Question:

I read in the literature that UONI 13 55 are good welding electrodes, so I decided to buy them and burn them, try them in practice, is it true? In reality, everything did not go as planned in theory. Please explain, when welding with reverse polarity, you have to add more current. But the SSSI still sticks, and the arc breaks. After several attempts, you light the arc again, move a dozen or two millimeters and the electrode goes out again. I just don’t understand how this “miracle” works, maybe I need to add more current? The weld metal is of good quality, there is little slag debris. What am I doing wrong?

| Read the article on the website: ESAB OK Electrodes |

Answer:

If you are just starting to weld with manual arc welding, then these electrodes are not very suitable for learning. Working with an SSSI requires some skill. Try to cook MP-3 or ANO-21 first, as soon as they start to come out, only then switch to UONI 13 55 for critical structures. Here are a few nuances that can help you: • Some manufacturers may simply produce low-quality electrodes. You need to purchase and cook with electrodes from different manufacturers, then you yourself will understand which one to give preference to. Even in the same package, one electrode can cook normally, while the other is defective, not to mention different packages! • Be sure to dry the electrodes before work or, in extreme cases, calcinate them (read the article on this topic) • It may also be that the output current of your inverter may differ from that shown by the indicator or the smooth adjustment knob. Measure the welding current de facto using a clamp. • Try welding without lifting, pressing into the coating and maintaining a minimum arc.

- Cook at an angle backwards, in this case the slag will fall on the already welded area

- In conditions of low mains voltage or voltage drops, a cheap Chinese device will not be welded with electrodes with basic coating. The problem can be solved: a) by connecting a choke to the circuit;

b) buy a professional welder

c) find a good electrical network.

- Do not forget also that UONI 13 55 was created for welding highly critical loaded metal structures that are assembled in the workshop. Therefore, careful preliminary preparation of the surface of steel workpieces is required for them. They do not tolerate dirt, corrosion, or moisture.

- There is no need to provide a lot of welding current. What is good for a rutile electrode cannot be used for a basic electrode. Forcing the process will reduce the quality of the seam.

If the current is too high, it is difficult to control the weld pool, metal evaporation is intense, and there is a large amount of spatter. Warping increases due to high thermal influence. When welding the ceiling and passing vertical seams, metal will flow out of the bath.

Focus on the following modes when welding with a three-millimeter electrode, depending on the position:

a) lower 80-100A

b) vertical 60-80A

c) ceiling 70-90A

For electrodes at the Losinoostrovsky plant, the current should be slightly lower than that indicated above.

PS UONI 13 55 can be taken with you to the store before purchasing an inverter to test it.

You need to burn the electrode without completely disconnecting the arc by connecting the inverter to a 30 m extension cord with a cross section of 1.5 sq. mm. If the arc does not go out and the electrode does not stick to the metal, then the welder is of high quality.

• Burn the main electrodes more and over time you will succeed!

Question:

I'm new to welding, but inquisitive. I just can’t understand why the SSSI does not recommend cooking with straight polarity? On the Internet, in instructions and video tutorials it is said directly - do not cook. But, I recently came across a video that clearly showed that there is no difference when welding UONII 13/55 in direct and reverse polarity. The quality of the seams is the same in the first and second cases, both during visual inspection of unstripped seams, and after cleaning with a grinder with a “hairy” circle. So, somehow I don’t believe all these writers. And the question is actually the following:

Explain the physics of the process, please, as a justification for the impossibility of cooking at straight polarity with UONI electrodes.

Answer:

In fact, the phrase “Welding with UONI 13/55 electrodes is carried out using DC current of reverse polarity” was not invented by those who like to “post” something like that on the Internet. This is the manufacturer's recommendation, which you can find on the relevant websites or, upon purchase, read on the packaging box.

What happens to the de facto SSSI when welding with straight polarity?

Initial conditions: the electrodes are calcined, everything is as expected.

