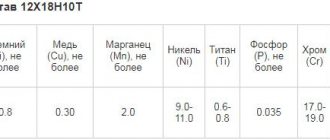

general characteristics

Laser welding of metals is carried out using special equipment. This method appeared not so long ago, but it has managed to gain great popularity. It is used in various industries to create a durable permanent connection. This welding method has high accuracy, good performance and excellent joint quality.

Heating and melting in the working area occurs using a laser beam. The light flux generated by the laser is monochrome. All waves have the same length. This is what greatly simplifies the control of flows, which is done by focusing lenses and deflecting prisms. The laser exhibits the phenomenon of wave resonance, which increases the launch power many times.

All these properties help to understand what laser welding is. During this technology, different welding machines can be used - semi-automatic, automatic and even robotic, which carry out work without human presence. Each of them delivers a laser beam that heats and melts a selected area of the metal product.

Devices

The equipment is presented in the form of large-sized machines or mobile devices:

- LAT-S is a machine designed for surfacing and welding of metal products. The device shows high technical characteristics; it is equipped with automatic coordinate machines, which increases the processing speed of complex structures.

- CLW120 is a laser welding machine that has pinpoint accuracy. Used for processing ferrous and non-ferrous alloys, stainless steel and titanium. The device operates on 220 V, so it is suitable for domestic use from an electrical panel.

Welder of the highest category Ivleev A.V.: “The vast majority of models for laser welding are equipped with a binocular; the element protects vision from the negative effects of a bright beam and improves the visibility of the part.”

With solid active element

The operating principle is based on the following aspects:

- A solid rod-shaped element is the source of the beam, it is located in a special chamber.

- The pumping lamp generates flashes of light that activate the working fluid.

Solid state laser circuit

The solid part is made from ruby; this material has shown high technical characteristics, safety and impeccable efficiency.

With elements based on a gaseous medium

These are high-performance machines that work in combination with gas protection . The active medium is a mixture of nitrogen, oxygen, and helium; it is supplied under high pressure, reaching more than 10 kPa. The working gases are excited by an electrical discharge. The efficiency of the device does not exceed 15%.

Nitrogen and helium transfer energy to carbon dioxide, which creates ideal conditions for obtaining a discharge.

Classification of gas lasers

Based on the cooling method, installations are divided into two large groups: with convective (intensive) and diffuse (slow) pumping. The latter is used in low-power single-beam lasers. It is advisable to install convective in powerful devices.

On the side of gas movement relative to the electrodes of the resonator mirrors and the gas chamber, convective lasers are divided into transverse and longitudinal pumping. The mixture is excited by a high-frequency or direct current discharge. A dual-circuit cooling system is responsible for cooling the resonator and optical elements; the working mixture is cooled by a water-gas heat exchanger.

Beam transport and focusing systems

This system includes protective beam guides, a mirror and a focusing element. The mirror is designed to change the trajectory of the beam and moves it into the working area. Low-power solid-state lasers are equipped with special prisms and refractive mirrors, which consist of a multilayer dielectric coating. Gas lasers have copper mirrors; more powerful devices use mirrors with a water cooling system.

The focusing element (tube) makes movements relative to the workpiece. The lens is fixed in it. Solid-state lasers are equipped with glass optical lenses; gas lasers use prisms made of zinc selenide or potassium chloride. Air curtains protect lenses from melting products.

The focal length to obtain high power should be about 100-150 mm. a decrease in this indicator leads to difficulty in removing harmful products.

When laser welding of carbide metal, the distance from the energy source to the working area is determined by the tabular method.

Gas protection

The purpose of a gas protection system is to reduce the likelihood of oxidation in and around the weld. It includes nozzles of different designs. These elements eliminate spatter and fumes that appear during welding. The nozzle is selected depending on the level of chemical activity of the materials, power, and melting depth. The gas with the most suitable composition is supplied to the working area.

Moving the beam and product

The welded products and the energy beam are moved by a CNC manipulator, which has several degrees of freedom, this indicator depends on the complexity of the process. Travel speed can reach 400 m/h.

When processing large parts with a large mass, it is more advisable to move the beam rather than the part. This process is realized through movable mirrors. The most promising system is to secure the tool in an automatic manipulator.

Hybrid installations

Hybrid arc welding is great for creating straight welds.

The main advantage of such installations is the complete fusion of all kinds of profiles without special preparation. The peculiarity of the method is the combination of an electric arc with an energy beam . It is used for fastening parts of large thickness at high speed in automatic mode and low heat transfer. The quality of the seams is at a high level.

