Mechanized submerged surfacing of cylindrical and flat parts is a development of manual surfacing methods using electrodes with thick, high-quality coatings. This method was developed by a team led by Academician E.O. Paton in 1938–1939 The essence of the method is that the welding arc burns between the electrode (wire) and the product under a 10...40 mm thick layer of dry granular flux with grain sizes of 0.5...3.5 mm (Fig. 1).

The flux is non-metallic granular powders, similar in composition to electrode coatings, and in general perform the same functions as coatings, namely:

- provide slag and gas protection of the weld pool and weld bead from environmental influences;

- alloy and deoxidize the deposited metal;

- promote stable arc burning due to ionization of the arc gap during the dissociation of flux components;

- the deposited metal is refined.

To carry out automatic surfacing of parts, a complex of machines, mechanisms and devices is required, which generally constitute an automatic installation. A device that ignites the arc, feeds the electrode wire as it melts, and ensures stable burning of the arc is called an automatic head for arc welding and surfacing, or an arc machine. The most important industrial value for repair and restoration surfacing are machines with a consumable metal electrode - wire or tape.

Rice. 1. Scheme of mechanized surfacing of metal under a layer of flux : 1 – current-carrying blocks; 2 – feed rollers; 3 – electrode wire; 4 – slag layer; 5 – layer of dry flux; 6 – slag crust; 7 – weld (welded metal); 8 – base metal; 9 – weld pool; 10 – electric arc

Advantages of the mechanized surfacing method

- Increased labor productivity by 6...8 times compared to manual arc surfacing.

- Reducing energy consumption by half due to higher thermal efficiency.

- High quality of the deposited metal due to reliable protection of the deposited layer from environmental influences.

- Possibility of obtaining deposited layers with a thickness of more than 2 mm.

- Less consumption of filler material as a result of eliminating losses due to spattering and reducing waste of electrode metal.

- Better working conditions for the operator due to the mechanization of the process and the absence of an open arc.

Flaws

- A large investment of heat into the material of the part, which increases the heat-affected zone and changes the results of the previous heat treatment of the part.

- After surfacing, heat treatment of the deposited layer or the entire part is required.

- Difficulties in holding a bath of molten metal on the surface of a cylindrical part (parts with a diameter of less than 50 mm are not welded).

- Reducing the fatigue strength of a part by 20...40% due to residual stresses, porosity and structural heterogeneity of the layer.

- Appears when loading flux into a hopper and sifting it after using silicate dust, which is harmful to the human body.

Submerged arc surfacing with solid metal wire

The deposited metal is alloyed by using alloyed wire, alloyed fluxes or dosed filling of alloying impurities onto the surface of the part being deposited. Sometimes the deposited metal is not subjected to alloying, and surfacing has the goal of restoring the required geometric dimensions and shape of the part.

Fused fluxes are used for automatic surfacing:

- high-silicon manganese grades AN-348A, OSN-45, AN-60;

- low-silicon manganese grades AN-10, AN-16, AN-22;

- high-silicon manganese-free grades AN-20, AN-28,48-OF-6. For surfacing high-alloy steels and alloys, low-silicon manganese and manganese-free fluxes with lower oxidizing ability are used - AN-30, 48-OF-6.

Automatic surfacing is most often used to restore cylindrical parts. Such parts are usually fused along a helical line. The axis of rotation is horizontal. This method ensures continuity of the process and high quality of work, symmetry of residual stresses with respect to the axis of the part. However, this method makes it difficult to retain flux and liquid metal in the surfacing zone.

To retain the flux, a special flux-holding device is used in the form of a specially shaped collar attachment located around the burner mouthpiece.

In order to retain the molten metal of the bath and liquid slag, the surfacing head of the machine is installed with some displacement of the end of the electrode wire from the zenith (Fig. 2).

Rice. 2. Surfacing of a cylindrical part under a layer of flux : 1 – product; 2 – hopper with flux; 3 – electrode wire; 4 – molten flux (slag); 5 – welding arc; 6 – deposited layer; 7 – slag crust

The magnitude of the displacement “e” depends on the diameter of the welded part and the parameters of the surfacing mode and is taken from 10 mm or more. The peripheral speed is selectable from 10 to 50 m/h. The smaller the electrode diameter, the lower the deposition speed should be selected. The deposition step is determined depending on the desired layer thickness, current and voltage ranging from 3 to 12 mm. The current strength for surfacing and the diameter of the electrode wire are set depending on the diameter of the part to be deposited.

Surfacing of cylindrical parts (crankshafts, crane wheels, support rollers and others) is carried out on special rotators or lathes specially adapted for this (Fig. 3).

Rice. 3. Installation UNV-3-5 for arc surfacing of bodies of revolution

Rice. 4. Welding tractor ADF-800 (a) and automatic welding machine A-1416 (b), used for surfacing parts under a layer of flux

The surfaces of flat parts are surfaced using equipment designed for welding with additional moving devices - automatic welding machines and welding tractors (Fig. 4).

