General information

The quality of steel used in the manufacture of metal

structures is determined by its mechanical properties: resistance to static influences, dynamic influences and brittle fracture at various temperatures; plasticity indicators - relative elongation; resistance to delamination - bending in a cold state. The values of these indicators are established by GOST. In addition, the quality of steel is determined by its weldability, which is guaranteed by the appropriate chemical composition of the steel and its production technology.

Based on their strength, steel is divided into three groups:

- low carbon steels (ordinary quality)

- high strength steel

- high strength steel

The mechanical properties of steel and its weldability depend on the chemical composition, heat treatment and rolling technology.

The basis of steel is ferrite. Ferrite has low strength and is very plastic, therefore in its pure form it is not used in building structures. Its strength is increased by carbon additives - low-carbon steels of normal strength; alloying with manganese, silicon, vanadium, chromium and other elements - low-alloy steels of increased strength; alloying and thermal hardening of high strength steel.

Main types and grades of steel used in construction

In construction, carbon steels of ordinary quality, high-quality structural carbon steels and low-alloy structural steels are mainly used.

Carbon steels of ordinary quality

contain carbon in the amount of 0.06 - 0.62%, as well as impurities of silicon and manganese in normal concentrations. When designating steel grades, the following may be indicated: delivery groups (A – mechanical properties, B – chemical composition, C – mechanical properties with additional requirements for chemical composition); production method (M – open hearth, B – Bessemer, K – oxygen-converter); additional indices (sp - calm steel, ps - semi-quiet steel, kp - boiling steel). In group A, the designation of the production method is often omitted, but this refers to open-hearth steel, and in the absence of an additional index, it means mild steel.

Carbon steel of ordinary quality group A

make brands: St 0, St 1, St 2, St 3, St 4, St 5, St 6, St 7;

steel of group B

- the same grades as steel of group A, but the letter B is placed in front of the steel grade (for example, B St 0, B St 1 kp);

steel of group B

- B St 2, B St 3, B St 4 and B St 5. As the number increases, the carbon content in the steel, its strength and hardness increase, but ductility and toughness decrease.

Quality structural carbon steel

supplied by chemical composition and mechanical properties and smelted in open hearths and oxygen converters. The established grades of this steel are: 05 kp, 08 kp, 08 ps, 10 kp, 10 ps, 15 kp, 15 ps, 15, 20 kp, 20 ps, 20, 25, 30, 35, 40, 45, 50, 55, 58, 60. Two numbers in marks show the average carbon content in hundredths of a percent.

In the marking of alloy steel

indicate the names of alloying additives and their content. The letter designations of alloying elements are accepted: C - silicon (at concentrations above normal), G - manganese (concentrations above normal), X - chromium, H - nickel, M - molybdenum, B - tungsten, T - titanium, etc. The first two digits brands indicate the average carbon content in hundredths of a percent. One number at the beginning of the mark indicates the average carbon content in tenths of a percent. If there is no number at the beginning of the brand, then the amount of carbon is 1% or higher. The numbers following the letters show the average content of this element as a percentage; if there is no number behind the letter, then the content of this element is about 1%. The letter A at the end of the brand indicates high-quality steel containing less sulfur and phosphorus. For example, 35 X N 3 MA is a high-quality alloy steel, with a carbon content of 0.35%, chromium and molybdenum - about 1%, nickel - 3%; G 13 is an alloy steel with a carbon content of 1% or higher, manganese - 13%.

Low-carbon and low-alloy steels are widely used for the manufacture of metal structures of bridges, supports, transport galleries, frame elements of buildings and structures, reinforcement of reinforced concrete structures, etc. Elements of metal structures are produced in a hot or cold state in various ways: rolling, forging, drawing, stamping, pressing (metal powders). After this, the steel is often subjected to thermal or mechanical treatment to harden it.

