Surfacing is the application of an additional layer of metal to the surface of various products and parts by welding.

This procedure not only restores the original properties of the part, but also gives it additional valuable characteristics. It is one of the simplest and most effective ways to return elements to functionality. Fusing can be done for various purposes :

- restoration of product geometry;

- giving the structure a new shape;

- formation of a layer with specific physical and mechanical properties;

- increasing wear resistance, anti-corrosion, strength, hardness and other properties of the base material.

The essence of the process is the interpenetration of hot materials into each other, occurring at the molecular level. To do this, the surface layer of the main product is heated until it melts to a small depth, and the additive is heated to a liquid state. The resulting connection has a high level of reliability. The main advantage of the technology is the ability to regulate the thickness of this layer within significant limits and apply the additive to elements of various shapes.

Below you will find a detailed overview of all types of surfacing, and then a detailed discussion of surfacing with electrodes.

Types of metal surfacing

Currently, a large number of surfacing methods are used in the industrial and manufacturing fields. Next we will look at the different types of surfacing depending on the type of surfacing material used.

Manual arc surfacing with coated electrodes

Surfacing with coated electrodes is the most universal method; it can be carried out in all spatial positions. It is used both in the industrial sector and in the domestic sphere.

- The popularity of this method is due to several reasons : simplicity, convenience, flexibility, and no need for special equipment.

- Main disadvantages : low productivity, difficult conditions for the performer, instability of the quality of the resulting layer, large penetration of the base material.

Fusing requires the performer to have certain skills.

It is necessary to melt both components at a minimum current. By determining the composition of the metal, the type of electrode is selected, and the thickness and shape of the workpieces affects the diameter of the welding rod. If the thickness of the deposited material is less than 1.5 mm. – then the diameter of the rod should be 3 mm. With a thickness of more than 1.5 mm. – 4-6 mm.

The surface of the part must be cleaned of various types of contaminants.

The need for preheating and subsequent heat treatment also depends on the brand of electrodes used.

Surfacing of steel products is carried out using direct current of reverse polarity.

This method involves the use of various patterns of surfacing welds.

When working with flat products, there are two main types:

- using narrow rollers (in the picture), each subsequent roller should overlap the other by 0.3-0.4 of its width;

- the use of wide rollers, which are obtained with increased transverse movements of the electrode.

Another type is the laying of narrow rollers at some distance from each other. The slag crust is removed after applying several rollers. Then the gaps are also filled with rollers.

Surfacing of cylindrical products is carried out in three ways:

- rollers along the generatrix of the cylinder;

- rollers in closed circles;

- along a helical line.

Cylinder surfacing will be analyzed in more detail below.

Manufacturers and retailers offer a wide range of coated surfacing electrodes. The most popular brands are:

OZN-6 are used for surfacing parts of equipment for various purposes, operating under conditions of significant shock loads and intense wear. Metal deposited using electrodes of this brand has increased resistance to cracking.

OZI-5 electrodes are used for welding of metal-cutting tools and dies. The deposited metal is highly resistant to crushing and abrasion under significant impact loads.

Manual arc surfacing can also be carried out with carbon, graphite or tungsten electrodes. Deposition with these welding materials has limited application and is therefore rarely used.

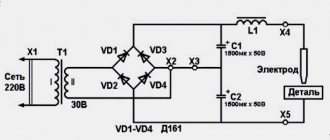

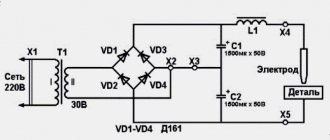

Vibro-arc surfacing is performed by vibrating the electrode, the amplitude of which is 0.75-1.0 times the diameter of the rod. The procedure is carried out using a reverse polarity current of 80-300 A. At the moment of contact between the main product and the electrode wire, a short circuit occurs, which heats both surfaces to the melting temperature.

This method allows you to obtain a durable and thin layer. At the same time, slight heating eliminates the deformation of the part.

The vibro-arc method is used for fusing external and internal cylindrical, external conical and flat surfaces. This method is also used to restore the following structures: shaft journals, mud pump rods, drill pipe joints and others.

