Categories of OKS

Search for GOSTs by categories of the All-Russian Classifier of Standards

- IT, electronics and household appliances

- Extraction and processing

- Manufacturing and construction

- Industry

- Machinery and equipment

- General provisions 01.

- Services, management and sociology 03.

- Mathematics, natural sciences07.

- Healthcare11.

- Environmental protection13.

- Metrology and measurements. Physical phenomena. 17.

- Tests. 19.

- Imaging technology. 37.

- Precise mechanics. Jewelry making. 39.

Classifier OKPD 2

OKPD 2 code search online, all classifier categories

Document status: no longer valid in the Russian Federation, entered into force on 01/01/2003 Title in English: Imperfections in metallic fusion welds. Classification, designation and definitions Date of update of information on the standard: 09/17/2019, at 09:59 (more than a year ago) Type of standard: Fundamental standards Start date of GOST: 2003-01-01 Validity period limited: 01/01/2014 Date of the last edition of the document : 2001-08-17

Document codes GOST 30242-97:

OKP code: 007200 KGS code: B05 OKSTU code: 0072 Number of pages: 11 Purpose of GOST 30242-97: This standard establishes the classification, definitions and symbols of defects in welds, heat-affected zones and base metal during fusion welding of metals The document was developed by the organization: State Committee of Ukraine for Standardization, Metrology and Certification The document was accepted by the body: Interstate Council for Standardization of Metrology and Certification, Protocol No. 11 Key words of the document: defects, violation of the shape of the seam, lack of penetration, lack of fusion, pores, solid inclusions, cracks

Regulatory references from the text of GOST 30242-97:

ISO: ISO 6520:1982

Amendments and changes to GOST 30242-97:

- Name, type:Registration date:beginning of validity:Link:

- Change to GOST 30242-97. Lost force in the Russian Federation

Type of change: Lost force in the Russian Federation Change number: Registration number: 1012-st New meaning: Lost force in the Russian Federation, from 01/01/2014 use GOST R ISO 6520-1-20122012-11-222014-01-01

- Page 1

- page 2

- page 3

- page 4

- page 5

- page 6

- page 7

- page 8

- page 9

- page 10

- page 11

Categories of OKS

Search for GOSTs by categories of the All-Russian Classifier of Standards

- IT, electronics and household appliances

- Extraction and processing

- Manufacturing and construction

- Industry

- Machinery and equipment

- General provisions 01.

- Services, management and sociology 03.

- Mathematics, natural sciences07.

- Healthcare11.

- Environmental protection13.

- Metrology and measurements. Physical phenomena. 17.

- Tests. 19.

- Imaging technology. 37.

- Precise mechanics. Jewelry making. 39.

Classifier OKPD 2

OKPD 2 code search online, all classifier categories

Document status: no longer in force in the Russian Federation Purpose of GOST 30242-97: This standard establishes the classification, definitions and symbols of defects in welds, heat-affected zones and base metal during fusion welding of metals Amendments and changes to GOST 30242-97 number of amendments to the standard -

1 , see amendments

"Z

NATIONAL STANDARD OF THE RUSSIAN FEDERATION

Welded steel pipes DEFECTS IN WELDED JOINTS

Terms and Definitions

Steel welded pipes. Defects of welded joints. Terms and definitions

Introduction date: 2021—06—01

1 area of use

This standard establishes terms and definitions in the field of defects in welded joints of steel pipes for various purposes.

This standard should be used when inspecting welded joints made during pipe production.

This standard does not apply to circumferential welded joints, as well as welded joints made during the installation of pipelines or pipe structures.

