Home / Welding technique

Back

Reading time: 6 min

0

7467

Defects in the weld joint lead to deterioration in its performance and visual characteristics. To detect connection defects, there are different methods for monitoring the quality of the work performed.

This could be as simple as inspecting a welded joint. Or more complex testing techniques: x-rays, equipment using ultrasonic waves.

What can be done if seam defects are detected? Is the part recycled? No. If the inspection reveals defects in the welding joints, they can be corrected.

This article will discuss in detail the options for welding defects and how they are corrected.

- Types of welding errors

- External defects Lack of penetration

- Undercuts

- Surges

- Burns

- Craters

- Hot or cold cracks

Defects in welds, methods for monitoring and eliminating defects

Welding is the most important and integral part of any construction.

Moreover, work related to welding is the most important, since the strength of structures as a whole or the load-bearing capacity of individual components and parts depends on them. Welding is the process of obtaining a permanent connection of parts by applying local heating.

Types of welding

Welding is done by applying fusion method or applying pressure method. These methods are in turn divided into:

- forge (forge) welding

- gas press welding

- resistance welding

- thermite welding

- electric arc welding

- electroslag welding

- gas-shielded arc welding

- atomic hydrogen welding

- gas welding.

During welding work, three main types of control are carried out: preliminary control, control during the welding process, control of the finished product.

Preliminary control

— includes checking the grade and composition of the base metal, the quality of filler wire, oxygen, carbide, acetylene, fluxes, checking the quality of the workpiece and assembly of parts for welding, checking the condition and operation of instrumentation and tools (pressure gauges, gearboxes, burners), as well as qualifications of welders.

Control during the welding process

- includes a systematic check of the welding mode, the serviceability of welding equipment and devices, checking the welder’s compliance with the established welding process, inspection and measurement of the seam with templates.

Weld defects and methods for eliminating them

1. Deviation in the width and height of seams, leg, seam waisting

. The dimensions of the seams do not meet the requirements of GOST.

Method of identification and elimination: external inspection of the seams and checking the dimensions with templates. It can be eliminated by cutting off excess metal, cleaning seams, and welding bottlenecks in the seam.

3. Time in the weld

- a weld defect in the form of a round-shaped cavity filled with gas. Pore chain is a group of pores in a weld located in a line.

Method of identification and elimination: external inspection, inspection of seam fracture; X-ray and gamma control, ultrasound control, magnetographic control method, etc. Plan out the accumulation of pores, clean, weld. Seal by forging during welding at a temperature of light red color of the seam.

4. Fistulas

- defects in the form of a funnel-shaped depression.

Method of identification and elimination: external inspection, remove by chopping or planing, clean, weld.

5. Lack of penetration

- a defect in the form of lack of fusion in a welded joint due to incomplete melting of the edges or surfaces of previously made weld beads.

Method of identification and elimination: external inspection of the fracture. Internal control. Completely removed (cut down or planed out, cleaned and welded).

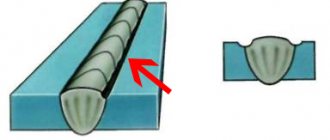

6. Sagging on the welded joint

- a defect in the form of leakage of weld metal onto the surface of the base metal or a previously made bead without fusion with it.

Method of identification and elimination: external inspection, trim the flow, remove it, cook the lack of penetration.

7. Slag inclusions

- defects in the form of slag inclusions.

Method of identification and elimination: external inspection of the seam fracture. X-ray and gamma control, ultrasound control, magnetographic control. Remove, clean, weld.

8. Cracks

— defects in the welded joint in the form of a rupture in the weld and (or) adjacent areas.

Method of identification and elimination: external examination, fracture inspection, X-ray and gamma control, ultrasound control and magnetographic method. Completely remove, clean, cook.

9. Burn

- a defect in the form of a through hole in the weld, formed as a result of the leakage of part of the metal of the weld pool.

Method of identification and elimination: external inspection, remove (cut down or plan), weld.

10. Crater

- a depression formed under the influence of flame pressure when welding suddenly ends.

Method of identification and elimination: external inspection, clean, weld.

11. Metal splashes

— defects in the form of hardened drops on the surface of the welded joint.

Method of identification and elimination: External inspection. Surface cleaning. Application of protective coating grade P1 or P2.

12. Overheating of metal -

the metal has a coarse-grained structure, the metal is brittle, fragile, and loose. Corrected by heat treatment. Reason: high power flame welding.

