Welding work using a semi-automatic machine is carried out either in a shielding gas environment or using a special flux-containing wire. Often, semi-automatic welding without gas with ordinary wire leads to the formation of an imperfect seam that is subject to rapid degradation.

The protective environment formed by gas or fumes from the flux-cored filler wire ensures good welding of surfaces and guarantees the absence of significant defects in the weld.

What is semi-automatic carbon dioxide welding?

Semi-automatic welding without gas and with gas is used in the following industrial sectors:

- shipbuilding and ship repair work;

- body work;

- pipeline construction;

- installation work;

- production of boilers and dimensional equipment;

- welding of surfaces during steel casting.

The operating principle of semi-automatic welding is as follows: carbon dioxide is supplied to the welding zone from a cylinder, which breaks down into carbon monoxide and oxygen under the influence of high temperature from an electric arc.

Carbon monoxide is ideal for protecting surfaces from oxidation, however, a mixture of carbon dioxide and oxygen contributes to the burning of alloyed additives and carbon from the joined products. This process leads to a decrease in the quality of the seam and the formation of a large number of pores in it.

To neutralize the disadvantages of welding in a carbon dioxide environment, a special filler material is used. The wire used in gas welding is an alloy based on silicon and manganese.

The most popular brands of filler wire are: Sv-08GS, Sv-08G2S. Additives are much more active than iron and oxidize first, thereby drawing oxygen onto themselves and preventing it from destroying the weld when performing mechanized welding.

Semi-automatic welding technology without gas

It is the use of flux-cored (cored, protective) wire that makes it possible to obtain high-quality welds without using gas cylinders. It is a hollow steel tube with a diameter of 0.8-2 mm, the cavity of which is filled with a special flux with additives.

The flux is composed of deoxidizing substances that prevent the absorption of oxygen, as well as slag-forming elements and various additives. These are manganese, iron, silicon, nickel and other alloying additives that make it possible to obtain the required melting temperature at low currents.

The composition of the flux, similar to the composition on the surface of standard electrodes, depends on the required characteristics of the materials being welded and the seam. When heated, the flux burns completely, forming a protective gas cloud around the area of molten metal.

Flux-cored wire is manufactured in various variations:

Flux-cored wire for semi-automatic welding without gas

- tubular simple;

- tubular two-layer;

- double-cavity with one bend;

- double-cavity with two bends.

The steel walls of the electrode wire are thin and cannot withstand sudden jerks, compression or bending. This must be taken into account when setting up the electrode supply mechanism, as well as during the welding process, avoiding jerking, turning and twisting of the welding machine hose.

Semi-automatic welding machines using this technology must be able to change reverse polarity to direct polarity. Semi-automatic welding without gas, as opposed to welding using gas equipment, requires a direct connection - a “minus” is applied to the electrode, and the workpiece to be welded is connected to the “plus”. This connection provides the higher temperature required to burn the flux powder and create a safety environment.

Features of welding in carbon dioxide

Semi-automatic welding scheme.

The main advantage of working in a carbon dioxide atmosphere compared to semi-automatic welding without gas is good control over the welding process. When using shielding gas, the operator clearly sees the arc burning and observes the cooking process itself.

If you use flux-cored wire, the welding area becomes covered with thick smoke, which limits your view and does not allow you to fully control the welding process.

Carrying out welding work in a carbon dioxide environment using semi-automatic equipment has the following advantages:

- Full use of the electric arc energy for impressive cooking speeds.

- High quality of the obtained welds.

- Possibility of welding in various spatial positions.

- Low gas consumption by the welder when welding semi-automatically.

- Relatively low cost of liquefied carbon dioxide.

- Possibility of joining materials of any thickness.

- Carrying out work on weight.

- High labor productivity.

- Almost complete absence of damage to the part. When repairing car bodies, local heating, which occurs during semi-automatic welding, allows you to carefully repair the product without serious damage to the paintwork.

- No need for flux supply and removal.

There are also disadvantages of welding in a carbon dioxide environment.

These include:

- Low quality of sold carbon dioxide mixtures.

- Weaker quality of welds compared to the use of argon mixtures.

- Inability to work with all metals.

- Difficulties in cleaning equipment after using carbon dioxide.

- Serious wear of components if incorrect welding parameters are set.

Overall, semi-automatic carbon dioxide welding is a very simple process that even a beginner can quickly master.

