Types of welded joints of reinforcement with brief characteristics and methods of welding them

When welding reinforcement, 4 main types of welded joints are used:

- Cross-shaped.

- Butt.

- Lap.

- Tavrovoe.

Depending on the type of connection, one of the welding methods can be practiced.

| Connection types | Welding method | Designation |

| Cruciform | Contact point | CT |

| Arc (manual) | Rp | |

| Mechanized with tacks | MP | |

| Butt | Contact butt | Co. |

| Mechanized submerged bath | Mf | |

| Bathroom with one electrode in inventory form | Rv | |

| Mechanized arc with cored wire and steel bracket | MP | |

| Bath-suture on a steel bracket | Rs | |

| Arc (manual) with multi-layer seams on a steel bracket | Rm | |

| Arc (manual/mechanized) with seams with rod overlays | Rn | |

| Overlapping | Arc manual or mechanized | Rsh |

| Contact for 1 relief on the plate | Kr | |

| Contact along 2 reliefs on the plate | Kr | |

| Tavrovoe | Arc (mechanized) submerged arc without additive | Mf |

| Arc (manual) submerged arc without additive | Russia | |

| Arc (mechanized) with seams in CO2 environment | Mz | |

| Arc (manual) with roller seams | Rz |

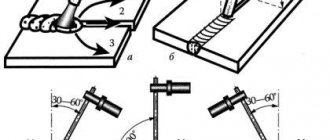

Depending on the type of welded joint and the welding method, different positions of the rods during welding can be used during welding: horizontal, vertical or any.

Automated methods are the most preferred. When producing reinforcing mesh in a factory, preference is given to resistance spot and butt welding, and when making embedded parts, preference is given to mechanized submerged arc welding or resistance relief welding.

Also, when installing reinforcement, you should use those welding methods that allow you to perform a non-destructive weld quality control procedure.

Bathtub joining of reinforcement is widely popular, as it is used with a fairly large cross-section of reinforcing bars, which reaches 10 cm.

Using bath joints, for example, flanges are attached to metal pipes, reinforcement posts and frames are connected, etc. Products produced using this method are distinguished by high strength and reliability.

The chemical composition of the fittings must comply with GOST 5781-82, GOST 10884-94 and other regulatory documents.

APPENDIX 2 (for reference). Assessment of performance qualities of welded joints

APPENDIX 2 Information

A comprehensive assessment in points of the performance qualities of welded joints (strength, ductility, impact strength, metallographic factors, etc.) depending on the type of joint and welding method, steel grade and reinforcement diameter, as well as operating (manufacturing) temperature under static loads is given in Table .31. When assessing performance under repeated loads, the point values should be approximately reduced by one compared to the accepted values under static loads. In this case, you should additionally use regulatory documents for the design of reinforced concrete structures of buildings and structures for various purposes.

Points for welded connections of reinforcement are assigned based on the condition of compliance with the regulated technology for the manufacture of reinforcement and embedded products.

For welded joints of hot-rolled reinforcing steel:

5 - equal strength to the original metal and ductile fracture are guaranteed;

4 - welded joint meets the requirements of GOST 5781 for steel in its original state;

3 - the welded joint meets the requirements of GOST 10922 for welded joints.

For welded joints of thermomechanically strengthened reinforcing steel:

5 - the welded joint meets the requirements of GOST 10884 for steel in its original state and is characterized by ductile fracture;

4 - temporary tensile strength of the welded joint may be lower than that normalized according to GOST 10884 by up to 5%;

3 - temporary tensile strength of a welded joint may be lower than that normalized according to GOST 10884 by up to 10%.

Evaluation of the performance qualities of welded joints under static load

Table 31

| Connection designation | Operating (manufacturing) temperature, °C | Reinforcing steels, classes, grades, diameters, mm | |||||||||||||||||||||||

| A-II | A-III | At-IIIC | A-IV | At-IVC | AV | At-V | A-VI | At-VI | |||||||||||||||||

| St5sp | St5ps, St5Gps | 10GT, up to 32 | 35GS | 25G2S | St5sp, St5ps | 20ХГ2Ц, 20ХГ2Т | 25G2S, 27GS, 28S | 23Х2Г2Т | 20GS, 20GS2 | 22X2G2S, up to 22 | 20GS, 20GS2, up to 32 | ||||||||||||||