The ADF-800 welding tractor is designed for welding and surfacing with electrode wire under a layer of flux. Works in conjunction with rectifiers VDU-1250, VDU-1202, VDU-630, etc. ADF800 is a self-propelled device in which the supply of welding wire, movement and protection of the arc occur automatically according to a specific program. The suspended self-propelled automatic machine A-1416 is designed for double-arc welding and surfacing with a solid wire under a layer of flux of low-carbon and alloy steels on direct current with welding speeds and electrode wire feed independent of the arc parameters. Deep regulation of the electrode wire feed speed and welding speed, obtained by replaceable gears, provides a wide range of applications for the machine.

Surfacing is carried out using separate beads along or across the surface to be deposited. It is advisable to carry out surfacing of lower but wider layers of metal with the electrode wire tilted at an angle of 40...50° to the horizon, the depth of metal penetration is two times less, the width of the deposited bead is greater under the same surfacing modes.

To obtain a wide layer, surfacing is used:

- multielectrode;

- multi-arc;

- with transverse vibrations of the electrode;

- steel tape.

Surfacing productivity is estimated in kg/h of deposited metal. For example, with manual arc surfacing, productivity is estimated in the range of 0.8...3 kg/h; automatic with one electrode – 2…15 kg/h; multi-electrode – 5…30 kg/h; electrode tape – 10…60 kg/h.

Automatic submerged arc welding technology

Every experienced welder understands the fact that atmospheric air entering the welding zone negatively affects the quality of the weld. Through its chemical reaction, it causes oxidation of the joint, which causes the formation of cracks. To avoid such complications, protective substances are used aimed at the welding area.

The most popular method of obtaining a reliable and strong connection between two metal surfaces is automatic welding using flux. Thanks to this method, even difficult metals can be bonded, such as copper, aluminum or stainless steel. Automatic welding takes less time and greatly facilitates the work, and the flux ensures the quality of the seam.

Submerged arc welding technology

The principle of working with flux is no different from conventional electric arc welding. The metal also melts under the influence of high heat from the welding arc.

But it is automatic welding that differs from all others in its convenience and speed. Most of the work is not done by a person, but by a machine that feeds the wire evenly and advances the heat source.

We are considering the option of using a layer of flux that covers the wire.

What is flux

Flux is a special composition that protects metal from oxidation by air. It is produced in powder, granular, paste and liquid form. Fluxes are fed in large quantities into the weld pool.

By displacing oxygen, they create an invisible coating for a reliable seam connection.

In addition, fluxes help ensure stable arc burning, do not create large amounts of spatter, and can improve the chemical characteristics of the metal.

Types of fluxes

Before purchasing flux, you should ask about its purpose. They are used for different types of metal:

- for carbon-containing and alloy steels;

- for highly alloyed compounds;

- for non-ferrous alloys.

Based on their composition, fluxes are divided into:

- fused, such fluxes are inexpensive and widely used by welders. Fused flux is a global component in protecting the weld, but nothing more;

- ceramic, if you need enhanced properties of the seam, then choose this type of flux.

And finally, according to their chemical properties, fluxes are:

- active, the mixture contains acids, which can subsequently lead to rust, so carefully knock down the resulting slag;

- passive, such fluxes are not used in automatic mode; their characteristics do not have the necessary properties. The only use of passive fluxes is in soldering, known as rosin or wax.

Which brand of flux to choose is up to everyone to decide for themselves. Russian manufacturers produce inexpensive and good flux, and foreign manufacturers can boast of stable quality. But in both cases, the protective properties of the substances really work. The main thing is to correctly follow the welding technology.

Pros and cons of submerged arc welding

Disadvantages of automatic welding:

- the possibility of welding is limited only to the lower seams;

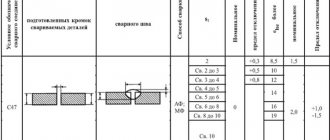

- it is necessary to more carefully prepare the edges of the products being welded. There is a certain state standard according to which products are cleaned using hardware. After all, automatic mode is a machine that cannot correct or move the edge of the surface;

- high price of equipment and components. But this price is justified, because automatic welding is mainly used on an industrial scale.

A big and fat plus is the absence of the human factor. The master does not need to stand in uncomfortable positions, inhale harmful fumes, control the arc, and, in principle, does not even need to be able to cook. All processes occur automatically.

The only thing you need to be well versed in is setting the correct machine settings. The machine will take on the rest of the work, performing the connection at the highest level, both in a single copy and for the millionth series.

The essence of the process

As mentioned above, automatic welding involves more thorough surface preparation. Dust, dirt, grease stains, paint residues, rust and other debris are unacceptable in the technological process. The welding process can only be started on clean and degreased metal.

The automatic process using flux can begin after setting the settings specified by the operator.

To set the correct settings, a person must have theoretical knowledge of the welding machine. The thicker the metal, the larger the diameter of the electrode used.

At the same time, the welding current and arc voltage increase. But the speed of work decreases with large metal thickness.

On the Internet you can find a lot of calculations when working with different connections. This topic is large-scale and we will not touch on it in this article. We recommend that you study it yourself.

The filler wire used for the flux composition takes part in welding. It would be a good option to choose a rod from the same material from which the welding element itself is made. The additive is supplied automatically; the specialist only needs to fill it into the mechanism.

Flux is poured into a specially designated compartment on the welding machine. Accordingly, flux consumption will be greater when welding thick metals. Any flux melts due to temperature heating, and when it gets onto the weld area, it does not harm its properties, and often improves them. During the welding process, the flux foams and forms metal slag on the joint surface. It needs to be removed.

