Home / Welding technique

Back

Reading time: 3 min

0

3361

Argon is a gas that is often used in welding. It is completely colorless, odorless and protects the metal from the bad influence of the atmosphere.

The main reason why it is so widely used in welding is its low price, because other protective gases sometimes have lower prices; craftsmen simply do not buy them, which reduces the quality of the weld.

- Introduction

- The most informative articles

- Advantages and characteristics of welding with argon

- How to weld aluminum with argon

- Features of welding ferrous metal with argon

- Welding stainless steel with argon

- Bottom line

What is argon welding

Hybrid technology, combining gas and electric welding methods, makes it possible to work with a wide variety of volumes and materials. It has proven itself excellent in welding cast iron, steel, copper and other metals. With its help, large steel pipes and miniature bronze hanger hooks can be welded well. Working with stainless steel is another example of the versatility of equipment and technology.

Without studying the theory of welding skills, it is impossible to become a good specialist. This is especially true for complex technologies, which include the argon method. In order to understand in detail the essence, advantages and features of the argon welding method, it is necessary to understand the physics of the processes that occur during operation. In order to connect two metal blanks together, it is necessary to melt some of their parts. And this can only be done by heating.

Raising the temperature involves the use of fire, which in turn requires oxygen. The latter enters into chemical oxidation reactions. And the faster the metal oxidizes, the more difficult it is to weld. Oxidation is one of the undesirable phenomena when welding metals.

During the chemical reaction, many small bubbles are formed inside the metal, which greatly deteriorate the mechanical characteristics of the weld. But it is almost impossible to work with aluminum: if there is a sufficient amount of oxygen, it simply burns.

Argon is designed to isolate the work area from the external environment. Its main function is to displace oxygen from this area. It is heavier than atmospheric air and replaces the entire volume around the welding arc. Inert gases do an excellent job of this task. In addition to argon, helium is used in welding. But it is used much less frequently due to its higher cost and consumption.

Another important nuance is that when working with helium, it is necessary to protect all parts of the body with special clothing. Nitrogen is used even less frequently: it is in demand when welding copper. Argon remains the main component for welding in a protected inert environment. This is where the colloquial name for the technology comes from.

Basic properties of argon

- Gas is heavier than air. Thanks to this, it displaces atmospheric oxygen and other unnecessary volatile compounds from the weld pool.

- Inert gases do not enter into chemical reactions with other elements. They do not participate in metal welding and do not affect the process in any way.

- It is important not to forget about one feature of argon: it becomes an electrically conductive medium when current with reverse polarity is applied.

Principles of welding performed in argon environment

Argon welding combines the features of electric arc and gas welding. This technological process combines with electric arc welding the mandatory use of an electric arc, and with gas welding it combines the use of gas, as well as some technological methods for forming a permanent connection.

Melting of the edges of the parts being connected and the filler material, with the help of which the weld is formed, is ensured by the high temperature created when the electric arc burns. Gas (in this case argon) performs protective functions, which should be discussed in more detail.

Welding of alloy steels, most non-ferrous metals and alloys based on them has some features, namely that, being in a molten state, interacting with oxygen and other impurities of the surrounding air, such metals are actively oxidized.

This negatively affects the quality of the weld being formed: it turns out to be fragile, pores form in its structure - air bubbles, which significantly weaken the connection. The ambient air has an even more negative effect on aluminum melted during welding. Under the influence of oxygen in the surrounding air, this metal begins to burn.

The optimal solution, which allows you to effectively protect the area of the joint being formed when welding non-ferrous metals and alloy steels, is the use of a shielding gas - this is argon. The high efficiency of using this particular gas is explained by its characteristics.

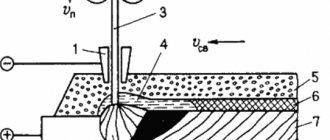

Scheme of operation of argon arc welding

Argon is significantly heavier than air (38%), so it easily displaces air from the welding area and creates its reliable protection. Being inert in nature, argon practically does not react with molten metal, as well as other gases present in the area where the welding arc burns. When welding with argon in reverse polarity, one important point should be taken into account: in this case, electrons are easily separated from the gas atoms, the flow of which transforms the gaseous medium into a conductive plasma.