To heat treatment of steel

include: a) hardening, b) tempering, c) annealing, d) normalization, e) cold treatment, f) chemical-thermal treatment (cementation, nitriding, chrome plating). For low-carbon steels, heat treatment increases the tensile strength by 20-25%, which reduces steel consumption by 13-18%. The economic efficiency of metal structures is increased by using high-strength steel (600-1000 MPa). To do this, they are alloyed with carbide-forming elements (for example, chromium, molybdenum, tungsten, niobium).

The elements are connected into a structure using welding, riveting, and bolts. Welding

is the process of producing permanent connections of metal products using local heating.

Based on the type of energy,

a distinction is made between chemical (gas, thermite) and electrical (arc, contact) welding;

according to the state of the metal in the welding zone

- plastic (heating the metal to a plastic state) and fusion welding;

according to the method of metal supply and welding

- manual, semi-automatic and automatic.

In construction, the most common are electric

arc fusion welding and

electric contact

welding in a plastic state (butt, spot, seam or roller).

Gas

welding is used to connect elements made of cast iron, non-ferrous metals, and building parts of small thickness.

Harmful impurities

These primarily include: phosphorus,

which, forming a solution with ferrite, increases the brittleness of steel, especially at low temperatures (cold brittleness) and reduces ductility at elevated temperatures;

sulfur,

which makes steel red-brittle (prone to cracking at temperatures of 800–1000 C) due to the formation of fusible iron sulfide. Therefore, the content of sulfur and phosphorus in steel is limited; So in carbon steel St 3, sulfur is up to 0.05% and phosphorus is up to 0.04%.

The mechanical properties of steel are adversely affected by saturation with gases that can enter the metal in a molten state from the atmosphere. Oxygen acts like sulfur, but to a greater extent and increases the brittleness of steel. Unfixed nitrogen also reduces the quality of steel. Hydrogen, although retained in an insignificant amount (0.0007%), but concentrating near inclusions in intercrystalline regions and located mainly along the boundaries of blocks, causes high stresses in microvolumes, which leads to a decrease in the resistance of steel, brittle fracture, a decrease in tensile strength and plastic properties become. Therefore, molten steel (for example during welding) must be protected from exposure to the atmosphere.

Firmly on target

Quite unique steel construction solutions were used during the construction of stadiums for the Olympics in Sochi and the 2018 FIFA World Cup. The baton of innovative construction solutions for sports facilities promises to be taken up by the planned construction of two stadiums in Novosibirsk and Omsk for the World Junior Ice Hockey Championship (2023).

The demand for the production of metal structures at the facilities of domestic enterprises is also increasing and the government plans to launch a large-scale all-Russian renovation, Federation Council member Oleg Melnichenko said recently. Some relevant departments have already given positive opinions on such a bill with some comments. The essence of the new law is to solve the long-standing problem of accelerated resettlement of Russians from dilapidated and dilapidated housing.

In addition, the portfolio of orders for Russian enterprises will be formed by large-scale plans for the modernization of social and transport infrastructure.

In the future, steel construction technologies may be widely used in housing construction. Industry experts highly appreciate the prospects of this segment. However, so far, in terms of the dynamics of the use of metal structures in construction, the Russian Federation lags behind leading countries. If, for example, in the UK, USA or Sweden the share of multi-storey buildings on a steel frame is about 65 percent, then in the Russian Federation it is only 13. According to estimates by the Techart consulting group, the forecast volume of commissioning of social construction projects in 2019-2024 could be almost 40 million square meters. At the same time, consumption of metal structures in the social segment alone can quickly grow to 2.14 million tons with the development of new projects and appropriate measures to stimulate steel construction.

The rapid construction of “anti-Covid” hospitals on steel frames helped save thousands of lives

The speed of deployment and efficiency of such structures have already proven to be in great demand during the pandemic. For example, since the beginning of the year, the Chelyabinsk Metallurgical Plant alone has produced more than 4.5 thousand tons of rolled metal for the construction of 14 infectious “anti-coronavirus” hospitals throughout the country. Medical facilities include both prefabricated centers for the fight against infectious diseases and permanent buildings in the Moscow region, Voronezh, Nizhny Novgorod, Saratov, Ufa, Orenburg, Novosibirsk and other cities. In addition, more than 5 thousand tons of fittings were previously produced and supplied for the construction of the medical center in Kommunarka alone, which has become the main treatment facility for coronavirus patients in Moscow.

