What the article is about:

Designation system for MIG/MAG, TIG and MMA welding

If earlier manual arc welding was designated simply and clearly (RDS), then today the designation system has changed. Especially when it comes to abbreviations such as TIG, MMA and MIG/MAG.

In order not to get confused by them, you need to understand what type of welding we are talking about in this or that case.

This article will look at the modern designation system: what MIG/MAG is, as well as what TIG and MMA welding are.

Designation system MIG/MAG, TIG and MMA

In the Soviet Union, manual arc welding was designated as RDS. This type of welding occupies a leading position in the industry. Manual arc welding is also actively used in everyday life, as the simplest and most reliable method of welding metals.

Today's designation for manual arc welding is MMA - Manual Metal Arc. This type of welding involves the use of an electric arc and coated stick electrodes. Electrodes can have a basic or rutile coating, but it must be present on the metal rod.

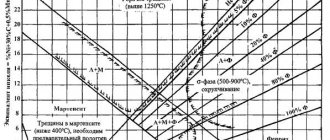

For some reason, many people confuse MMA welding with a consumable electrode with a coating with TIG welding. Electrodes are also used for TIG welding, but only without coating. Non-consumable electrodes are made of tungsten, and they do not provide any protection for the weld pool, but serve only to form the future seam.

TIG welding uses inert gases and tungsten electrodes. It is worth noting that in some countries, for example, in Germany, this type of welding is designated somewhat differently, namely WIG (Wolfram Inert Gas).

Also, you can often find another designation for welding with non-consumable electrodes, for example, GTA (Gas Tungsten Arc). In this case, in addition to inert gases (helium, argon or nitrogen), a welding arc operating from alternating and direct current also acts as the formation of a welding arc.

Welding - methods, types, GOSTs, designations

Welding, one of the most progressive methods of connecting the component parts of a product, has significant advantages over casting and riveting. There are many types of welding and methods for their implementation, for example: manual arc welding (GOST 5264-80*), automatic and semi-automatic submerged arc welding (GOST 11533-75), gas-shielded arc welding (GOST 14771-76*), contact welding ( GOST 15878-79), etc. (For more details, see GOST 19521-74. Welding of metals. Classification.)

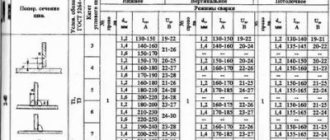

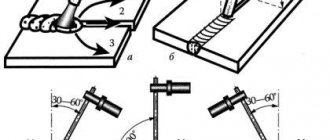

Equally numerous are the symbols for seams of welded joints and welding methods, established by both state and industry standards. Basic information sufficient for the correct depiction and designation of the most widely used types of welding is provided here. Connections are distinguished: butt (Fig. 8.95, a, b), lap (c, d), corner (e, f), T-shaped (g, h), end (i). They are designated by the first letters - S, N, U, T, Tr, respectively.

The edges of the parts to be welded can be prepared: with flanging (a), without bevels (c, d, e, g), with a bevel of one edge (f), with a bevel of both edges (b), with two symmetrical bevels of one edge (h) , with curved bevels, locking, etc. The seam can be one-sided (a, b, c, e, g) or double-sided (d, c, h), with a remaining or removed lining. In the drawings, the digital designation is added to the letter designation: C1, C2, SZ, ... HI, H2, NZ, ... U1, U2, ... T1, T2, TZ, characterizing the type of edge preparation and the thickness range of the parts being welded, for example (Fig. 8.95, a-h): a - butt joint with flange edges, thickness of welded sheets 1...4 mm - C1, b - the same, with bevel of both edges, thickness 3... 60 mm C7; c - lap joint without beveled edges, thickness 2...60 mm, one-sided seam - HI; d - lap joint with the same conditions, but the seam is double-sided - H2; d - corner connection without beveled edges, sheet thickness 1... 30 mm - U4; e - corner connection with a bevel of one edge, sheet thickness 3...60 mm - U7; g - T-joint, one-sided seam, without beveled edges, sheet thickness 2...30 mm - T1; h - T-joint, double-sided seam with two bevels of one edge, sheet thickness 12...100 mm - T9. (For more detailed information, see GOST 5264-80.)

The protruding part of the weld above the surface of the base metal is called the weld convexity (Fig. 8.96). The following symbols can be used in the symbol of a seam (Fig. 8.97):

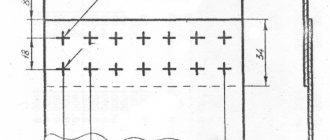

No. 1 - for an intermittent weld with a chain arrangement of welded sections, indicating the length of the section / and step t (Figure 8.98, a); No. 2 - for an intermittent seam with a staggered arrangement of welded areas, indicating the dimensions l and t (Fig. 8.98.6); No. 3 - if it is necessary to remove the convexity (see Fig. 8.96) with an indication (or without indication) of the roughness of the treated seam surface; No. 4 - when it is necessary to process weld sagging and unevenness with a smooth transition to the base metal; No. 5 - when it is necessary to indicate the size of the cross-section leg of the seam (in lap, corner and T-joints); No. 6 - when making a seam along a closed line; No. 7 - when making a seam along an open line, if the location of the seam is clear from the drawing; No. 8 - when welding is carried out during installation of the product.