The technology for welding in a gas such as argon may involve the use of consumable as well as non-consumable electrodes (such as tungsten rods). The diameter of tungsten electrodes, which is known to be exceptionally refractory, is selected using special reference books. The choice of this parameter is influenced by the characteristics of the parts being connected.

Tig welding methods

Argon welding is divided into three types depending on the technology used:

- manual, performed with a non-consumable tungsten electrode (this technology is designated by the abbreviation RAD);

- automatic, taking place in an argon environment using non-consumable electrodes (welding designation for this type is AAM);

- automatic, performed in an argon environment using consumable electrodes (the name of this technology is AADP).

According to the international classification, a argon arc welding machine or welding performed using a tungsten electrode in a protective environment of any inert gas is designated by the abbreviation TIG (Tungsten Inert Gas).

Classification of argon welding by type

The division is carried out based on the level of mechanization of the process. There are three types of argon welding:

- Manual . Both the filler wire and the torch itself are moved by the welder. For such work, exclusively non-consumable tungsten electrodes are used.

- Semi-automatic . In this case, the torch is controlled by the welder, and the wire feed is controlled by the mechanism.

- Automatic . The torch and wire move mechanically, and the operation of the machine is controlled by the operator. Nowadays, it is not uncommon to find installations that operate even without human intervention. Robotic systems are used, for example, in pipe welding.

Correctly sharpen the tungsten electrode

Sharpening a tungsten electrode, more precisely the method and angle of sharpening, has a significant impact on the shape of the arc and its behavior and, as a consequence, on the shape of the weld and the service life of the non-consumable electrode.

For sharpening, it is necessary to use wheels with fine abrasive grains (the ideal option is a diamond wheel). It is advisable to use grinding wheels with a grain size of 40 or less (the size of the abrasive parts is less than 400 microns), since in this case the marks from the abrasive on the surface will be less deep and less precious tungsten will be ground off during the sharpening process. Deep grooves from the abrasive cause energy loss and unstable arc behavior. It is advisable not to work with other materials on the abrasive wheel where the cleaning is carried out. their particles can be deposited on the surface of the electrode.

Sharpening of a tungsten electrode must be done in the longitudinal (along the axis of the electrode), and not in the transverse direction.

Since tungsten electrodes during the manufacturing process have a grain structure that is located along the axis and sharpening in the transverse direction is grinding across the grain. But this is not as significant as the fact that electrons flow with high density along the surface of the electrode and, if the grooves from sharpening are located across it, it is more difficult for electrons to overcome them. Since the arc looks for places with the least resistance, it may not occur at the end of the tungsten electrode, but in the grooves from grinding and will rotate around the pointed end, which in turn causes overheating of the electrode and its rapid wear.

If the abrasive marks are located lengthwise, electrons flow evenly to the pointed end of the electrode with less resistance. In this case, the arc ignites at the end, is more stable and heats up the tungsten electrode less, which increases its service life.

During the sharpening process, make sure that the metal does not overheat. A sign of overheating is a change in the color of the surface and indicates that oxides have formed on the surface, which have greater resistance than tungsten and will prevent the arc from igniting.

The sharpening angle of the tungsten electrode plays a major role when welding with argon.

The blunter the sharpening angle >30°:

- harder arc ignition;

- narrower weld seam;

- more welding current is required;

- increasing the possibility of arc wandering;

- increasing the depth of metal penetration;

- longer service life of the tungsten electrode.

The sharper the sharpening angle <30°:

- easier arc ignition;

- wider weld seam;

- less welding current is required;

- reducing the possibility of arc wandering;

- reducing the depth of metal penetration;

- shorter service life of a tungsten electrode.

During the AC argon welding process, a significant amount of heat is generated at the end of the non-consumable electrode, which melts the tungsten, so it is necessary to make a slight blunting, which will allow the formation of a ball of molten tungsten at the end.

The tungsten electrode sharpening machine allows for perfect sharpening.

What is needed for argon welding

The method of welding metal using inert gas implies great possibilities in terms of choosing equipment and materials. This can sometimes be confusing for new welders. But in fact, their fears of doing the wrong thing are completely unfounded. Most of the equipment and accessories on the consumer market are universal and suitable for a wide range of jobs.

Installations designed for argon-arc welding are divided into three groups:

- Specialized . Designed specifically for performing the same type of work. Most often in demand in industry, when you need to quickly and accurately process workpieces of the same type.

- Special . Another type of equipment in demand at industrial enterprises, which is designed to work with workpieces of the same size.

