Published on July 14, 2015 Category: Mechanics |

A welded I-beam is a direct competitor to a rolled beam. As soon as the difference in the cost of a ton of sheet metal from which welded I-beams are made and a ton of hot-rolled I-beams is significantly reduced on the metal market, ...

...welded beams are beginning to rapidly increase their share of the metal construction market.

However, the use of welded beams in the manufacture of metal structures is determined not only by economic, but often also by organizational and technological reasons.

Finding, purchasing and delivering a small number of rolled I-beams is often more difficult, expensive and time-consuming than welding these beams from sheets with the appropriate equipment, specialists and technology.

Ordering ready-made welded beams on the market today is also not a problem. Our metallurgical plants rarely roll I-beams with a height of more than 600 mm and/or on special order, and this niche is successfully filled by a welded beam. It is incomparably longer and more expensive to reconfigure a rolling mill than to reconfigure the production of welded I-beams to a different standard size.

With competent and scrupulous development of projects, the use of a welded beam instead of a hot-rolled one allows the customer to save significant sums of money due to careful determination of the cross-sectional dimensions of the profiles used.

Drawing of elements of a tower made of pipes

A number of tower elements are designed in the drawing: B20 - vertical belt of the tower {on the prismatic section of the barrel}; B60 - inclined belt of the tower {on the pyramidal section}; B48 - spacer, the packaging of which is clamped between the flanges of adjacent sections of belts; B52 is a spacer attached to the gusset on the belt {like assembly mark 4 on the B20 belt}. The belt elements have flanges with holes at the ends.

View drawing

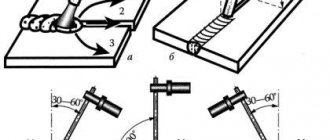

Possible defects

During welding of an I-beam, due to non-compliance with the technology, crystallization of the steel occurs due to high temperature. Due to phase discrepancies, internal stresses arise in the metal. Strength and rigidity decrease, and the risk of corrosion increases.

When welding steel sheets, other defects are possible:

- violation of the shape of the seam; deviation from the shape of the outer surfaces or the geometry of the joint;

- burns, when the melt flows out of the bath, holes form in the seam;

- undercuts – grooves along the joint boundary;

- cracks forming in places where the seam breaks;

- slag or tungsten inclusions in the diffusion layer; at high welding speeds, refractory oxides are formed.

Metal products with defects are unreliable; they will not withstand heavy bending or torsion loads. They are discarded and boiled again if possible.

Drawing of blast furnace hearth casing elements

The casing of a blast furnace hearth is a spatial sheet structure formed by cylindrical and conical surfaces. A fairly complete picture of the geometric design of the forge can be obtained from the installation diagram {see. sheet 16}. The drawing in question shows the following characteristic elements of the casing: support belt A1, two elements of the cylindrical part A3 and A5 and one element of the conical part A24.

View drawing

Manufacturing process

The technology for manufacturing welded I-beams is not too complicated, but its requirements must be strictly observed at each stage of processing. Errors inevitably lead to a decrease in the rigidity of the structure. Usually they are produced according to GOST requirements. It is also possible to produce them according to the technical conditions of the enterprise . Specifications for the production of steel welded I-beams provide for dividing the process into the following stages:

- Design and calculation . At this stage, the loads that the structure must withstand should be calculated. Using the formulas of applied mechanics (strength materials so beloved by students), the strength and rigidity of the structure is calculated, its geometric dimensions and material requirements are determined. Working drawings are being built.

- Cut out the blanks . They are cut from sheet metal using a gas, plasma or laser cutting machine. Metal samples are necessarily taken and sent to the laboratory to confirm the chemical composition and physical and mechanical properties.

- Milling of blanks . The longitudinal ends are chamfered and the edges of the welds are cut.

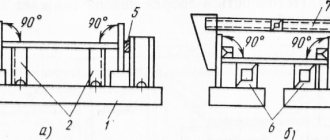

- Assembly operations . The parts are placed in special equipment that precisely fixes the workpieces in the correct position relative to each other and eliminates thermal deformation of the product. Products with a unique design and small series are welded manually; in mass production, automatic welding machines are used. Typically, assembly is carried out in two stages: in the first, the T-shaped profile is assembled, in the second, the second strip is welded to it. The method of guiding the electrode is chosen depending on the thickness of the sheet to ensure complete penetration and high-quality seam geometry. Particularly thick products must be welded in several passes.