Result: The arc goes out for no reason at first glance. It lights up only when touching slag that has not yet hardened. There is no other way to light it.

The electrode sticks and the flux coating is difficult to melt. The arc goes out because the electrode rod burns out a couple of millimeters inside the unmelted coating.

That is, there is not enough temperature to melt the coating, and there is no protection for the weld pool.

When welding with reverse polarity, everything is different.

The physics of the process will de jure be explained to you in detail, perhaps by process engineers involved in electrode production... Here we will briefly outline our vision of the process from a theoretical point of view.

In order to understand what prevents you from welding with UUSI electrodes at straight polarity, you need to know how the choice of polarity affects the welding process.

.If we observe the reverse polarity recommended by the manufacturer, we get a “plus” sign on the electrode, and a “minus” sign on the product. But the specificity of the physical processes lies precisely in the fact that when welding with reverse polarity, an anode spot is formed on the electrode, and a cathode spot is formed on the product. Accordingly, the flow of electrons is directed from the cathode to the anode and the electrode heats up more. A temperature arises sufficient for the normal welding process to proceed. What is not observed under normal conditions when welding with direct polarity.

The use of universal electrodes avoids this problem.

Add a comment Cancel reply

You must be logged in to post a comment.

What is an electrode and what is the coating for?

An electrode is a piece of metal wire with a special coating - coating. During welding, the core melts due to the temperature of the arc. At the same time, the coating burns and melts, creating a protective gas cloud around the welding area - the weld pool. It blocks access to oxygen contained in the air. As the coating burns, part of it turns into a liquid state and covers the molten metal with a thin layer, also protecting it from interaction with oxygen. So the coating ensures good quality of the seam.

The welding electrode consists of a core and a protective coating

Before starting welding, any electrode is inspected: the coating should not be chipped. Otherwise, you will not achieve uniform heating and a high-quality seam. Also pay attention to the tip of the electrode: the thickness of the coating should be the same on all sides. Then the arc will come out in the center. Otherwise it will be displaced. For experienced welders this is not a big deal, but for beginners it can create significant problems.

It is necessary to monitor the moisture content of the coating. Some of them ignite very poorly in high humidity (for example, SSSI). Due to such “capriciousness” of the coating, they need to be stored in a dry place, ensuring as airtight packaging as possible. You can put the box in a bag, and also put in a few bags of salt that come in shoe boxes.

You should not buy wet electrodes: they can, of course, be dried, but their characteristics will decrease. If it does happen that the electrodes become damp, you can dry them in a regular household oven at low temperatures (they are usually indicated on the packaging). The second way is to put it in a dry, well-ventilated area for a long time.

Coating (protective coating) of electrodes can be: basic, rutile, cellulose and acidic.

Types of coating and their characteristics

There are only four types of coatings:

Basic (USSI) and cellulose coatings are only suitable for DC welding. They can be used on critical seams: they create a strong, elastic seam that is resistant to impact loads.

There are more than 200 brands of electrodes for welding, about 100 of them can be used in manual arc welding

The other two (rutile and acidic) can work with both alternating and direct current when welding. But acidic coating is very toxic: you can work indoors only if the workplace is equipped with forced exhaust.

Rutile coating has a greenish or blue tint, the electrodes are easy to ignite. They ignite well even if the inverter has a low open circuit voltage (for reliable ignition of the main coating, a good current-voltage characteristic is required; how to choose an inverter welding machine, read here.). When welding with rutile electrodes (MP-3), the metal hardly splashes, but there is a lot of slag and it is not easy to remove: you have to work with a hammer.

How to choose electrodes for inverter welding

First of all, the composition of the core is selected: it must be similar to the type of metal being welded. Structural steel is the most commonly used material in households. The electrodes should be made from the same wire. Sometimes you still have to cook stainless steel. Then the core should also be made of stainless steel, and for highly alloyed and heat-resistant ones it is made of metal with the same characteristics.