According to experts, in general the situation on the metal structures market is quite favorable. According to the head of the RSPM Committee on Metal Structures, Sergei Maslennikov, large factories have large portfolios of orders, production is fully loaded, and the execution of individual orders is even postponed until next year.

As for the coated steel market, according to the expert, there is still a noticeable rush of demand, which is supported by the demand of individuals for further processing products - corrugated sheets, metal tiles, etc. There is also an increased demand for sandwich panels, since now, at the end of the construction season, builders are trying to close the “thermal loop” of the buildings and structures being built.

The global steel market also has an impact on the domestic Russian one. Today, the foreign market is experiencing increasing dynamics for most items. Prices for steel billets are steadily increasing and have already reached pre-crisis levels. And the price level for long products on the world market today actually corresponds to the price level on the spot market within the country. This is due to the recovery of the Chinese economy, which serves as a driver of global demand in this segment. The weakening of the ruble also entails an inevitable increase in prices on the country’s domestic spot market, but the seasonality of long products and the lack of the necessary effective demand may deter rolled steel producers from such hasty steps in the near future, experts say.

The regulatory and legal framework of the industry is gradually being brought to a common denominator. As Tatyana Nazmeeva, project manager of the Engineering Center of the Association for the Development of Steel Construction, said, changes to the Code of Rules “Load-bearing and enclosing structures” regulating the use of metal structures will come into force in the near future. According to her, to date, all the proposed changes have undergone public discussions, and the final version has been prepared.

Steel construction technologies meet all the principles of efficiency and environmental friendliness

And another aspect of steel construction has recently become increasingly important. In our country, high-class environmentally friendly real estate is becoming increasingly in demand. Over time, this trend will intensify, allowing it to increasingly unlock the potential of metal structures in all segments of civil engineering. Since steel can be processed many times without losing quality, this approach saves significant amounts of resources and also reduces emissions of pollutants into the atmosphere.

As Dmitry Berezutsky, a representative of the Green Building Council, noted: “It is obvious that steel construction technologies meet all the principles of environmental friendliness, effective development of territories and the development of the most complex spaces.” It is obvious that the use of metal structures as the preferred construction material, taking into account the use of effective innovative solutions and the developments of advanced domestic and foreign experience, will be increasingly involved in the Russian construction market. The demand for standard solutions in the construction of social and other facilities, as well as the environmental friendliness and variability of this type of construction projects in individual housing construction - all these prospects create a steady demand for the products of domestic manufacturers of metal structures.

Heat treatment

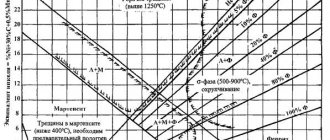

In addition to alloying, a significant increase in the strength, deformation and other properties of steel is achieved by heat treatment due to the fact that under the influence of temperature, as well as heating and cooling modes, the structure, grain size and solubility of the alloying elements of steel change.

The simplest type of heat treatment is normalization. It consists of reheating the rolled product to the temperature of austenite formation and subsequent cooling in air. After normalization, the steel structure becomes more ordered, internal stresses are relieved, which leads to an improvement in the strength and plastic properties of rolled steel and its impact toughness. Therefore, normalization, being the simplest type of thermal improvement of steel, is used quite often.

With the rapid cooling of steel heated to a temperature exceeding the phase transformation temperature, hardening is obtained. For hardening, it is necessary that the cooling rate be higher than the phase transformation rate.

The structures formed after hardening give the steel high strength. However, its ductility decreases, and its tendency to brittle fracture increases. To regulate the mechanical properties of hardened steel and the formation of the desired structure, it is tempered, i.e., heated to a temperature at which the desired structural transformation occurs, held at this temperature for the required time and then slowly cooled.