The principle of semi-automatic wire welding.

Characteristic features of carbon dioxide welding technology are:

- Carrying out the process on reverse polarity of direct current. This approach allows you to obtain a stable electric arc and avoid various deformations. In addition, reverse current seriously reduces the consumption of filler wire, which allows you to use the semi-automatic welding machine in an economical mode.

- Possibility of using direct current polarity for metal surfacing. When performing such work, the efficiency of surfacing materials is higher.

- Possibility of working with a wire welding machine powered from an alternating current network. To use this functionality, you must use an oscillator.

Modes of semi-automatic welding in a carbon-oxygen oxygen atmosphere are divided into:

- welding with forced short circuits;

- work with the transfer of large droplets;

- welding with continuous burning of an electric arc.

The carbon dioxide consumption rates when using semi-automatic equipment are:

- 8-9 liters per minute when welding with wire from 0.8 to 1 millimeter in diameter.

- 9-12 liters with 1.2 mm wire.

- 12-14 liters when connecting products using filler wire with a diameter of 1.4 millimeters.

- 15-18 liters with high-quality welding of parts with 1.6 mm wire.

- 18-20 liters when welding with thick two-millimeter wire.

When welding ferrous metals, carbon dioxide from a semi-automatic welding machine leaves at a rate of approximately 8-9 liters per minute.

In addition to the diameter of the wire, gas consumption is affected by: welding method, current strength and speed of work.

Selection of wire for a semi-automatic machine

Before starting work, you must select a wire, the grade of which depends on the thickness of the sheets being connected and the type of metal. The strength of the seam and the speed of work depend on the correct selection. The welder needs to know whether it is possible to use wire designed for a gas environment to perform the work. The use of such materials is allowed, but it should be taken into account that due to the lack of a protective atmosphere, the quality of the material in the joint area decreases.

Types of additives

Types of filler wires:

- Standard steel with a copper-plated surface, designed for joining or restoring the surface of parts made of carbon or low-alloy steel. The copper layer is applied electrochemically, which provides protection against the formation of galvanic couples and corrosion of the core material. It has a stable chemical composition and, due to its simple production technology, has a low cost. Semi-automatic welding without gas with ordinary wire is not recommended due to insufficient quality of the seam.

- To connect parts made of carbon steels, wire with additional alloying components (for example, chromium, vanadium or tungsten) is used. The material ensures the formation of uniform seams with increased strength corresponding to the characteristics of the base metal.

- When welding stainless steels, wire with a chemical composition close to the parameters of the base material is used. Depending on the alloying additives, welding materials are divided into soft or hard; there is a category of heat-resistant materials. It should be taken into account that the refusal of a protective gas atmosphere leads to the appearance of pores or saturation of the melt with foreign impurities. Welding stainless steels with standard wire (both with gas supply and without protection) is not recommended due to the poor quality of the weld.

- When welding aluminum alloys, a special wire with additives is used to stabilize the material in the joint area. Please note that the welding material must be stored in sealed packaging. Under the influence of the atmosphere, a refractory oxide film is formed on the surface, which prevents arc burning. Welding technology without gas for aluminum alloys is rarely used due to the poor quality of the joint. To create a permanent connection, a semi-automatic device with a supply of chemically inert argon is used.

- Special flux-cored wire for semi-automatic machines without gas, containing rutile-based flux. Suitable for welding in any position; during surfacing, it provides a high rate of accumulation of metal on the surface of the workpiece. Allows filling of corner joints or narrow gaps with melt; the formed seam has a neat appearance and does not contain thermal cracks.

We recommend reading: The principle of acetylene welding with oxygen

Types of filler wires for semi-automatic machines without gas.

Pros and cons of cored wire

Advantages of powder-based materials:

- a large selection of diameters (from 0.6 to 2.4 mm in increments of 0.1 mm), which allows you to connect sheets of different thicknesses;

- the ability to weld carbon or alloy steels, as well as galvanized metal;

- no need to deliver or connect cylinders with a protective environment;

- equipment mobility;

- increased speed of work.

Flux cored wire welding has its disadvantages:

- increased cost of work due to the high price of welding materials;

- decrease in seam quality (compared to technology using an atmosphere of protective gases).

Wire consumption calculation

To calculate the need for filler material per 1 linear meter of joint, use the formula N=G*R, where:

- N – required parameter;

- G is the mass of the melt in the formed joint 1 m long;

- R is a correction factor indicating the ratio of deposited metal to the mass of spent wire.