Electroslag surfacing is based on the use of heat generated when current passes through molten slag. The main feature of this method is high productivity. In an hour of work, a performer can obtain hundreds of kilograms of deposited metal. Other characteristic features of ESP: lack of spattering, economical consumption of filler materials and electricity, low heating and cooling rates have a negative effect on the structure of the deposited layer, and a slight tendency of the metal to form pores . [ads-pc-2][ads-mob-2]

For your information! To obtain a stable process, it is necessary that the depth of the slag bath be at least 30 mm. Failure to comply with this rule leads to instability of the process.

Electrodes of various cross-sections can be used as filler material: rods, plates, etc.

Main advantages: the process remains stable in a wide range of current densities: 0.2-300 A/mm2, the ability to deposit layers of large thickness in one pass, this method can be used to work with materials prone to cracking, the ability to give the deposited metal the desired shape .

The main disadvantages: overheating of the main product in the heat-affected zone due to the high heat input of the process, the need for complex and unique equipment, the impossibility of obtaining thin layers, significant preparation time.

Automatic plasma surfacing complex SBI (Austria)

Currently, the plasma cladding method . The heat source is a high-temperature compressed arc produced in special burners. The filler material can be surfacing powder, tape, wire, electrode, etc.

Plasma surfacing with the supply of two consumable electrodes into the bath provides high productivity.

A universal subtype of plasma surfacing is surfacing with powder injection into an arc. When performing such work, a combined type burner is used, which produces two types of arc: direct and indirect. Surfacing powders are fed from the feeder to the burner using a transport gas and are blown into the arc there. During its stay in the arc, most of the powder melts, and it falls on the surface of the main product in the form of droplets.

Before starting welding, the working surface should be cleaned of various contaminants: rust, moisture, scale and oil.

When applying the first surfacing layer, each previous bead must be overlapped by 20-30% of its width.

- Main advantages : high quality of the deposited layer, small depth of penetration of the base metal, high adhesion strength, the ability to obtain layers of small thickness.

- Disadvantages : relatively low level of productivity, presence of complex equipment.

Submerged arc surfacing has several characteristic features: high productivity, great versatility and wide possibilities for alloying the base metal.

There are four types of submerged arc surfacing:

Electric arc surfacing with tape is widely used . The arc that occurs at the end of the electrode strip moves from one edge to the other. These cyclic movements result in a dissipated heat input into the main product.

2. Multielectrode electric arc surfacing . The essence of the process is that the arc automatically occurs at the end of either one or the second electrode, which are located at some distance from each other and have a common current conductor. The arc moves from one rod to another, causing the rods to alternately melt.

3. Multi-arc electric surfacing . This type is in many ways similar to the multielectrode method. Only here the number of electric arcs corresponds to the number of electrodes.

4. Vibrating submerged arc surfacing involves performing the process using oscillatory movements of the electrode.

In addition to the advantages already listed, submerged arc cladding has the following advantages: low losses of electrode metal, absence of radiation.

Disadvantages : large penetration of the base metal, the need to use flux-forming devices, surfacing can only be carried out in the lower spatial position, when working with small-diameter parts and deep internal surfaces, there are difficulties in removing the slag crust.

Surfacing in shielding gases

The most popular method is surfacing with a consumable electrode in a carbon dioxide environment, which is characterized by availability and low cost. This method allows you to work with parts of small diameters and apply layers with a thickness of 0.5 to 3.5 mm on them.

- Main advantages : excellent quality of deposited metal, high productivity.

- Disadvantages : increased level of spattering; to obtain a high-quality additional layer, the use of special wire is necessary.

Surfacing in an inert gas environment is carried out with a consumable and non-consumable electrode.

In the first case, the arc occurs between the electrode and the base metal. Deposition is carried out under automatic electrode wire feeding conditions. The protective medium is a mixture of argon with oxygen or carbon dioxide.

In the second case, graphite electrodes serve as non-consumable electrodes.

tungsten carbon electrodes (in the picture). The filler material is introduced into the arc zone in the form of wire or powder. When surfacing with a carbon rod, surfacing powders are poured onto the main surface and then melted. The deposited layer is of low quality due to the presence of pores, non-metallic inclusions and other defects. When using tungsten rods, an arc occurs between the base metal and the tungsten electrode.

