high quality of established labor standards, optimal level of labor intensity;

- meet the required level of accuracy;

- be convenient for calculating labor costs in an institution and determining the labor intensity of work;

- provide the possibility of using them in automated systems and personal electronic computers for collecting and processing information.

4.4. According to the scope of application, regulatory materials are divided into intersectoral, sectoral and local.

4.5. Establishing the amount of labor required to perform the work is organically connected with the establishment of qualification requirements for the performers of these works.

4.6. The degree of differentiation or consolidation of standards is determined by the specific conditions of labor organization.

4.7. Along with the standards established for work that is stable in terms of organizational and technical conditions, temporary and one-time standards are applied.

4.8. Temporary standards are established for the period of mastering certain works in the absence of approved labor standards for a period of no more than 1 (one) year, which can be established by summary expert methods of labor standardization.

4.9. Permanent standards are developed and approved for a period of no more than 5 (five) years and have technical validity.

4.10. Labor standards established on the basis of analytical methods of labor standardization, indicating qualification requirements for the performance of work and focused on the fullest use of all working time reserves in terms of duration and level of labor intensity, and pace of work are considered technically justified. Tariffing of work and determination of qualification requirements for employees are carried out in accordance with the norms of the legislation of the Russian Federation.

4.11. Along with the standards established by current regulatory documents for work that is stable in terms of organizational and technical conditions, temporary and one-time standards will be applied.

4.12. One-time standards are established for individual work that is of an isolated nature (unscheduled, emergency, etc.). They can be calculated and experimentally statistical.

4.13. Temporary experimental and statistical standards for time, number, production or service are established in the absence of technically sound regulatory materials on labor for performing these types of work in the institution. Experimental statistical standards are established on the basis of an expert assessment of a labor standardization specialist, which is based on systematized data on the actual time spent on similar work for the previous period of time. The validity period of temporary standards should not exceed three months (for frequently repeated work), and in case of a long process - for the period of performance of the necessary work. Persons responsible for standardization bear personal responsibility for the correct (reasonable) establishment of temporary labor standards.

4.14 Work collectives must be notified of the introduction of temporary or one-time labor standards before the start of work.