To calculate the wire, a special formula is used.

To determine the parameter G, use an equation of the form G=A*B*L, where:

- A – cross-cut area of the seam in mm²;

- B – density (depends on the chemical composition);

- L – joint length.

Since material costs depend on the position of the connection line in space, the coefficient X is introduced into the formula for calculating parameter N, equal to:

- 1.0 – for lower joints;

- 1.05 – for inclined surfaces;

- 1.1 – for vertical partitions;

- 1.2 – for ceiling structures.

The given calculation algorithm is developed for welding in a gas environment and does not take into account metal spattering when the protective atmosphere is abandoned. It is recommended to introduce a correction factor of 1.2...1.4 into the formula, which allows to compensate for the release of part of the melt from the weld pool.

It should be noted that the consumption depends on the qualifications of the welder, the characteristics of the equipment used and the base material, as well as the diameter of the filler wire.

Refueling the device

Installation algorithm into the device:

- Carefully place the reel onto the guide shaft of the device. It is necessary to hold the free end of the filler material to prevent accidental unwinding of the spool.

- Insert the tip into the groove of the guide roller.

- Press the toggle switch to turn on the electric drive in idle mode at maximum feed speed.

- Pull the wire through the sleeve and then the torch tip (do not let it get stuck).

Hold the free end of the filler material.

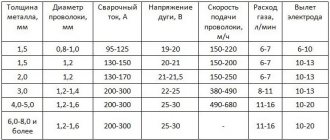

Modes of semi-automatic welding in shielding gases

Carbon dioxide welding allows you to join many types of metals and alloys.

The choice of operating mode of the equipment depends on the thickness of the metal being welded; for example, pipe welding should be done with the following settings:

- wire diameter – 1.2 millimeters;

- welding current – 130-170 amperes;

- arc voltage – 21-21.5 volts;

- filler material supply speed – 150-250 meters per hour;

- gas consumption – 6-7 liters per minute;

- electrode extension is 10-13 centimeters.

Based on the data above, we can conclude that a 10-liter cylinder, when evaporated, produces about 5 cubic decimeters of gas, can provide about 6 hours of continuous operation of the welding machine. The most optimal parameters for the working pressure of carbon dioxide should be selected depending on the materials being welded.

Welding work in hard-to-reach places can be carried out using filler wire with flux. This approach allows you to do without a heavy cylinder of liquefied carbon dioxide.

Drawing of semi-automatic welding with shielding gas.

Each welding machine comes with documentation that clearly describes the optimal operating modes of the equipment. In addition, the accompanying papers usually contain data on setting up the device depending on the thickness of the products being welded.

When carrying out work, remember the following rules:

- with increasing welding current, the depth of the weld increases;

- arc voltage directly depends on length;

- the feed rate of the filler element should be calibrated so as to ensure stable combustion of the welding discharge;

- Electrode stickout directly affects the quality of the seam, and, therefore, the optimal parameters should be empirically calculated.

Most modern semi-automatic welding devices are assembled on the basis of an inverter power source. This design allows you to connect the equipment to an alternating current network.

When connecting inverter welding, the use of special equipment is not required, since all the required rectifier and high-frequency transformer are installed in the power source itself.

https://youtu.be/OvpbnoHZlSM

Preparing for work

The control panel of a semi-automatic welding machine without gas contains several control elements, including:

- semi-automatic welding current switch;

- adjustment of filler wire feed speed;

- on/off timer for spot soldering;

- mount for welding gun.

All welding machines that allow joining metals in carbon dioxide must go through a series of stages in preparation for work:

- Checking equipment grounding. According to fire safety and the GOST standard, all welding equipment must be connected to a grounding conductor.

- Network check. Semi-automatic devices are very vulnerable to various voltage deviations in the electrical network.

- Selecting the operating mode. The equipment is configured for a specific type of welding work.

- Diagnostics of the performance of the torch and filler wire supply system.

- Checking the quality of wire. The filler material must not have any peeling, damage or dents.

Necessary equipment and types of wire

For connection without gas, any device with the ability to switch reverse polarity to direct polarity can be suitable. When using wire with flux, select a semi-automatic welding machine without gas. In this case, it is necessary to connect the terminals of the equipment, as when working with electrodes. The result will be increased arc output energy, as well as temperature at the weld.