2 Normative references

This standard uses normative references to the following standards:

GOST R S8904/ISO/TR 25901-1:2016 Welding and related processes. Dictionary. Part 1. General terms

GOST R 58905/ISO/TR 25901*2:2016 Welding and related processes. Dictionary. Part 2. Welding processes

GOST R ISO 6520*1 Welding and related processes. Classification of geometry and continuity defects in metallic materials. Part 1: Fusion welding

GOST R ISO 6520-2 Welding and related processes. Classification of geometry and continuity defects in metallic materials. Part 2. Pressure welding

Note - When using this standard, it is advisable to check the validity of the reference standards in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or using the annual information index "National Standards", which was published as of January 1 of the current year, and on issues of the monthly information index “National Standards” for the current year. If an undated reference standard is replaced, it is recommended that the current version of that standard be used, taking into account any changes made to that version. If a dated reference standard is replaced, it is recommended to use the version of that standard with the year of approval (adoption) indicated above. If, after the approval of this standard, a change is made to the referenced standard to which a dated reference is made that affects the provision referred to, it is recommended that that provision be applied without regard to that change. If the reference standard is canceled without replacement, then the provision. It is recommended to accept it in the part that does not affect this link.

Official publication

Available versions of GOST 30242-97 for downloading:

Date added to file version:Downloads:Size:Download link:12/12/2011 02:57 833 0.32 Mb12/12/2011 03:03 917 0.48 Mb

Content:

Welding is one of the most popular metalworking processes, allowing the connection of steel parts in a variety of designs. Due to the chemical heterogeneity of metal surfaces, the crystallization of metals during the creation of a weld, the interaction of the liquid metal forming in the weld pool with solid particles of the part, and for a number of other reasons, defects often occur during the welding process. Their presence not only reduces the quality of the finished structure, but also makes its further operation life-threatening.

If, during quality control, defects are found that affect the strength and reliability of the product, then correction of welding defects in such cases is a mandatory measure.

What defects occur during welding work?

Depending on the causes of occurrence, size, shape and location on the seam, different types of defects are distinguished. To understand which methods of eliminating defects in welded joints will be the best, you first need to determine their type and why they occurred.

According to the classification according to GOST 30242-97, the following groups of defects are distinguished:

- cracks in welds, which can be transverse, longitudinal, radial and others;

- violation of the shape of the seam due to the formation of sagging, undercuts, burns, bulges, displacements and other flaws;

- the presence of pores, cavities, fistulas, and craters at the welding site. They can accumulate in one area or be distributed evenly throughout the entire seam;

- unwelded areas and unfused edges;

- the presence of solid (oxide, metal, slag) inclusions and inclusions in the weld.

Based on their location, defects are divided into internal, external and through. A specific digital designation by the classifier is set for all defects in welded joints, and methods for eliminating them are selected in accordance with the numbers marked in the places where they are present.

Group 4. Lack of fusion and lack of penetration

401 Non-fusionen lack of fusion (incomplete fusion)

fr manque de fusion (collage)

Note - In some countries the terms “colage noir” and “colage blanc” are used depending on whether oxide inclusions are present or absent in places of non-fusion

Lack of connection between the weld metal and the base metal or between individual weld beads. There are non-fusions: 4011 on the side; 4012 between rollers; 4013 at the root of the weld 402 D Lack of penetration (incomplete penetration)en lack of penetration

(incomplete penetration)

fr manque de penetration

Failure of fusion of the base metal along the entire length of the weld or in a section, resulting from the inability of the molten metal to penetrate the root of the jointDefect detection methods

After welding, the resulting seam must be checked for the presence or absence of defects. This is the only way to understand whether welding defects need to be eliminated or not.

Various methods are used to identify defective areas:

- visual inspection . The result will be more accurate if the inspection is carried out using devices with a magnifying effect;

- magnetic method , in which the defect is determined by the degree of wave distortion;

- flaw detection . The presence of deficiencies is indicated by a change in the color of the welded joint after contact of the surfaces with a special identifying composition, for example, kerosene;

- ultrasound examination . Carried out using a flaw detector, defects are determined by sound waves by measuring their reflection;

- radiation method . Welded joints are X-rayed, as a result, all details of the defect are visible in the resulting image.

The quality of the joints obtained during the welding process is indicated by markings. Each professional welder has his own mark, which he puts on the welding site.

- GOST 9467-75

Elimination of welding defects

If during control tests a defect is found that is unacceptable for the safe operation of structures, then the inevitable process is the elimination of defects in welded joints.