| Up to 28 | Up to 40 | Up to 28 | Up to 40 | Before 18 | Up to 28 | Up to 40 | Before 18 | Up to 28 | Up to 40 | Up to 32 | |||||||||||||||

| K1-Kt K2-Kt | Above 0 | 5 | 4 | 4 | 5 | 5 | 4 | 5 | 5 | 4 | 5 | ND | 5 | ND | 4 | ND | 4 | ||||||||

| Up to -30 | 3 | 4 | 4 | ||||||||||||||||||||||

| Up to -40 | 4 | 3 | ND | 3 | 4 | 3 | 4 | 4 | 3 | 3 | |||||||||||||||

| Up to -55 | ND | ND | 3 | ND | ND | ||||||||||||||||||||

| K3-RR | Above 0 | 3 | ND | 3 | ND | 5 | ND | 3 | ND | 4 | ND | 4 | ND | 3 | ND | ||||||||||

| Below 0 | ND | ||||||||||||||||||||||||

| S1-Ko S2-Kn S3-Km S4-Kp | Above 0 | 5 | 4 | 5 | 5 | 4 | 5 | 4 | 5 | 4 | 5 | 4 | ND | 3 | ND | ||||||||||

| Up to -30 | 3 | ||||||||||||||||||||||||

| Up to -40 | 4 | ND | 4 | 3 | 4 | 3 | 4 | 3 | 4 | 3 | ND | ||||||||||||||

| Up to -55 | ND | ND | 3 | ND | 3 | ND | 3 | ||||||||||||||||||

| S5-Mf S6-Mp S7-Rv S8-Mf S9-Mp S10-Rv | Above 0 | 5 | 4 | 4 | 5 | TN | 5 | 4 | TN | 5 | 4 | ND | |||||||||||||

| Up to -30 | 4 | 3 | 4 | 3 | 4 | 3 | |||||||||||||||||||

| Up to -40 | 3 | ND | 3 | ||||||||||||||||||||||

| Up to -55 | ND | ND | 3 | ||||||||||||||||||||||

| S11-Mf S12-Mp S13-Rv | Above 0 | NC | 3 | NC | 4 | NC | |||||||||||||||||||

| Up to -30 | 3 | ||||||||||||||||||||||||

| Up to -40 | |||||||||||||||||||||||||

| Up to -55 | ND | ||||||||||||||||||||||||

Continuation of table 31

| Connection designation | Operating (manufacturing) temperature, °C | Reinforcing steels, classes, grades, diameters, mm | |||||||||||||||||

| A-II | A-III | At-IIIC | A-IV | At-IVC | AV | At-V | A-VI | At-VI | |||||||||||

| St5sp | St5ps, St5Gps | 10GT, up to 32 | 35GS | 25G2S | St5sp, St5ps | 20ХГ2Ц, 20ХГ2Т | 25G2S, 27GS, 28S | 23Х2Г2Т | 20GS, 20GS2 | 22X2G2S, up to 22 | 20GS, 20GS2, up to 32 | ||||||||

| Up to 28 | Up to 40 | Up to 28 | Up to 40 | Before 18 | Up to 28 | Up to 40 | Before 18 | Up to 28 | Up to 40 | Up to 32 | |||||||||

| S14-Mp S15-Rs S16-Mo S17-Mp S18-Mo S19-Rm | Above 0 | 5 | 4 | 4 | 5 | TN | 5 | 3 | TN | 5 | 4 | 5 | ND | ||||||

| Up to -30 | 4 | 3 | 4 | 4 | 3 | ||||||||||||||

| Up to -40 | 3 | ND | 3 | 4 | |||||||||||||||

| Up to -55 | ND | ND | 3 | 3 | |||||||||||||||

| S20-Рм | Above 0 | 5 | 5 | 4 | 4 | 5 | TN | 5 | 4 | TN | 5 | 5 | ND | ||||||

| Up to -30 | 4 | 3 | 4 | 4 | |||||||||||||||

| Up to -40 | 4 | 3 | 3 | 3 | 4 | ||||||||||||||

| Up to -55 | ND | 4 | ND | 3 | 3 | ||||||||||||||

| S21-Rn | Above 0 | 5 | 5 | 5 | 4 | 5 | 5 | 4 | 5 | 5 | 5 | 4 | 5 | 4 | 4 | ||||

