Since childhood, our parents instilled in us that we should not watch how a welder works - otherwise you will go blind. They also scolded us for trying on other people’s glasses and moving our eyes to the tip of our nose. Modern mothers and fathers reprimand their children for their habit of surfing social networks in the dark and generally sitting at the computer for a long time. But which of these is really harmful to the eyes, and which is nothing more than a common myth? Read what pediatricians and ophthalmologists think about this.

- What happens when you look at welding?

- What if you look at the sun?

- How dangerous are monitors?

- What about gadgets in a dark room?

- Is it possible to bring your eyes to your nose?

- How dangerous is it to try on someone else's glasses?

- How to protect your eyes?

What happens when you look at welding?

Photo: MKvarda/pixabay.com

It’s not for nothing that welders work in masks - looking at welding is really harmful. But it’s impossible to go blind from this, and the most unpleasant thing that awaits you is photokeratitis, or a burn of the cornea. With this disease, a person begins to experience pain in the eyeballs, photophobia, or cannot open his eyes at all.

This usually happens within six to twelve hours from the moment of receiving the burn. However, after a day or two, these symptoms disappear and vision is restored. So watching a pipe being welded is dangerous, but not fatal.

What not to do?

Many people prefer not to see a doctor, but to solve the problem at home, through self-medication or traditional medicine. Meanwhile, there are a number of contraindications for ophthalmic burns.

- You should not put aloe juice or honey in your eyes.

- Do not rinse eyes excessively with tap water. It's better to take bottled water.

- Don't rub your eyes.

- Do not use the first eye drops you come across. They all have different compositions and different effects. The likelihood of making the situation worse is very high.

What if you look at the sun?

Essentially, this is the same as looking at welding: if you don’t take your eyes off the sun for a long time, you can get photokeratitis, the symptoms of which are described above. However, it is not at all necessary to look specifically at the sun - you can get a burn by looking at any surface that reflects the sun's rays well, for example, water, sand or snow.

But that's not all : in addition to photokeratitis, you can damage the retina, so much so that you will see dark spots in front of your eyes for the rest of your life. Or get cataracts, which will make themselves felt in old age, and, sadly, all this one way or another leads to complete loss of vision. So it’s better to wear sunglasses when going out into the sun, and to watch the eclipse with the help of special equipment.

Symptoms of injury

Electroophthalmia has several degrees of severity depending on the severity of the burn. Accordingly, the symptoms of injury vary. However, it does not necessarily come from looking at a sparkling arc, but a thermal burn may occur in the absence of a mask from high temperature. However, most often this is a light burn of the mucous membrane, which negatively affects the cornea and retina.

Common signs of such visual damage are:

- photophobia;

- severe lacrimation;

- redness of the whites;

- acute pain in the eyes;

- spasms of the eyelids.

After receiving an injury, you should visit a doctor as soon as possible to determine the severity of the injury. Indeed, with significant damage, vision may deteriorate and irreversible changes in the structures of the eyes may occur.

How dangerous are monitors?

Photo: Mateusz Dach/pexels.com

Not a single scientific study has proven the irreparable damage that computer monitors cause to the eyes. True, ophthalmologists still agree with the existence of computer vision syndrome, in which the image before the eyes blurs, the eyes get tired and pain occurs in the head and neck. It occurs because while working at the computer we blink less often, and the cornea becomes dry. However, you can get rid of this syndrome: you need to contact an ophthalmologist and try to choose the right lighting in the workplace.

First aid

Sometimes workers using a welding machine do not pay attention to discomfort and pain in the eye area. This is not correct, since only timely qualified assistance can preserve vision and improve the condition of the victim.

If signs of electroophthalmia are detected, then it is necessary:

- Prescribe a pain reliever, for example, analgin or ketanov. Additionally, you need to give an anti-inflammatory drug (tavegil, diclofenac).

- Rinse your eyes with clean water; you can use still water for drinking.

- Remove, if any, foreign objects from the surface of the cornea (usually metal shavings). To do this, use cotton pads or napkins, which must be sterile.

- A cold compress is placed on the eyelids to reduce swelling and inflammation.

- Treat the surface with antibacterial or antiseptic ointment (for example, tetracycline).

After emergency measures are taken, the victim must be taken to an ophthalmologist as soon as possible, who will conduct the necessary diagnostics and prescribe treatment.

Types of Welding Machines

There are a large number of models of welding machines of different types on the market.

Of all their diversity:

- transformers;

- rectifiers;

- inverters;

- semi-automatic;

- machine guns;

- plasma;

In a home workshop, transformers are most often used because of their low cost, and inverters because of their simplicity and ease of use. The rest require either special working conditions, achievable only in production, or special training and long-term acquisition of skills.

Transformer

The design of such devices is extremely simple - it is a powerful step-down transformer, in the secondary winding of which a working electrical circuit is connected.

Transformer welding machine

Transformer advantages:

- unpretentiousness;

- survivability;

- simplicity;

- cheapness.

Flaws

- very large weight and dimensions;

- low arc stability;

- AC operation;

- causes voltage surges in the supply network.

Such a device requires skill and extensive experience from the welder. It is not suitable for teaching a novice welder how to weld correctly.

Inverters

The inverter device has a much more complex design. The inverter unit repeatedly converts the input mains voltage, bringing its parameters to the required ones. Due to the transformation of high frequency current, the dimensions and weight of the transformer are many times smaller.