Welding in automatic mode using flux speeds up the work, but the speed does not affect the quality of the seam.

conclusions

We told you about automated flux welding, but there are both semi-automatic and manual welding using this composition. But we’ll talk about these technologies next time. We ask experienced craftsmen to share their tips and recommendations regarding automatic submerged arc welding.

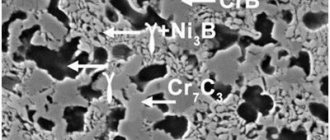

Automatic submerged surfacing with electrode strip

Research by the Institute of Electric Welding named after. E.O. Paton of the National Academy of Sciences of Ukraine showed that with automatic surfacing under a layer of flux, instead of electrode wire, you can use a tape of small thickness (0.3...1.0 mm) and large width (10...100 mm or more). When surfacing with tape, a small depth of penetration of the base metal is obtained due to the low current density and at the same time reliable penetration is ensured. The share of participation of the base metal in the formation of the weld bead ranges from 5 to 15%. High productivity of the surfacing process is achieved through the use of high currents without increasing the penetration depth of the base metal and the application of a large width bead in one pass.

The minimum current density, determined by the ratio of the current strength to the cross-sectional area of the electrode strip, ensures a stable surfacing process. Typically, the current density when surfacing with tape is about 10 A/mm2, while the arc voltage is Ud = 22...36 V, the surfacing speed is from 4 to 12 m/h. Depending on the mode, a layer with a thickness of 2.5 to 8 mm can be deposited in one pass.

Electrode strips of various compositions are used for surfacing. For example, ductile iron strip can be used for wear-resistant surfacing. Using AN-28 flux and an automatic arc voltage regulator, you can obtain good bead formation with a hardness of 40...50 HRC. At the same time, the wear resistance of the deposited layer is several times greater than the wear resistance of structural steel. It is possible to obtain a deposited layer not only from cast iron, but also from various wear-resistant steels and non-ferrous metals. For corrosion-resistant coatings, strips made of steels 12Х18Н9Т, 12Х18Н10Т, YuХ18Н9Б, 10Х19Н11МЗ, 20Х13Н4Г9, 10Х13 are widely used. When using such tapes, the best results in forming a deposited layer are obtained by pumice-like flux AN-26, and when surfacing with a tape of steel 20Kh13N4G9, flux 48-OF-10. When surfacing, beads are formed that have the correct shape, and the slag crust is easily separated.

For surfacing products from non-ferrous alloys (bronze, copper), the following grades of tape are produced: BrAMts9-2, BrBNT1.9, BrKMts3-1, BrA5, BrOF6.5-0.15, BrOTs4-3, BrOTsS4-4-2.5. Fluxes are used as a protective medium, as well as protective gases - argon, helium, nitrogen and their mixtures. The best protection is argon, which provides reliable arc protection and minimal penetration of the base metal. Surfacing with BrAMts9-2 bronze tape can be carried out using AN-348A, AN-60, AN-20, AN-26 fluxes.

For surfacing parts made of nickel alloys, you can use strips of manganese nickel of the NMTs2.5 and NMTs5.0 grades or pure nickel of the NP1, NP2, NP3 and NP4 grades. Nickel tapes containing strong deoxidizers (1.5% Al and 2.0...3.5% Ti), or tapes and fluxes containing 2...3% Nb and 3% Mn are also used.

Equipment for surfacing

Automatic surfacing under a layer of flux is carried out on special installations, the main elements of which are a lathe with a surfacing head instead of a tool holder and an arc power source. To reduce the spindle rotation speed, the lathe is converted by installing a reduction gearbox between the machine drive motor and the driven pulley, designed to rotate the part at a speed of 2-5 rpm.

For automatic surfacing of crankshafts under a flux layer, special installations have been developed that do not require modification. One of them - OKS-5523 - operates in semi-automatic mode. A special feature of this installation is the stepless regulation of surfacing speeds and the presence of universal center shifters.

Converters PSG-500, PSU-500-2, rectifiers VS-600, VKS-500-1, etc. are used as current sources for automatic surfacing. Surfacing heads A580M, OKS-1031B, OKS- are used to supply electrode wire to the surfacing zone. 1252A, etc.

Mechanized electric arc surfacing in protective gases

In industry, various methods of electric arc welding and surfacing are used in shielding gases: argon, helium, carbon dioxide. In many cases, these methods make it possible to restore or strengthen the surfaces of products whose surfacing is difficult by other methods. In addition, gas-electric welding creates opportunities for automation of surfacing operations where the use of automatic and semi-automatic submerged arc welding is impossible. At the same time, labor productivity increases significantly and the cost of surfacing work decreases.

Developed by professors K.V. Lyubavsky and N.M. Novozhilov’s method of welding with a consumable electrode in a carbon dioxide atmosphere made it possible to obtain tight seams when welding low-carbon, low-alloy and high-alloy austenitic steels.

The essence of the method is that air (oxygen, hydrogen, nitrogen, water vapor, etc.) is pushed out of the welding zone by a jet of carbon dioxide, and the oxidation of the metal molten by the arc by carbon dioxide itself is compensated due to the increased content of deoxidizing elements in the electrode wire (Fig. . 5). The quality of welded joints is significantly influenced, especially in semi-automatic welding, by the welding technique.