Method of identification and elimination: external inspection, eliminate overheating by heat treatment.

13. Burnt metal -

the presence in the metal structure of oxidized grains that have low cohesion due to the presence of an oxide film on them. Occurs when there is an excess of oxygen in the flame (if this is not required by the technical process, as when welding brass). Burnt metal is fragile and cannot be repaired. It can be identified by the color of the tarnish (on steel).

Method of identification and elimination: the burnt metal must be completely cut out and the area welded again.

Types of defects

All types of low-quality connections are divided into three main groups:

- External are those types that can be seen when inspecting a welded joint. This type includes: cracks, undercuts, sagging, craters.

- Internal - detected only after flaw detection, which necessarily includes mechanical processing of the joint and x-rays.

- Through – imply the presence of fistulas, burns and through cracks. That is, they are visualized both outside and inside.

Theoretical task “Testing” (basis of questions for the “Welding” competency)

Theoretical task "Testing"

(base of questions for the “Welding” competency)

1. How are the properties of a welded joint determined?

2. The quantitative content of which chemical element determines whether an iron alloy belongs to steel or cast iron?

3. How does high sulfur and phosphorus content affect the weldability of steel?

4. Specify the reasons for the formation of cold cracks?

5. How does weldability change with decreasing carbon content in steel?

6. What is called “inclusion”?

7. What is a defect called a “weld crater”?

8. What is a welding rectifier?

9. What is the no-load mode of a welding transformer?

10. How should the ground wire from the welding source be connected to the workpiece being welded?

11. What is the main insulating means of protection against electric shock?

13. How are medium-length seams (350-1000 mm) preferably welded?

14. What current-voltage characteristics can welding power sources have?

15. Which area is missing from the welding arc?

16. What is called the static current-voltage characteristic of the arc?

17. What structural elements characterize the shape of the edges?

18. What determines the choice of electrode diameter for manual arc welding?

19. How is the welding current adjusted in the ceiling position, compared to welding in the lower position?

20. How does uneven heating during welding affect the amount of deformation of the base metal?

21. What letter of the Russian alphabet denotes carbon and nickel in the marking of alloy steels?

22. How do the parameters of the hardening process differ from the parameters of the steel tempering process?

23. What is called an “undercut”?

24. How should the defective section of the seam be welded if the welding was carried out with preheating?

25. Does arc voltage depend on its length in manual arc welding?

26. Specify the symbols of seams for manual arc welding?

27. What are the requirements for the storage room for welding materials?

28. How are long seams of metal structures (over 1000 mm) preferably welded?

29. In what cases should hand-held power tools (included in the welding equipment kit) be turned off and disconnected from the electrical network?

30. Is it possible to perform welding work in areas of constantly active and potentially dangerous production factors not related to the nature of the welding work?

31. Which zone in the welding arc is called the anode spot?

32. What parts does an electric arc consist of?

33. What is a weld in fusion welding?

34. What welding deformations are called residual?

35. Why is preliminary and accompanying heating performed during welding?

36. Indicate the reasons for the formation of hot cracks.

37. What defects are allowed to be eliminated by the welder (without involving the work supervisor) during the welding process?

38. What are the requirements for the quality of the repaired seam section?

39. Indicate the reasons for the formation of lack of penetration during manual arc welding.

40. Should tack welds that have unacceptable external defects (cracks, external pores, etc.) be removed based on the results of visual inspection?

41. How are fistulas in a weld seam corrected?

42. What is indicated in the symbol of a weld in the drawing?

43. Which line represents an invisible weld in the drawing?

44. What is welding with straight polarity current?

45. What is the purpose of blunting the cutting edges at the root?

46. What are the types of welded joints?

47. What determines the choice of welding current in manual arc welding?

48. How do oxides in a weld affect the properties of the welded joint?

49. What does the letter “A” mean in the marking of steel 30ХМА, 30ХГСА?

50. What determines the choice of a light filter for a welder’s mask?

51. Up to what voltage in an electrical installation is protective grounding not required?

52. What happens to the dimensions of the weld pool when the product is heated before welding under constant welding conditions?