- Universal . It has become the most widespread and in demand among a wide variety of categories of users - from professionals to novice welders.

In addition to the device, additional equipment is also needed:

- tungsten torch and consumables;

- contactor – used to connect power to the burner;

- cylinder with a reducer for inert gas;

- relay - responsible for connecting the oscillator or contactor;

- rectifier – converts voltage to DC 24V;

- timer - used to control the period of time for blowing the working area with argon;

- ammeter – measures current strength;

- power supply valve;

- battery to stabilize the AC circuit;

- filter – controls high voltage pulses.

To operate, you will need two transformers: the main and auxiliary. The oscillator is connected in parallel with the power source. It is required to supply a high-frequency pulse, with the help of which an arc is ignited between the metal and the non-consumable tungsten rod. In a household network, the voltage is 220 V and the frequency is 50 Hz. After the oscillator, these figures are 6,000 volts and 500,000 Hz.

To work with workpieces of large thickness or to increase the productivity of welding equipment, additional equipment is required:

- a special burner into which several electrodes are inserted at the same time. As a result, a good quality seam is obtained at a higher torch speed;

- device for preheating filler wire.

Pulsating current supply makes it possible to make micro-pauses in work, which contribute to the crystallization of the melt and improve the quality of the seam.

Know what material is to be welded

Regardless of the welding method, special attention must be paid to the brand and characteristics of the parts being welded. It is also important to know the conditions under which the weld and the structure as a whole will be used.

First of all, this factor influences the choice of the right brand of welding consumables that are best suited for given conditions.

For example, if high demands are placed on the structural homogeneity of the weld with the base metal, it is necessary to select welding materials that fully satisfy all requirements.

Before you start welding aluminum or welding stainless steel, you need to know the grade of metal in order to select the right welding materials. because Depending on the chemical composition, different alloys exhibit a tendency to increased deformation and crack formation. Some metals and their alloys require preheating or heat treatment, which affects the selection of the correct welding material.

When welding products made of steel 20 with a thickness of up to 100 mm, no preheating is required, and for steel 12Kh1MF, starting with a thickness of 6 mm, preheating of products to a minimum temperature of 200°C and subsequent heat treatment of the weld are required.

Before TIG welding aluminum alloys with a non-consumable electrode, you always need to know what grade of aluminum is to be welded in order to choose the right welding material. Typically, manufacturers indicate on the packaging what grades of alloys these welding materials are intended for.

Welding with an inverter in argon

Inverters are used both in industrial enterprises and in home workshops. There is a whole class of argon arc welding equipment on the market that converts the incoming AC voltage to DC. Inverters are perfectly adapted to voltage surges that plague domestic power supply networks everywhere.

The inverter for argon arc welding is lightweight, compact in size and reliable. It is suitable for work in different conditions and is unpretentious in maintenance. It is with this type of equipment that it is easiest for novice welders to learn.

Argon burners

The torch applies voltage to the tungsten rod and serves to form an inert gas shield around the work area. It is important to pay maximum attention when choosing it, as well as selecting consumables. As mentioned above, argon arc technology is based on the use of tungsten electrodes, which do not melt, and inert gases. From this follow the main criteria by which you need to select a burner:

- maximum permissible power and current;

- Is there a tungsten rod holder included?

- it is desirable that the nozzle be made of ceramic;

- burner cooling option when working with thick and thin workpieces;

- versatility of burner use. This means the possibility of its communication with welding machines of various types;

- power supply cable length.

The operation of the burner can be described step by step as follows:

- Everything starts working at once: the cooling system circulates, inert gas is supplied to the burner, and the welding machine itself starts.

- Immediately after the formation of the protective layer, the gas arc is initialized. The workpieces are heated to the melting temperature. At this moment, you need to feed the filler wire into the working bath.

- Next, the filler wire, together with the tungsten rod, moves in the direction of the joint of the workpieces.

Non-consumable electrodes

Manual argon arc welding is usually equipped with non-consumable tungsten electrodes. They are best suited for welding stainless steel and non-ferrous metals with high chemical activity - aluminum, titanium, magnesium.

The electrode is mounted in the current supply collet of the torch with a ceramic nozzle, which directs flows of inert gas to the working area. The system is water-cooled. The diameter of the electrode directly depends on the current strength, which is selected depending on the thickness of the workpiece. Due to the fact that when welding metals in this way there is no splash, the burners are equipped with a mesh filter, which serves to uniformly distribute the flow of inert gas.