The reliability of the gas protection of the welding zone from air, the cooling rate of the metal, the shape of the weld, and the conditions for removing gas bubbles and non-metallic inclusions from the weld pool depend on the distance, angle of inclination and nature of the movement of the torch.

Rice. 5. Scheme of surfacing in a carbon dioxide environment : 1 – mouthpiece; 2 – electrode wire; 3 – burner; 4 – tip; 5 – burner nozzle; 6 – electric arc; 7 – weld pool; 8 – weld bead; 9 – restored product

The process of repair welding and surfacing in carbon dioxide must be carried out using a short arc. When welding at currents of 200...250 A, the arc length should be in the range of 1.5...4.0 mm, since increasing the arc length increases the splashing of liquid metal and causes waste of alloying elements. Welding is possible on direct current, as well as on alternating current using an oscillator.

Automatic surfacing in a shielding gas with a consumable electrode is carried out by feeding wire from a cassette to the welding site at a constant speed through a current-carrying nozzle. Shielding gas from the cylinder is supplied through a hose through the torch nozzle to the place where the arc burns. The effectiveness of gas protection depends on the design features of the gas supply nozzle, the distance between the end of the nozzle and the surface of the part, as well as the deposition rate, shielding gas pressure and air movement at the deposition site. Surfacing in protective gas allows you to mechanize the work process in any spatial position. For surfacing in a carbon dioxide environment, carbon and low-alloy wire with a diameter of 0.8 to 3 mm is used. Wire with a diameter of 0.8...1.6 mm is used for minor wear of parts and for surfacing cylindrical parts of small diameters with any wear. The maximum thickness of the deposited single-pass layer in this case is 1…2.5 mm. The surface of the wire should be free of rust and various contaminants that lead to the formation of porosity and reduce the stability of the arc. Wire cleaning can be done either mechanically or chemically. The chemical composition of the electrode wire must be such that it is possible to sufficiently deoxidize the molten metal bath, alloy it and obtain a dense deposited metal. When surfacing carbon and low-alloy steels, silicon and manganese are used as deoxidizing agents.

For surfacing steel and cast iron products in a carbon dioxide environment, wire grades Sv-12GS, Sv-08G2S, Sv-Kh13, Sv-Kh17, Sv-06Kh19NT, Sv-18KhMA, Sv-08Kh20N9G7T are used.

For welding in CO2, flux-cored wire of the PP-18T, PP-4Kh2V8T, PP-Kh12VFT brands is also used.

The use of wire grades Sv-12GS, Sv-08GS, Sv-08G2S for surfacing produces a deposited metal that is not very hard and wear-resistant. Such wires are used mainly to restore the geometric parameters of a product.

During surfacing operations there is no need to obtain deep penetration of the base metal. Therefore, the main factors are: stable arc burning, productivity and quality of surfacing work. From the point of view of process stability, it is recommended to take the current strength depending on the wire diameter according to the following data:

| diameter (mm) | 0,8; | 1,0; | 1,2; | 1,6; | 2,0; | 2,5; |

| current (A) | 60…120 | 80…160 | 90…260 | 120…350 | 200…450 | 250…550. |

The decrease in current should correspond to a decrease in the electrode wire feed speed.

An increase in arc voltage leads to an increase in the width of the deposited metal bead, an increase in metal losses due to spattering, waste and oxidation, the quality of the deposit deteriorates, and pores appear. Therefore, it is recommended to withstand a certain arc voltage depending on the current strength:

| current (A): | 60 | 100 | 140 | 200 | 250 | 300 | 400; |

| voltage (V): | 18 | 19 | 20 | 22 | 25 | 28 | 30. |

Carbon dioxide surfacing has especially great advantages over submerged arc surfacing when restoring cylindrical parts of small diameters (10...20 mm).

Electrode wire stickout has a significant impact on the stability of the surfacing process. A large overhang causes excessive heating and burnout of the wire at the point of contact with the current-carrying device. The higher the current density, the smaller the electrode stickout should be.

When surfacing in a CO2 environment, the beads should overlap each other by 1/3 of the width, which gives a more even surface of the deposited metal.

Surfacing of steels with a high carbon content or alloying impurities must be done with preheating of the part and with higher heating of carbon dioxide. Otherwise, hardening of the metal in the heat-affected zone is possible, which leads to the appearance of microcracks and impairs the machinability of the metal with a cutting tool.

For welding with a consumable electrode in a carbon dioxide environment, semi-automatic and automatic machines of both Russian and foreign production are used.

Submerged arc welding

A detailed acquaintance with welding work and processes indicates that air has a negative impact on the quality of the connection. The required fastening can be achieved using a protective medium, which includes fluxes or inert gases.

The most common use of fluxes is in industrial conditions, due to the fact that when using this method, a reliable fastening is guaranteed to be formed.

Use implies automatic or semi-automatic mode; some production lines use robotic installations.

Submerged arc welding

Submerged arc welding technology

The automated welding process involves the presence of bulk flux supplied directly to the product. When the arc is ignited, the electrode wire melts, acting on the metal base.

As a result of the reaction of the metal with the substance, which are integrated at the welding site, a gas bath consisting of welding fumes is formed. Submerged arc welding is used in automatic or mechanized production.

The main purpose of the cavity in the welding method under consideration is the formation of a protective shell to avoid the effect of oxygen on the metal.