You can perform all the work around the house or at a construction site using just a few brands of electrodes:

They are recognized by many as the best electrodes for beginners who work with inverter welding machines: they are easier to work with, at the same time, they allow you to weld high-quality seams even without significant experience. Below are the characteristics and general application of those consumables that many experts consider good electrodes for an inverter. In any case, they are often recommended for beginning welders to gain experience.

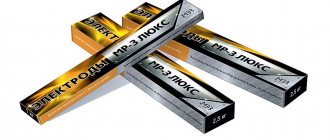

Electrodes with rutile coating MP 3

These are perhaps the most popular welding electrodes for inverters among beginners: UONI 13/55 (To enlarge the picture size, right-click on it)

Most often, beginners are advised to start mastering welds with MP-3 electrodes. They light up easily, even with a not very good current-voltage characteristic of the welding machine, provide good protection for the weld pool, and make it quite easy to control its position. If the electrode does not ignite, calcine it at a temperature of 150-180° for 40 minutes.

They are used in devices with alternating current (welding transformers) and direct current (welding rectifiers and inverters). Inverters are usually connected with reverse polarity (+ on the electrode). Suitable for any type of seam, except vertical from top to bottom.

MP 3 electrodes are not picky about the quality of the surfaces being welded. They can be used even on untreated, rusty and wet parts. Welding is carried out with a medium (2-3 mm) or short arc.

The MP 3 feature is very important for novice welders: they “hold” the arc well and are easy to work with. This is why not all professionals love this brand: they call them sparklers. They cook too softly: slow movements are necessary for good heating. What the pros don't like, is just what beginners need. Try to start learning welding with MP3. Everything should work out for you.

| Electrode diameter LEZ MR-3, mm | Length, mm | Recommended welding current, A | Pack weight, kg | Price, rub |

| 2,0 | 250 | 40-60 A | 1,0 | 146 |

| 2,5 | 300 | 60-100 A | 1,0 | 120 |

| 3 | 350 | 70-100 A | 1,0 | 95 |

| 4 | 450 | 80-170 A | 1,0 | 91 |

| 5 | 450 | 130-210 A | 1,0 | 91 |

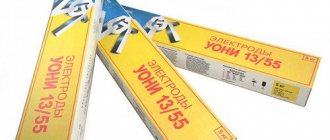

UONI 13/55 with basic coating

Electrodes preferred by professionals for the UONI 13/55 inverter (To increase the size of the picture, right-click on it)

These are perhaps the most widespread and popular electrodes with a basic coating. They are recommended for welding carbon and low-alloy steels. Suitable for connections of critical structures. The seams are resistant to shock loads and ductile, and withstand low temperatures well.

How to choose the diameter of the electrode, how to connect it and what current strength to set

Choosing the brand of electrodes for the inverter is not all. Even if you have made your decision, at least three questions remain:

- what electrode diameter to use when welding;

- what current to set;

- Which output “+” or “-” should the electrode be connected to?

First things first. Let's start with what diameter of the electrode is needed for welding. In general, it is recommended to proceed from the thickness of the metals being welded: for small thicknesses, an electrode is taken with a diameter of the same size as the metal. If you are welding metal 3 mm thick, then use electrodes of a similar size. If you are cooking something thicker, take 4 mm accordingly. But large electrodes will be difficult for beginners to work with. Start mastering welding with a metal thickness of 3-4 mm. To do this, use 3 mm electrodes, or as they say “three”.

General recommendations for choosing the diameter of the electrode depending on the thickness of the metal

Regarding how to connect the electrodes to which output. The technical specifications on the package most likely indicate what polarity the electrode is intended for. When connecting in reverse, an electrode is connected to the positive output, and a clamp is connected to the negative output, which is attached to the part. With direct polarity, a plus is placed on the part, and a minus is applied to the electrode. How it looks on a welding inverter is shown in the photo.