Aging is promoted by:

- mechanical effects and especially the development of plastic deformations (mechanical aging);

- temperature fluctuations leading to changes in the solubility and rate of diffusion of components and therefore to their release (physico-chemical aging, dispersion hardening). Low heating (up to 150 – 200 C) can dramatically enhance the aging process.

With plastic deformation and subsequent slight heating, the intensity of aging increases sharply (artificial aging). Since aging reduces resistance to dynamic impacts and brittle fracture, it is considered a negative phenomenon. Steels that are contaminated and saturated with gases, such as boiling steel, are most susceptible to aging.

Undeoxidized steels boil when poured into molds due to the release of gases; such steel is called boiling steel

and turns out to be more clogged with gases and less homogeneous.

Boiling steels, having fairly good yield strength and tensile strength, have poor resistance to brittle fracture and aging.

To improve the quality of low-carbon steel, it is deoxidized by adding silicon from 0.12 to 0.3% or aluminum up to 0.1%; silicon (or aluminum), combining with dissolved oxygen, reduces its harmful effects. When combined with oxygen, deoxidizers form silicates and aluminates in a finely dispersed phase, which increase the number of crystallization sites and contribute to the formation of a fine-grained steel structure, which leads to an increase in its quality and mechanical properties. Deoxidized steels do not boil when poured into molds, which is why they are called calm steels.

Calm steel is more homogeneous, welds better, and better resists dynamic influences and brittle fracture. Mild steels are used in the manufacture of critical structures exposed to static and dynamic influences.

Semi-calm

The quality of steel is intermediate between boiling and calm. It is deoxidized by a smaller amount of silicon - in the amount of 0.05 - 0.15% (rarely by aluminum).

Classification of construction steels. Selection of steels for building structures

According to strength properties

steels are conventionally divided into three groups: normal strength

(σу

< 29 kN/cm2);

increased strength (29 kN/cm2 ≤ y

< 40 kN/cm2);

high strength (σу

≥40 kN/cm2).

Increasing the strength of steel is achieved by alloying and heat treatment.

By chemical composition

steels are divided into carbon and alloy steels.

carbon steels

consist of iron and carbon with some addition of silicon (or aluminum) and manganese. Other additives (copper, chromium, etc.) are not specifically introduced and can get into the steel from the ore.

The main alloying additives are silicon (C), manganese (G), copper (D), chromium (X), nickel (N), vanadium (F), molybdenum M), aluminum (U), nitrogen (A). The composition of alloying additives is indicated in the name of the steel: the first two digits in the steel grade correspond to the carbon content in hundredths of a percent, then the additives and their content are listed, rounded to whole percents; the number I is usually not included. For example: 09G2S. 14G2AF.

Depending on the type of delivery

Steels are divided into

hot-rolled

and

heat-treated

(normalized or thermally improved). In the hot-rolled state, steel does not always have an optimal set of properties. During normalization, the structure of the steel is refined, its homogeneity increases, and viscosity increases, but there is no significant increase in strength. Thermal improvement (quenching in water and high-temperature tempering) makes it possible to obtain high-strength steels that are highly resistant to brittle fracture. A significant reduction in the costs of thermal processing of steel can be obtained if hardening is carried out directly from rolling heating.

According to the degree of deoxidation

steels can be

boiling, semi-calm,

calm.

Unoxidized steel boils during casting due to the release of gases: such steel is called boiling and turns out to be more clogged with gases and less homogeneous.

Mechanical properties vary slightly along the length of the ingot due to the uneven distribution of chemical elements. This especially applies to

the head part, which turns out to be the most loose (due to shrinkage and the greatest saturation with gases), and the greatest segregation of harmful impurities and carbon occurs in it. Therefore, the defective part, which is approximately 5% of the ingot mass, is cut off from the ingot. Boiling steels, having fairly good yield strength and tensile strength, are less resistant to brittle fracture and aging.

Normal strength steel

(y < 29 kN/cm2). This group includes low-carbon steels (C235...C285) of varying degrees of deoxidation, supplied in a hot-rolled state.