The mechanized burner has a slightly different design. In addition to the elements already listed, it is additionally equipped with a flywheel for raising and lowering the tungsten electrode. The current-carrying collet is attached using a threaded connection for changing rods of different diameters.

Consumable electrodes

Semi-automatic and automatic argon arc welding is most often equipped with a torch with a consumable electrode. During operation of the machine, the arc is maintained between the surface to be welded and the filler wire. Depending on the performance of the installation, the cooling system can be air or liquid. The nozzle design and operating principle are completely identical to analogues equipped with non-consumable rods.

The essence of the welding process

The current strength determines the quality of the weld and productivity, being the main and most important welding parameter.

The heat necessary for a reliable connection comes from the electric arc. It forms between the electrode and the metal being welded. To form and burn an electric arc, there is a device - a generator, which supplies the required amount of current. There are two types of these devices.

Alternating current generator – transformer.

The current leaving the device takes the form of a square wave, which changes its polarity with frequency depending on the generator. In this case, the rectifier converts the mains current into alternating current suitable for welding.

DC generator - inverter or rectifier.

Both methods are for beginners, but you need to start with direct current. The current output from the device has the form of a constant wave. In this case, the alternating current of the network is converted into direct current. There are two options for connecting the inverter poles to the material being welded:

with straight polarity - the electrode is connected to the negative pole of the inverter, and the part is connected to the positive pole;

with reverse polarity – the electrode is connected to “+”, the part – to “–”

Features of welding with straight polarity: increase in the amount of heat in the product and decrease in the electrode; the metal melting zone is narrow but deep. This is the main tig welding mode for all types of complex metals and alloys.

With reverse polarity : heat input into the product is reduced, and heat input into the electrode is increased. The weld pool is wide, but not deep. In addition, there is the effect of cathodic cleaning of the metal surface, when the oxide film is destroyed. This improves edge fusion and seam formation.

Aluminum and magnesium, as well as their alloys, can and should be welded using alternating current.

There are also generators that produce pulsed direct current - pulse inverters. Such generators have devices that change the amplitude of the welding current by superimposing square waves on the base direct current. The result is a periodic pulsation of the arc. In pulse mode, a seam is formed by continuously superimposing welding points on top of each other.

Mainly used on thin products, when it is necessary to maintain the required temperature to avoid burning through the metal and, at the same time, not to disturb the penetration depth.

Adjusting process parameters on a welding machine

Before starting work, you need to adjust the indicator values so that the seam is the right size and of good quality. The device is adjusted depending on the type of metal, its thickness and working gas.

Each welding machine is supplied with a table for setting welding parameters. Based on the table, on the front panel we set the tig mode and the main indicators:

- current strength;

- gas purging time before the start – 0.5, and at the end – 1.5 seconds;

- the current value for igniting the arc is 25% of the operating current;

- the rise period to the operating current value is 0.2–1.0 sec;

- The current decay time and its value for crater filling are selected depending on the thickness of the metal.

According to the table, we initially set the gas flow rate under normal conditions to 8-10 l/min.

You need to start cooking on a similar test piece. If the arc is not stable and goes out, then the current must be increased. If the metal burns or deposits form, reduce the current.

We increase the gas supply if the arc is unstable and the seam is crooked. After finishing, when the arc has been extinguished, we blow on the welding zone for some time to avoid oxidation of the seam and electrode. Modern devices are equipped with many functions and, if not, for example, purge time or something else, then the welder controls the process independently.

Preparing parts

Unlike other types of welding, tig is very sensitive to contamination. This should be taken into account by all beginners. Therefore, parts should be cleaned especially carefully: degrease with solvent and sand the surface to be welded until shiny.

Before welding, sand the rod if necessary, and be sure to wipe it with alcohol.

Thick parts are cut by chamfering at an angle of 45°. This will ensure good penetration. Fix the position of the parts relative to each other using tacks or clamps.

How to cook with argon

It would be a good idea for novice welders to learn the basic rules and procedure for performing operations when working with argon welding:

- The working surface is cleaned of foreign inclusions: dirt, oil, grease, paint, etc. It is important to perform proper cleaning, since the metal connection does not tolerate any dirt. Any cleaning methods are allowed, including mechanical and chemical.