To eliminate identified deficiencies, the following methods for eliminating weld defects are used:

- lack of fusion, foreign inclusions, small internal cracks are subject to mechanical cutting or complete cleaning, after which re-welding is carried out;

- elimination of large and deep cracks is carried out by welding after preliminary mechanical cleaning or drilling;

- welding in thin layers or surfacing is used to eliminate undercuts and incomplete seams;

- the deposits are destroyed mechanically using an abrasive tool;

- Heat treatment eliminates overheating of the metal.

These are the main methods for correcting defects in welded joints, which are used to eliminate defects. After the design is corrected, control tests are repeated and only if there are no defects, their further operation is allowed.

Features of defect correction

If structures made using welding do not meet technical specifications due to defects, then it is important not only to choose the right methods for eliminating defects in welds, but also to accurately carry out all the necessary actions.

In steel products, defective welds should be corrected by plasma arc cutting or gouging, after which these areas are treated with abrasive wheels. By surfacing a thread weld, undercuts are eliminated, and surfacing is performed along the entire length of the defect. When correcting irregularities and sagging mechanically, you need to monitor the overall cross-section and not allow it to be underestimated.

Before repairing fistulas in a weld, it is necessary to first cut it out, thoroughly clean the resulting cavity, and then re-weld the product.

In order to efficiently eliminate weld defects and carry out effective methods for eliminating them, you should follow a few simple rules:

- the length of the area to be corrected must exceed the length of the defect;

- the width of the cutting must be such that the maximum size of the new seam does not exceed more than twice its width until the defect is eliminated;

- there should be no burrs or sharp depressions on the surfaces of the samples, the outlines should be smooth and without sharp protrusions;

- When performing welding in areas adjacent to the defect, it is necessary to ensure overlap of the base metal.

In structures made of titanium, aluminum and alloys of these metals, the elimination of defects is permitted only by mechanical methods: sharp or abrasive grinding. In some cases, cutting down is allowed.

If, during repeated inspection, defective areas are again discovered, then such structures must again be corrected. On the same section of the weld, the number of corrections should not exceed three, otherwise the metal structure is made from scratch.

- What is GOST 16037-80

Defects in welded joints

In welding production, it is customary to distinguish the following types of defects (Figure 3.15):

- Defects in the preparation and assembly of products for welding.

- Seam shape defects.

- External and internal defects.

Preparation and assembly defects

Typical types are incorrect bevel angle of edges in seams with V-, X- and U-shaped grooves, too large or small blunting along the length of the joined edges; inconsistency of the gap between the edges; mismatch of joining planes leading to displacement of the edges, too large a gap between the edges, delamination and contamination of the edges.

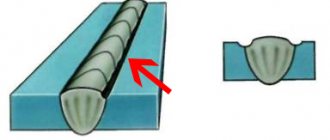

The shape and dimensions of welds are usually specified by technical specifications, indicated on drawings and regulated by standards: structural elements b - weld width, reinforcement height C and penetration depth h.

Main defects

– uneven width and height of reinforcement, local mounds and saddles. These types of defects are most common in manual electric arc welding.

Such defects reduce the strength of the connection and indirectly indicate the possibility of the formation of internal defects.

Defects in welded joints are characterized as both unacceptable and acceptable. Unacceptable defects are digested again.

Finished welded joints are first of all subjected to external inspection to identify external defects (cracks, weakening of the seam, sagging, undercuts, burns, local weariness, porosity, etc.).

Cracks:

hot (technological) and cold. Hot - in rigidly fixed structures of alloy steels (especially with insufficient quality - Smax). Cold – quenching theory (Cmax) Seq = 6.25 and hydrogen.

Surges

are formed as a result of the flow of molten metal onto unmolten metal.

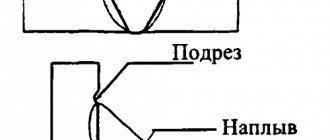

Undercuts

are formed along the edges of the weld in the base metal (depth from tenths to several mm). Burn-throughs are defects in the form of a through hole in the weld (the first root layer or thin metal, or flow through a large gap).