Possessing relatively low strength, these steels are very ductile: the length of the yield plateau is 2.5% or more, the ratio σу/σу

= 0.6...0.7. Good weldability is ensured by low carbon content (no more than 0.22%) and silicon. Corrosion resistance is average, so structures made of steel of normal strength should be protected with paint and other coatings. However, due to its low cost and good technological properties, ordinary strength steel is very widely used for building metal structures. The consumption of these steels accounts for over 50% of the total. The disadvantage of low-carbon steels is their tendency to brittle fracture at low temperatures (especially for boiling C235 steel), so their use in structures operating at low subzero temperatures is limited.

High strength steels

(29 kN/cm2 <

σу

< 40 kN/cm2). High-strength steel (C345...C390) is obtained by introducing alloying additives during smelting. Mainly manganese and silicon, less often nickel and chromium, or heat-strengthening low-carbon steel (C345T). In this case, the plasticity of steel is slightly reduced and the length of the yield plateau is reduced to 1...1.5%

High-strength steels are slightly less weldable (especially steels with a high silicon content) and sometimes require the use of special technological measures to prevent the formation of hot cracks.

In terms of corrosion resistance, most steels in this group are close to low-carbon steels. Steels with a higher copper content (S345D, S375D, S390D) have higher corrosion resistance.

The fine-grained structure of low-alloy steels can significantly increase their resistance to brittle fracture.

High strength steels (σу

≥ 40 kN/cm2). Rolled high-strength steel (C440...C590) is produced, as a rule, by alloying and heat treatment.

High-strength steels may not have a yield plateau (at y>50 kN/cm2), and their ductility (relative elongation) is reduced to 14% or lower. The ratio σy/σu

increases to 0.8…0.9. which does not allow plastic deformations to be taken into account when calculating structures made from these steels

Selection of steel for steel structures.

The choice of steel is made on the basis of variant design and technical and economic analysis, taking into account the requirements of the standards. In order to simplify the ordering of metal, when choosing steel, one should strive for greater unification of designs,

reducing the number of steels and profiles. The choice of steel depends on the following factors affecting the performance of the material:

— temperature of the environment in which the structure is installed and operated; this factor takes into account the increased risk of brittle fracture at low temperatures;

— the nature of the loading, which determines the characteristics of the material and structures under dynamic, vibration and variable loads;

— type of stress state (uniaxial compression or tension, plane or volumetric stress state) and the level of stresses arising (heavily or lightly loaded elements);

— the method of connecting elements, which determines the level of intrinsic stresses, the degree of stress concentration and the properties of the material in the connection zone;

— thickness of rolled products used in the elements. This factor takes into account the change in steel properties with increasing thickness.

When choosing steel, it is necessary to take into account the group of structures.

To the first group

include welded structures operating in particularly difficult conditions or directly exposed to dynamic, vibration or moving loads (for example, crane beams, work platform beams or elements of overpasses that directly bear the load from rolling stock, truss gussets, etc.). The stressed state of such structures is characterized by a high level and high frequency of loading.

Structures of the first group operate in the most difficult conditions, which contribute to the possibility of their brittle or fatigue failure, therefore

The highest demands are placed on the properties of steels for these structures.

To the second group

include welded structures operating under static load under the influence of uniaxial and unambiguous biaxial tensile stresses (for example, trusses, frame crossbars, floor beams and other tensile, tension-bending and bending elements), as well as structures of the second group in the absence of welded joints.

What is common to structures in this group is the increased risk of brittle fracture associated with the presence of a tensile stress field. The probability of fatigue failure here is less than for structures of the first group.

To the third group

include welded structures operating under the predominant influence of compressive stresses (for example, columns, racks, supports for equipment and other compressed and compressed-bending elements), as well as structures of the second group in the absence of welded joints.

To the fourth group

auxiliary structures and elements are included (braces, half-timbered elements, stairs, fences, etc.), as well as structures of the third group in the absence of welded joints.