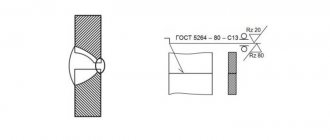

Signs are made with thin lines. The height of the signs must be the same as the height of the numbers included in the designation of the seam. The symbol of the seam can also include a letter designation of the welding method, for example, automatic welding is designated A, semi-automatic - P (GOST 11533-75), spot contact - Kt, seam - Ksh (GOST 15878-79), etc. Figure 8.99 shows the full symbol of a standard seam or a single weld point according to GOST 2.312-72: 1 - designation of the standard for the types and structural elements of welded joints; 2 - alphanumeric designation of the seam; 3 - symbol of the welding method according to the standard indicated in paragraph 1 (may not be specified); 4 — sign and size of the leg; 5 - dimensions l and t for an intermittent seam, placed respectively before and after the sign for the chain or staggered arrangement of the welded sections (see Fig. 8.97); design diameter for a single weld point; the same - for a weld of contact spot or electric rivet welding, plus sign No. 1 or No. 2 and step; calculated width of the seam of contact roller welding plus the multiplication sign; size l, sign No. 1 and size l for intermittent seam; 6 - sign for removing the convexity of the seam (see Fig. 8.96) or a smooth transition, roughness parameter of the processed seam, sign of the seam along an open line.

Depending on the welding conditions, one or another of its structural components may be excluded from the symbol. The designation of a non-standard weld includes only these poses. 5 and 6 or only pos. 5. According to GOST 2.312-72, the seam of a welded joint, regardless of the welding method, is conventionally depicted as a solid main (visible seam) or dashed (invisible seam) line. Single welding points are indicated by a “+” sign with a height and width of 5... 10 mm, line thickness s (see Fig. 8.101, c). Invisible welding points are not depicted. The symbol of the seam is applied on the shelf of a leader line drawn from the image seam on the front side (Fig. 8.100, a) or under the shelf of a leader line drawn from the back side (Fig. 8.100.6).

Note. The front side of a one-sided seam is taken to be the side from which welding is performed, and that of a double-sided seam with asymmetrically prepared edges is the side from which the main seam is welded (Fig. 8.101a). With symmetrically prepared edges, either side can be taken as the front side. The leader line begins with a one-sided arrow (see Fig. 8.99 and subsequent ones). Examples of designations (Fig. 8.101): a - butt joint seam with a bevel of one edge, double-sided, with removal convexities on both sides, with the required roughness of the treated surfaces, performed by manual arc welding in accordance with GOST 5264-80. On the left is the cross-sectional shape of the seam, the symbol of which is C8. The material of the welded parts is carbon steel with a thickness of 3...60 mm; b - the upper seam (shown in the drawing as a dashed line) of an overlap joint, the lower one - a T-joint. Both welds are intermittent chain seams (leg height is 5, l=50 and l=100 mm), performed by manual arc welding when installed along open lines; c - lap joint, carried out by resistance welding, at three welding points, the estimated diameter of the point is 5 mm; d - connection at an obtuse angle with a bevel of one edge (U4), performed in accordance with GOST 23518-79 by arc welding in inert gases with a consumable electrode (EM) along a closed line.

The seams of welded joints of plastic parts (polyethylene, polypropylene and vinyl plastic, see GOST 16310-80) are designated in the same way. If there are identical seams, the designation is applied to one image, and for the rest, leader lines with shelves are drawn to indicate the seam number (Fig. 8.102 ,a, b) or without shelves, if all seams are the same (Fig. 8.102, c).

If all the welds shown in the product drawing, although of different types, are performed according to the same standard, for example according to GOST 5264-80, its designation is not indicated on the shelf, but is given a link in the technical requirements.

What does MIG/MAG welding mean?

MIG/MAG - denotes exclusively semi-automatic wire welding in a protective gas environment. That is, if different types of electrodes are used for MMA and TIG welding, then only wire is used for MIG and MAG welding.

In this case, MIG welding is performed in an inert gas environment, and MAG welding is performed in an active gas environment. This is actually their main difference. You can read more about MIG and MAG welding on the website.

Semi-automatic welding is widely used in production. This is the second type of welding after manual arc welding, which is actively used today throughout the world.

The characteristic properties of semi-automatic welding are a smooth and beautiful welding seam without slag. Semi-automatic welding, simply irreplaceable when repairing cars and other equipment.

It also has another designation - GMA (Gas Metal Arc).

Applications:

Application form for welder certification (individual)

Welder Certification Application Form

Application form for certification of a welding production specialist (individual)

Application form for certification of a welding specialist

Welder Renewal Application Form

Specialist Renewal Application Form

NAKS-Astrakhan LLC complies with the requirements of the Certification System for welders and welding production specialists and is registered in the NAKS register under No. YUR-13AC.