Arc surfacing with flux-cored strips and wires

This method does not require the use of flux or shielding gases. Therefore, the main characteristics of this method are simplicity and maneuverability.

It also creates the opportunity for the performer to work with parts of complex shapes, deep internal surfaces, small-diameter elements, etc.

Arc stability and protection of the molten metal from nitrogen and oxygen from the air are guaranteed by the presence of the necessary core components of the electrode material.

Gas surfacing

This method uses a gas flame produced by special burners as a heat source. Surfacing materials can be wires, rods and rods. The deposition process involving these materials is practically no different from electric arc surfacing.

Recently, gas-powder surfacing has become widespread. This method allows you to strengthen parts with a complex configuration with a thin layer of metal from 0.1 to 0.3 mm. This does not dilute the base metal. The powder is fed into the work area through an oxygen gas flame. As a result of heating, the powder in a plastic and molten state reaches the surface of the part. It then hardens and forms a deposited layer of metal.

- Advantages : low penetration of the base metal, versatility of the technology, the ability to obtain thin layers of deposited metal.

- Disadvantages : low productivity, instability of the quality of the deposited layer, low coefficient of use of filler materials.

Laser surfacing is performed using a highly concentrated energy source - a laser beam. This method does not require the use of vacuum chambers. Rods, tapes, and coatings can be used as filler material.

- Pros : high adhesion strength, low and controlled penetration of the base metal, the ability to obtain thin layers - up to 0.3 mm, slight deformation of parts; ability to work with hard-to-reach surfaces; the laser beam can affect several places at once.

- Disadvantages : low productivity, low efficiency of the entire process, it is necessary to have complex and expensive equipment.

[ads-pc-3][ads-mob-3] Electron beam surfacing is performed in a vacuum and is the melting of base and filler materials with an electron beam. The electron beam allows you to regulate the heating of both the base and filler materials. Moreover, this happens separately, which allows mixing of the two materials to a minimum. Flux-cored or solid wire can be used as filler material.

- Advantages : slight penetration of the base metal, the possibility of obtaining layers of small thickness.

- Disadvantages : the complexity of the equipment and its high cost, the need for biological protection of the performer.

Electrical contact surfacing is carried out with wire or powder using a special apparatus.

- Advantages : high productivity, low energy consumption, no need for a protective environment, minimal thermal impact zone due to short pulse duration.

- Disadvantages : limited range of processed products. This method is used to restore the following parts: shafts, axles, rods, drums and other elements, the wear of which does not exceed 1-1.5 mm in diameter.

For friction surfacing, a filler rod is used, which is pressed with its end against the surface to be deposited and rotated relative to the longitudinal axis.

This method has not found active use due to the low relief of the deposited layer.

Explosion surfacing. Cladding using explosion energy is carried out using explosion welding technology.

- Advantages : the ability to work with metals that are difficult or impossible to join using other methods, no penetration of the base metal, minimal level of product deformation.

- Disadvantages : the need for special testing grounds, significant preparation time, limited range of parts that are processed by this method.

Restoration of parts by metal surfacing

Those who operate various mechanisms sometimes have to face the need to weld metal in one place or another on a part. A broken mounting hole, a surface worn out during operation, a chipped edge of a metal-cutting tool, a worn bearing bushing. In all these cases, you can do without replacing the part by restoring it by welding metal onto the worn part. Surfacing a metal part allows not only to restore the original properties of the product, but also to give it completely new valuable qualities. In particular, by melting a layer of carbide metal onto a low-carbon steel base, you can obtain a wear-resistant working element or cutting tool.

Welded jaws

Surfacing is the process of applying one molten metal (called filler) to the surface of another (called base). In this case, the base metal is also melted to a small depth to form a homogeneous compound. The purpose of surfacing can be different: restoring the lost geometry of a part or giving it a new shape, forming a surface layer with specified physical and mechanical properties (such as increased hardness, wear resistance, antifriction, corrosion resistance, heat resistance, etc.), hardening by surfacing.