The presence of hidden internal defects in welded joints is monitored by various physical methods: X-ray scanning, scanning with rays of radioactive isotopes (cobalt - 60, cesium - 137), magnetographic method, magnetic powder method and ultrasonic flaw detection, leak detection testing.

Each of these methods has its own specific features that determine its sensitivity and scope of application.

Figure 3.15 – Types of weld defects and causes of their occurrence

Testing products for tightness (limiting the penetration of liquid or gas), or leak detection testing, is carried out using easily penetrating media (liquids or gases), which are clearly distinguishable visually or using instruments.

Internal defects include pores, slag inclusions, lack of penetration, lack of fusion and cracks. Pores are formed due to contamination, moisture in the flux or electrode coating, or insufficient protection in a protective gas environment. Lack of penetration due to poor cleaning of edges from scale, rust, slag, arc wandering due to magnetic blast; incorrect choice of welding mode (current and arc voltage, welding speed), etc.

In addition to quality control, external inspection and the use of various physical methods check the compliance of the mechanical properties and chemical composition of welded joints with the requirements of technical specifications and technological instructions for welding on witness samples.

Quality control of raw materials, technology and qualifications of welders

To ensure high quality welded joints, control of source materials (base metal, electrodes, welding wire, fluxes, shielding gases, etc.) is necessary. The quality of source materials is established on the basis of certificate data, for which compliance with the requirements of a given technological process for welding products is determined. In the presence of external defects, as well as in the absence of certificates, starting materials are allowed only after chemical analysis, mechanical tests and weldability tests.

https://www.youtube.com/watch?v=ZbnEIr5ITFc

When inspecting the base metal, special attention is paid to the areas to be welded - they must be cleaned of dirt, oil, paint, and rust.

The rolled products are checked for the presence of delamination, scale, uniformity of sheet thickness, etc.

Electrodes and welding wire are checked by performing test welding to establish the quality of materials in terms of the nature of melting, ease of slag separation and quality of weld formation. They must meet the requirements of current GOSTs.

Weldability is the property of a metal to form, with the established welding technology, a connection that meets the requirements determined by the design and operating conditions of the product. Weldability is usually controlled in two cases: when selecting materials and developing welding technology, for example, at the project stage or during technological preparation of production. The second check is related to possible deviations of the properties of the base metal, wire, batch of electrodes and fluxes from the certified values.

Control during the welding process is of great importance for quality assurance. This includes the control methods noted above, including monitoring the serviceability of welding equipment and welding fixtures and compliance with established welding modes (current, voltage and welding speed). Such control is carried out by technologists, foremen and other engineering and technical workers responsible for the work of a given site, workshop, or enterprise.

Careful systematic control of the preparation of products for welding and the welding process will not be effective without checking the level of preparedness of welders. For example, when welding pipes during installation, more than 70% of defects occur due to the fault of the welders.

To check the qualifications of welders, the enterprise administration organizes a qualification commission with the participation of an inspector from Gosgortekhnadzor. Tests must be carried out periodically. At the same time, tests are carried out on the theory and practice of welding work, including welding of samples of the corresponding product. Samples are welded under the same conditions and spatial positions as the real product (for example, pipes - rotary and non-rotary joints). After external inspection, the welded samples are checked using the provided non-destructive testing methods and are also subjected to mechanical tests.

The number of samples for testing is regulated by the “Rules for Certification of Welders”.

Soldering materials > Theory according to TCM >

Source: https://dprm.ru/tkm/defekty-svarnyh-soedinenij

Interesting video

Back forward

Defects in joints during fusion welding of metals. Classification, designation and definitions

On this page you can find information about the standard, and also download GOST 30242-97 for free .

| Information about GOST 30242-97 | |

| Category OKS | OKS - All-Russian Classifier of Standards/Mechanical Engineering/Welding, hard and soft soldering/Welding seams and welding |

| Designation | GOST 30242-97 |

| Status | active |

| Name Russian | Defects in joints during fusion welding of metals. Classification, designation and definitions |

| English name | Imperfections in metallic fusion welds. Classification, designation and definitions |

| Text update date | 19.01.2010 |

| Description update date | 19.01.2010 |

| Effective date | 01.01.2003 |

| Publication date | 17.08.2001 |

| Last modified date | 23.06.2009 |

| Area and conditions of application | This standard establishes the classification, definitions and symbols of defects in welds, heat-affected zones and base metal in fusion welding of metals |