Initially, the feeding mechanism is debugged. The resulting distortions can damage the material and reduce the quality of the connection. When choosing equipment, consider:

- small size for quick movement;

- smooth adjustment of the electric arc;

- use of various materials.

The following types of wire are distinguished:

- with flux core;

- with metal powder core.

Wire for semi-automatic machine

Equipment setup

The selected parameters will help you connect metal parts with a high-quality seam. Pre-requisite:

- determine the amount of electric current to be supplied to the equipment terminals;

- configure the inverter welding machine according to the specified parameters;

- install a set of gears on the feed mechanism;

- make a test seam on a piece of metal;

- After making sure that the parameters are set correctly, perform a metal connection.

Setting up and connecting welding equipment

High-quality welding in carbon dioxide is only possible with preliminary fine-tuning of the equipment.

Filled wire for semi-automatic welding.

Before starting welding work, welders must:

- Insert filler wire.

- Check the feed rollers. The components must be compatible with the filler material used. If the rollers are installed from the wrong wire, the drive component must be replaced.

- Place the wires in the appropriate groove.

- Secure the adjusting shaft. You need to press without using unnecessary force, since if you press too hard, the wire will be seriously deformed and impede the operation of the welding arc.

- Unfold the feed sleeve.

- Remove the nozzles and tip.

- Make sure that the filler wire extends 10-15 centimeters from the torch.

- Attach the tip and nozzle.

- Connect the liquefied gas cylinder to the device through the reducer.

- Secure the supply hose using clamps.

Preparing metals for welding in CO2

Semi-automatic welding with carbon dioxide allows you to weld metals of any thickness.

Classification of manual arc welding in shielding gas.

The subtleties of preparing products for cooking depend on the thickness of the metal:

- Thin metal sheets up to 1 millimeter are welded using edge flanging. The absence of such processing is allowed, but in this case the gap between the welded surfaces should not be more than 0.5 millimeters.

- Sheets with a thickness of 1 to 8 millimeters can be welded without cutting edges. The maximum allowable gap is 1 millimeter.

- Thicker metal, up to 12 millimeters thick, requires additional processing in the form of a V-shaped cutting.

- Products with a thickness of over 12 millimeters are recommended to be welded after performing an X-shaped cut.

Before performing work directly, products must undergo the following procedures:

- Complete cleaning of welded edges. Removal of dirt and scale can be done using a shot blasting or sandblasting unit. If there are none, you can clean the surfaces with simple sandpaper.

- Sticking surfaces. Preliminary welding in several places is carried out using electrodes E42 or E42A.

Advantages and disadvantages

Advantages of the technology:

- increased welding speed;

- improving the appearance of the seam material;

- the ability to carry out work in any spatial position;

- joining thin metal sheets without the risk of burning;

- possibility of welding elements made of light alloys or dissimilar substances.

The technology increases the speed of welding. The main disadvantage of semi-automatic welding is the gas cylinder, which must be moved along with the equipment. In cramped conditions it is not always possible to install a container, and excessive lengthening of the hoses worsens the conditions for supplying the protective medium and does not allow quick adjustment of the gas volume. The welder can refuse to use cylinders and weld with a special wire containing flux.

We recommend reading Connection technology using bath welding

The advantage of the technology is a reduction in the cost of work and a reduction in the weight of transported equipment. At the same time, they take into account the increased price of raw materials or difficulties in finding quality material. In addition, it is impossible to weld workpieces made of alloy steels or aluminum alloys without a protective gas atmosphere.

The resulting seam will have insufficient strength or will collapse when the standard force is applied.

How to properly weld with a semi-automatic machine?

The technology of semi-automatic welding in a carbon dioxide atmosphere is very simple and understandable. The only thing that is required of the welder is to maintain the correct wire extension and move the torch in a timely manner at a uniform speed.

If these conditions are correctly met, semi-automatic welding with flux-cored wire without gas allows you to obtain an even weld without sagging or caves.

Experts have developed several simple recommendations that will make semi-automatic welding seem like a very simple task for beginners:

- Before starting welding work, make sure that gas is coming from the torch. Carbon dioxide for welding must enter the working area under a pressure of 0.02-0.03 kilo Pascal. In the presence of draft, wind and other factors, the pressure should be adjusted to compensate for losses.

- The burner angle should be between 65 and 75 degrees.

- The welding must be done from right to left. This approach allows for a better overview of already welded areas.