- Editing operations . After completing all the seams, it is necessary to check and correct, if necessary, all deviations of the resulting product from the specified geometric shapes. For this purpose, hot or cold straightening mills with massive rolls are used, which correct all deformations that arise during beam welding.

Shot blasting can be added to the technology as an additional finishing touch. It knocks down scale and slag and compacts the surface layer of the metal, increasing the strength of the product.

How to cook it yourself?

Taking on this difficult operation for a home workshop makes sense for those craftsmen who already have sufficient experience in welding. Or there is an opportunity to hire an experienced welder. As blanks you will need a steel sheet made of high-alloy durable alloys . It is better if the cutting is carried out at a metal warehouse using a stationary installation. When cutting with a gas cutter, the loss of expensive metal will be noticeable.

You will also need equipment for welding I-beams under submerged arc or in an atmosphere of shielding gases.

After assembly and straightening, the product will need to be completely cleaned and painted to protect against corrosion..

How to avoid deformation?

If you simply weld the seams of a beam, then thermal deformations are almost inevitable. The product will move, bend or tighten with a screw. To minimize the risk of distortion, the following description of the technology should be observed:

- assembly is carried out on a special slipway inclined at an angle of 45°, this allows you to form an even seam with the correct leg;

- weld two strips into a T-shaped tee;

- first, the workpieces are grabbed by spot welding every 10-15 cm;

- Next, the seam is welded on both sides with obligatory edging, so that the hypotenuse of the seam is horizontal;

- straightening is carried out using manual or mechanized rollers;

- repeat the operations for the third strip.

The method of welding the seams starting from the ends towards each other is also used.

Bunker drawing

In order to increase the degree of factory readiness, in some cases structures are manufactured in blocks. This allows you to significantly reduce the volume of assembly and welding during installation, and reduce construction time. The drawing in question shows a block of crane beams, which includes two beams, a brake plate with stiffeners and vertical connections between the beams.

View drawing

Features and Benefits

A welded I-beam is made from sheet steel, which is cut into individual plates. To fasten the plates, the following operations are performed: edge cleaning, milling and metal welding. The main advantage of welded beams is their low metal consumption and simplicity. No equipment is needed to produce an individual spare part, and the cost of sheet steel will be minimal. The welded beam has high strength and reliability, does not deform under high loads, and withstands the effects of chemical reagents and high temperatures.

The main area of application of I-beams is the construction of various objects - houses, warehouses, factory premises, frame structures. I-beams are suitable for creating long spans, overpasses, bridges, floors, platforms, and crane structures. Depending on the type of structure, there are several types of I-beams - normal, wide-flange, column, sloped, reinforced. The use of welded beams in construction has many advantages:

- Reduction in the total weight of the structure by 10-20%. This is achieved due to the fact that welded I-beams are produced in different sections. This allows you to select a part to create any design.

- Universal composition. The metal welding method allows you to connect almost any type of steel, so an I-beam can be made even from dissimilar materials. This simplifies the selection of steel and reduces the cost of producing spare parts.

- Possibility of creating asymmetrical walls. Welding can be used to connect any metal surface. Therefore, it can be used to connect even metal walls that are asymmetrically located relative to each other.

- Minimum scraps and debris. A welded I-beam is made from flat blanks, which are created by cutting metal sheets. During welding, a minimum of debris is generated. Therefore, this production technology is economical, and cuttings are generated to a minimum during operation.

Crane beam block drawing

In order to increase the degree of factory readiness, in some cases structures are manufactured in blocks. This allows you to significantly reduce the volume of assembly and welding during installation, and reduce construction time. The drawing in question shows a block of crane beams, which includes two beams, a brake plate with stiffeners and vertical connections between the beams.

View drawing

Application of welded beams manufactured by our plant

Welded beams manufactured by our company are used in many sectors of the national economy. A wide variety of structures have been built from our beams:

- building,

- overpasses,

- bridges,

- overpasses,

- floors,

- suspended structures,

- long spans of production workshops,

- communication lines and much more.

The variety of types, strength of welded beams and their reliability have made these metal products very popular at any construction site.

The capacity of our plant allows us to produce welded beams of any type and length, which can be used in metal structures to create any frame, including roofing or wall, and in the installation of floors. We are pleased to offer a large assortment of beams, with different profiles and metal thicknesses, which not every manufacturer of metal structures can afford.