| Up to -30 | 4 | 4 | 4 | 3 | |||||||||||||||

| Up to -40 | 4 | 3 | 4 | 3 | 4 | 4 | 3 | 4 | 3 | 3 | |||||||||

| Up to -55 | 3 | 3 | 3 | ND | ND | ND | ND | ||||||||||||

| S22-Ru | Above 0 | NC | 4 | ND | 4 | ||||||||||||||

| Up to -30 | 3 | 3 | |||||||||||||||||

| Up to -40 | |||||||||||||||||||

| Up to -55 | ND | ND | |||||||||||||||||

| S23-Re | Above 0 | 4 | ND | 4 | ND | 5 | 4 | ND | 4 | ND | 4 | ND | 4 | ND | |||||

| Up to -30 | 3 | ||||||||||||||||||

| Up to -40 | 3 | ND | 4 | 3 | 3 | 3 | 3 | ||||||||||||

| Up to -55 | ND | ND | |||||||||||||||||

Continuation of table 31

| Connection designation | Operating (manufacturing) temperature, °C | Reinforcing steels, classes, grades, diameters, mm | |||||||||||||||||

| A-II | A-III | At-IIIC | A-IV | At-IVC | AV | At-V | A-VI | At-VI | |||||||||||

| St5sp | St5ps, St5Gps | 10GT, up to 32 | 35GS | 25G2S | St5sp, St5ps | 20ХГ2Ц, 20ХГ2Т | 25G2S, 27GS, 28S | 23Х2Г2С | 20GS, 20GS2 | 22X2G2S, up to 22 | 20GS, 20GS2, up to 32 | ||||||||

| Up to 28 | Up to 40 | Up to 28 | Up to 40 | Before 18 | Up to 28 | Up to 40 | Before 18 | Up to 28 | Up to 40 | Up to 32 | |||||||||

| S24-Mf S25-Mp S26-Rs S27-Mf S28-Mp S29-Rs | Above 0 | 5 | 5 | 5 | 5 | 5 | TN | 5 | 4 | TN | 5 | 4 | 5 | ND | |||||

| Up to -30 | 4 | 4 | |||||||||||||||||

| Up to -40 | 4 | 3 | 4 | 3 | 4 | ||||||||||||||

| Up to -55 | 3 | 3 | 3 | 4 | |||||||||||||||

| S30-Mf S31-Mp S32-RS | Above 0 | NC | 4 | NC | 4 | ND | |||||||||||||

| Up to -30 | 3 | 3 | |||||||||||||||||

| Up to -40 | |||||||||||||||||||

| Up to -55 | ND | ND | |||||||||||||||||

| N1-Rsh | Above 0 | 4 | 3 | 4 | 3 | 5 | 5 | 4 | 3 | 5 | 4 | 4 | 5 | 4 | 5 | 4 | |||

| Up to -30 | 3 | 3 | 3 | 3 | |||||||||||||||

| Up to -40 | ND | 4 | 3 | 4 | 3 | 4 | 4 | ||||||||||||

| Up to -55 | 3 | 4 | ND | 3 | ND | 3 | ND | 3 | ND | ||||||||||

| N2-Kr N3-Kp N4-Ka | Above 0 | 5 | ND | 5 | ND | 5 | 5 | ND | 5 | ND | 5 | ND | |||||||

| Up to -30 | |||||||||||||||||||

| Up to -40 | 4 | 4 | 4 | 4 | 4 | ||||||||||||||

| Up to -55 | 3 | 3 | 3 | ||||||||||||||||

| Т1-Мф Т2-Рф Т3-Мж | Above 0 | 5 | 4 | 5 | 4 | 3 | 5 | 4 | 4 | ND | |||||||||

| Up to -30 | 4 | 3 | ND | 4 | 3 | ||||||||||||||

| Up to -40 | 3 | 3 | |||||||||||||||||

| Up to -55 | ND | 4 | ND | ND | |||||||||||||||

Continuation of table 31

| Connection designation | Operating (manufacturing) temperature, °C | Reinforcing steels, classes, grades, diameters, mm | |||||||||||||||||