Laser welding technology

The operating principle of laser welding is based on the following properties:

- coherence . This indicator is based on the relationship between the phases of the thermal field of the laser beam in different zones;

- monochromatic . This property is characterized by the small width of the spectral lines emitted by the source;

- direction . When carrying out the welding process, the beam does not dissipate as it moves from the source to the product being welded.

Thanks to these indicators, the power of the laser beam increases, it ensures precise, measured melting and evaporation of metals in the welding zone. The source can be at some distance from the welded area, and the presence of a vacuum in the area of the laser weld pool is not required.

So how does laser welding work? When connecting products using a laser beam, the following processes are observed:

- Elements that are prepared for connection are tightly connected to each other along the line of the future connection.

- Next, a laser beam is aimed at the joint area.

- The generator turns on. During this, uniform heating, melting and evaporation of particles at the edges begins.

- Due to the fact that the cross-section of the laser beam is small, the molten metal fills all the micro-irregularities and defects of the products that fall within the laser beam’s action area.

Important! Laser welding has a positive feature - during it a welded joint with high density is formed. But porosity and other defects that are inherent in other welding methods are absent during this technology.

Due to the fact that the laser beam moves along the joined surfaces at high speed, metal oxidation does not occur during the welding process. Using a beam, you can make two types of seams - continuous and intermittent. Using the first option, stainless steel pipes are welded where high tightness is required. The second type is used when welding small structures that have surface damage.

Technology

physical characteristics

Laser welding of metals differs from other types of welding technologies in its high energy density in the heating spot - up to 1 MW per sq. cm. This ensures a high rate of heating and cooling of the weld zone, which significantly reduces the thermal effect on the heat-affected zone. Therefore, the welding process does not cause structural changes in the material, leading to softening, deformation and cracking.

The size of the focusing spot of an industrial installation can vary from 0.2 to 13 mm. The depth of material penetration is directly proportional to the laser radiation energy, but also depends on the location of the focal plane of the beam. During a welding operation, a zone of molten material is mixed along a predetermined path with a laser beam, creating a weld along the line of motion. It turns out to be narrow and deep, so its shape is fundamentally different from the welds of other welding technologies.

Types and modes of laser welding

Laser welding technology includes two types of welding joints: spot and seam. In this case, industrial installations can generate two types of laser radiation: continuous and pulsed. For a point connection, only pulsed radiation is usually used, and for a suture connection, both continuous and pulsed radiation are used. In the second case, the weld is formed by overlapping pulsed heating zones, so the welding speed depends on the pulse frequency. Spot welding is usually used to join thin metal parts, and seam welding is used to form deep welds.

Hybrid laser welding refers to welding technologies that use filler materials. In this case, welding equipment is supplemented with wire, tape or powder feed mechanisms. Filler materials are fed into the melting zone synchronously with the movement of the welding head, and their thickness corresponds to the width of the weld and the diameter of the spot.

Technological features

The speed of movement and energy modes of the welding process depend on the width of the weld, as well as on the type and thickness of the materials being welded. For example, steel sheets 20 mm thick are welded with a gas laser at a speed of several hundred meters per hour. This figure is an order of magnitude higher than the limiting characteristics of electric arc welding.

Laser technology is especially effective when working with alloy steels, cast iron, titanium, copper, copper alloys, thermoplastics, glass and ceramics. The high energy density in the heating spot destroys surface oxide films, preventing the formation of new oxides. This allows laser beam welding of titanium, aluminum and stainless steel without the use of fluxes or inert gases.

Advantages and disadvantages

The advantages of laser welding have made this technology popular and in demand. But just like other welding works, it has negative aspects that must be considered first.

Among the advantages of welding are:

- Laser beam welding can be used for a variety of materials - from metals and magnetic alloys to thermoplastics, glass, and ceramics.

- High accuracy and stability of the heating spot trajectory is observed.

- Small size of the welded joint. This is what makes it invisible.

- There is no heating of the heat-affected area. As a result, minimal deformation of the welded parts is observed.

- When heated, no combustion products are formed and no X-ray radiation appears.

- High chemical purity of the welding process. This is due to the fact that additives, fluxes, and electrodes are not used during welding.

- Suitable for welding in hard-to-reach places, can be used at a great distance from the laser location area.

- Can be used for welding elements that are located behind transparent materials.