Download GOST 30242-97 Direct link to this page:

https://metall4all.ru/gost/gost-30242-97/

Other standards:

GOST 30430-96, GOST 30482-97, GOST 30756-2001, GOST 5264-80, GOST 5.1215-72, GOST 5.1929-73, GOST 5.917-71, GOST 7871-75, GOST 8713 -79,V GOST 9087-81 Search by name:

V

General principles for classifying defects

Weld defects are divided into internal and external. Internal defects include unfavorable deviations from microhardness and structure that are identified in the weld. External defects include those that are detected by visual inspection. In practice, major weld defects are examined and evaluated in comparison with perfectly executed welds on workpieces made of the same materials.

An important principle of classification is the characteristic features of defects, which can relate either to the quality of the seam, or to its unacceptable shape or size.

The first group of defects includes:

- Existing gas inclusions (bubbles);

- Inclusions of slag, flux or metal particles;

- Seam discontinuities.

The second group includes:

- What is the short number 3242, how to get money back for SMS or subscription

- Distortion of the root of the seam (undercut);

- Cracks of various spatial orientations;

- Other surface defects, for example, burn-through grooves, sagging, uneven surface of the seam, etc.;

- Inadmissible displacement of the axes of the workpieces being welded.

GOST 30242-97 establishes that these defects are often the result of non-compliance with technological welding conditions and subsequent thermal/mechanical treatment of the finished welded joint. At the same time, defects that may be caused by the low-technological nature of the welded structure must be prevented even at the stage of pilot testing of such a structure.

Drawings and photographs of specific defects are usually provided in the texts of the relevant regulatory documents.

Ik

512

513

Uneven seam width

en irregular width fr largeur irreguliere

Deviation of width from the set value along the weld seam

514

Uneven surface en irregular surface fr surface irreguliere

Rough unevenness

shape of the seam reinforcement surface along the length

515

Concavity of the root of the seam en root concavity fr retassure a la racine

Shallow groove on the root side of a single-sided weld caused by shrinkage (see also 5013)

Description of types of weld defects

Given in accordance with the accepted designations of the International Welding Institute and the requirements of ISO 6520-82.

Cracks

External and internal cracks can occur anywhere: in the weld metal, in adjacent areas, or in any other element exposed to the high temperature of the weld. Cracks are of a fatigue nature and contribute to the destruction of the welded structure during its operation.

These defects are divided into four groups:

- Hot cracks. Occur during the welding process or shortly after the formation of the seam;

- Cold cracks that may appear several hours or days after welding;

- Crater-shaped cracks. They are characteristic of the end points of the fusion zone, when the welder moves to a new area and is about to use the remaining part of the electrode. They are dangerous because they can cause an avalanche-like appearance of new cracks;

- Internal cracks, characterized by a sharp change in the macrostructure of the solidified melt zone. They pose a particular danger to structures that will be operated under dynamic and shock loads.

It is necessary to distinguish between macro- and microcracks: the latter are detected only when examining the product under a microscope, the magnification of which should be 50x or more. Cracks can be located along the axis or in the perpendicular direction. Cold and crater cracks often appear in the form of diverging rays.

Porosity

The presence of pores indicates voids present in the weld metal. They weaken the mechanical strength of the connection. Porosity can be single or group, when several adjacent voids are observed, oriented along the axis of movement of the electrode.

The following types of pores are found inside the weld:

- Superficial, caused by traces of gas bubbles; such pores have a plan shape approaching a circle;

- Sleeve-shaped (elongated), which are formed by the overlap of adjacent gas bubbles;

- Chain, which are formed by unblocked gas bubbles;

- Shrinkage cavities that appear directly at the edges of the seam during the solidification of the melt.