| A-II | A-III | At-IIIC | A-IV | At-IVC | AV | At-V | A-VI | At-VI | |||||||||||

| St5sp | St5ps, St5Gps | 10GT, up to 32 | 35GS | 25G2S | St5sp, St5ps | 20ХГ2Ц, 20ХГ2Т | 25G2S, 27GS, 28S | 23Х2Г2С | 20GS, 20GS2 | 22X2G2S, up to 22 | 20GS, 20GS2, up to 32 | ||||||||

| Up to 28 | Up to 40 | Up to 28 | Up to 40 | Before 18 | Up to 28 | Up to 40 | Before 18 | Up to 28 | Up to 40 | Up to 32 | |||||||||

| T6-Ks | Above 0 | 5 | ND | 4 | ND | 5 | 4 | ND | 5 | 4 | ND | ||||||||

| Up to -30 | |||||||||||||||||||

| Up to -40 | 4 | 3 | 3 | 4 | 3 | ||||||||||||||

| Up to -55 | 3 | 4 | 3 | ||||||||||||||||

| T7-Ko | Above 0 | 5 | 4 | 5 | 4 | 5 | 4 | 4 | 5 | 4 | 4 | 5 | ND | ||||||

| Up to -30 | 4 | 3 | 3 | ||||||||||||||||

| Up to -40 | 4 | 3 | 3 | 3 | 4 | 3 | 4 | ||||||||||||

| Up to -55 | 3 | ND | 3 | ND | 4 | ND | 3 | ND | |||||||||||

| T8-Mv T9-Rv | Above 0 | 5 | 4 | 5 | 4 | 5 | 5 | 4 | 5 | 4 | 3 | ND | |||||||

| Up to -30 | 4 | ||||||||||||||||||

| Up to -40 | 4 | 3 | 4 | 3 | 3 | 4 | 3 | ||||||||||||

| Up to -55 | 3 | 3 | 4 | 3 | 3 | ||||||||||||||

| T10-Ms T11-Mts T12-Rz | Above 0 | 5 | 4 | 4 | 5 | 4 | 5 | 4 | 3 | ND | |||||||||

| Up to -30 | 4 | 3 | 4 | ||||||||||||||||

| Up to -40 | 3 | 3 | ND | 3 | 3 | ||||||||||||||

| Up to -55 | ND | ND | 4 | ND | 3 | ND | |||||||||||||

| T13-Ri | Above 0 | 5 | 4 | 4 | 5 | NC | 5 | 4 | NC | 5 | 4 | ND | |||||||

| Up to -30 | 4 | 3 | 4 | 4 | |||||||||||||||

| Up to -40 | 3 | ND | 3 | 3 | 3 | ||||||||||||||

| Up to -55 | 3 | ND | 4 | ND | 3 | ||||||||||||||

Notes:

1. The performance qualities of all types of welded joints of class AI reinforcement of the St3sp and St3ps brands must be assessed in the same way as class A-II reinforcement of the 10GT brand, and class AI reinforcement of the St3kp brand - as of class A-II reinforcement of the St5sp and St5ps brands.

2. The performance qualities of cross-shaped connections of wire reinforcement of classes BP-I and BP-600 are not regulated by this annex due to the lack of requirements for the chemical composition of steel. The quality requirements for such connections are given in GOST 10922.

3. Class A-II fittings of grade 10GT can be used up to a temperature of minus 70 °C inclusive.

4. Welded connections of At-VCK class reinforcement are rated one point lower than connections made of At-V class reinforcement at operating temperatures up to minus 40 °C inclusive.

5. Welded joints C16-Mo, C18-Mo and N4-Ka are rated one point lower than the joints given in the same group.

6. The letters ND, TN and NTs respectively indicate that connections are not allowed for use, connections are technologically impracticable and connections the use of which is impractical.

Types

GOST 8713-79 submerged arc welding.

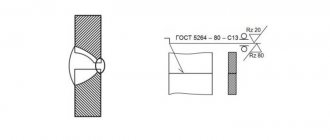

welded connections. main types, structural elements and dimensions Seams produced by manual arc welding in accordance with GOST 5264-80 are divided into types according to the location of the joined elements. The regulatory document identifies the following compounds:

- butt;

- corner;

- overlap;

- onlay.

The butt joint is considered classic and is more common than other types. It connects – joins the ends of parts, sheets and pipes. The connection is strong and can withstand tensile, torsional, and bending loads. As a result of butt welding, one element of a part smoothly flows into another and continues it.