Of course, for infrequent work it is not profitable to purchase a carbon dioxide cylinder. In such cases, a method of cooking without carbon dioxide will come, based on the use of a special filler wire with flux.

When connecting products made of non-ferrous metals, it is extremely important to choose the right wire. For example, it is best to solder aluminum products using a filler material containing aluminum, manganese and magnesium.

Welding methods

Semi-automatic welding in a carbon dioxide environment can be performed in two ways:

- Angle forward. In this case, the arc moves from right to left, the metal melts less and the weld bead turns out to be quite wide. This cooking method is ideal for joining thin metal.

- Angle back. The approach involves moving the electric arc from left to right. The method is suitable for welding thick metals because it provides a large penetration depth and a narrow seam.

Scheme of welding under slag.

The welding method without using gas deserves special mention.

This technique has many advantages:

- Full mobility. Due to the absence of heavy gas cylinders, welding can be carried out even in the most inaccessible places.

- Large selection of specialized wires. Today there are a huge number of filler materials with built-in flux.

- Simplified welding process.

- There is no need to constantly refill the cylinder. For small repair shops there is no point in keeping an expensive cylinder. Therefore, infrequent welding work is best carried out using flux-containing wire.

However, the gasless type of welding also has its disadvantages, among which are:

- high cost of consumables;

- increased requirements for wire selection;

- the need for a current polarity switch button on the device;

- difficulties in selecting optimal operating modes;

- poor visibility of the weld due to haze;

- difficulties when welding sheets less than 0.15 centimeters thick;

- release of a large amount of harmful substances that have a detrimental effect on the body;

- weak mechanical properties of the wire, which do not allow it to be pinched with a roller.

It is important to note that welding work can be carried out using ordinary wire, however, the resulting seam in this case will be loose and short-lived.

Step-by-step welding process

Welding without gas is usually carried out in accordance with the following algorithm:

Semi-automatic welding circuit diagram.

- Selection of the optimal current value depending on the thickness of the products being connected.

- Setting the reverse polarity current on the equipment.

- Selecting the solder wire feed speed. When using flux-containing wire, it is important to ensure that the gears do not pinch it.

- Checking the set parameters on a test sample. Small pieces of metal are optimal for this stage. During the setup process, you should monitor the stability of the welding arc and the amount of flux produced.

- Set the switch to the forward position.

- Pressing the welding start button.

- Ignition of the electric arc.

- Rotate the burner 5 degrees relative to the vertical axis.

- The electrode begins to move along the intended connection. To avoid the risk of cracks, the first layer should be boiled at low current.

- Completing a weld by filling the crater with molten metal.

- Stop the welding machine and disconnect it from the power supply.

Advantages and disadvantages of semi-automatic welding without gas

The use of semi-automatic welding without gas, in comparison with traditional technology in an environment of inert or active gas coming from a cylinder, has both pros and cons. The advantages include:

- mobility of the equipment - no need for a bulky gas cylinder and additional hoses;

- no need for constant refueling of the cylinder and associated economic costs;

- the ability to form a more accurate seam;

- possibility of direct observation of the welding process (through a protective mask);

- the ability to influence the parameters of the arc and the chemical structure of the weld by using flux with different fillings.

Among the disadvantages of semi-automatic welding without gas, experienced welders note:

- significant price of a wire electrode with flux;

- the need for gentle use of the wire due to its fragility;

- the difficulty of choosing the optimal welding mode - it is determined by the chemical composition of the flux;

- the need to clean the seam from slag;

- the need for a semi-automatic welding machine to have the ability to change polarity.

One of the most promising areas in this area is semi-automatic welding without gas.

Despite the existing disadvantages, semi-automatic welding without gas is recognized as the best option for domestic use with limited volumes of work. This is the best choice both in terms of the price of consumables and the ease of working with the equipment.

Semi-automatic welding without gas at home is very popular. The necessary equipment, high-quality and inexpensive, is easy to find in specialized stores. The absence of a bulky gas cylinder makes the welding process much more convenient, and the quality of work remains high. But a novice welder needs to take into account the high cost of flux-cored wire and obtain preliminary advice from an experienced specialist.

Carbon dioxide consumption during welding for semi-automatic welding machine

Semi-automatic welding in a carbon dioxide environment requires the constant presence of carbon dioxide in a special cylinder.