- 20 seconds before starting welding work, supply inert gas to the work area. Take the wire and the torch in your hands, which should be placed closer to the surface to be welded. An arc forms immediately after power is applied.

- Guide the burner along the joint line, avoiding transverse movements. Do not feed the filler wire into the welding zone too quickly, as this will cause metal spattering. It is best to move it slightly ahead of the burner and add or subtract with quick progressive movements.

- It is important to achieve the shortest arc possible. In this case, the seam will be narrow, deep and aesthetically pleasing. Particular attention should be paid to this nuance in cases of working with a non-consumable electrode.

- The torch and filler wire must be inside a protective sheath of inert gas.

- The crater must be welded by lowering the voltage supplied to the burner, but not by interrupting the arc. The inert gas supply is shut off 15 seconds after welding is completed.

Features of welding work in argon environment

The working body of welding equipment used to connect metal parts in a protective gas environment (including argon) is a torch. It is into the burner (in its central part) that a tungsten electrode is inserted, the projection of which should be within 2–5 mm. Fixation of the electrode inside such a torch is ensured by means of a special holder: a tungsten rod of any required diameter can be inserted into it. To supply shielding gas, the welding torch is equipped with a ceramic nozzle.

Working principle of argon welding

The required temperature during argon welding, as mentioned above, is created by an electric arc. The weld is formed using filler wire, the composition of which should best match the composition of the metal being processed.

Let us list the main stages of welding of the type in question, which uses a tungsten electrode.

- The surfaces of the parts to be joined are thoroughly cleaned from dirt, traces of oil and grease, as well as from oxide film. This cleaning is mandatory and can be done mechanically or using chemicals.

- Ground must be connected to the parts to be connected. This can be done either directly (if the parts are large) or through the metal surface of the work table (if the parts are not large). The filler wire, which is important, is not included in the electrical welding circuit, but is supplied separately.

- The welding current is set on the welding equipment. This parameter is selected depending on the characteristics of the workpieces being joined.

- After turning on the current, the torch with the electrode is brought as close as possible to the parts to be welded, without touching their surface. The optimal distance at which the torch is placed from the surface of the workpieces to be joined (this must be maintained during the welding process) is 2 mm. Holding the electrode at such a short distance allows you to thoroughly melt the metal being joined and get a beautiful and neat weld.

Diagram of welding equipment for welding in argon

- The supply of shielding gas is turned on in advance - 15–20 seconds before the start of welding. The argon supply is not turned off immediately after welding is completed, but a little later - after 5-10 seconds.

- The torch and filler wire are slowly guided only along the seam being formed, without making transverse vibrations. The filler wire, which is located in front of the torch, is introduced into the electric arc zone very smoothly, without making sudden movements. Otherwise, the molten metal will splash heavily.

- When welding, the electric arc is ignited without the electrode touching the surfaces to be joined. It is necessary to adhere to this rule for several reasons. Firstly, the ionization potential of argon is very high, which makes it difficult to effectively use a spark from touching the electrode to reduce it. When a consumable electrode is used for welding, metal vapors are generated when it touches the parts being joined. Their ionization potential is significantly lower compared to argon, which facilitates the process of igniting an electric arc. Secondly, if you touch the surface of the parts being joined with a tungsten electrode, it becomes dirty, which interferes with the quality of welding work.

TIG welding process close up

Many people naturally wonder how an electric arc can be ignited in a gas such as argon if its ionization potential is too high and the electrode itself does not touch the surface of the parts being connected. For this, an oscillator is used, which converts the current coming from the electrical network with conventional parameters into high-frequency pulses with a voltage value of 2000–6000 V and a current frequency of 150–500 Hz. It is these impulses that make it possible to ignite an electric arc without the electrode coming into contact with the parts being connected.

Modes

The operating mode of the welding machine must be selected carefully, taking into account all the initial data. The result largely depends on this. So:

- Direction and polarity of current. The determining criterion is the metal with which you have to work. Most steel workpieces, including stainless steel, require forward direct current. Regarding non-ferrous metals, magnesium and aluminum, everything is exactly the opposite. It is best to choose alternating current with reverse polarity.

- The consumption of inert gas is determined by two factors - operating conditions and argon supply rate. Welding metal in an open area with strong winds entails increased consumption of inert gas. Therefore, you should always have at least two sides protected from the wind.