Surfacing can be done on any surface - flat, conical, cylindrical, spherical. Its thickness can also vary within wide limits - from a few fractions of a millimeter to a centimeter or more.

Basic principles of surfacing

In its main aspects, surfacing technology is similar to welding technology. It faces the same tasks as welding - protecting the deposited metal from gases contained in the air, obtaining a dense weld metal, without pores, cracks and foreign inclusions. Therefore, it is important to read the general article about welding, with articles about welding of relevant metals (copper welding, cast iron welding, aluminum welding, stainless steel welding) and about electrode coatings, otherwise there will be no understanding, for example, why calcinate the electrodes before surfacing and what the consequences will be if it cannot be done, or why the polarity of the electrode connection is important. When surfacing, basic principles must be observed, consisting of a number of requirements:

- It is necessary to strive for minimal penetration of the base metal. This is achieved by tilting the electrode in the direction opposite to the deposition stroke.

- There should be as little mixing of the deposited metal with the base metal as possible.

- We must try to achieve minimal residual stresses and deformations in the part. This requirement is largely ensured by compliance with the two preceding ones.

- It is necessary to reduce allowances for subsequent processing of the part to acceptable values. In other words, you need to deposit exactly as much metal as necessary, and no more.

Various methods of metal surfacing are used - electric arc, gas, electroslag, induction, plasma, pulse-arc, vibrating arc, and powder surfacing. Arc surfacing is most widely used.

Surfacing materials exist in various forms. These can be filler rods, powder mixtures, surfacing coated electrodes, flux-cored and solid wire. Electric arc surfacing mainly uses coated electrodes, filler rods and wire.

Surfacing with coated electrodes

Surfacing with coated surfacing electrodes is one of the main methods used both in industry and in everyday life, due to its simplicity, convenience, and the absence of the need for special equipment.

A large number of brands of electrodes are produced that create a surfacing layer with different characteristics that ensure the required quality of products for operation in certain conditions. Surfacing requires certain skills in operation. It is necessary to melt both components at a minimum current and voltage, so as not to increase the share of the base metal in the deposit. The composition of the metal will determine the type of electrode, and the thickness and shape will determine the diameter of the electrode. The arc voltage determines the shape of the deposited bead; as it increases, the width of the bead increases and the height of the bead decreases, the arc length and the oxidation of alloying impurities, especially carbon, increase. In this regard, they strive for a minimum voltage, which must be consistent with the arc current.

Surfacing of steel parts is carried out, as a rule, by direct current of reverse polarity (on the “plus” electrode) in the lower position.

Direct (left) and reverse (right) polarity of electrode connection

Parts made of low-carbon and low-alloy steels are usually welded without preheating. But often preheating and subsequent heat treatment are required to relieve internal stresses. More detailed requirements for surfacing are provided in the documentation for the surfacing electrodes used. For example, for the OZI-3 electrode the following technological features are given: “Cladding is carried out in one to four layers with preheating to a temperature of 300-600°C. After surfacing, slow cooling is recommended. It is possible to surfacing using the bath method at high conditions. Calcination before surfacing: 350°C, 1 hour.”

Before surfacing, the surface of the part is cleaned of oil, rust and other contaminants.

Various layouts of surfacing welds are used. In the case of flat surfaces, two main types of surfacing are distinguished - the use of narrow beads with overlapping each other by 0.3-0.4 of their width, and wide beads obtained by increased transverse movements of the electrode relative to the direction of passage.

Surfacing of metal with narrow beads

Surfacing of metal with wide transverse movements of the electrode

Another way is to lay narrow rollers at some distance from one another. In this case, the slag is removed after applying several rollers. After this, the beads are also fused in the gaps.

To avoid warping of parts, it is recommended to carry out deposition in separate sections, “randomly”, and to begin laying each subsequent roller on the opposite side in relation to the previous one.