Also, the design of the electrode wire reacts to flux, subjecting the material to processing, allowing for a high-quality seam to be obtained.

Submerged Arc Welding Diagram

During the arc removal process, the product changes from a molten state to a solid state, forming a hard layer that is easily removed from the surface of the product. Automatic submerged arc welding technology involves a cycle of removing excess material using a special mechanism. The technology has many advantages that allow the method to be used in any enterprise.

- It is possible to combine parts using increased current. Most industries use current from 1000 to 2000 A; for comparison, arc welding does not exceed 650 Amperes. In normal mode, increasing the current has a detrimental effect on quality by spattering the metal. When using the substance, it is possible to increase the power to 4000 A, which allows you to obtain the finished material in combination with the speed of the process.

- The process involves the formation of an arc under a layer of flux operating at great depth. This condition makes it possible not to worry about pre-treatment of welded joints.

- Increased clutch speed allows for more welding work. For comparison, making a seam with identical parameters using arc welding can take 10 times more time.

- The gas bubble formed during the process avoids splashing of hot metal during the process. This condition allows not only to obtain a strong seam, but also to observe safety precautions when working with high temperatures. Due to this, energy and tools are saved.

The welding mode is determined depending on some required characteristics of the seam. Main criteria:

- electrode diameter;

- electric current, its polarity;

- speed performance indicators and voltage;

- composition characteristics.

Download GOST 8713-79

There are also a number of additional parameters depending on the tools used.

What does the use of flux give?

A chemical substance based on many components is called flux. It is used when necessary to comply with standards, to protect metal products from corrosive conditions during subsequent operation.

Welding flux

The main tasks that the substance can solve:

- stable burning of the welding arc;

- improved properties and shapes of the seam;

- providing a weld pool that protects the metal;

- the use of various fasteners allows you to change the composition of the chemical mixture to obtain the required characteristics.

In addition to the above advantages, the main advantage is the ability to create a mechanical joining process. Various chemical compounds are used in automatic lines.

Chemical composition of various brands of flux

Each method has its drawbacks, and the use of flux is no exception:

- work is performed only with the joint in the lower position;

- assembly of parts must comply with the parameters of fitting and edge processing;

- production is carried out only on a rigid support, suspended impact on the material is not possible;

- the cost of auxiliary materials is high, so the method is used in critical structures.

Welding aluminum or other non-ferrous metals is impossible without the use of flux, regardless of the joining method. However, there is a possibility that solid oxide will form and be forced to the surface during the process.

Joining non-ferrous metals by welding involves the use of various compositions. The component part is divided into manganese, low silicon, oxygen-free products. Fused compositions have the structure of pumice, alloying properties exist in ceramic products, improving fastening properties. Components of the main varieties:

- Salt compounds are rich in fluorides and chlorides. With their help, manual argon arc welding is performed using active compounds and slag remelting.

- Oxide mixtures have found their purpose in joining fluoride parts, as well as low-alloy materials. This product is distinguished by its silicon content and has up to ten percent fluoride compounds.

- Mixed products are used for high-alloy steels; the structure is made up of all the elements listed in the first two materials.

Choosing the right flux is quite difficult without the appropriate experience; automatic submerged arc welding requires high-quality material.

The type and characteristics of the composition are determined by the technical documentation.

Submerged arc welding modes for steels

Automated welding is carried out in such a way that the operator only performs debugging of the equipment in the appropriate operating mode. Sequence of actions and technology:

- Flux is automatically supplied to the parts to be joined, the layer height is adjusted in relation to the thickness of the metal, and the product is taken from a specially designated hopper.

- The cassette mechanism feeds the electrode wire, without which the process is impossible.

- The operating speed is selected in such a way that a high-quality weld pool is formed, preventing metal spattering.

- A product with a lower density floats to the surface of the bath, which does not affect the properties of the seam. Unused material is mechanically collected to save money.

The main positive quality is the increased speed through mechanized submerged arc welding. Thanks to this, the method is used by various industries and has proven itself to be a reliable and durable way to connect welded parts.

The seam is made according to several characteristics, and operating modes are selected depending on this. A common type is cold welding, used at low temperatures to join non-ferrous metals.

Each material has a technical specification with permitted welding parameters.

In the absence of instructions, the substance is selected for use using a sample method; it is important to follow some tips:

- A high quality connection can only be achieved with a stable arc. The parameter is adjusted by selecting the speed level of the melting tool and the current strength.

- The speed performance is affected by the degree of wire extension, as well as the alloy composition.

- The current strength directly depends on the depth, and the voltage can be used to adjust the width of the seam.

The mechanism of operation of fluxes during welding

Thus, it is possible to select the required substance as accurately as possible. It is necessary to understand that you should not neglect control, because... The connection may be disrupted during further use.

Equipment for submerged arc welding

At production facilities, an assembly-type stand is used, on which it is possible to fix the elements being processed in a stationary state. The requirement for reliable fastening is especially observed, because During work, the part may shift, resulting in an uneven weld. Often, instead of full-fledged expensive submerged arc welding equipment, mobile heads are used.

Submerged arc welding machine

A trolley equipped with an electric drive and a mechanical welding head is called a tractor. This device is capable of moving along the seam directions or directly to the parts.

