Repair shops often replace exhausted batteries of various construction, computer and household equipment. Since the batteries in them consist of a block where the contact connections are made by micro-welding, during repairs it is necessary to remove the used element and put a new one in its place, recreating reliable contact between them. This uses spot welding for batteries. You can create such a device yourself using one of several technologies described below.

How to weld using a battery

- January 15

- 21 ratings

Many people, working in a garage or in a country house, were faced with the need to connect parts by welding, without having a welding machine. In some situations, battery-powered welding is possible. It is not always acceptable, as it has a number of limitations. However, the undeniable advantage of such work is the simplicity and accessibility of welding.

The device of an inverter welding machine.

Welding from a battery can also be carried out using inverter machines that are connected to the battery. Some car owners specifically purchase batteries for welding work. At the same time, spot welding performed using a battery is much more durable than soldering. How to carry out welding work from a car battery, what parts and materials are needed for this, will be discussed below.

Brief description of welding methods

Classification of types of welding.

People who weld quite often regularly face the problem of voltage drops in networks under high welding loads, which occurs both when using old welding transformers and new inverter machines. Often, when connecting welding devices, the voltage drops by at least 30 Volts. Such a drop is serious and may affect the operation of household appliances.

Therefore, before starting welding work, according to the legislation of the Russian Federation, it is necessary to warn all neighbors who are powered from the same line. This creates a lot of inconvenience, and neighbors may refuse to carry out such work. The way out of this situation is battery welding.

When and where it first appeared is unknown, but the first documented (filmed) process was in the 60s of the last century.

The authors are Soviet polar explorers who traveled to the site in cars.

The physics of this process is no different from conventional welding. Just like ordinary welding, welding from a battery occurs when an electric arc is formed. In this case, a permanent welding connection also occurs at the molecular level - the heated metal begins to melt, forming a seam.

Assembly diagram of a welding machine for soft welding.

At the moment, such welding can be performed in three ways (conditional division):

- Spot welding using bare contact wires. Requires a minimum of preparation, materials, and labor costs. It happens very quickly, the connection is much weaker than a conventional weld. During such welding, copper wires will protrude as electrodes.

- Connecting multiple batteries to a battery pack. This will allow welding work to be carried out using carbon electrodes of small diameter (up to 3 mm). In this case, the diameter of the electrode depends on the maximum current supplied by the battery.

- Connecting several batteries into a battery and connecting an inverter welding machine to it. In this situation, welding work is carried out as standard, only the power source changes.

The choice of welding method depends on the materials of the parts being welded. Thus, the connection of non-ferrous and alloyed metals must be performed by spot welding (point 1) or carbon electrodes (point 2).

Ferrous metal connections are made only with welding inverters (point 3). Inverters can also weld non-ferrous metals, but since the welding process using inverters is not new, there will not be a detailed description here. The only thing worth noting is the need to connect 3-4 batteries of the same capacity and the same output current into one battery. It is worth noting that the inverter quickly drains the battery from which it is powered. Therefore, it is necessary to constantly monitor the charge level by connecting a measuring device to the battery.

Return to contents

Gas shielded welding diagram.

All these processes have their advantages and disadvantages, so the practical use of batteries for welding depends on specific conditions, financial capabilities and the availability of necessary materials. The positive points include the following:

- Ability to carry out welding work in extreme conditions. For example, on the road, in the field, etc.

- Possibility of welding in the absence of specialized equipment. However, in the absence of an inverter, only non-ferrous metals can be welded.

- No voltage drops in networks. Since the process is carried out using an autonomous energy source, it does not harm the operation of the network.

- Ability to work under almost any external conditions. If the equipment is properly connected, welding can occur in hot or cold (temporary), during precipitation, etc. To do this, it is necessary to strictly follow certain rules for performing such work.

- Dead batteries can be reused after recharging.

However, this process has a number of disadvantages:

- The main disadvantage is the rapid discharge of the battery. Therefore, it is very important to monitor its capacity. To do this, a measuring device is installed in the circuit.

- Intensive discharge of batteries significantly reduces their service life. Therefore, it is necessary to constantly monitor the battery’s ability to hold a charge and replace batteries that do not hold a charge.

- Financial expenses. If only one car battery is needed for spot welding, then for welding with carbon electrodes or to connect an inverter, a minimum of three batteries are required, which are connected in series.

- Many people, when using batteries for welding, often neglect safety rules. However, despite the apparent simplicity of such work, it is possible to receive various injuries when performing it.

Return to contents

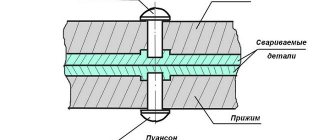

Spot welding diagram.