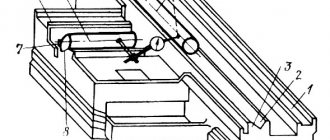

Surfacing of a cylindrical surface is carried out in three ways - by beads along the generatrix of the cylinder, by beads along closed circles and along a helical line. The last option (along a helical line) is especially convenient in the case of mechanized surfacing, in which the part is given uniform rotation during the surfacing process.

Metal surfacing on the cylinder

Welded Metal Cylinder

To restore and increase the service life of cutting, stamping and measuring tools, as well as parts of mechanisms operating under intense wear, surfacing of working surfaces with hard alloys is used, which are compounds of metals such as titanium, tungsten, tantalum, manganese, chromium and others with boron , carbon, cobalt, iron, nickel, etc.

In the manufacture of new tools and parts with carbide surfacing, parts made of carbon or alloy steels are used as blanks (bases). In the case of repairing parts with a lot of wear, before surfacing with hard alloys, preliminary surfacing is done with low-carbon steel electrodes.

To obtain better surfacing, prevent the formation of cracks and reduce stress, in many cases it is advisable to heat the workpieces to a temperature of 300°C or higher.

Surfacing of metal-cutting tools and dies

. Metal-cutting tools and dies operating during cold and hot stamping are overlaid with electrodes OZI-3, OZI-5, OZI-6, TsS-1, CI-1M and other grades. The metal deposited with these electrodes is highly resistant to abrasion and crushing at high specific loads and high temperatures - up to 650-850°C. The hardness of the deposited layer without heat treatment ranges from 52 HRC (OZI-5) to 61 HRC (OZI-3). 1-3 layers with a total thickness of 2-6 mm are deposited. Before surfacing, the part is heated to a temperature of 300-700°C (depending on the brand of electrode).

Surfacing of knives

Surfacing of parts exposed to abrasion without impact loads

. If it is necessary to obtain deposited metal of particularly high hardness, you can use electrodes for surfacing T-590 and T-620. They are specially designed to coat parts subject to intense abrasion. Their rod is made of low-carbon steel, but the coatings include ferrochrome, ferrotitanium, ferroboron, boron carbide and graphite. Thanks to these materials, the hardness of the deposited metal can reach 62-64 HRC units.

Due to the fact that the deposited metal is brittle and prone to cracking, products deposited with T-590 and T-620 electrodes are not intended for use under conditions of significant shock loads. Surfacing of carbide metal is carried out in one or two layers. If it is necessary to deposit a greater thickness, the lower layers are deposited with low-carbon steel electrodes, and only the final layers are deposited with carbide electrodes.

Surfacing of parts exposed to abrasion and impact loads

. Parts made of manganese steels (110G13L and similar), operating under conditions of intense surface wear and high shock loads (in particular, working parts of construction and earth-moving equipment), are overlaid with OMG-N, TsNIIN-4, OZN-7M, OZN-400M electrodes , OZN-300M and other brands. When using them, the hardness of the deposited metal in the second layer is 45-65 HRC at high viscosity values.

Surfacing of mill parts (hammers)

Auger surfacing

Surfacing of stainless steels

. For surfacing parts made of stainless steel, electrodes TsN-6L, TsN-12M-67 and other brands are used. The rod of these electrodes is made of stainless high-alloy wire. In addition to high corrosion resistance, the deposited metal also has resistance to scuffing, which makes it possible to use these electrodes for surfacing sealing surfaces in reinforcement products.

When using some electrodes for surfacing stainless steels, it is recommended to carry out preliminary and concomitant heating of the part to a temperature of 300-600°C and carry out heat treatment after surfacing.

Surfacing of copper and its alloys

. Surfacing of copper and its alloys (bronze) can be carried out not only on a copper or bronze base, but also on steel and cast iron. In this case, bimetallic products are created that have the necessary performance qualities (high resistance to corrosion, low coefficient of friction and other valuable properties inherent in copper and its alloys) and at the same time have a much lower cost in comparison with parts made entirely of copper or its alloys

Aluminum bronzes, in particular, which have high anti-friction properties, work very well in friction units, so they are welded onto worm wheels, crackers and other parts that operate under friction conditions.