Direct and reverse polarity of connection on the welding inverter

How are these two connection types different? The flow of electrons has different directions. As you know, electrons move from minus to plus. Therefore, when welding, it turns out that the element that is connected to “+” heats up more. By changing connection modes you can control the intensity of metal heating.

Let's consider several situations. For example, you have a 3 mm electrode, 2 mm metal. If you apply “+” to a part, burnout may result. Therefore, in this case it is better to use reverse polarity, at which the electrode will heat up more. If you want to weld 6 mm metal with the same three, it is better to do it with direct polarity: this way the heating of the metal will be deeper and the weld will be stronger.

Welding current

In general, when installing an electrode, the welding current strength for the inverter is set depending on the diameter of the electrode used. In general, there are recommendations on each pack, but you can do without them: take 20-30 Amperes of current for each millimeter of diameter. It turns out to be a fairly wide range, but then you also need to consider how you will lay the seam: with or without tearing. For welding without separation, lower currents are used, for welding with separation, higher currents are used.

What current should be used to cook with different electrodes (general recommendations, carefully select experimentally)

For example, for an electrode with a diameter of 3 mm, the calculated current is from 60 A to 90 A. They actually work in the range from 30 Amperes to 140 Amperes. When welding without separation, the current is set to about 70-90 A, with separation - 90-120 A. These parameters can “walk” in both directions: it also depends on the speed of movement of the tip of the electrode, on the grade and “fluidity” of the steel being welded, on the position of the seam (for vertical and horizontal seams they put a little less, for the ceiling - even less).

In general, even the currents recommended by the manufacturer are far from a requirement. Start with them, and then select them so that it is convenient for you to work and the seam turns out well. You should get a high-quality connection, and you will select the ratio of current strength and speed of movement experimentally. In this case, focus on the condition of the weld pool. It is your main indicator of quality.

Errors that may occur during welding

Now you know not only how to choose electrodes for inverter welding, but also how to connect them, what diameter you need them for this work, and how to select the current for each type of electrode and weld. Now let's talk a little about electrode holders.

Electrode holders

One of the welding cables has a holder into which the welding electrode is inserted. They are of two types:

- with a trigger key, the electrode is clamped in them automatically when the spring-loaded key is released, and released when you press it;

- threaded - the handle twists and unwinds, releasing or clamping the inserted electrode core.

Which one is better? It's up to you to decide, but if you accidentally press a key, you may drop the electrode while welding. Nothing bad happens, but it’s unpleasant...

When choosing an electrode holder, the main thing is to pay attention to the current strength for which it is designed. Choose according to the maximum parameter that is available for your welding machine.

How to connect the cable to a welding electrode holder with a threaded clamp is shown in the video.

The disadvantage of the clothespin holder is that over time, the spring that presses the electrode core weakens, and the contact deteriorates. I have to install a new one. Watch the video to see how to do this on a clothespin holder.

Connecting the welding electrode holder is easy. There is just one caveat: with frequent use, the welding cable gets chafed by its edge. You can, of course, shorten the cable and re-terminate it, but you don’t always want to cut off even 10-20 cm. To prevent this from happening, find a hose whose inner diameter is the same as or slightly smaller than the outer diameter of the welded cable. Cut a small piece of it - 15 centimeters - and cut it lengthwise. Now you can put it on the cable, pull it up and secure it there.

UONI electrodes from the brands Hobex, ESAB-SVEL, Monolith, Plasma, Most and others are widely popular among welders. These electrodes guarantee the strength and stability of the welded structures - provided that you already have some welding skills. Let's take a closer look at the advantages of the UONI 13 55 brand and what you need to know before purchasing them.

Electrodes UONI or MP-3

Electrodes UONI or MP-3 - which is better to choose, what is the difference

Electrodes are selected as close as possible to the composition of the metal to be welded. Steel cannot be welded with aluminum electrodes, and vice versa.