As we wrote above, our enterprise uses modern equipment, the plant is also equipped with automated process control, and subsequent automatic and “manual” quality control, which together allows us to achieve high quality indicators of our products.

Types of manufactured welded beams

- normal;

- wide-flange;

- columnar;

- with shelves parallel to the edges;

- with sloped edges;

- for the installation of overhead tracks;

- for reinforcement of mines.

The production of a welded beam varies , as we have noted more than once above. For its production and use, some letter designations are used:

- “B” – with a standard stripe;

- “U” – narrow stripe;

- “W” – wide stripe;

- “D” – with an average bandwidth;

- “M” – used for overhead tracks;

- “K” – columnar – shelves are equal in width to the length of the profile.

Other advantages of manufacturing welded beams

Compared to hot-rolled beams, welded beams have other advantages. In particular:

- Several types of steel can be used in one product;

- It is possible to make walls and shelves of asymmetrical cross-section, which gives designers freedom of thought and the opportunity to implement almost any architectural project;

- You can avoid waste if the welded beam is manufactured to a predetermined length;

- Reliability is guaranteed by ultrasonic testing of the weld.

Drawing of the installation diagram of the cylindrical part of the decomposers

The installation diagram of the cylindrical part of the decomposer {apparatus for producing alumina} is presented by its general view, vertical section, as well as the required number of horizontal sections. The general view shows the division of the cylindrical part into belts, as well as the height binding {to the annular seams} of brackets for hanging the assembly scaffolding.

View drawing

Additional functions of an I-beam in private housing construction

The floor itself does not necessarily have to consist only of metal I-beams. Often they are used only in the most intense places, and wooden I-beams are installed between the metal parts.

Why is that? The fact is that welding requires highly qualified workers. Further, in ordinary literature and Internet sites there is not that variety of components and ready-made design diagrams for installing such a ceiling; a competent engineer is really required here, and even we only give recommendations. In addition, metal is not cheap. And the quality of welding is very important. It must work for a long time, even under conditions of corrosion or changing loads.

Therefore, this option not only has the right to life, but is also quite practical:

And finally, a metal I-beam often serves as an additional functional element, which has value in any household:

What does it represent?

According to the production method, I-beams are divided into welded and hot-rolled.

The welded I-beam is assembled from three strips of strong high-carbon steel using electric arc welding .

The advantages of this design over hot-rolled ones are:

- the ability to carry high loads, this makes the element suitable for covering large spans;

- a special profile increases rigidity and resistance to bending, since the upper strip works in compression, and the lower one in tension;

- ability to work in difficult conditions, with changes in temperature and humidity, in aggressive environments;

- after strength calculations, reduce the linear weight of rolled products and the total weight of structures;

- possibility of manufacturing beams with asymmetrical and variable cross-section length.

I-beams are perfect for the construction of prefabricated structures . They are widely used in commercial and industrial, as well as in public and private construction.

Despite the high weight of steel beams, their increased load-bearing capacity can significantly reduce the overall weight of the building.

Classification of hot-rolled I-beams

According to the cross-sectional shape, hot-rolled I-beams are divided into two groups: with a slope of the internal edges of the flanges (manufactured according to GOST 8239-89 and 19425-74 for special types) and with parallel edges of the flanges (GOST 26020-83).

I-beam with sloped internal edges of the flanges

Products manufactured in accordance with GOST 8239-89 have an acceptable edge slope of no more than 12%. Rolling accuracy: increased (“B”) and normal (“C”).

Special purpose beams (GOST 19425-74) are used for:

- “M” – structures of overhead tracks (the slope of the internal edges of the shelves is no more than 12%);

- “C” – reinforcement of mine shafts (slope can reach 16%).

Possibilities

In addition to the advantages, the use of welded steel beams will allow each buyer to:

- Increase the width of the building span, as they are longer;

- Order different parameters and sizes, there are a huge number of GOST standards for I-beams, so that every customer can find suitable parameters;

- The architecture of the structure, as mentioned above, can be completely diverse.

Thus, the welded beam has a huge number of advantages, which is why it is widely used in all areas of construction. The use of welded beams has helped people improve the quality of structures of buildings and various structures, increase their safety, and therefore safety for people.