Surfacing of parts made of technically pure copper can be carried out using Komsomolets-100 electrodes or filler rods made of copper or its alloys. When surfacing copper on copper, preheating to a temperature of 300-500°C is used.

It is advisable to subject the deposited layer to forging at a copper temperature above 500°C.

If surfacing with bronze is required, you can use OZB-2M electrodes, which, in addition to the base copper, also contain tin, manganese, nickel and iron. Products deposited with OZB-2M electrodes have high surface wear resistance.

Surfacing of copper and its alloys is carried out using direct current of reverse polarity in the lower position.

Surfacing in shielding gases

Along with surfacing with coated electrodes, surfacing can also be carried out at home in a shielding gas environment - using the MIG/MAG method (with automated wire feed) or TIG (tungsten electrode) with filler rods.

For protection, various gases can be used: argon, carbon dioxide, helium, nitrogen - depending on the type of metal being deposited. When restoring carbon steel parts by surfacing, you can use cheaper carbon dioxide. Considering the fact that CO2 oxidizes the molten metal, the surfacing wire in this case must have deoxidizing agents (manganese, silicon, etc.).

Surfacing of copper and its alloys can be carried out in nitrogen, which is neutral with respect to copper.

High-alloy steels, magnesium- and aluminum-based alloys are fused in argon, helium or a mixture thereof.

Surfacing with a non-consumable tungsten electrode is carried out in argon and helium. In general, inert gases, especially argon, are universal, suitable for welding and surfacing of almost any metal.

Solid welding wires (Sv-08GS, Sv-08G2S, Sv-12GS) and special surfacing wires (Np-40, Np-50, Np-30KhGSA) are used as materials for semi-automatic surfacing of carbon and low-alloy steels. For surfacing stainless steel, stainless steel wire is used. Surfacing can also be carried out with flux-cored wire, which makes it possible to obtain a deposited layer with special properties.

When restoring parts by surfacing using the MIG/MAG method, a direct current of reverse polarity is used, as in the case of MMA, which ensures less penetration of the base metal. When using a tungsten electrode (TIG method), straight polarity is used to prevent melting of the tungsten electrode. You should try to surfacing with as short an arc as possible to avoid metal spattering.

When using the content of this site, you need to put active links to this site, visible to users and search robots.

Literature

Surfacing of gear teeth

The gear is a part of many mechanisms and machines used in various industries. The most common defects of this element are wear of the teeth along the length and thickness, chipping, formation of scoring, cracks and scratches. The most effective restoration method is surfacing of worn parts.

If no more than two teeth in a row break in not particularly critical mechanisms, repairs are allowed, including the following procedures: the defective teeth are cut out, 2-3 holes are drilled along the width of the tooth, threads are cut into them, pins are made and screwed into the prepared holes, the pins are welded to the gear and the metal is deposited by electric welding, the deposited layer is given the shape of a tooth.

Restoration of worn gear teeth can also be carried out with special electrodes for surfacing, for example OZN-300. Before work, the product is cleaned of contaminants.

How it's done. The nominal dimensions of the teeth are maintained using a copper template made from an undamaged tooth.

When restoring gears with several defective teeth, repairs are carried out only on the worn side of the tooth. For this purpose, sormite alloys are used, surfacing is carried out using the gas or electric arc method. Surfacing is carried out using electrodes TsS-1 and TsS-2. The work is performed on direct and alternating current of reverse polarity. Then the teeth are ground.

Schemes for surfacing layers at the gear tooth and cavity

The performer can also use stalinite, a powdered alloy that is melted with a carbon or steel electrode using a direct current of reverse polarity. Then the powder in a plastic state is applied to the part in a layer 3-4 mm thick. Borax should be used as a flux.

For repairing the ends of teeth with wear along the length of 2.2-8.2 mm. It is recommended to use automatic surfacing of each worn tooth separately. The process is carried out using flux cored wire. The weld metal is formed in a cooled copper mold.

Welding and surfacing under a layer of flux

Reduction by this method is carried out with an electric arc, which burns under molten flux. Thus, an elastic shell is created that protects the molten metal from contact with air. Fluxes also maintain arc stability, deoxidize, alloy, and refine the deposited metal.