Application area

The automated method makes it possible to put on a conveyor belt the production of various large structures. The most common areas where the method is applied are:

- Shipbuilding uses large-scale assembly; when using flux welding, it is possible to assemble in sections, which reduces the time for production as a whole.

- Requirements for high parameters of abutting surfaces allow the device to be used in the manufacture of various tanks.

- Gas pipes of large diameters.

Technology does not stand still; every year it becomes more advanced. Submerged arc welding allows the production of large, high-quality products by machine. Some manual work takes several days, but mechanized lines produce the finished product in a matter of minutes.

, please select a piece of text and press Ctrl+Enter.

general information

Automatic submerged arc welding is a technology whose essence is no different from classical arc welding. The metal melts due to the high temperature that is formed due to the electric arc. Below is a diagram of automatic submerged arc welding.

The only difference between automatic welding and any other is that most of the processes are performed not manually, but using special machines. For example, wire feeding and arc movement. Well, in our particular case, all these operations are performed under a layer of flux applied to the surface of the metal.

The role of flux

With automatic welding everything is clear. But what about flux? What it is?

Flux is a special substance (can be produced in the form of powder, granules, pastes and liquids) with positive properties.

Fluxes are fed in a thick layer directly into the welding zone, protecting it from the negative effects of oxygen.

Flux also protects the metal itself, promotes stable arc burning, reduces the likelihood of metal spattering, and even changes the chemical composition of the weld if necessary.

Types of fluxes used

Before you carry out submerged arc welding, it would be nice to know what types there are. First of all, all fluxes are divided according to their intended purpose. They can be used for welding carbon and alloy steels, for high-alloy steels and for non-ferrous metals. This is the first thing you should pay attention to before purchasing flux.

Fluxes can also be fused or ceramic. Their difference is in composition. In most cases, fused flux is used, since it is relatively universal and inexpensive.

With its help, you can effectively protect the weld pool from oxygen. But don’t expect any special qualities from the fused flux. If you need truly excellent weld properties, then choose a ceramic flux.

It provides excellent quality.

Also, fluxes can be chemically active and chemically passive. Active flux contains acids that can not only protect the metal during welding, but also lead to corrosion.

So be sure to remove flux thoroughly after use. Passive fluxes are not used in automatic welding because they do not have sufficient properties for this.

Often you will find a passive substance when soldering in the form of wax or rosin.

By the way, about the manufacturers. This is a long-standing debate among all beginners and experienced welders. Some people believe that domestic companies produce inexpensive and effective flux, while others are all for imported components. We will not say unequivocally which is better, we will only say that in practice, both domestic and imported fluxes perform well if the welding technology is followed.

Advantages and disadvantages

Automatic flux welding has many advantages. Its main advantage is the ability to fully automate the welding process. A welder does not even need to know how to weld; it is enough to know how to set up the equipment. Also, this welding method guarantees excellent quality of welded joints, since there is no human factor.

The technology of welding parts by automatic surfacing under a layer of flux also has its disadvantages. Firstly, you can only weld the bottom seams. Also, the parts must be very precisely fitted, because the machine forms a seam in a clearly defined place, and any mistake during joining will lead to defects. In addition, very careful preparation of the metal is required before welding.

Please note that you will not be able to weld metal by weight. The part will need to be fixed on a horizontal surface and the root of the welded joint will need to be pre-welded. Another significant drawback is the high cost of both automatic welding equipment and components.

Now that you know everything, it's time to find out what automatic submerged arc welding technology is.

Welding technology

First of all, before welding, it is necessary to prepare the metal. Each metal has its own preparation, but we will give general recommendations. It is necessary to clean the part from dirt, paint and corrosion. Then you need to thoroughly clean the surface using a wire brush or grinding wheel. Only after the preparatory operations can you start welding.

Submerged arc welding technology is simple due to the fact that many processes are performed not by a person, but by a machine.

The master does not need to light the arc, monitor its stability, select the wire feed speed, and so on. All you need to do is set the submerged arc welding modes correctly.

Essentially, give the machine a program of action. Below is a table listing the modes of automatic submerged arc welding.

These are automatic submerged arc welding modes for butt joints. Naturally, there are other types of joints, so for them it is necessary to calculate the welding modes. Here we will not touch on this topic, since it is very extensive (there are so many types of compounds, so many formulas), so study this information yourself. There are many calculation methods on the Internet.

The work also uses a special filler wire for submerged arc welding. Its feeding is also automated; you just need to load the reel into the feeding mechanism. We recommend purchasing wire made from the same metal as the part.

Now a little about flux. It is also supplied automatically, only it must first be poured into a special tank. The thickness of the flux layer depends on the thickness of the metal being welded. The thicker the metal, the more flux is needed.

A natural question may arise in your mind: does flux melt? And does it affect the structure of the seam? Yes, of course, flux melts under the influence of temperature. But at the same time, it does not violate the structure of the seam in any way, but only improves it. But at the same time, the frozen flux turns into slag, which must be removed after welding. Leftover unused flux can be reused.

This technology of using flux in automatic welding can significantly increase the speed of work without losing quality.