Spot welding using a battery is considered the most primitive. To complete this you will need one battery, wires, and a pair of terminal blocks. But let's take a closer look

Before performing welding work (this applies not only to spot welding), it is necessary to follow some safety rules. The first is eye protection. Naturally, in field conditions a person will not have a welding shield (mask), just as most car enthusiasts do not have one in garages. However, sunglasses can provide minimal protection during short-term work. The next important point is the insulation of the wires. It must be intact and not collapse. Since such welding work requires a current of at least 150 amperes, it is necessary to protect yourself from electric shock. Lastly, as when performing any complex work, attentiveness and accuracy are required.

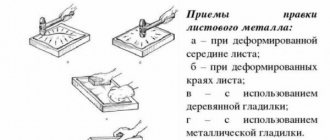

To assemble a spot welding device, it is necessary to connect insulated wires with a cross-section of at least 5 mm to the battery terminals (the choice of cross-section depends on the battery current), the correct selection of the wire cross-section is monitored during operation - the wires should not get hot. The wire leads should be connected to a terminal block (Soviet BZN will do) with a rated current of about 200-250 amperes. Next, wires are connected to the terminals, which will serve as electrodes. They must be rigid, their cross-section must coincide with the cross-section of the output wires, and they must be insulated. Next, their terminals are placed at a distance of up to 3 mm from each other (however, they should not be in contact) and the wires are fixed in this position with improvised materials (household feed-through terminals are well suited for fixing). The ends of the wires are stripped of insulation, and the device is ready for use.

To weld 2 parts, they should be connected to each other, and the cleaned wires of the device should be attached to the connection point on one side. Important: for welding, only the ends (section) of the wires are applied, and it is necessary to ensure an even cross-section of each wire (for this, the i.x is equalized with a needle file).

Return to contents

To perform such welding, it is necessary to connect 3 or more car batteries into a battery. Connections are made with large cross-section wires. Wires with powerful crocodiles at the end are connected to the battery terminals. Crocodiles act as clamps. One clamps the electrode, the other clamps the working part.

The further process is carried out similarly to conventional welding. It is important not to use thick electrodes (maximum cross-section - 3 mm). You should be careful when working, since crocodiles have a large uninsulated surface area.

expertsvarki.ru

Own experience of cooking from a car battery

We will look at our own experience of using a car battery to power an inverter unit. You can test it yourself and duplicate our work to verify what you have received.

It should be noted that one regular car battery will not be enough. Know this is a fact. At first we wanted to power the inverter from one car battery.

Welding was carried out at low current, using electrical connections 2 mm thick. The arc hardly ignited. The seam went with considerable effort. Then they took out two car batteries and connected them one by one.

The process moved forward slightly, but the result of the work was not perfect. The seam was made easier, but the arc did not burn constantly. In the end, the result is an extremely damaged seam.

Electrical connections stick to the metal, which has led to an increase in their number. In general, the result was unsatisfactory.

Since we had one more battery in stock, we connected it to the others. This method turned out to be the most viable.

When using three auto batteries, the power of the unit increased significantly. It is quite possible to achieve uninterrupted operation of welding equipment.

We conducted experiments with various indicators. They made the power either more or less, using electrical connections 4 mm thick. The workflow was successful.

Of course, cooking from a car battery is not as easy and convenient as from a regular electrical outlet. But if you carefully monitor the welding arc, you can set up the work correctly. When powered by three auto batteries, welding works better.

During our research, we learned that charging three auto batteries can also be suitable for cutting thin metal. It just doesn't come out neat enough.

Remember to watch the tension. Don't set very high scores. Car batteries can make the final voltage higher, up to very large numbers.

In this case, you will burn the metal. In principle, observe the welding process very carefully. These works do not tolerate inattention and negligent attitude. You will have to try to achieve a good result.

Welding with battery electrodes

E-veterok.ru Wind and solar energy I have heard about welding from car batteries for a long time, and there is also a video on YouTube confirming this. And in principle, I had no doubt about this because the characteristics of the batteries allow this to be done. Firstly, there is a large current, up to 600A from a 55Ah battery, and with a battery of larger capacity there is an even greater maximum current, so even a large excess of current is obtained rather than a lack of it. But in general, a year ago I needed to weld a motorcycle frame and a side trailer for it, but there was nowhere to connect a welding inverter at the dacha. At my dacha I have my own electricity, a small solar power plant is installed, and there is a 12-220 volt converter installed there with a maximum power of only 1 kW, and naturally it will not handle welding. But at that time I had four batteries in my power station, two of 65Ah each, and two more of 90Ah each, so I decided to see for myself that it was possible to cook from a battery. In general, I brought two batteries to the welding site and connected the battery in series at 24 volts. The electrodes were 2.5 mm in diameter.

I will say that it was possible to brew, and quite well, but most likely there was not enough voltage because the arc was very poorly ignited and good welding was not achieved, since the arc barely burned and often simply went out. But what surprised me was that if the electrode gets stuck, it heats up to red in a second and melts. I haven’t observed this with conventional welding, but here you have to be more careful, the electrodes burn out in one fell swoop when they stick.