- Quick reconfiguration when switching to the production of a new product.

- The welds are of high quality and strength.

Despite the fact that laser welding is a popular method that is excellent for car body repairs and for working with various structures and metal products, it is still worth considering the pros and cons of the technology. As we understand, it has quite a lot of advantages, but we should not forget about the disadvantages.

Particular attention should be paid to the following negative qualities:

- Laser welding equipment is expensive. Also, components and spare parts are quite expensive. For this reason, this technology is used only in production and enterprises. And some craftsmen resort to making laser welding with their own hands, but this requires some knowledge, and you also need to have diagrams, drawings, instructions;

- Laser arc welding has a low efficiency rate. For solid alloys it is 1%, and for gas alloys it can be 10%;

- dependence of the efficiency of the welding process on the reflectivity of the workpiece;

- high requirements for the qualifications of service personnel;

- special requirements for premises in which laser equipment is located. This applies to vibration, humidity and dust indicators.

Pros and cons of technology

Laser welding has become widespread due to the following positive qualities:

- high connection strength;

- no need for additional mechanical processing;

- speed of work;

- minimum heating zone;

- possibility of high-precision shaped connection.

Despite all the positive aspects, laser welding is narrowly focused due to the following reasons:

- high cost of equipment;

- difficulty in selecting specialists;

- presence of vibration when operating the device;

- low equipment efficiency.

Conditions and methods of laser welding

Laser welding of stainless steel, alloys and materials must be carried out in accordance with certain specifications. To obtain increased beam power, precise focusing is required. At the moment when the beam intensity indicators become higher than the maximum value, it is passed through the central area of the front mirror and then through a system of guide prisms to the working area.

Laser welding of stainless steel and other metals can be carried out at different locations of the products being welded. The depth of penetration of the metal structure can be adjusted in a wide range - from surface to through. The working process can be carried out with a continuous beam or intermittent pulses.

Note! Laser pulse welding is suitable for joining and processing thin sheet metal products. In addition, this technology can easily weld profiles with complex structures and parts with large thicknesses.

It is worth considering that laser welding of aluminum, copper, stainless steel and other metals can be carried out in several ways:

- Butt method . Does not require additives or flux. There may be a joint between metal products, but its size should be no more than 0.2 mm. The same indicator is considered the limit for focusing the laser beam on the joint. The welding process is carried out using “dagger” penetration of metal surfaces over the entire thickness, while an intensity of laser radiation of up to 1 mW/cm2 is observed. In these situations, the seam needs to be protected from oxidation; argon or nitrogen is suitable for this. But helium can prevent breakdowns of laser radiation.

- Lap method . During welding, the sheets are superimposed on each other, their connection is made by powerful radiation. During welding, local pressure is applied to the products. The maximum gap between the surfaces of metal products during operation should be no more than 0.2 mm.

Fixed standards

In 2021, the following state standards are in force that impose requirements for laser welding:

- GOST ISO 15609-4-2017 – contains technical requirements for the certification of welding procedures for metallic materials. Part 4 of this document covers laser welding;

- GOST 28915-91 - describes the main types of laser pulse welding, structural elements and dimensions.

Types of lasers

Laser welding of aluminum alloys, copper, stainless steel and other metals and materials can be carried out with different lasers. The devices come in solid-state and gas-based types. Each type is selected according to the purpose of the equipment. But we should not forget about the important characteristics of each type.

Solid State

Laser welding of copper, aluminum, stainless steel, silver, plastic and even glass is carried out using a solid-state laser. It requires the main component - a ruby rod; it can also be made of glass with neodymium. Typically this element is located inside the lighting chamber.

At the moment when light with high power is supplied to the chamber at a certain frequency, excitation of atoms occurs in the crystal at that moment. All this leads to the emission of light, which has waves of the same length. The end parts of the rod element consist of reflecting mirrors. One of them is partially transparent. Energy comes out through it in the form of laser radiation.

It is worth noting! Solid-state lasers have low power. This figure can vary from 1 to 6 kW.

Gas

Gas-type lasers are considered more powerful and productive devices, in which a gas mixture acts as an active body. However, laser welding of titanium, copper, aluminum, and stainless steel, which is carried out using these devices, has important features:

- Gas is pumped from the cylinders using a pump. For this, a gas discharge tube is used.

- An electric current discharge occurs between the electrodes, which causes energetic excitation of the gas mixture.

- In the end zones of the gas-discharge tube there are special mirrors through which laser beams are passed.