At first glance it may seem irrational, but oxygen is present in the argon mixture. Its share is small and does not exceed 5% of the total volume. It would seem that this would negatively affect the quality of the seam. But no. In small doses, oxygen performs a positive function: it burns small harmful impurities. They react with the gas and burn.

We do argon welding at home

Although argon arc welding technology is complex and is characterized by many technical nuances, many home craftsmen manage to complete the work using improvised means. To do this, you must have inverter welding, although in some cases it can be replaced with a retrospective transformer installation. Naturally, it is necessary to have a cylinder with inert gas, a mask and a reducer.

In addition, to implement the idea of a homemade argon apparatus you will need the following tools:

- electric drill, grinder and conventional welding machine;

- wrenches, screwdriver, hacksaw, pliers;

- tester, ammeter, micrometer, voltmeter.

The current source can be made from a welding transformer and a rectifier, which in this case will need to be combined with an oscillator. The primary winding must be made of copper wire up to 0.8 mm thick. For the secondary winding, copper of a much larger diameter will be required - no thinner than 3.5 mm.

The gas burner will be next in importance. It is advisable to use brass for the body, and the nozzle itself can be machined from copper. Heat-resistant rubber is suitable for sealing the joint between these two components. Moreover, it is not difficult to make a gasket from flexible material.

Argon will be supplied to the burner through a copper tube, which is inserted into a hole in the housing, and the joining seam is sealed. The same line will become an excellent conductor of current, which is necessary for igniting and maintaining the arc. The tungsten electrode must have a sharp end that is ground at an angle of approximately 45 degrees. The approximate length of the rod will be 25-30 cm.

It is important to understand that making equipment for argon arc welding at home is quite a difficult task. And not always “the game will be worth the candle.” If the equipment is rarely used, the cost of its production may never be recouped. Very often it is much more practical to use the services of a specialist with his own equipment or to purchase a ready-made device in the budget price segment.

What metals are boiled with argon?

The operating principle of argon arc welding determines a wide range of its applications. This refers not only to the area of use, but also to the materials being processed. It can be used to join cast iron, steel (including stainless), titanium, aluminum, as well as other ferrous and non-ferrous metals.

We work with aluminum

Without argon, connecting two aluminum workpieces is not only problematic, but almost impossible. The metal, which is common in everyday life and in the industrial sphere, is one of the most difficult in this regard. The difficulties are due to the properties of aluminum. at the slightest contact with oxygen, a protective film of aluminum oxide instantly forms on its surface.

In itself it is not a problem. The point is different: the melting point of the oxide is much higher compared to aluminum. The inert gas is heavier than air and when directed into the working area, it displaces oxygen from there, preventing the oxidation of the metal and the formation of a protective film. Under such conditions, the aluminum itself and the filler wire melt at a suitable temperature, and the welding seam turns out to be quite strong and visually pleasing.

Assumes the use of alternating current. Reverse polarity significantly increases the melting point due to cathodic purification of the metal oxide. And vice versa. Straight polarity makes it possible to form a short and stable arc. However, the power is not enough to destroy the oxide film. Conclusion: Reverse polarity is necessary, since this improves the quality of the weld.

It is possible to use direct current when welding aluminum workpieces. But in this case, another inert gas is needed - helium. But it is much more expensive than helium and is consumed much more actively. In addition, working with direct current is very difficult from a technical point of view.

For any technology for welding aluminum parts, surface pretreatment is very important. It cannot be neglected, regardless of the welder's skill level. Cleaning is carried out in the following order:

- parts of the workpieces intended for welding are degreased with a solvent;

- the oxide film is removed mechanically or chemically;

- The cleaned surface is allowed to dry.

Cooking copper

High resistance to aggressive environments and corrosion distinguishes copper from other non-ferrous metals in terms of chemical reactivity. When working with it, experienced welders do not use pure argon, but its mixture with helium (added in smaller proportions). Tungsten electrodes are used both consumable and non-consumable. The current is selected constant.

When it is necessary to cook workpieces with a thickness of 4 mm or more, they must be preheated to a temperature of 800 degrees Celsius. The filler wire can be pure copper or copper-nickel alloy. It is often replaced with rods of a similar composition. During operation, the arc is stable and stable.

Due to the high thermal conductivity, the welded edges must be cut. If the thickness of the workpieces does not exceed 12 mm, then it is enough to cut one of the two edges. For larger thicknesses, it is advisable to process both sides.