Two types of fluxes are used for welding and surfacing:

- Ceramic, consisting of metallic and non-metallic components, which allows alloying in a wide range.

- Fused ones do not contain metal components, so the possibilities of alloying are limited to tenths of a percent. Compared to ceramic types, these fluxes are cheaper, provide better protection, and remove slag from seams more easily. Fused fluxes with a high silicon content are used when applying layers of carbon, low-alloy steels.

Surfacing under a layer of flux

Submerged arc surfacing of metal is carried out using uncoated welding wire. The diameter (1 - 6 mm) is determined by the thickness of the layer being created, the shape of the rollers, and the dimensions of the parts. To increase productivity, restoration is carried out using strip electrodes up to 10 cm wide or simultaneously with two wires fed by different mechanisms.

Restoration is performed using direct current with reverse polarity. On round parts, the rollers are placed in increments of 2 - 6 wire diameters. To reduce deformation on a flat surface, surfacing is carried out through a bead or alternately in different areas.

Surfacing of rail ends

Photo source: specserver.com

The operation of high-speed trains requires good condition of the rails. Wheel impacts lead to deformation, crushing and bending of the ends of the rails. Restoration by surfacing is a standard technique.

Before starting work, all flattened and peeled metal is removed from the rail. To do this, it is recommended to use a chisel, emery wheel or other tool. To increase the deposition rate, it is necessary to preheat the ends of the rails.

The following surfacing technologies are used on Russian railways to restore rail ends:

1. Manual arc surfacing is performed with a piece electrode of the K-2-55, OZN-300, OZN-350 brands. The rollers are applied in three ways: along, across the rail and diagonally. The best results are obtained when working with the second method. The average width of the roller is 24-30 mm. This value may vary depending on the diameter of the rod, current strength and other factors.

There is also the possibility of fusing a bunch of electrodes: 2-3 rods arranged in a comb. This method improves productivity. Surfacing should begin at the end of the rail by applying a bead. The arc is excited on the inside, making a small indent from the end. The deposition of the first bead is also completed by moving slightly away from the end of the rail. The ends of each of these rollers are brought to the end of the previous roller and the crater is sealed there. The overlap of adjacent rollers should be 1/5-1/6 of the width of the previous roller. The work ends with grinding the ends of the rails along the rail.

2.

as a filler material when performing semi-automatic electric arc surfacing . This method has several advantages compared to the manual arc method: high quality of work, significant labor productivity.

The work is carried out in stages:

- defect measurement;

- preparation of equipment for surfacing;

- removal of defects by grinding;

- installation of surfacing apparatus on rails and setting work boundaries;

- heating the working area;

- performing the main process - deposition;

- mechanical processing with an abrasive tool after natural cooling.

Surfacing is carried out in one or several words, depending on the depth of the defect.

Surfacing of cylinders and planes

To restore the surface of cylinders, the following fusing methods are used:

1. Surfacing with coated electrodes is carried out in three ways: a) with rollers along the generatrix of the cylinder (longitudinal surfacing); b) rollers in closed circles (circular surfacing) and c) along a helical line.

Products of small diameter and considerable length should be processed using the first method . A bead is fused onto the cleaned surface. Then the part is rotated 180° and a second bead is deposited on the opposite side. Afterwards, the product is rotated 90° and the third bead is fused, and after 180° - the fourth. Next, a fifth bead is deposited, which overlaps the first. It should be noted that before applying the next roller, the previous ones must be cleared of slag.

The second method implies that the part must rotate around its axis during the entire working process. The latter option is especially convenient in the case of mechanized surfacing, in which the part rotates uniformly .

2. Automatic submerged arc surfacing ensures a wear-resistant layer. This method can be carried out with welding or flux-cored wire, strip electrode, flux-cored tape. Here two methods should be distinguished: deposition is carried out along a generatrix or along a helical line.

To restore flat products, it is necessary to cover large areas with minimal penetration of the base metal . A short video of surfacing with a plowshare will give you an idea of the operation.

to repair flat surfaces :

Narrow rollers are used; each subsequent roller is located overlapping the previous one by 0.3-0.4 of its width; slag is removed immediately from all weld beads.