- When performing laser welding of frames, car bodies and other products, the electrodes are connected to a power source.

- The cooling process of laser devices is carried out by a water system.

But still, gas devices have a significant drawback - large dimensions. But laser units that have transverse gas pumping are small in size. General power indicators of equipment start from 20 kW and above. Thanks to this, metals with a thickness of up to 2 cm can be welded at speeds of up to 60 meters per hour.

Laser welding of silver, copper, aluminum, titanium, stainless steel and other metals is carried out under atmospheric conditions. It requires a vacuum, but the molten metal must be protected from the influence of air. Gases, usually argon, are used for this. Due to the fact that there is a high thermal power of the beam on the surface of the element being welded, increased evaporation of the metal occurs. The vapors are ionized, resulting in scattering and screening of the laser beam.

Laser welding of glass, plastics and products made of various metals, during which gas mixtures are used, is characterized by the fact that in addition to the shielding gas, plasma suppression gas penetrates into the welding area. The material used is helium, which is much lighter than argon; it will not scatter the laser beam. To simplify the process, many experienced welders often use combined gas mixtures that have plasma suppression and protective properties.

Features of gas dynamic lasers

Gas-dynamic units have high power indicators. Carbon monoxide acts as the active body. It is heated to 3000 K and passed through a Laval nozzle. At the exit from the nozzle, a rapid decrease in pressure and gradual cooling of the gas mixture are observed.

Application area

The greatest welding efficiency is observed in products with a thickness of up to 10 mm . The method is not widely used for economic reasons, since the cost of installation and additional equipment is high.

This processing is used in cases where other types of welding cannot be used and precise preservation of the structure of the part is required after all manipulations. The concentrated impact of the energy beam guarantees minimal changes in the properties and geometry of the product. This is an excellent solution for joining difficult-to-weld metals, without the need for additives, vacuum chambers and other additional elements.

Application of hybrid installations

Laser welding of car bodies, various structures with thick elements and components with a gap is carried out using additional filler materials. For these purposes, a wire feed is used, which ignites an electric arc. Thanks to this, the space between the plates is filled and a connection with high strength is created.

Important! When laser welding a car or thick metal structures, the weld pool is protected by blowing with inert gas, which is supplied through a nozzle fixed next to the laser head.

Laser welding of bodywork and other high-thickness products is carried out on a table or equipment stands. The process is carried out in several stages:

- At the initial stage, the metal is cleaned of scale, oil stains, signs of water, and moisture.

- The parts are then tightly fitted end to end.

- Chemical etching of the surface of a metal product is performed.

- Laser welding is configured with the required parameters set depending on the type of metal being welded.

- Next, the head from the welding equipment is moved to the line where the connection begins, and the welding start button is pressed.

- During the welding process, it is necessary to constantly monitor the beam entering the joint area.

Devices with elements based on a gaseous medium

Gas laser welding equipment is more powerful compared to solid-state analogues. Such installations operate using high-voltage sources. Both types of source modes are supported: pulsed and constant.

A hand-held laser device of this type is characterized by longer waves, as well as high operating power. The most common are gas-dynamic devices. Gases are used as the active medium, the temperature of which can reach three thousand degrees.

The power of gas installations allows welding metal sheets up to twenty millimeters thick. It is worth noting that in this case, neat, high-quality seams are also formed, and due to the localization of the thermal effect, the products are not deformed after welding.

The operating principle of the devices is similar to solid-state ones, but instead of a rod, the lamp irradiates a gas mixture under pressure of several atmospheres.

The electrodes periodically cause an electrical discharge in the mixture. After multiple reflections from the end mirrors, a coherent beam passes through the optical system and irradiates the working area.

https://youtu.be/bKYiZLsFn_k

Features of welding thin-walled products

The main advantage of laser welding is its diversity. For each type of work you can select suitable instruments and devices. But when choosing them, you should rely on the type and characteristics of the materials that will be welded. Typically, solid-state lasers and gas-based devices are used for thin-walled products. But the first option is considered the most preferable.

Laser welding of small thicknesses is always performed using solid-state lasers. It is suitable for working with small products. Often these are microelectronic elements, for example, thin wire leads with a diameter of 0.01 to 0.1 mm.

Solid state laser spot welding is often performed using a solid state laser device. But it is suitable for products made of foil structure with a point diameter of 0.5-0.9 mm. Using this method, a sealed cathode connection is made on picture tubes of modern televisions.