Instead of a conclusion

Semi-automatic machines for surfacing in shielding gases

Semi-automatic PDG-603 (Fig. 6, a) is intended for mechanized arc welding and surfacing in a shielding gas environment, as well as self-shielding flux-cored wire of products made of low-carbon and structural steels. The semi-automatic machine has smooth control of welding parameters, the setting of three independent welding modes, a feed attachment with four

driving gear rollers, a remote control panel, as well as water cooling of the torch when welding at maximum conditions.

Rice. 6. Semi-automatic machines for arc welding and surfacing in shielding gases : a – semi-automatic PDG-603; b – semi-automatic “Midicom-160”

The semi-automatic machine PDGO-501-1 is designed for semi-automatic welding and surfacing of metal with a consumable electrode both in a protective gas environment and with flux-cored wire. The wire feed speed is adjustable in steps from 95 to 725 m/h, wire diameter is 1.2...3.2 mm. The semi-automatic machine is placed on a light trolley along with a device on which a coil of electrode wire weighing up to 80 kg can be placed. The semi-automatic welding kit may include:

- power supply VDG-506 with arc voltage regulation from 18 to 50 V;

- torch for current up to 300 A for welding in a shielding gas environment;

- torch with a current of up to 500 A for welding with flux-cored wire;

- welding wires and control cable with a range of 10 m. Semi-automatic “Midicom-160”. , Russia. Small-sized semi-automatic welding “Midicom-160” (Fig. 6, b) is designed for manual arc welding on direct current with a consumable electrode in a shielding gas environment

low-carbon, alloy, and stainless steel with a total thickness of up to 4 mm. Can be used to perform a variety of welding and installation work in car repair and construction. The semi-automatic device consists of a power transformer, a rectifier and an LC filter of welding current, an electrode wire feeder with a reel and a flexible working hose, a shielding gas supply device, an electronic control unit, a selection of operating modes and indications, and a forced cooling system.

The semi-automatic MIG 305 C/S is used for welding metals of any thickness and chemical composition with solid or flux-cored wire in shielding gases.

Technical characteristics of the semi-automatic device

- Current 40…300 A

- Mains voltage 3380 V

- Current at duty cycle = 35% 285 A

- Current at duty cycle = 60% 215 A

- Current at duty cycle = 100% 170 A

- Open circuit voltage 16…47 V

- Number of voltage adjustment stages 20

- Weight 130 kg

The most favorable conditions for the formation of a metal bead are observed during surfacing in inert monatomic gases argon and helium (Fig. 7). In argon, there are two types of metal transfer through the arc: large-droplet transfer without short circuits with slight spattering at a subcritical current and jet transfer at a current greater than the critical value. The type of metal transfer through the arc gap affects the form of penetration of the base metal and the formation of the deposited bead. Surfacing with jet transfer of electrode metal is undesirable, since this significantly increases the depth of penetration of the base metal.

In helium, droplet transfer is observed with short circuits of the arc (low current and voltage) and without short circuits at increased current and voltage with slight spattering of the electrode metal.

Rice. 7. Scheme of the surfacing process with electrode wire in an argon environment : 1 – welded product; 2 – burner; 3 – electrode wire; 4 – shielding gas; 5 – gas nozzle; 6 – welding arc; 7 – weld pool; 8 – weld bead; 9 – protective atmosphere

A bead of metal deposited in a helium environment has less convexity than in argon, since argon increases the surface tension of the liquid metal. The use of an Ar+He mixture allows you to take advantage of the advantages of both gases.

Surfacing with flux-cored wire and flux-cored strip

A very promising method for restoring and strengthening the surfaces of parts, which can significantly increase labor productivity compared not only with manual but also mechanized welding in carbon dioxide, is welding and surfacing with flux-cored wire. Its distinctive feature compared to other mechanized methods is that it combines the advantages of both manual welding - simplicity and mobility, and mechanized welding in carbon dioxide - greater productivity and high quality of welded joints.

The use of flux-cored wire for surfacing operations allows one to significantly expand the range of welded steels, since for most of them it is impossible to obtain the corresponding monolithic alloyed wire metallurgically.

The idea of using electrodes with a strong conductive shell and a less durable “core”, the composition of which can be changed, was put forward in the 19th century by the great Russian inventor N.N. Benardos, the founder of electric arc welding. In the 30s, for the first time in the history of welding technology, Soviet engineer V.E. Sakhnovich experimentally proved the possibility of using electrodes consisting of a thin-walled steel tube and a welding flux core for automatic open arc welding, i.e., without external protection with carbon dioxide or flux. He used electrodes made from seamless steel tubes into which powdered dry flux was poured; the ends of the tubes were welded, and they were crimped by 1.5...2.0 mm in order to compact the charge. They were named V.E. Sakhnovich “electrodes with internal coating”. In the early 60s, at the Electric Welding Institute named after. E.O. Paton proposed a tubular electrode wire, called “cored wire for welding”. Flux-cored wire welding is constantly being improved, and this mechanized arc welding method is increasingly used both in our country and abroad.

Automatic and semi-automatic surfacing with flux-cored wire

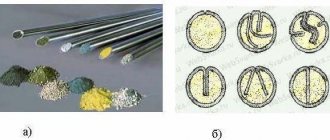

Flux-cored wires are tubular wires with a complex internal cross-section filled with powdery filler (Fig. 8). The filler has a composition suitable for welding electrode coatings. The mass of powdered filler ranges from 15 to 40% of the weight of the wire.