The butt connection is used most often when a pipeline is laid and large flat parts, such as platforms, are created. The thickness of the connected elements can be the same or different. Depending on the thickness of the material, the edges are cut. Seams are manually welded in one or several layers.

The corner joint can have a mutual position of 90⁰, as well as an acute and obtuse angle between the elements being connected.

Assessment of performance qualities of welded joints

A comprehensive assessment of the performance qualities of welds is carried out from the point of view of their strength, impact strength, ductility, etc. It is carried out taking into account external factors:

- The type of connection that was used.

- Welding method.

- Steel grades and diameters of reinforcement used.

- Operating and production temperatures.

To assess the quality of welding of reinforcement under static load, GOST provides Table A1.

If performance qualities are assessed under repeatedly repeated loads, then it is recommended to reduce the score by 1. Also in the assessment process, it is recommended to focus on GOSTs and standards for the design of reinforced concrete structures of buildings and structures.

Thus, the provisions of GOST 14098-2014 establish the requirements for welding work on reinforcement. They involve the use of several methods of joining reinforcing rods. Among them are cruciform, butt, lap and tee.

APPENDIX 1 (mandatory). Terms and explanations

APPENDIX 1 Mandatory

TERMS AND EXPLANATIONS

Table 30

| Term | Explanation |

| Bath welding | A process in which the melting of the ends of the joined rods occurs mainly due to the heat of the molten metal bath |

| Bathroom mechanized welding | A welding process in which the filler wire is fed into the welding zone automatically and the arc or holder is controlled manually |

| Bath single-electrode welding | A welding process in which electrode material in the form of a single (piece) electrode is fed manually into the welding zone |

| Mechanized arc welding with flux-cored wire | A welding process in which electrode material in the form of flux-cored wire is fed automatically into the welding zone |

| Inventory form | A reusable device (copper, graphite) that ensures the formation of deposited metal during welding and easy removal after welding |

| Steel bracket | An auxiliary element that ensures the formation of a weld seam, which is an integral part of the connection and takes up part of the load when the connection operates in the structure |

| Cross connection | Connection of rods welded at the intersection |

| Settlement (mm) of rods in cross-shaped connections | The amount of pressing of the rods into each other in the area heated during resistance welding to a plastic state |

| Combined load-bearing and forming elements | Elements consisting of the remaining steel half-bracket and the inventory copper half-mold |

| Mechanized submerged arc welding without filler metal | A process in which the entire welding cycle is carried out in a predetermined automatic mode |

| Manual arc welding with low mechanization submerged arc without filler metal | A process in which auxiliary operations are partially mechanized and the entire welding cycle is performed manually |

TERMS AND EXPLANATIONS

SP 260.1325800.2016 thin-walled steel structures made of cold-formed galvanized profiles and corrugated sheets. design rules (with change n 1)

Table 30

| Term | Explanation |

| Bath welding | A process in which the melting of the ends of the joined rods occurs mainly due to the heat of the molten metal bath |

| Bathroom mechanized welding | A welding process in which the filler wire is fed into the welding zone automatically and the arc or holder is controlled manually |

| Bath single-electrode welding | A welding process in which electrode material in the form of a single (piece) electrode is fed manually into the welding zone |

| Mechanized arc welding with flux-cored wire | A welding process in which electrode material in the form of flux-cored wire is fed automatically into the welding zone |

| Inventory form | A reusable device (copper, graphite) that ensures the formation of deposited metal during welding and easy removal after welding |

| Steel bracket | An auxiliary element that ensures the formation of a weld, which is an integral part of the connection and takes up part of the load when the connection operates in the structure |

| Cross connection | Connection of rods welded at the intersection |

| Settlement (h, mm) of rods in cross-shaped connections | The amount of pressing of the rods into each other in the area heated during resistance welding to a plastic state |

| Combined load-bearing and forming elements | Elements consisting of the remaining steel half-bracket and the inventory copper half-mold |

| Mechanized submerged arc welding without filler metal | A process in which the entire welding cycle is carried out in a predetermined automatic mode |

| Manual arc welding with low mechanization submerged arc without filler metal | A process in which auxiliary operations are partially mechanized and the entire welding cycle is performed manually |