This is a universal device for sharpening drills, blades, scissors and knives.

The Energomash TS sharpening machine is designed specifically for use in domestic needs; its energy consumption is optimized, which makes it quite economical. The dimensions of the device allow it to be stored on a shelf with tools. The material from which the body and removable blocks are made is plastic, due to this, vibration and noise during operation are minimal.

Model 6010С is distinguished by its practicality in operation, which is ensured by its design. The Energomash TS 6010S machine is supplied with a block for turning drills, a device for sharpening knives and scissors, as well as a structure for sharpening blades and chisels.

Drill sharpening

A block for sharpening drills is installed on the power part, then the drill is fixed in the squeezing device so that it can move.

Machine for sharpening drills and knives Energomash TS-6010S

Next, the drill is brought along the guide until it touches the stop. Then it must be turned until the drill blades touch the edges of the guide. Then it is necessary to tighten the clamping device, thereby fixing the position of the drill. Turning can be carried out as long as the drill is in contact with the grinding wheel.

Tips for use

- When working on the Energomash TS 6010S machine with your own hands, experts advise removing excess blocks that are not used in the process of sharpening a particular tool. Due to this, the risk of incorrect installation of the blade or drill relative to the abrasive disc is minimized;

- With active use of the Energomash TS 6010S machine with your own hands, the abrasive discs will gradually wear out. Since they have standard parameters, when purchasing a sharpening device, you should immediately purchase several spare wheels;

- Before purchasing Energomash TS 6010S, be sure to check what is included in its package. Unscrupulous sellers remove factory components from the packaging, offering to buy them for a fee;

- Examine the external condition of the device. The machine must be free of damage, defects and play

. Make sure that there are no gaps between the parts that are not provided for by the design of the factory sharpening unit; - Check the adequacy of the warranty provided and the cost. The Energomash plant provides a 14-month warranty on its machine

. As for the cost, the recommended price is 2.8 thousand rubles; - If the check shows that the machine is of really high quality and has no damage, it can be purchased;

- After purchase, read the factory instruction manual. When operating, performing preventive maintenance, and repairing the Energomash TS 6010S machine, you should rely on it;

- Perform all processing operations step by step, according to the original manufacturer's manual;

- There is no need to organize a grounding loop when connecting a sharpening machine yourself. This is due to the fact that the device has double high-quality insulation;

- Before you start sharpening a tool on the Energomash TS 6010S machine, make sure that it complies with the capabilities of the sharpening equipment. If the tool goes beyond the above restrictions on length, width, diameter, you will not be able to sharpen it efficiently;

- When processing drills, blades, cutting edges of sharpened tools, do not neglect personal protective equipment. Wear gloves on your hands, glasses on your eyes, and protective clothing that covers your skin

. Flying chips when sharpening tools can cause some trouble, leading to burns and eye damage.

Reviews clearly demonstrate that learning how to use the Energomash TS 6010S home sharpening machine is not difficult. As an alternative, you can purchase a sturm bg6010s sharpening machine. Its price is a little more than 2 thousand rubles

. It has completely identical technical characteristics with the exception of minor differences.

Having a sharpening machine in your home workshop is important if you regularly deal with drills, knives, scissors, and chisels. Many people use hand sharpeners, but they do not achieve the same level of quality in tool processing.

Energomash TS 6010S is an inexpensive, multifunctional grinding equipment. For 2.5 thousand rubles you get an excellent tool for sharpening all kinds of cutting tools

. Having such a unit at home or in a workshop greatly simplifies the process of maintaining tools in working condition, completely ready for use.

The serviceability of any cutting tool is determined by the quality of sharpening of its cutting edge. And since serious tools are made of steel, which has high hardness, the requirements for the machines with which they will be sharpened are quite high.

Safety precautions

Mastering and using the Energomash TS 6010S sharpening machine for its intended purpose is available to almost everyone, with the exception of children under 18 years of age.

This is due to the high degree of safety of the device, which allows both an experienced owner and a housewife to work on it.

Despite the high degree of protection of the device from unauthorized entry of foreign objects and body parts into the device, a number of safety requirements must be observed.

Cleanliness and order in the workplace. The absence of dust and various types of fine debris will ensure the preservation of the service life of the bearings used in rotating units, which will have a positive effect on the life of the machine.

Absence of flammable liquids and gas in the workplace. Due to the fact that the sharpening process may be accompanied by a fan of sparks, it is highly recommended not to allow them to come into contact with fabrics and substances that could ignite.

Headdress and neat appearance. Before work, it is recommended to remove jewelry and remove hair, or put it in proper condition, which prevents it from getting into the area of the grinding wheel.

Eliminate the possibility of water getting into the device. It is not recommended to work outdoors, in rooms with high humidity or in the rain.

Before you start working, you should check the machine for chips and malfunctions.

The machine is not equipped with grounding, as it has double insulation.

Design and functions

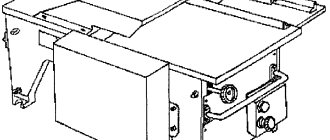

Photo of sharpening machine Energomash TS 6010S

Energomash TS 6010S has achieved high performance due to its innovative design.

- The main block of the machine is a cube;

- There is an electric motor inside it;

- A sharpening stone is installed on the electric motor shaft;

- To process various types of tools, the sharpening machine is equipped with appropriate attachments;

- The attachments are mounted in special grooves located on the front side of the sharpening equipment;

- The same fasteners are located on the sides;

- Depending on the work performed on the Energomash TS 6010S grinding device, the user can easily make the appropriate settings for the unit with his own hands.

Energomash TS 6010S is designed to perform three main tasks.