The powder included in the flux-cored wire, when melted by an electric arc, performs the following functions:

- provides gas and slag protection of the weld pool from environmental influences;

- promotes deoxidation of the weld pool;

- alloys the weld;

- stabilizes the arc discharge.

Rice. 8. Flux-cored wires for welding and surfacing : a – appearance; b – wire sections

According to the method of protection, flux-cored wires are divided into self-shielding and those used with additional protection with gas (CO2) or flux. Self-shielding wires, as a rule, are used both for the production of welded structures and for surfacing parts. Flux-cored wires, used with additional protection, are mainly used for surfacing work.

Surfacing with flux-cored wire with internal protection is based on introducing into the wire core, in addition to alloying components, also slag-forming and gas-forming materials. The use of flux and gas protection when surfacing with such wire is not required. The alloying elements of the flux-cored wire pass into the seam, and gas and slag-forming materials protect the metal from nitrogen and atmospheric oxygen. In the arc, a thin film of molten slag covers the droplets of liquid metal and insulates them from the air. The decomposition of gas-forming materials creates a flow of protective gas. After solidification, a thin slag crust forms on the surface of the weld bead, which may not be removed when applying subsequent layers. When surfacing, various self-protecting flux-cored wires are used. For surfacing low-carbon layers, welding wires of the PP-AN3 type and others are used. For surfacing parts operating at high pressures and elevated temperatures, flux-cored wire PP-3ХВ3Ф-О is used (the letter “O” in the designation of the grade of flux-cored wire indicates that this flux-cored wire designed for open arc surfacing). Surfacing of parts subject to intense abrasive wear is carried out using self-shielding flux-cored wire PP-U15X12M-O. Flux-cored wires have been developed for correcting (welding) defects in steel castings (PPs-TMV6, PPs-TMV29, PPs-TMV14, PPs-TMV15, VELTEC-N210, VELTEC-N215).

The technology for surfacing with self-shielding flux-cored wire is basically no different from the technology for surfacing in carbon dioxide. An open arc makes it possible to accurately guide the electrode and observe the process of formation of the deposited layer, which is of great importance when surfacing parts of complex shapes.

The advantages of this method: the use of less complex equipment compared to the equipment used for submerged arc surfacing and shielding gas, as well as the ability to perform surfacing work in the open air; productivity increases compared to submerged surfacing and shielding gases, and the cost of surfacing is reduced. Flux-cored wire makes it possible to use alloying substances more economically, and therefore is very promising. Recommended grades of flux-cored wire for surfacing various parts are given in the appendix. 2.

Typically, flux-cored wires are used for semi-automatic hose welding. Due to the possibility of observing the formation of a seam, the technique of surfacing various products is practically no different from the technique of surfacing them in shielding gases with a consumable electrode. When multilayer welding or surfacing with flux-cored wire, the surface of the previous layers should be thoroughly cleaned of slag.

Surfacing with flux-cored wires has its disadvantages. The low rigidity of the tubular structure of flux-cored wire requires the use of feed mechanisms with limited wire compression force in the feed rollers. Surfacing can be carried out only in the lower and rarely in the vertical position. This is explained by the fact that the resulting weld pool of increased volume, covered with liquid-flowing slag, is not held in the vertical and overhead positions by the force of surface tension and arc pressure. A significant disadvantage of flux-cored wires, which hinders their widespread industrial use, is the increased likelihood of pores forming in welds, caused by the presence of voids in the wire. In addition, unmelted components of the core, passing into the weld pool, contribute to the appearance of gaseous products. Moisture that gets into the filler during storage of the wire, as well as grease and rust, traces of which are on the metal sheath, also increases the likelihood of pore formation.

For automatic surfacing of parts with flux-cored wire, surfacing installations UD-209, UD-609, UNP-350-1, etc. are used. Typically, such installations include a manipulator-rotator based on a lathe, an arc power source, a welding head with a wire feed mechanism, control panel, protective gas cylinder. A schematic diagram of such installations is shown in Fig. 9.

Rice. 9. Diagram of a typical installation for automatic surfacing of cylindrical parts with flux-cored wire : 1 – part to be welded; 2 – manipulator-rotator; 3 – welding head; 4 – power supply; 5 – control panel; 6 – tailstock; 7 – protective gas cylinder

Powder surfacing strips

Powdered tapes are produced on special mills equipped with rollers for forming and rolling the casing tape. The mill has a metering device for feeding the charge and a cage of rolls for compacting this charge, forming a core of powder strip. The drawing process, in contrast to the production of all-metal tape, is absent in the production of flux-cored tape. The tape is usually made with a width of 40...50 mm. Powder-cored tapes are used for surfacing products made of various structural alloys, but mainly steel or cast iron. When surfacing with flux-cored strips, fluxes or shielding gases can be used as a protective medium. Some tapes can be used without additional protection. For example, flux-cored tapes PL-AN101 and PL-AN102 are universal. They are designed for both submerged arc and open arc surfacing. Basically, flux-cored belts are used in cases where the size of the worn surface is quite large and the degree of wear is small. For example, flux-cored tapes PL-U40Kh38G3RTYU and PLU30Kh30G3TYU are used for submerged surfacing of parts of construction and road machines operating under conditions of abrasive wear: the first - in the absence of impacts, the second - for parts experiencing abrasive wear with shock loads.

961