The connection of small and thin-walled products is carried out at minimum power. If welding is performed in pulse mode, then it will be necessary to increase the duty cycle of the pulse and reduce its duration. But in continuous mode it is necessary to increase the laser speed.

Features of working with thin-walled materials

Welding of parts of medium and large dimensions is carried out by melting throughout the entire thickness. For these purposes, high concentration sources are used. The main nuance when processing thin-walled products is the risk of burning through the sheet. To avoid such a result, it is necessary to control the following indicators:

- power;

- focusing;

- speed of movement of the energy beam.

To connect thin-walled workpieces, the installation should be set to the minimum power setting . A continuous type installation must have an increased speed of movement of the contact spot.

In pulse mode, the pulse duration is reduced and the duty cycle is increased. If the flux density is too high, then they resort to defocusing the beam, which reduces the useful effect, but eliminates the possibility of burning and splashing of liquid metal.

Application of laser welding for glass and plastic products

Laser welding of plastics and glass is carried out using solid-state machines. They have a simple device - two electrodes are installed in a reflective tube, and in the space between them there is a mixture of ionizing gases.

Note! Solid state equipment is often used to repair glasses made of plastic and glass. It has gained particular popularity when welding frames, this is due to the fact that this process does not require the use of solder.

Welding of plastic and glass products is carried out in the same sequence as the connection of metal elements:

- the surfaces of parts that will be welded are thoroughly cleaned of dust, stains, and various contaminants;

- then the installation and electrode are prepared for subsequent work;

- The focusing lens is adjusted. If a defocused lens is used, the laser beam will be blurry and it will not be possible to create a local melting of the metal. A properly focused beam should have a circular shape;

- the required value of welding power is set.

Differences in welding technology for parts made of different metals

Different metals are welded in accordance with different technological standards. Working with steel workpieces requires preliminary cleaning of contaminants, including rust. Also, the product must be thoroughly degreased and dried.

Technology for welding thick metal.

The presence of moisture in the area where parts are connected can lead to increased hydration and, as a result, to a decrease in its strength and durability.

Due to the high speed of the beam, laser welding machines allow the formation of a seam without oxides. As a result, it becomes possible to join stainless and titanium alloys without flux and inert gases.

This unique ability makes such installations indispensable when welding especially critical structures.

Developments in technology in recent years have made it possible to create a compact device for manual laser welding. Today there are many models presented in stores. All of them boast different parameters and functionality.

Of course, the cost of such installations remains quite high. Nevertheless, the purchase of this device will undoubtedly quickly pay for itself. Especially when it comes to a large amount of work.

Models of laser welding machines

We have looked at what laser metal welding is and how it is carried out, but you still need to know the models of devices that are used to carry it out. Mobile and compact equipment can be used for it.

The following laser devices are often used in industry:

- Kvant-15 laser welding . The device is the most expensive and multifunctional. It is used in seam and spot welding technology for joining various metals and alloys with a penetration depth of up to 2-3 mm. Also used when cutting tool, structural, high-alloy alloys.

- LAT-S . This installation is used for laser welding and surfacing of metals. Has high power and performance. The equipment can be equipped with coordinate tables, which makes it possible to process complex products.

- MUL-1 . This is small-sized equipment that is used for laser welding and surfacing of metals. It can be used to solder items made of silver and gold. The use of laser welding in jewelry allows for easy welding with high precision. It is even possible to connect the frames of plastic glasses.

Manual laser welding is carried out using the following devices:

- WELD-WF . Portable device suitable for welding hard-to-reach areas. Its device includes a manipulator that connects to the fiber. Power is 1.5 kW;

- CLW120 . Manual unit with low power. It is suitable for the jewelry field which requires maximum precision. It can also be used for laser spot welding. Power is 10 kW.

Manual welding

Technological progress in recent years has made it possible to create a compact machine for manual laser welding. There are many models on the market with different parameters and functionality.

They allow you to:

- repair of small and miniature structures;

- spot welding;

- surfacing operations;

- repair of small molds;

- soldering of electronic components;

- disinfection of medical products.

Manual welding

The cost of such devices is still significant. It will pay off provided there is a large amount of work.

How to make a laser cutter for your garage

Many people are interested in how to make laser welding on their own? Since the equipment is quite expensive and not everyone can afford it, you can try to make a simple cutting machine yourself using a laser. With it, you can cut a variety of patterns on durable steels, cut metal components, or join simple steel products.