In most cases, the amount of gas used during cooking depends on the following parameters:

- quality of filler material;

- weather;

- type of metals being welded.

In addition, the calculation formulas include the thickness of the wire and the operating current. A standard forty-liter cylinder contains about 25 kilograms of carbon dioxide. When connecting the container to a semi-automatic machine, thanks to a chemical reaction, the welder can obtain up to 510 liters of the working gas mixture from one kilogram of carbon dioxide.

The consumption of CO2 shielding gas during semi-automatic welding under ideal conditions is approximately 8-9 liters of gas per minute, which allows for up to 24 hours of continuous operation.

Welding modes in shielded gases for non-ferrous metals require a significantly higher mixture consumption:

- The connection of aluminum products consumes up to 15-20 liters of gas mixture.

- The process of forming a seam between copper parts takes about 12 liters per minute.

- Connecting magnesium products will require up to 14 liters of mixture per minute.

- The consumption for cooking nickel is 10-12 liters.

It is important to note that during the preparation of equipment, consumption of protective gas is allowed up to 10% of the total volume stored for all work.

Flux cored self-shielding wire.

The theoretical calculation of welding wire consumption when operating semi-automatic equipment should take into account the following parameters:

- type of metal being welded;

- The diameter of the wire;

- presence or absence of shielding gas;

- characteristics of welding equipment;

- the place where the work is performed, for example, for ceiling welding the material consumption is higher, and for semi-vertical welding it is lower.

As a rule, the consumption of the filler component does not exceed 1.5% of the entire mass of the structure. Before welding, it is necessary to carefully calculate the amount of materials required for the work so as not to interrupt the welding process.

Wire consumption for welding without gas depends on:

- the quality of the components used;

- wire thickness;

- type of metal product.

Safety precautions

Welding work is a rather dangerous process, depending on the attentiveness, professionalism and equipment of the master.

The best protection options for wire welding include:

- Eye protection. To fully protect your eyesight, the welding machine operator should be equipped with special safety glasses and a mask.

- Air filtration. When performing welding work using flux-cored wire, it is necessary to provide the specialist with appropriate protection. Respirators or filter masks can help protect against harmful fumes of chemical elements.

- Protection from drops of molten metal. Do not neglect working clothes, since a drop of hot metal can seriously injure the worker.

Table of shielding gas consumption and wire feed speed.

Safety precautions when performing welding work include the following rules:

- Perform welding work exclusively from a wooden platform. The use of metal flooring is strictly prohibited.

- The light used to illuminate the cooking area must be powered from a 12-volt network.

- Belaying the master must be done using ropes attached to the belt. To ensure the mobility of the master, the length of the safety cables must be at least two meters.

- The welder's workplace must be equipped with exhaust systems that effectively purify the air and remove harmful impurities. Some fluxes used in welding without gas can cause serious poisoning if inhaled.

- Moving welding workpieces must be done strictly while wearing work gloves.

- Carrying out work in open areas during precipitation is strictly prohibited.

The technology of semi-automatic welding in a carbon dioxide environment allows for high-quality joining of materials. However, if the workplace is not well ventilated, carbon dioxide can suffocate the worker and cause serious health problems.

Features of the method

Additives that are used when welding without gas make it possible to reduce the diameter of the wire to 0.8-2 mm, and at low currents to obtain the required degree of metal melting.

Using this method, it is possible to obtain high-quality and reliable seams when fusing products of any thickness, as well as significantly increase the efficiency of the semi-automatic machine.

Semi-automatic welding of metal workpieces without shielding gas provides a number of advantages, the main of which are:

- eliminating the need to carry heavy cylinders;

- significant savings on gas mixtures, the refilling of which costs a lot of money;

- a variety of methods for forming additive compositions (using flux, powder and similar fillers);

- the ability to control the location of the welding cut directly through the mask.

When welding metals semi-automatically without gas mixtures, some professionals manage to produce from 20 to 40 meters of connecting “threads” per hour.

Features of semi-automatic welding include the use of gas-replacing attributes such as wire consumables.

The wire is produced in the form of a thin steel tube, the diameter of which is selected to be about 0.8 mm (similar to welding in a gas environment). Its internal cavities are filled with a special powder flux, its composition reminiscent of the coating of standard electrodes.

During the welding process using a semi-automatic machine and with strong heating, the filling composition completely burns out. As a result, a cloud of gas appears in the resulting bath, which reliably protects against the access of oxygen.