Fistulas are a type of pore. A fistula is a cavity (or group of cavities) in the shape of a pipe, which was formed during the process of release of welding gases from the thickness of the metal. Unlike ray-shaped cracks, they have an oval-like cross-section.

Pores can be external or internal. The latter are detected only by instrumental control methods.

Inclusions

They are particles whose chemical composition, properties and structure differ from the corresponding indicators of the base metal. There are the following types of inclusions:

- Solid, various shapes; they may have one or more sharp corners;

- Slag - group or single;

- Flux;

- Oxide;

- Metal (most often these are particles of the electrode metal - tungsten or copper).

In turn, slag inclusions are divided into stitch and lens inclusions; in the latter case, one of the surfaces will be convex.

Surface inclusions are easily identified by external examination. The danger of such defects is the weakening of the strength properties of the welded joint.

Structural defects

These include lack of penetration of the metals forming the weld and their incomplete fusion after welding. As a result, the parent and filler metals do not bond properly.

Lack of fusion is characterized by the presence of gaps between sections of the weld, which are observed in the lateral or end zones; in the latter case, the root of the weld is weakened, and the sensitivity of the joint to alternating loads increases. A type of non-fusion is overlap, which is observed at the top or bottom edge of the weld. In case of lack of penetration, the chemical composition of the metal in the weld zone is heterogeneous and does not correspond to the required macrostructure and mechanical properties of the finished joint. The depth of the weld is insufficient, which is easily revealed by external inspection.

Section defects

They are a consequence of a violation of welding technology, or insufficient qualification of the welder, when the dimensions of the weld do not correspond to the specified ones.

There are:

- Angular deviations in weld geometry;

- Undercuts - burning out of a part of the metal on the outer or inner part of the roller;

- Uneven seam surface;

- Weights or shrinkage grooves;

- Increased convexity of the metal in the melt zone;

- Metal leaks from the opposite side of the welding bead;

- The displacement of parts of the welded structure is linear or angular;

- Burns with the formation of cavities or even through holes;

- Warping;

- Asymmetry of the root of the seam.

The digital designation of each of the listed defects is available in GOST 30242-97.

splashing

After joining, particles of burr - a solidified melt, drops of which were thrown out - often remain on the surface of the metal. Since spattering increases the temperature of individual elements of the workpiece, as the number of spatters increases, the size of the distortions also increases. Metal spatter not only degrades the appearance of the welded structure, but also damages equipment and sometimes damages welding cables.

Other weld defects

All defects in welds and joints that are not listed above are classified as “other”. These include the following types of defects:

- Random arc. As a result of accidental arcing, local damage occurs to the surface layer of the base metal adjacent to the weld area.

- Metal spatter is droplets that are formed from weld metal or filler metal during the welding process. They stick to the surface of the cooled weld metal or base metal located in the heat-affected area.

- Tungsten spatter - created by particles of tungsten thrown from the molten electrode onto the base metal or onto the weld.

- Surface scoring is a defect that occurs due to the removal of a temporarily welded fixture.

- Thinning of the metal occurs during machining. In this case, the thickness of the metal has a value that is less than the permissible value.

Permissible defects in welded joints are deviations, the presence of which does not reduce the operational properties of the welded joint and their presence is permitted by regulatory documentation. All other defects, as a rule, can be corrected by welding. It is not allowed to correct the quality of welding more than twice, as overheating or burnout of the metal may occur.

Causes of welding defects

The causes of occurrence are grouped depending on the type of defect (see table):

| Name of defect | Possible reasons |

| Lack of fusion and lack of penetration | Insufficient width of the welding groove, too large a gap between the products being welded, electrode diameter larger than recommended for a given weld size, increased (or too low) electrode speed, insufficient arc current at high voltage, excessive weld root surface, polarity violation when welding with direct current , placing the electrode at the wrong angle |

| Cracks | Hot cracks are caused by the high thermal conductivity of the metals being welded, and cold cracks are caused by residual deformation of the steel workpieces (cold cracks are usually not observed when welding other metals). Crack formation is typical for poorly cleaned workpieces, deviations from the technology, and incorrectly selected geometric dimensions of the welded products |