53. What do the letters and numbers mean in the marking of steels and alloys?

54. Indicate how St3kp differs from St3sp?

55. For what purpose is the normalization of steel structures carried out?

56. Why are the parts to be welded assembled with a gap?

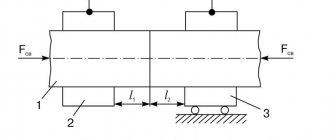

57. How are plates deformed in the longitudinal direction after welding?

58. Specify the most correct definition of the concept of weldability?

59. What is meant by the heat resistance of a metal?

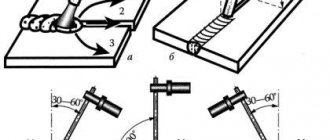

Reasons for the formation of undercuts during welding

The reason for the formation of an undercut during welding is when welding is performed either at elevated conditions or at high speed. Also, the result may be the choice of an incorrect angle of inclination to the thinner edge of the part, which in turn causes it to overheat.

Research shows that as the temperature of a solid surface decreases, its wetting with liquid metal worsens and improves with increasing temperature. Therefore, one of the main factors affecting wetting is temperature. On horizontal planes, wetting plays a key role because Due to the action of surface tension forces, liquid metal on a cold surface tends to compress, reducing its area and the surface it occupies, which leads to the formation of an undercut in the weld. In the vertical plane, i.e. When welding fillet and horizontal welds, an additional reason is the flow of liquid metal under the influence of gravity.

Incorrect use of gas shield, incorrect welding technique and welding position are additional causes of weld undercut.

Welding undercuts have always been a serious problem in the welding industry, so in recent years more and more manufacturers of welding equipment and materials have been making attempts to solve this problem.

The presence of undercuts causes a significant stress concentration near this defect and can cause local or general destruction of the structure. Longitudinal recesses reduce the cross-section of the base metal in the heat-affected zone. As a result, welded seams do not easily withstand dynamic loads and cracks may occur in these areas. When testing welds for tension and bending angle, the destruction of the metal begins from the undercut, with a significant reduction in mechanical properties.

How are fistulas in a weld seam corrected?

CORRECTION OF WELD DEFECTS

DISCONFIGENT STEEL

9.1. Defects in welds identified during the welding process or after its completion must be corrected by welding or removing the defective area followed by welding.

9.2. All welds that have the following unacceptable defects must be corrected:

a) non-compliance of the shape and size of welds with the requirements of standards, technical specifications or drawings for the product;

b) cracks, burns, undercuts, lack of penetration, fistulas;

c) recesses between seam beads exceeding 2 mm;

d) volumetric defects of a round or elongated shape (pores, slag inclusions) with a maximum size of a single defect of more than 4 mm and a total area of inclusions of more than 50 mm 2 for any 100 mm of weld length.

9.3. Areas of welds to be repaired are marked with paint or colored chalk.

9.4. Removal of defective sections of seams must be done mechanically: by milling, cutting with a pneumatic chisel, processing with a grinding wheel (the use of plasma, oxygen-flux, air-arc gouging with subsequent cleaning of the cutting surface to a depth of at least 1 mm is allowed).

9.5. The quality of preparation for welding of areas where defects have been removed is checked by a quality control department employee and a production foreman before welding in order to identify defects.

9.6. Correction of defective areas of the weld must be carried out according to technological processes using filler materials and welding methods recommended by this technical guidance material.

9.7. If there are defects that require double-sided cutting, it is allowed to correct the defective area sequentially - first cutting and welding are done on one side, then on the reverse.

9.8. Deformation (warping) of sections of structures can only be corrected in a cold state.

9.9. Correction of undersized welds is carried out by additionally melting beads onto the previously cleaned surface of a previously made seam.

9.10. Correction of oversized welds is carried out by local grinding or local trimming with a pneumatic chisel, followed by sanding with an emery stone to ensure smooth transitions of the seams to the base metal.

9.11. Sagging and sagging of welds in places of transition to the base metal must be corrected by filing, grinding or local hemming, followed by sanding with an emery stone to obtain a smooth transition from the seam to the base metal.

9.12. Unfilled craters of welds must be corrected by welding over previously cleaned metal. Welding must be done using electrodes of minimal diameter.

9.13. Correction of welds with lack of penetration, burns and cracks is carried out by removing the defective area to healthy metal and subsequent welding.

9.14. If a crack is detected in a weld, before cutting out the defective section of the seam at the ends of the crack, it is recommended to carry out drilling with countersinking in order to limit the crack and determine its depth. Removal of the crack is confirmed by the absence of chip bifurcation and etching.

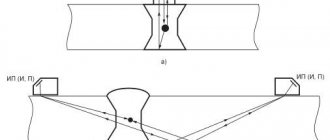

Defects of group 4 - Lack of fusion and lack of penetration

Non-fusion

Lack of fusion (401) - lack of connection between the weld metal and the base metal or between individual weld beads.