To make this you will need a laser pointer. Additional components will also be needed:

- a flashlight that runs on batteries;

- an old DVD-ROM from which you will need to remove the matrix with a laser drive;

- soldering iron and screwdrivers.

At the initial stage, it is necessary to completely disassemble the drive of the old computer disk drive. It is from this that you need to remove the device. Everything should be done carefully and carefully so as not to damage the main device. The drive must be a write drive.

Afterwards, the red diode is removed; it is this that burns the disk while recording information to it. Using a soldering iron, the diode mounts are soldered. This item is very sensitive and should not be thrown.

Next, the laser pointer is disassembled; you can watch how this is done in a video on the Internet. The diode from the pointer is replaced by a red light bulb from the drive. The body part is made from a flashlight. And rechargeable batteries will be needed to power the laser cutter.

Using a Solid State Laser

Solid-state lasers are used with special-purpose electrodes. They come in ruby, glass, and with the addition of neodymium.

In the figure below you can see a detailed diagram. The power of this device is no more than 6 kW. In this regard, solid-state lasers are used for welding parts of small thickness.

This laser allows welding of gold elements, nichrome, tantalum. It becomes possible to melt wire up to 1 mm thick. Spot welding of foil parts is also acceptable.

Possible seam defects

Laser welding tests are often carried out in factories to prevent possible seam defects. But still, even proper preparation does not always protect against deformation, lack of penetration and other unpleasant situations.

The following laser welding defects are distinguished:

- Lack of welding of the seam.

- Formation of pores and cracks.

- Sagging, craters, welded shells.

- Foreign inclusions.

- Burns.

These phenomena often occur when technology is not followed. The welder must correctly set the settings in the equipment depending on the metal being welded. In addition, he must clearly control the process and monitor the movement of the laser beam across the welded area.

Laser welding technology is a popular method of joining different metals, as well as glass, plastic and precious metals, which allows you to obtain a high-quality and durable connection. But still, before starting it, it is necessary to carefully consider the important features and principles of technology on which the final result depends. In addition, for the process to be carried out correctly, you must have experience and skills.

Using a Gas Laser

Gas lasers are stronger than solid-state lasers, therefore, their range of use is larger. Here argon replaces electrodes. The figure below shows a detailed diagram. Large size and weight are a big disadvantage of such lasers.

However, behind the weighty frame hides a power that reaches 20 kW. This means that the device is capable of welding elements without slowing down (the average welding speed is 60 m per hour).

The most impressive lasers are gas-dynamic. The gas must be heated to ultra-high pressure in order for it to function. The device welds metal at a speed of 200 m per hour and produces 100 kW.

They are used exclusively in large enterprises.

With this installation you can weld: aluminum; stainless steel; glass The scope of use of this equipment is very impressive. However, there is an important detail to consider.

During laser welding, the welding area must be protected from oxygen, as the weld may be of poor quality. Since the metal instantly evaporates, the light beam dissipates very quickly.

To prevent this, it is necessary to supply a gas that inhibits the plasma. Helium is often used for this, since it is not a barrier to argon and does not allow the laser to scatter.

Professionals use a combination of argon and helium in the process in equal proportions, simultaneously implementing 2 options: protective and suppressive.

Equipment used and welding process

Installations that allow cooking with an intensified light beam, regardless of the size of the equipment, are of two types: solid-state and using gas. Their principle of working with metal is similar, but their methods of converting light into energy are different. They also differ in efficiency, which affects their use in life.

Solid State Installations

In the video you can see that some devices cook with a laser continuously, while others pulse. The first type of welding is performed with devices based on a solid rod. Pink ruby is often used. When passing light through which the ions release their energy reserves. The ends of the rod are coated with silver, which actively reflects light. As a result of this mirror effect, the ions are directed in a spiral around the rod. Their movement rotates and new ions continue to connect to it. The converted light with amplified energy passes through a series of glasses and is focused by a lens into a beam. The head of the apparatus directs this beam onto the surfaces to be welded. The laser feed is continuous, which makes it possible to weld thin elements. But connecting thicker parts requires concentrated energy. Therefore, other installations were invented.

Gas apparatus

For laser welding, where deep penetration is required, an alternative method for converting light has been developed. The initial source in them is a tube with gas. The tank is covered with mirrors on each side. The electrodes inside produce a discharge that releases electrons in the gas. Photons are copied and the energy of the atoms is increased. Lenses direct the flow of light onto the product. The supply of voltage in a pulse promotes maximum concentration of energy at the output. Thanks to this, welding of metals up to 10 mm thick is possible.