Certification takes place in the following areas:

Certification of welders (I level) and welding production specialists of II, III levels of professional training in accordance with the requirements of the “Rules for the certification of welders and welding production specialists” (PB-03-273-99) and “Technological regulations for the certification of welders and welding production specialists” (RD 03-495-02).

Groups of technical devices:

- GDO - Mining equipment;

- GO - Gas equipment;

- KO - Boiler equipment;

- MO - Metallurgical equipment;

- NGDO - Oil and gas production equipment;

- OKHNVP - Equipment for chemical, petrochemical, oil refining and explosion-hazardous industries;

- PTO - Lifting and transport equipment;

- SK - Building structures.

Welding (surfacing) methods:

- AAD - Automatic argon arc welding with non-consumable electrode;

- AADN - Automatic argon arc surfacing;

- AADP - Automatic argon arc welding with consumable electrode;

- APG - Automatic welding with consumable electrode in active gases and mixtures;

- APS - Automatic welding with self-shielding flux-cored wire;

- AF - Automatic submerged arc welding;

- AFLN - Automatic surfacing with a submerged strip electrode;

- AFPN - Automatic surfacing with submerged arc electrode;

- G - Gas welding;

- ZN - Welding with embedded heater (polymer materials);

- MADP - Mechanized argon arc welding with a consumable electrode;

- MP - Mechanized welding with consumable electrode in active gases and mixtures;

- MPG - Mechanized welding with flux-cored wire in active gases and mixtures;

- MPS - Mechanized welding with self-shielding flux-cored wire;

- MSOD - Mechanized open arc welding with alloy wire;

- MF - Mechanized submerged arc welding;

- NG - Welding with heated gas;

- NI - Welding with a heated tool (polymer materials);

- PAK - Soldering;

- RAD - Manual argon arc welding with non-consumable electrode;

- RADN - Manual argon arc surfacing;

- RD - Manual arc welding with coated electrodes;

- RDN - Manual arc surfacing with coated electrodes;

- T - Thermite welding;

- ES - Electroslag welding.

To pass certification in the field of welding production, the following documents are required for each certified welder:

- Application for certification on the enterprise’s letterhead in accordance with the requirements of the “Rules” (the application must be registered by the enterprise as an outgoing document); Please note that an application for certification of a specialist or welder in electronic form can be submitted as primary information, but for the final execution of certification certificates, when appearing for certification, you must provide a completed application in paper form (with a blue seal and the signature of the manager enterprises). After receiving the application, a contract for certification, methodological and technical support for certification is drawn up.

- A copy of the education document;

- A copy of the work record book (an extract is possible) or a certificate from the place of work certified by the personnel department of the enterprise;

- Consent to the processing of personal data;

- Two photo cards 3x4 cm, color.

To pass certification in the field of welding production, the following documents are required for each certified specialist:

- Application for certification on the enterprise’s letterhead in accordance with the requirements of the “Rules” (the application must be registered by the enterprise as an outgoing document); Please note that an application for certification of a specialist or welder in electronic form can be submitted as primary information, but for the final execution of certification certificates, when appearing for certification, you must provide a completed application in paper form (with a blue seal and the signature of the manager enterprises). After receiving the application, a contract for certification, methodological and technical support for certification is drawn up.

- A copy of the education document;

- A copy of the work record book (an extract is possible) or a certificate from the place of work certified by the personnel department of the enterprise;

- A copy of the industrial safety protocol (certificate);

- Consent to the processing of personal data;

- Two photo cards 3x4 cm, color.

The employer presents the candidate to NAKS-Astrakhan LLC and documents the accuracy of the information about him. Copies of documents of each certified person are certified by the Customer or at the center upon presentation of the original documents. When passing certification, NAKS-Astrakhan LLC provides those being certified with the necessary regulatory and technical documentation.

Certification procedure

Before certification, special training is carried out for welders and specialists who have professional training in the field of welding production and possess practical skills at the level of the requirements of PB-03-273-99 and relevant regulatory documents. Special training must be carried out before certification (primary, additional, periodic and extraordinary). After completing special training, YUR-2TsSP (Special Training Center) issues a Certificate of completion of special training.

Certification of welders (in accordance with PB-03-273-99 and RD 03-495-02) includes the passing of practical, general and special exams by the certified welder. Certification begins with welders passing a practical exam. If a welder does not pass the practical exam, then he is not allowed to take further exams and is considered to have failed the certification. A welder can be re-certified after additional practical training, no earlier than after 1 month. Certification of welding production specialists includes two exams: general and special (including a practical task).

Upon successful completion of the YUR-13AC certification, it issues:

- A certification certificate registered in the Personnel Register of the certification system for welders and welding production specialists of the National Agency for Welding Control (NAKS).

- Certification protocol signed by the chairman of the commission and members of the commission.