Argon-arc welding of stainless steel with foreign metal

Usually there is a need to attach a steel element with anti-corrosion properties to alloys with a small amount of carbon in the composition. To do this, you just need to choose a suitable additive that contains nickel and chromium. Alloying additives are found in the following wire grades: Y310, Y310S, Y309, Y309L, Y309Mo. If you need to attach ordinary ferrous metal, you can use one of the following techniques:

- piece electrodes with winding in MMA mode;

- tungsten conductors, infusible;

- using inert gas.

The first two methods are less effective. When arcing, there is less filling of the seam with oxygen, which means less oxidation. But if you decide to use the first method, then you will need a table with suitable brands of electrodes:

| Brand | Type | Rod material K | Deposition rate, r/a. emergency | Application |

| ozl-8 | e-07 x20n9 | sv-04 x19n9 | 12-14 | chromium-nickel steels, when the weld is not subject to strict requirements against intercrystalline corrosion |

| ozl-3 | e-10x17 n13s4 | sv-15x-18n12s-4tyu | 11,5-12,5 | type 15x18n12s4tyu. Likewise |

| zio-8 | e-10x25 n13g2 | sv-07x-25n13 | 13,3 | structures and pipelines made of two-layer compounds. Likewise |

| uonii-13/nzh | e-12x13 | in-luna_2012 | 10-12 | responsible systems made of chrome 08x13, 12x13 |

| ozl-22 | e-02x21 n10g2 | sv-01x-18n10 | 12-14 | structures made of x8n10 |

| ozl-14a | e-04 x20n9 | sv-01 x19n9 | 10-12 | chromium-nickel, when the weld metal is not subject to strict requirements against intercrystalline corrosion |

| ozl-36 | e-04 x20n9 | sv-01 x19n9 | 13-14 | Likewise |

| ozl-7 | e-08x20 n9g2b | sv-01 x19n9 | 11,5-12 | Likewise |

| tsl-11 | e-08x20 n9g2b | sv-07x19-n10b | 1-12 | chromium-nickel, when stringent requirements are imposed on the weld metal against intercrystalline corrosion |

| tsl-9 | e-10x25-n13g2b | sv-07 x2513 | 10,5-11,5 | chromium-nickel on the alloy layer side of two-layer steels. Likewise |

| ozl-20 | e-02x20-n14g2m2 | sv-01x17-n14m2 | 12,5-14,5 | structures made of 03x16n15m3, 03x17n14m2. Likewise |

| niat-1 | e-08x17 n8m2 | sv-04 x19n9 | 10-11 | welding of structures made of chromium-nickel and chromium-nickel-molybdenum; most suitable for welding thin sheet metal |

| EA-400/10у | e-07x19-n11m3g2 | sv-01x19-n11m3 | 12 | connection of power equipment housings and pipelines operating in contact with an aggressive environment at temperatures up to 350° C |

| ha-400/10t | e-07x19-n11m3g2 | sv-01x19-n11m3 | 14,5 | Likewise |

Advantages and disadvantages

Argon welding has few disadvantages and listing them is not difficult:

- the equipment is technically complex, and its setup requires certain knowledge and skills;

- The method cannot be used by beginners due to its technical complexity.

Against this background, the advantages look much more impressive:

- high quality seams;

- due to moderate heating of the metal, there is no deformation of the welded seam;

- unique ability to work with a wide range of metals;

- welding of non-uniform workpieces is allowed;

- The use of high-temperature mode can significantly speed up the work.

The list shows that the shortcomings are minor and solvable problems. While the advantages are due to the characteristics of the equipment and technology. Exclusive capabilities that cannot be obtained using any other technology.

Features of welding ferrous metal with argon

Ferrous metals are classically considered to be iron and its alloys. Such metals rarely act independently; more often they are taken as raw materials, produced, for example, cast iron, or used for processing for steel production.

Rarely, but sometimes situations arise when you need to deal with pure iron.

This is a very difficult task, but this gas makes it a lot easier. Like any method, argon welding has advantages and disadvantages. And if you need to get a passable result, you will have to strictly adhere to the technology.

This article talks about all this, it will also talk about how to choose a welding mode, what safety rules should be followed, and in particular fire safety. Because welding is not a simple matter and unsafe situations often arise.