| Undercut | Excessive arc force (during multi-pass welding), increased electrode dimensions and low speed of movement at the edges, excessive arc current and voltage, incorrect electrode angle |

| Various inclusions | Poor cleaning of the metal after the previous pass, incorrectly selected electrode angle, too much (or, conversely, insufficient) welding current, mismatch between the melting temperatures of the flux and the weld metal |

| Porosity | use of poorly cleaned workpieces for welding, use of electrodes with a high hydrogen content, increased speed of electrode movement, discrepancy between the actual current-voltage characteristics of the arc and the specified values |

| Warping | The use of inflated values of welding current and voltage (especially for thin-walled products), increased speed of electrode movement, the use of multi-pass welding with small-diameter electrodes, insufficient clamping of parts being welded |

| splashing | Preliminary surface treatment with special compounds, reducing the current while simultaneously increasing the voltage, using electrodes with high humidity, using only recommended brands of fluxes |

In especially critical cases, test welding is performed with testing of process modes.

Lack of fusion and lack of penetration: causes

Lack of fusion and lack of fusion

Defects - lack of fusion and lack of fusion - are the lack of connection between the base material and the metal of the welded joint.

Non-fusion occurs at high speeds of the welding process and current strengths of more than 15000C. To prevent non-fusion, it is necessary to reduce the welding speed, reduce the time gap between the formation and filling of the groove, and thoroughly clean the welding area from oils and contaminants. Non-fusion can be located:

- at the root of the weld;

- on the side;

- between the rollers.

Lack of penetration occurs due to the inability of the molten metal to reach the root of the weld. There may be several reasons for lack of penetration:

- insufficient welding current;

- electrode movement speed is too high;

- increased arc length;

- the bevel angle is too small;

- distortion of welded edges;

- insufficient gap between edges;

- incorrectly selected – increased – electrode diameter.

- slag getting into the gaps between the edges;

- inadequate choice of polarity for this type of electrodes.

Lack of penetration is a very dangerous and unacceptable welding defect.

A DIY resistance welding machine is a great option if you want to save money. If you often make barbecues, then a grill that you can make yourself will be useful to you. Detailed instructions in this article.

Don't know what you need for gas welding? For a detailed list of required materials, follow the link.

How to identify defects in a weld

External defects are detected visually, and internal ones - by destructive and non-destructive testing methods. The first include bending tests (which are carried out after complete removal of the flash) and determination of the impact strength of the joint, and the impact location is taken at a distance of 15...20 mm from the welded joint. Hardness measurement is also often used at a distance of 3...5 mm from the joint; it should not be higher than 285 HB.

Of the non-destructive testing methods, ultrasonic flaw detection is most often used.

Types of solid inclusions in a weld

Solid foreign inclusions, both metallic and non-metallic in nature, having at least one acute angle in their configuration, are unacceptable defects in the welded joint, since they play the role of stress concentrators. An additional danger of these defects is that they are not visible from the outside. They can only be detected by non-destructive testing methods.

Slag inclusions in a welded joint

Solid inclusions are divided into the following types:

- Slag inclusions are slag trapped in the weld. Depending on the conditions under which they were formed, they can be linear, disconnected, or others. The reasons for their formation are high speeds of the welding process, contaminated edges, multi-layer welding, if the seams between the layers are poorly cleaned. The shape of these defective inclusions is very diverse, so they can be much more dangerous than round pores.

- Fluxes, which serve to protect the metal from oxidation, cause the formation of flux inclusions. Just like slag inclusions, flux inclusions are divided into linear, isolated and others.

- The reasons for the formation of oxide inclusions can be: an insufficiently clean surface of the base or filler metals, pulling a hot welding rod out of the gas protection area, improper preparation of the edges - their dullness is too strong.

- Particles of foreign metals - tungsten, copper or others form metallic inclusions. The reason for their formation can be erosion of the tungsten electrode or accidental ingress of metal particles from the outside, as well as when copper shavings are used for ignition.