Hybrid installations

To weld thick parts and products with a gap, additional filler material is required. To do this, a wire feed is used, which ignites an electric arc. This allows you to fill the space between the plates and create a high weld seam. The bath is protected by blowing inert gas through a nozzle fixed next to the laser head. It is noticeable in the video that the process is carried out very smoothly: the wire melts along the connection line, and the laser forms a seam from it.

Welding with laser systems is performed on a table or stands from the machine, in the following sequence:

It is important to clean the metal from scale, oil or water; the parts must be fitted tightly into the joint; chemical etching of the metal is performed; the head of the device is brought to the connection start line and the button is activated; constant monitoring of the beam entering the joint area is required.

Welding with amplified and converted light energy allows you to obtain durable and beautiful seams, which is especially important on thin metal products. This ensures high speed of work and safety of the welder.

That is why this type of welding is widely used in industry and repair shops.

Conditions for laser work and safety precautions

Focusing is required to produce a powerful beam. It is achieved through several successive reflections. When the intensity threshold value is exceeded, the flow enters the center of the front mirror, from where it is fed into the guide prisms and exits into the working area. Laser welding is carried out in any conditions: with different options for the location of parts and the depth of penetration. The connection is formed pointwise or continuously.

We recommend reading: The principle of acetylene welding with oxygen

The welding process has some features that can lead to injury to the worker if safety precautions are not followed:

- There should be no foreign objects in the path of the beam. If a welder's hand gets into the work area, the person gets a deep burn.

- Before starting welding, you need to check the integrity and serviceability of the main elements of the installation. Otherwise, the quality of the seam decreases, and the master risks injury.

- There should be no flammable objects in the workplace.

The essence and main advantages of laser beam welding

When the surface of a body is irradiated with light, the energy of quanta (portions) of light is absorbed by this surface. Heat is generated and the surface temperature rises. If light energy is concentrated on a small area of the surface, high temperatures can be obtained. This is the basis for welding with a light beam from an optical quantum generator - a laser.

What is a laser

The term “laser” comes from the first letters of the English phrase: “Light amplification by the stimulated emission of radiation.” Translation: "Amplification of light by inducing emission of radiation." Three scientists are behind the theoretical substantiation and development of lasers: Academician N. G. Basov, Academician A. M. Prokhorov and American physicist C. Towns. In 1964, this discovery earned them the Nobel Prize.

Academician Basov described the laser as follows: “This is a device in which energy, for example thermal, chemical, electrical, is converted into the energy of an electromagnetic field - a laser beam. With such a conversion, some energy is inevitably lost, but what is important is that the resulting laser energy is of incomparably higher quality. The quality of laser energy is determined by its high concentration and the ability to transmit over a considerable distance.”

Types and principle of operation of laser

The main elements of a laser are a pump generator and an active medium. Based on active media, solid-state, gas and semiconductor lasers are distinguished.

Solid State Lasers

In solid-state lasers (Fig. 1), the active medium most often used is pink ruby rods - aluminum oxide Al2O3 with an admixture of chromium ions Cr3+ (up to 0.05%). When irradiated, chromium ions transform into a different energy state—they become excited—and then release their stored energy in the form of light. At the ends of the ruby rod, a layer of a reflective substance (for example, silver) is applied so that an opaque mirror is formed at one end and a translucent mirror at the other. The radiation of chromium ions, reflected from these mirrors, circulates parallel to the optical axis of the rod, exciting new ions - an avalanche-like process occurs.

There is a rapid release of radiant energy, which is emitted by a parallel beam through a translucent mirror and focused by a lens at the welding site. The output power of solid-state lasers reaches 107 W with a beam cross section of less than 1 cm2. A huge concentration of energy is achieved at the focus, allowing temperatures of up to a million degrees to be achieved.

Rice. 1. Scheme of a solid-state laser: 1 - ruby rod; 2 - pump generator; 3 - reflector; 4 - opaque mirror; 5 - cooling medium; 6 - power supply; 7 - translucent mirror; 8 - light beam; 9 — focusing lens; 10 - workpieces

When operating in pulsed mode, a significant disadvantage of a solid-state laser is its low efficiency (0.01...2.0%). Higher power and greater efficiency are provided by lasers operating in continuous mode. For example, a solid-state laser based on yttrium aluminum garnet doped with neodymium atoms (approximately 1%).