In turn, there are consumable electrodes, those with coating, and non-consumable ones, without coating. Tungsten is used to make non-consumable electrodes, hence the name tungsten electrodes.

Among the numerous brands of electrodes, the most popular are UONI and MP-3 electrodes. Both types of electrodes are used for welding critical structures made of low-alloy and carbon steels.

However, despite this, they have a difference. You can find out which one exactly from this article.

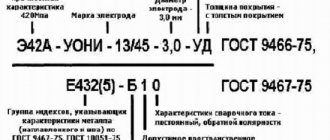

Decoding the electrodes

The name of these welding electrodes comes from the abbreviation UONI-13, which denoted a coating for electrodes patented in 1940. It deciphers like this:

electrodes UONI 13 55

What is noteworthy is that GOST 9466 - 75 prescribed the use of a slightly different abbreviation - UONII-13 (“universal coating of scientific research institute No. 13”). Currently, any of these abbreviations may be indicated on packs of these consumables, but in documents it is always written UONII.

The manufacturer usually indicates the following code on the packages of UONI 13 55: E50A-UONI-13/55 SM-4.0-UD GOST 9467-60. This means that the product is an electrode for arc welding, the weld will have a strength of at least 50 kgf per mm2 and will have plastic properties, the product brand is UONI 13/55 SM, the diameter is 4 mm, carbon and low-carbon steels can be welded, electrode coating thick, the product is standardized according to GOST number 9467, approved in 1960.

decoding of markings

Depending on the type of electrodes of the UONI brand, the marking may vary. For example, the diameter can be 2 mm, 2.5 mm, 3 mm or 5 mm, tensile strength - e42, e46, e50, etc., modifications are 55k, 55r, 55u, etc.

You can read all about electrode markings here.

Features of application

The main technical characteristics of welding electrodes Uoni 1355 consist of the following items:

- for welding with these products you need to use reverse polarity current;

- a special coating of carbonates and fluoride formations, through which the weld practically does not contain gases and other unnecessary impurities;

- Low-carbon steel is used for the rod, which contributes to the long durability of the seam;

- the coating does not contain various organic compounds, due to which such electrodes have a low level of exposure to moisture;

- During the manufacturing process of electrodes, the formation of various irregularities, cracks or swellings is completely eliminated.

We recommend! Technical characteristics of welding electrodes ANO-4

The above factors contribute to the creation of a seam that is not subject to aging and loss of its properties under different temperature conditions.

When welding with electrodes, it is necessary to control the cleanliness of the parts being joined, because the presence of traces of rust or various oils will cause the appearance of pores, and the connection itself will not be reliable. In addition, “stretching” the arc also negatively affects the quality of the weld.

The key competitive advantage of such products over analogues is that the weld is produced with a low hydrogen concentration and is more resistant to the appearance of microcracks during the crystallization process. The most effective result when carrying out actions with Uoni 1355 electrodes can be obtained when welding with a small arc using the supported method.

According to GOST 9466-75, the weight of products in a pack should not exceed:

- 3 kg – for product diameters up to 2.5 mm;

- 5 kg – for a diameter of 3.0 – 4.0 mm;

- 8 kg – for diameters over 4.0 mm.

Purpose of electrodes UONI 13 55

Welding electrodes UONI 13 55 are suitable for manual welding using an arc. Welding can be done in overhead, horizontal, lower, inclined positions, as well as in a vertical position from top to bottom. As mentioned above, they can weld low-alloy and carbon-containing metals. The welding seam is wear-resistant and protected from corrosion. The carbonates and fluoride compounds that make up the coating of the UONI electrode prevent the formation of hot cracks and give the weld plasticity and high impact strength. Therefore, this consumable is used when welding thick metal, correcting casting defects, and manufacturing parts that can withstand high pressure, low temperatures and long-term loads.

Electrodes Monolit UONI are widely used in shipbuilding.

Recommendations from specialists on the selection of welding technology

- It is better to weld fairly thick structural elements using the bath technology in the lower position of the weld.