3.9 Select the cross-section of a single-span rolled steel deck beam. Design linear load on beam q=33.0 kN/m, span 7 m. С245, gс

=1

Solution:

1. Preliminary selection of beams is carried out according to the formula:

| M = | ql2 | = | 33.0 × 7 | = 202.1 kN × m |

| 202,1×100 | ||||

| W | = | Mmax | = | = 752cm3; |

| red | c1 | × Ry × gc | 1,12 × 24 ×1 | |

| 2. | We accept | I-beam | 40B1. Wx=803.6 cm3; Ix=15750cm4; | Sx=456cm; |

m=48.1kg/m; tw=7mm.

3. We carry out a check taking into account the self-weight of the beam according to two limit states.

Low-carbon steels of ordinary quality

From the group of low-carbon steels of ordinary quality produced by the metallurgical industry in accordance with GOST 380 - 88, steel grade St3 is widely used in construction.

Steel grade St3 is produced boiling (ST3kp), semi-quiet (St3ps) and calm (St3sp).

Depending on the purpose, steel is supplied in the following three groups, which indicate the properties by which steel is standardized:

A - by mechanical properties;

B - by chemical composition;

B - according to mechanical properties and chemical composition

Since it is necessary to ensure strength and weldability for load-bearing building structures, as well as adequate resistance to brittle fracture and dynamic impacts, steel for these structures is ordered according to group B, i.e., with a guarantee of mechanical properties and chemical composition.

Steel grade St3 contains 0.14 – 0.22% carbon.

According to GOST 380 - 88, steel marking is done as follows: first put the corresponding letter designation of the steel group, then the grade, then the deoxidation method and finally the category; for example, steel of group B (supplied according to mechanical properties and chemical composition) grade St3 is semi-quiet, category 5 is designated VSt3ps5.

The category indicates which mechanical properties of steel are preserved at temperatures of -20 and +20 degrees Celsius. Ordinary quality steels are divided into 5 categories. The table of standardized indicators by category is given in GOST 535-88.

St3sp5 decoding what 5 means

Each category of steel is characterized by its specific chemical composition. It largely determines the scope of application of the workpieces being created and the difficulties that arise during heat treatment.

The chemical composition of St3 steel makes it one of the most common materials that can be found on the market. It is difficult to imagine modern construction work without this metal.

The key points regarding the chemical composition are the following:

- As previously noted, the main chemical elements are iron and carbon. The first element has a concentration of 97%, carbon is only 0.14-0.22%. It is carbon that determines the hardness index and some other physical and chemical properties of the structure.

- The structure includes a relatively small amount of alloying elements. The main elements are chromium and nickel, the concentration of which is 0.3%. Copper is included in the composition at the same concentration.

With a large number of varieties of steel, the concentration of harmful impurities, which are phosphorus and sulfur, is strictly controlled in the one under consideration. In addition, the composition contains nitrogen in high concentrations, which accounts for about 0.1 mass.

Structural carbon semi-quiet steel ST3ps: explanation, characteristics

Among the wide range of carbon-containing steels intended for the construction of supporting structures, the most popular is an alloy of ordinary quality - St3ps steel. The fact is that this specimen does not have a description of the welding regulations, is practically not susceptible to corrosion and has tempering hardness. It is produced by passing the material through open-hearth furnaces.

Steel St3ps

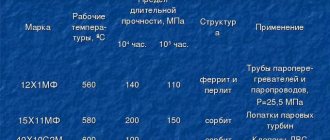

Increased and high strength steels

For many types of structures, high-strength and high-strength steels are used.

Increased and high strength steels are supplied in accordance with GOST 19281 - 89 and GOST 19282 - 89. Depending on the standardized properties (chemical composition, tensile strength, yield strength, impact strength at different temperatures and after mechanical aging), according to GOST these steels are divided into 15 categories with a guarantee of mechanical properties at temperatures from -70 to +20 degrees Celsius.

The use of high-strength steel leads to metal savings of up to 20–25%, and high-strength steel – 25–50% compared to conventional carbon steel.