Gas lasers

Gas lasers have even higher efficiency and power. They most often use CO2 or a mixture of gases as the active medium. Pump generators can be spark gaps or an electron beam.

A typical gas laser design is a gas-filled tube bounded on two sides by strictly parallel mirrors: opaque and translucent (Fig. 2). As a result of an electrical discharge, fast electrons appear between the electrodes inserted into the tube, which excite gas molecules. Returning to a stable state, these molecules form light quanta in the same way as in a solid-state laser. Gas lasers can operate in continuous mode. Solid-state and gas lasers of pulsed and continuous action are used for welding.

Rice. 2. Gas laser circuit: 1 - discharge tube; 2 - opaque mirror; 3 - power supply; 4 - vacuum pump; 5 - translucent mirror

How does the laser welding process work?

Laser welding is performed in air or in shielding gases: argon, CO2. A vacuum, as with electron beam welding, is not needed here, so large structures can be welded with a laser beam.

The laser beam is easily controlled and adjusted using mirror optical systems, easily transported and directed to places that are otherwise difficult to reach. Unlike the electron beam and electric arc, it is not affected by magnetic fields, which ensures stable formation of the seam.

Laser welding is characterized by a high concentration of energy in a spot with a diameter of 0.1 mm or less. It is characterized by a small volume of the weld pool, a small width of the heat-affected zone, and high heating and cooling rates. In practice, this means that laser welding provides technological strength of welded joints and small deformations of welded structures. For example, laser welding a fork to a car's driveshaft increases the life of the driveshaft by three times compared to arc welding. The main factors: the cross-sectional area of the weld is reduced by more than half, and the welding time is reduced by several times. There are virtually no fork deformations that cause premature wear.

The main energy characteristics of the laser welding process are the power density E of laser radiation and the duration t of its action. With continuous radiation, t is determined by the duration of the exposure time, and with pulsed radiation, by the duration of the pulse. Exceeding the upper limit E causes intense volumetric boiling and evaporation of the metal. This leads to metal emissions and weld defects. In practice, laser welding is carried out at E = 106...107 W/cm2. At E < 105 W/cm2, laser radiation loses its main advantage - high energy concentration. Changing E and t allows laser beam welding of various structural materials with thicknesses from several micrometers to tens of millimeters.

The speed of continuous wave laser welding is several times higher than the speed of traditional fusion welding methods. For example, a steel sheet 20 mm thick is welded with an electric arc at a speed of 15 m/h in 5...8 passes, the seam width is 20 mm. Using a continuous laser beam, this sheet is welded at a speed of 100 m/h in 1 pass with a seam width of 5 mm. However, pulsed laser welding is comparable in speed to traditional welding methods.

Design and types of equipment used

The structure of the unit depends on the type of emitter included in its composition.

Solid state devices

The design includes elements made of ruby and neodymium-doped glass. They are activated by the luminous flux emitted by powerful arc lamps. The units operate in constant radiation mode. They are characterized by high frequency, low power and efficiency. Solid-state machines are used for welding small-sized parts.

Gas welding devices

Such units are suitable for welding thick workpieces made of steel and other metals. Radiation generated in a gas environment is characterized by high power. The installation is capable of connecting parts up to 2 cm thick. It has a fairly high efficiency. The operation of the device is complicated due to the introduction of a fragile glass tube into the design.

Hybrid installations

Such devices were created for joining metal workpieces of large thickness. Together with the laser head, the device circuit includes an electric arc torch. Additionally, a feeding mechanism is installed that removes consumables into the weld pool.

Manual models

Small devices operate on the principle of standard units. The need to use compact parts when assembling makes the devices expensive. They are used to create miniature metal structures and solder microcircuits.

Types of devices

There are two main types in laser welding of stainless steel, gas welding and solid state. A solid-state device differs from a gas device in that a completely different wavelength is present, and since it is short, the power in the device is reduced. Most often, in such equipment operation, the pulse mode is used, due to which its continuity is formed much less frequently. In this case, laser welding of stainless steel occurs due to the presence of an active element. The laser radiation goes beyond the glass rod, and a solid-state active element appears in its place.

Devices with the principle of gas action can operate both in pulse mode and in non-intermittent mode. There is much more power here than with a solid-state device. It is possible to use equipment with transverse pumping, and it will be possible to save in size, since the equipment itself is considered compact. In such situations, the maximum width of the metal for welding will be about 2 cm. In this method, the active elements are burning gases.