- Working with drills. To sharpen a drill with your own hands on the Energomash TS 6010S, the multifunctional machine is equipped with a V-shaped guide

.

A sharpened drill is inserted there and fixed. Next, you need to turn on the electric motor

. The operator should rotate the block until the sharpening tool no longer contacts the drill. - Knives, scissors. The design of Energomash TS 6010S does not provide for the presence of functionality with which the angle is adjusted

. For this reason, the device allows only the formation of the primary edge of the cutting tool. To polish the blades of knives and scissors, you will need to use a separate unit. - Blades, chisels and chisels. The most functional part of the Energomash TS 6010S is the unit responsible for sharpening these tools. It is distinguished by the presence of a mechanism for adjusting the angle in relation to the whetstone

.

Additionally, the machine received magnets

. With their help, high-quality fixation of the sharpened tool is ensured.

The attachments and attachment fixing units located on the front side of the machine are the weak points of the Energomash TS 6010S. This is explained by the fact that the presented components are made from plastic, which is why they are quite fragile. Therefore, when sharpening, you should not apply too much force, otherwise breakage may occur.

Main characteristics

Photo of sharpening machine Energomash TS 6010S

Energomash TS 6010S is designed for do-it-yourself work at home. This predetermined the characteristics with which the manufacturer equipped his multifunctional machine.

- Power. Since the unit is designed for do-it-yourself work, the power of Energomash TS 6010S is 100 W.

- Nutrition. The multifunctional sharpening unit operates from a regular 220V household network, which greatly simplifies its operation.

- Rotation frequency. Despite its low power, the Energomash TS 6010S machine provides an impressive rotation speed of 2019 rpm.

- Dimensions. Weighing 1.8 kilograms, the machine measures 18 by 20 by 15 centimeters. The low weight means that the machine may move during sharpening

. To prevent this, it is recommended to fix the device on a desktop or workbench. For these purposes, the manufacturer Energomash TS 6010S has provided special eyes. - Grinding wheel grit: 180.

- Drill diameter. On the sharpening machine you can use drills with a diameter of 2-10 millimeters.

- Width of sharpened blades. Energomash TS 6010S allows you to sharpen a blade whose width ranges from 6-51 millimeters.

Specifications

The power unit consists of an electric motor, its power consumption is 100 watts. It allows you to spin the grinding wheel up to 6700 rpm at idle.

The electrical parameters of the motor are designed for a home network - 230 V and 50 Hz.

The grinding wheel has diameters:

- 49.3 mm;

- 10.2 mm;

- 7.5 mm.

The block parameters allow you to sharpen drills with a diameter from 2 to 10 mm. The parameters of the blocks for sharpening blades and chisels allow you to sharpen workpieces with a width from 6 to 51 mm.

Dimensions:

- the height of the device is 180 mm;

- length – 200 mm;

- width – 150 mm.

Weight is 1.8 kg.

Technical characteristics of the Energomash TS-6010S machine

General characteristics of sharpening machines

All units of this type are divided into two large groups:

- universal;

- special.

Using units belonging to the first group, you can sharpen the cutting surfaces of most types of cutting tools. These machines consist of several units, each responsible for its own strictly defined group of sharpened tools.

The second group includes profile units capable of performing a large volume of work on sharpening one type of cutting tool:

- cutters;

- circular saws;

- drills and so on.

Both of them are equipped with various electronic equipment that controls the progress of sharpening the cutting surfaces. The design of these machines allows them to be placed both temporarily and permanently on any horizontal surfaces.

General requirements

Due to the fact that the machine is not made for use in industrial production, all its parts are made of relatively inexpensive material based on plastic. You should be careful when sharpening; you should not use force when installing the sharpening blocks, as well as during sharpening itself.

Technologically, the machine is designed in such a way that it allows you to install the required block and carry out sharpening without much effort. If you encounter difficulties with the installation of a particular unit, you need to make sure that the installation diagram is followed, try to reinstall and reconnect the machine. Before using the device, you must read the instructions for use and the passport that should come with the device.

Features of tool sharpening

Before starting work, you need to master the skills of adjusting equipment according to the operating instructions. Do not forget about the safety requirements when working with power tools and use the required protective equipment.

Each machine has its own limitations, for example:

- maximum working width;

- maximum drill diameter.

Universal machines require initial calibration and setup.

It is necessary to set the distance between the blade and the grinding wheel. For additional protection, a special transparent screen is used that prevents sparks from flying towards the user. Do not press the tool with excessive force during processing, as the part may bend, sharpening will not occur correctly, and the working edge will deteriorate. It is important to clearly know the sharpening angle, which is adjusted using adjusting screws or sliders. In universal machines, the work part is fastened using special brackets, which are made in the shape of the letter P. After the first start, it is important to create light contact of the part with the circle; as a rule, for most universal machines, the left hand is used to feed the part transversely, and the right hand to feed the part longitudinally.

An important factor is the smooth movement of the part; the working edge should move along the edge of the working plane of the circle. As mentioned above, one of the main factors in sharpening is the choice of the right equipment, that is, a grinding wheel that is suitable in all respects for processing the type of steel from which the part is made.

Reviews

Irina, 23 years old.

My husband recently purchased this unit for his own purposes. Soon he went on a business trip, but never got around to kitchen appliances. The need arose to sharpen kitchen knives, and together with the children I had to deal with the unit myself. I took the instructions for use and was surprised to find that such a seemingly incomprehensible device was so easy to put into operation. I sharpened everything I could in the kitchen. I'm waiting for my husband to show off.

Mikhail, 57 years old.

All my life I sharpened drills with a needle file, then I became interested in the machine, in principle, I’m happy with the purchase, I don’t regret the money spent. A very practical machine to use.