Normal and high strength steels

Thus, an analysis of the mechanical properties of general purpose steels shows that they are not inferior in strength (guaranteed yield strength 235 MPa) to shipbuilding steels of grades B, D and E, but worse in cold resistance. Therefore, steel grades VSt3kp, VSt3ps, VSt3sp and VSt3Gps are recommended to be used only for welded structures that operate at moderate temperatures and loads. Rolled products from these steels are qualified by the standard as products of the first quality category, while rolled products from steels A, B, D and E are classified as the highest quality category. Increased resistance to brittle fracture of steels V, D and E was achieved by changing their chemical composition by increasing the manganese content to 1.5% and by significantly improving metallurgical production technology. In agreement with the USSR Register, aluminum used for steel deoxidation can be partially replaced with titanium or niobium, which grinds grain.

High-strength shipbuilding steels are also divided into categories - A, D and E. Steels with a guaranteed yield strength of 315 MPa (32 kgf/mm2) A32, D32 and E32 must provide an impact force of at least 31 J;

steel A36, D36 and E36 (with guaranteed σТ≥355 MPa) - not lower than 34 J and steel of the third strength level (σТ≥390 MPa) - not lower than 36 J. Impact work values for category A steel are determined at a test temperature of 0 °C , for steel category D at -20 °C and for steel category E at -40 °C. Such high values of mechanical properties are achieved thanks to the rational choice of steel composition (Table 5.5), improvement of the technology of their smelting, deoxidation, modification, casting and rolling. A particularly noticeable increase in the complex of mechanical properties of steels was achieved by microalloying with niobium. Such steels after heat treatment—normalization or hardening with high tempering—have a uniform fine-grained structure and, therefore, high resistance to brittle fracture. In a number of cases, in agreement with the USSR Register, heat treatment can be replaced by controlled rolling. Table 5.5. Chemical composition of low-alloy shipbuilding steel of increased strength (GOST 5521—

| steel grade | Element content,% by weight | |||||||||

| C, no more | Mn | Si | Cr | Ni | Cu | Mo | Al | Nb | V | |

| A32 | No more than 0.06 | — | — | |||||||

| D32 | No more than 0.06 | — | — | |||||||

| E32 | 0,18 | 0,9-1,6 | 0,15-0,50 | No more than 0.20 | No more than 0.40 | No more than 0.35 | No more than 0.08 | 0,015-0,06 | — | — |

| A36 | No more than 0.06 | 0,02-0,05 | 0,05-0,1 | |||||||

| D36 | 0,015-0,06 | 0,02-0,05 | 0,05-0,1 | |||||||

| E36 | 0,015-0,06 | 0,02-0,05 | 0,05-0,1 | |||||||

| A40 | No more than 0.06 | — | — | |||||||

| D40 | 0,12 | 0,5-0,8 | 0,8-1,1 | 0,6-0,9 | 0,5-0,8 | 0,4-0,6 | — | 0,015-0,06 | — | — |

| E40 | 0,015-0,06 | — | — | |||||||

Note. Steels of these grades contain P no more than 0.0355% by weight, S - no more than 0.035% by weight. A dash in the table means that there are no requirements of the standard.

The mechanical properties of rolled products of the highest quality category from high-strength steels are given in Table.

5.6 and 5.7. With increasing sheet thickness, the guaranteed level of work of destruction decreases somewhat. The USSR Register regulates the areas of expedient use of high-strength steels along the length and height of the ship's hull, depending on the stresses operating in the hull. Table 5.6. Mechanical properties of rolled products of the highest quality category under tension

| steel grade | Tensile strength σВ MPa (kgf/mm2) | Yield strength σт MPa (kgf/mm2), (not less) | Relative elongation, δ, %, not less |

| A32, D32, E32 | 470—590 (48—60) | 315 (32) | 22 |

| A36, D36, E36 | 490—620 (50—63) | 355 (36) | 21 |

| A40, D40, E40 | 530—690 (54—70) | 390 (40) | 19 |

Table 5.7. Minimum impact work KV, J (kgf m), when testing rolled products of the highest quality category (not less)