- Standard arc welding can be used when joining metal structures made of reinforcement. Welding work can be performed in any spatial position of the seam joint with a short arc using a constant current of reverse polarity.

UONI welding electrodes prefer the use of an inverter, since the rectifier cannot provide a stable arc. It is better to take electrodes with a smaller diameter - they will heat the welded product less. To cool the metal, it is worth preparing copper pads.

Specifications

The coating of UONI 13 55 electrodes is basic. The rods consist of welding wire Sv-08 or Sv-08A. The ratio of the weight of the electrode to the weight of the deposited metal is 1.6 kg to 1 kg. Deposition rate - 9 g/Ah. Alloy includes carbon, sulfur, phosphorus, manganese and silicon.

The main mechanical properties of the UONI electrode are reflected in the table.

mechanical properties SSSI 13 55

The length of the products is 350 mm with a diameter of 2-3 mm and 450 mm with a diameter of 4-5 mm. The weight of an electrode with a diameter of 2 mm is 10 g. If the diameter is 2.5 mm, 3 mm, 4 mm, 5 mm, then the weight will be 17-18 g, 26-27 g, 59-61 g, 95 g, respectively.

The consumption of UONI electrodes is 10-15% lower compared to electrodes of some other brands, because their coating contains iron powder, which compensates for the metal burned out or splashed during welding.

How to read labels

Designation example: E50A-UONI-13/55 SM-4.0-UD GOST 9467-60.

The entry is deciphered as follows:

- E – electrode for arc welding.

- 50 – temporary tensile strength of the seam is 50 kgf/sq. mm.

- A – the joint has plasticity and impact strength.

- UONI is a brand inherited from the name of the UONI-13 coating developed in 1940. The abbreviation means “universal coating of scientific institute No. 13.”

- 13/55 is a type of product.

- SM-4.0 – made of welding wire with a diameter of 4 mm.

- U – designed for joining carbon steel workpieces.

- D – thick layer of coating.

Instead of “U” the following letters may be present in the marking:

- L – alloy steel.

- T – heat resistant.

- B – highly alloyed.

- N – intended for repairs using surfacing method.

Instead of "D" there may be the following letters:

- C – medium thickness coating.

- M – thin.

In GOST 9466-75 this electrode is called “UONII” (universal coating of a research institute). Such an abbreviation must be indicated in design and other documentation.

Difference between UONI and MR electrodes

Beginners often wonder which is better - SSSI 1355 or MP3. We hasten to clarify the situation.

Both grades are designed for joining carbon and low-carbon steels, the only difference is in the characteristics of the current required for welding. MP3 electrodes are used for welding with any type of current, and the polarity does not matter.

SSSIs can cook efficiently only with direct current; the polarity must be reversed. In this case, the constant cannot be replaced by a variable, otherwise the electrode will stick and the welding arc will not burn evenly. Considering this nuance, you can avoid metal spattering and weld defects.

SSSI electrodes

Welding work is often performed at enterprises, as well as at home. The complexity of the work depends on the characteristics of the welding machine and other tools used. For home use, the welding process is not possible without an inverter. Metal melting occurs through the use of melting elements, the quality of which directly determines the work process. The most common electrodes UONI 13/55 allow you to create strong connections and are capable of welding various grades of metals.

Preparing the SSNI electrode for operation

If you assume that a special electrode such as SSSI does not require preparation before use, then you are deeply mistaken. A pack of consumables is not always spent at one time, and it may happen that some of the electrodes are waiting their turn in an already leaky package.

Then, in this case, before welding the metal, it is worth calcining the electrodes, since the UUNI coating tends to absorb moisture. You can use temperatures up to 300 - 400 degrees Celsius: the products do not contain organic substances and therefore tolerate long-term heating. After calcination, you need to place the electrodes in a special case.

Please note: the electrode is subject to heat treatment no more than 3 times, its total time should not exceed 4 hours.