There are non-fusions:

— on the side (4011)

— between the rollers (4012)

— at the root of the weld (4013)

Non-fusion is formed during arc welding due to the fact that the arc did not melt part of the joint edge and did not form a seam with its participation.

Most often, non-fusion is formed due to incorrect choice of corner shape and groove, poorly cleaned surface of the edges, poor cleaning of the seam between passes, chemical heterogeneity of the metal, incorrect welding conditions (low current, high welding speed).

Lack of penetration

Lack of penetration (incomplete penetration) (402; D) - lack of fusion of the base metal along the entire length of the seam or in a section, resulting from the inability of the molten metal to penetrate the root of the joint or a local failure of fusion between the elements being welded, between the weld metal and the base metal, or between individual layers of the seam for multilayer welding.

Incomplete penetration (lack of fusion) in butt joints can occur in the middle of the section during double-sided welding or at the root of the seam during single-sided welding, both without a lining and on a forming lining, due to its uneven fit.

A characteristic feature of the lack of fusion is its ends, which have the form of a crack, the dimensions of which, for example for the AMg6 alloy, are commensurate with the intergranular distances. Lack of penetration may also be accompanied by the presence of pores and oxide inclusions.

In welded joints that are not sensitive to lack of penetration under static loading, the weakening of the weld section can be compensated for by strengthening or penetration. For example, strengthening the seam in the joints of low-carbon steel pipes with annular lack of penetration along the entire length at the root of the seam under static loads completely compensates for the weakening of the section created by lack of penetration up to 20% of the pipe wall thickness. Welded joints that are not sensitive to lack of penetration under static loads may reduce static strength during sectional or multi-layer welding at low temperatures (from -60 to -70 ° C). This is due to repeated heating, which creates local thermoplastic deformation and aging of the metal. In areas of lack of penetration, the reserve of ductility decreases - embrittlement, which leads to a sharp decrease in strength.

As a result of lack of penetration, the cross-section of the weld is reduced and local stress concentration occurs, which ultimately reduces the strength of the welded joint. Under vibration loads, even small lack of fusion can reduce the strength of the connection by up to 40%. Large lack of root penetration can reduce the strength by up to 70%.

Lack of penetration at the root of the weld occurs when the current is insufficient or at an increased welding speed, lack of penetration at the edge of the weld occurs when the electrode is displaced from the axis of the joint, lack of penetration between layers occurs when the previous layers are poorly cleaned, or there is a large volume of deposited metal. Also, the reason for the formation of lack of penetration is poor cleaning of the metal from scale, rust and impurities, a small gap during assembly, a large bluntness, a small bevel angle of the edges, insufficient welding current, high welding speed, displacement of the electrode from the center of the joint.

Areas with lack of fusion have to be cut down to the base metal, cleaned and welded again.

Tightness of welds

Author:

Igor

Date of:

10.03.2018

- Article

- Photo

- Video

Checking the tightness of welds is necessary when the product is operating under pressure, with liquid and gaseous media. This applies to pipelines, tanks, reservoirs and similar structural elements. Roller and spot welds are inspected. Describes the requirements for testing the tightness of welded seams according to GOST 3242-69.

All types of control are aimed at identifying and eliminating low-quality products upon acceptance; their use is determined by precise computing instruments, tools and technologies that allow you to learn how to test a weld for leaks with an accuracy of microns.

Testing the tightness of a welded joint

Determination of seam tightness

"Important! The finished product is checked by the manufacturer during operation; this procedure is carried out by the owner within the specified time frame in the regulatory and technical documentation.”

There are several verification methods, each of which has a narrow focus. It is important to use the method that is most appropriate under specific conditions.

Control methods are selected depending on the operating conditions of the product:

- chemical properties of the working environment;

- physical parameters: pressure;

- temperature;

- operating time.

Effective ways to correct welding errors and defects

Defects in the weld joint lead to deterioration in its performance and visual characteristics.

To detect connection defects, there are different methods for monitoring the quality of the work performed. This could be as simple as inspecting a welded joint. Or more complex testing techniques: x-rays, equipment using ultrasonic waves.

What can be done if seam defects are detected? Is the part recycled? No. If the inspection reveals defects in the welding joints, they can be corrected.

This article will discuss in detail the options for welding defects and how they are corrected.

- Types of welding errors

- External defects Lack of penetration

- Undercuts

- Surges

- Burns

- Craters

- Hot or cold cracks