Inverter

Inverter advantages:

- low weight and dimensions;

- stabilized voltage and current in the circuit;

- additional anti-stick and hot start functions;

- possibility of precise adjustment of current and arc parameters;

- does not cause voltage surges in the supply network.

The inverter also has disadvantages:

- high price;

- low frost resistance.

It’s best to start learning how to cook properly with an inverter. The stability of the arc parameters and additional functions that make starting easier and preventing “sticking” will allow the beginner to concentrate on the seam and quickly master the technology.

Working with welding without special clothing: unpleasant consequences

Personal protective equipment, buy in Minsk

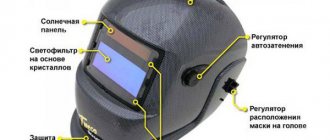

that our online store offers is not a luxury item, a whim or another useless waste of money. Welding gloves, overalls, masks, special shoes, glasses - all this is an opportunity to protect yourself from the risks associated with welding.

What could be the unpleasant consequences of skimping on your own defense? In first place are electric shocks, leading not only to shock and burns, but also to brain damage, not to mention death. In order to prevent such situations, it is recommended to use dry gloves and wear shoes with soles made of rubber or rubber.

Thermal effects and splashes of molten metal are other dangerous factors that await a welder without a uniform. Excessive exposure to heat provokes heatstroke or overheating, noticeable by dizziness, drowsiness, irritability and nausea. More serious consequences are caused by metal shavings, hot slag, drops of molten metal and electrode particles. Once on the skin, all this becomes the cause of thermal burns of the skin and mucous membranes, injury to the organs of vision, etc.

The intense light radiation associated with arc welding damages the eyes, while infrared rays cause cataracts and corneal damage. As you understand, you need to buy a Chameleon welding helmet as a matter of priority, because a minute of work without eye PPE is enough to catch “bunnies”.

Huge doses of ultraviolet radiation directed at unprotected skin provoke the appearance of burns on it and increase the likelihood of developing dermal cancer.

High noise levels are sources of impaired hearing quality, nervous tension, increased blood pressure and the onset of cardiac pathologies. Therefore, for the hearing organs, personal protective equipment, the price of which is much lower than the cost of further treatment for occupational diseases, is mandatory for use when working with noise levels above 85 dB.

Smoke, gas, dust and fumes, harmful compounds emitted by hot metals, electrodes and fluxes are the cause of respiratory problems, kidney diseases, reproductive difficulties, and deterioration in general health. Is it worth saving on all this if your life is tightly connected with welding?

What are the degrees of burn?

In total, there are four degrees of severity of eye burns from welding, depending on this, the appropriate method of therapy is selected.

First degree . It is characterized by severe itching, burning, and the cornea may become cloudy. Signs of irritation in the first degree may go away on their own within a few days, and no therapy will be needed. Second degree . There is acute pain in the eyes, photophobia, and a film may form on the conjunctiva. The second degree refers to the average. Third degree . A severe form of the disease, in which acute pain turns into aching pain, the eyelids visibly swell, vision becomes blurry, and bright flashing flashes appear in the eyes - they are also called “welding bunnies.” There is a feeling of sand or a foreign body under the eyelids. Fourth degree . A very dangerous form of electroophthalmia. As a result of such a burn, necrosis (tissue death) may begin, the eyelids cease to open fully, and the cornea becomes whitish.

After receiving a burn, you need to take the first preventive measures (rinsing with purified water, cold compress on the eyes, taking an anesthetic) and wait for the doctor to arrive or visit him yourself. It is dangerous to use drops in the eyes, the pharmacological effects of which you do not know. Some liquids contain preservatives, which slow down the regeneration process and provoke even greater inflammation. Only a specialist can prescribe the appropriate remedies.

Welding Basics

To learn how to weld correctly, you need to understand the physical foundations of the welding process. Any welding machine creates in a small working area at the junction of two parts being welded a temperature above the melting point of the metal being welded, the so-called weld pool. In it, the part of the metal of both parts that has turned into liquid is mixed with each other and with the metal of the molten electrode. After the temperature decreases, the metal from the weld pool crystallizes, connecting the welded parts into one whole. By slowly moving the weld pool following the arc along the joint, the welder obtains a seam. High temperatures in amateur welding machines are achieved in two ways:

- electric arc;

- gas burner. Gas torch How to solder with an electric arc correctly

Electric welding is safer, since there is no risk of gas explosion, and is easier to learn for those who are just learning how to weld properly.

An electric arc is created by passing a high current through the air gap between the parts being welded and the electrode.

Nuances for beginners in welding

There are several nuances that can be useful to anyone who wants to learn how to cook correctly:

- Do not forget about grounding and the importance of regularly checking the quality of contact between the clamp and the workpiece.

- Check the cable insulation regularly.

- The current strength is selected immediately after connecting the ground.

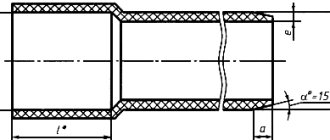

- Before igniting the arc, the electrode should be installed at an angle of approximately 60 degrees to the plane of the part, and the distance between its end and the part is about 0.5 cm.

Electrode positions during welding

By mastering increasingly complex types of seams and joint configurations, the home craftsman will be able to learn how to weld correctly and will provide his household with all the necessary welded structures.