Just recently, at the beginning of February (2016), I needed welding again, but I already had three 90Ah batteries. I was making a frame for a wind generator. With three batteries connected in series, welding turned out to be excellent and with a lot of current. I started welding with 2 mm electrodes, and at first I even burned a few holes in the metal because the current was too high. Then I welded with 2.5 mm electrodes, but the current was still too high and I had to cook very carefully so as not to burn through the thin 3 mm metal. I even cut such metal freely with electrodes. Then I didn’t have any other electrodes, but I think 4 mm electrodes would have gone freely under such a current. In general, it cooks perfectly, except for the fact that the current is too high, which there is nothing to limit. But you get used to it, and it’s quite normal to brew something even serious.

But it’s better not to deeply discharge the batteries, otherwise they will deteriorate quickly, but the high current will do them no good. I will say that from three 90Ah batteries you can easily burn 15-20 electrodes each and the batteries do not discharge much, and such a number of electrodes is already decent.

Below are some photos of batteries and welding

This is what the batteries themselves look like when they are connected in series; my welding wires are 35 kW. These are actually 2 mm electrodes. 2.5 mm electrodes. In this photo you can see the penetration from the back side, I didn’t specifically photograph the welding process itself, so I didn’t capture the specific quality of the welding, but in general it cooks well. And here is the result of the welding, the frame for the wind generator is welded.

If anyone is interested in the wind generator itself and welding, I wrote an article about making a wind generator and there is a video there where you can see what I did and how I welded it. That's all, if there is anything new I will write in the following articles.

E-VETEROK.RU wind and solar energy - 2013 Mail: Google+

e-veterok.ru

Introductory information

In theory, everything seems much simpler. But in application, certain conditions must be met. The current in the electrical network must remain uninterrupted and not fall below 180 Volts.

Or your welding unit must cope with low voltage work. Such equipment is not cheap.

It is not even discussed that you must have access to electricity. But some country houses and dachas, garages located far from the urban area are not connected to electricity.

What to do in this case. Our opinion comes down to buying a fuel generator for welding. But not everyone wants to spend extra money, especially if you rarely use welding.

Even to carry out non-long-term welding. In our review we will write whether it is possible to carry out welding tasks using a 12 Volt battery. Is it really necessary to take such risks?

How to make a welding machine from a car battery

Home » Useful tips » Homemade products » How to make a welding machine from a car battery

In the life of every man, a situation may arise when he needs to perform a small amount of welding work, but there is no welding machine at hand. As a rule, in such a situation, many people fall into despair, because they believe that there is currently no alternative to a welding machine. Of course, there is no alternative, you cannot make a welding machine from car batteries, it will not completely replace standard installations, but a small amount of work will help get it done.

Do-it-yourself welding machine from car batteries

Welding machine from a car battery

Let's note it right away! Our homemade product is not safe, it can harm your health and damage car batteries, which are not considered cheap.

The essence of the homemade product: if two welding machines are connected in series, you will get a welding machine that will have two functions:

- can cut metal;

- weld metal.

For homemade products you need the following materials:

- Two car batteries. It is desirable that the current be 700 A or higher. Voltage does not play a role in this matter, because only current is involved in welding.

- You also need two wires 1 meter long. Their cross section is 12 mm2.

- An electrode that is at hand.

Assembling the welding machine step by step

First of all, you need to install two batteries side by side, it is advisable to think about a stand to make it more convenient to work with them.

Then we connect the wires, there are several subtleties here:

- If it is necessary to weld metal, we connect the minus to the electrode, and not the plus to the workpiece.

- When cutting metal, connect the electrode to positive and the workpiece to negative.

Then we connect the electrode and try to weld carefully.

What is important to know

An important point is the choice of wire. If its cross-section is too large, you risk burning your batteries. Therefore, we strongly recommend using wires with a small cross-section, because it is better if the wire itself burns out (it is cheaper to replace it).

You can adjust the current strength (A) depending on the cross-section and length of the cable. The optimal length is 1 meter and cross-section 12 mm2. But, if you are making such a homemade product for the first time, try using a wire of a smaller cross-section, this will avoid possible problems.

Remember! It is prohibited to handle the electrode or wire with bare hands. Try using any available means that will help avoid direct contact.

Why is it safe

As a rule, most men think that this can burn the battery. Of course, no one is immune from this, but such a welding machine is considered quite safe. For example, a starter uses more electrical current during starting than welding. Accordingly, there will be no shock to the car battery. But, it is worth understanding that its operation should be minimal so that the battery does not overheat.

Working with a homemade welding machine

It is also necessary to carefully monitor the condition of the electrode, the correct connection and heating. If something confuses you, it is better to repeat the connection again; it won’t take long, but it will help keep the battery completely intact.

Remember! You can only work with such a homemade welding machine in rubber gloves and boots, because the current can cause serious harm to your body.

Video on the topic

We found detailed instructions online that will tell you how to make a welding machine from a battery in emergency conditions. Read also:

SIP wire characteristics.

Read how to make a glass with light here.

DIY soldering iron.

vse-elektrichestvo.ru