| steel grade | Test temperature, °C | Rolled thickness, mm | ||

| 5—7,5 | 7,5—9,5 | 10 or more | ||

| A32 | 0 | 31 (3,2) | 26 (2,7) | 22 (2,2) |

| D32 | —20 | |||

| E32 | —40 | |||

| A36 | 0 | 34 (3,5) | 28 (2,9) | 24 (2,4) |

| D36 | —20 | |||

| E36 | —40 | |||

| A40 | 0 | 36 (3,7) | 30 (3,1) | 25 (2,5) |

| D40 | —20 | |||

| E40 | —40 | |||

The design temperature of structures located above the ballast waterline is assumed to be equal to the minimum ambient temperature. The temperature of structures constantly in contact with sea water is equal to 0 °C.

In domestic shipbuilding practice, low-alloy steel grades 09G2, 09G2S and 10HSND have been successfully used for many years (Table 5.8).

These steels are in many ways analogues of the high-strength shipbuilding steels discussed above. Thus, steels 09G2 and 09G2S have a guaranteed yield strength of 290-300 MPa, and steel 10KhSND - 390 MPa (Table 5.9). Ship hull steels with a yield strength of 355 MPa were not previously produced by industry. This created certain difficulties when choosing steel for a specific purpose. Table 5.8. Chemical composition of low-alloy steels (GOST 19282-73)

| steel grade | Element content,% by weight | |||||

| C | Si | Mn | Cr | Ni | Cu | |

| 09G2 | ≤0,12 | 0,17—0,37 | 1,4—1,8 | ≤0,30 | ≤0,30 | ≤0,30 |

| 09G2S | ≤0,12 | 0,5—0,8 | 1,3—1,7 | ≤0,30 | ≤0,30 | ≤0,30 |

| 10HSND | ≤0,12 | 0,8—1,1 | 0,5—0,8 | 0,6—0,9 | 0,5—0,8 | 0,4—0,6 |

Table 5.9. Mechanical properties of rolled products of the first quality category

| steel grade | Rolled thickness, mm | Tensile strength σВ, MPa (kgf/mm2) | Yield strength σт MPa (kgf/mm2) | Relative elongation, δ, % | Impact strength KCU—40, J2 (kgf m cm2) |

| no less | |||||

| 09G2 | 4 | At least 440 (45) | 300 (31) | 21 | — |

| 5—9,5 | 300 (31) | 34 (3,5) | |||

| 10—20 | 300 (31) | 29 (3) | |||

| 21—30 | 290 (30) | 49 (5) | |||

| 09G2S | 32—60 | At least 450 (46) | 290 (30) | 21 | 49 (5) |

| 10HSND | 4 | 530—690 (54—70) | 390 (40) | 19 | — |

| 5—9,5 | 39 (4) | ||||

| 10—15 | 39 (4) | ||||

| 16—32 | 49 (5) | ||||

GOST 27772-88

Since 1988, GOST for rolled steel for building steel structures was introduced. In this GOST, steel grades of ordinary quality, increased and high strength are given new names, for example S245, S390, S590K. The letter C means construction steel, the numbers conventionally indicate the yield strength of rolled products (the physical properties of steel), the letter K is a variant of the chemical composition. According to this GOST, steels are divided into 4 categories with a guarantee of mechanical properties at temperatures of -40, -70 degrees and after mechanical aging.

This GOST does not replace those mentioned above, but exists in parallel. So, according to different GOST standards, the same grade of steel can be designated by two names, for example, C235 and VSt3kp2 are the same steel. The conversion table for steel names is given in Appendix No. 1 to GOST 27772-88.

Products – Tekhmashholding – group of companies, official website

- In the production of metal structures, C245 steel is a low-carbon grade used for building structures.

Decoding steel C245

In the designation of steel, the letter C means “construction”, the numbers 245 are the yield strength (T) in megapascals (MPa). In more conventional units σT = 24.5 kg/sq. mm.

Among other parameters characterizing the mechanical properties of steel, we note the tensile strength = 370 MPa (37 kg/sq. mm).