Laying narrow rollers at a certain distance from one another is one of the simplest methods. The slag should be removed after applying several beads. After this, the beads are also fused in the gaps.

Wide-layer surfacing is a more advanced technology. Transverse oscillatory movements are imparted to the electrode.

Multi-electrode surfacing and electrode strip surfacing are characterized by increased productivity.

To obtain a wear-resistant layer, surfacing should be performed using flux-cored wire and open-arc tape. In this case, transverse vibrations with the required range are imparted to the electrode. This case is characterized by the absence of a slag crust of significant thickness.

In electroslag surfacing, flux-cored wire or solid wire can be used as the electrode material. [ads-pc-4][ads-mob-4]

To main§ 57. OVERLAYING CARBIDE ALLOYS

Surfacing materials

Surfacing

is the process of fusing a layer of metal on the surface of a product to change dimensions or impart special properties (hardness, anti-corrosion, wear resistance, etc.).

Surfacing can be performed using metal pieces: electrodes, steel surfacing wire (tape) and hard alloys. Hard alloys

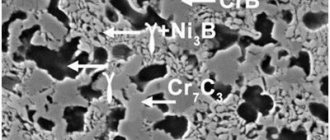

are alloys of carbide- and boride-forming metals - chromium, manganese, titanium, tungsten and others with carbon, boron, iron, cobalt, nickel, etc. They can be cast or powder.

Cast hard alloys include rod sormite, supplied in the form of rods with a diameter of 6 - 7 mm

and a length of 400 - 450

mm

, containing 25 - 31% chromium, 3 - 5% nickel, 2.5 - 3.3% carbon, 2.8 - 3.5% silicon, up to 1.5% manganese, up to 0.07% sulfur and 0.08% phosphorus, the rest is iron, as well as other alloys. Cast hard alloys are used for surfacing dies, measuring tools, machine parts and mechanisms operating under conditions of intense wear. Surfacing is carried out with an acetylene-oxygen flame, a carbon electrode, and also a tungsten electrode in an argon environment. Powdered hard alloys include stalinite and sormite. Powdered stalinite contains 24 - 26% chromium, 6 - 8.5% manganese, 7 - 10% carbon, up to 3% silicon, up to 0.5% sulfur and phosphorus, the rest is iron. Metal electrodes for arc surfacing are manufactured according to GOST 10051-62, according to which electrodes are classified depending on the chemical composition and hardness of the deposited metal (a total of 25 types of electrodes are provided).

Surfacing methods

Currently, a large number of different surfacing methods are used in industry. Manual arc surfacing.

Surfacing is performed with metal consumable single electrodes, a bunch of electrodes, recumbent plate electrodes, tubular electrodes, direct and indirect arcs and three-phase arcs.

Surfacing with electrodes can be performed in all spatial positions. It is performed by sequentially applying beads, deposited when the electrode melts, onto the surface of the product. The surface to be deposited must be clean (cleaned to a metallic shine). The surface of each applied roller and the place for applying the next roller are also thoroughly cleaned of slag, scale and splashes. To obtain a continuous monolithic layer of deposited metal, each subsequent bead must overlap the previous one by 1/3 - 1/2 of its width. The thickness of single-layer surfacing is 3 - 6 mm

.

If it is necessary to deposit a layer more than 6 mm

, a second layer of beads is deposited perpendicular to the first one.

In this case, the first layer of rollers must be thoroughly cleaned of splashes, scale, slag inclusions and other contaminants. Submerged arc surfacing.

According to the method of execution it can be automatic or semi-automatic, and according to the number of wires used - single-electrode and multi-electrode.

Surfacing wires used for submerged surfacing are divided according to their design into solid and flux-cored, and according to their shape into round and strip. Arc surfacing in protective gases with tungsten (non-consumable) and wire metal (consumable) electrodes.

Argon, nitrogen, hydrogen and carbon dioxide are used to protect the arc.

Labor productivity during surfacing is assessed by weight; or area (dimensions) of deposited metal. Vibro-arc surfacing.

This surfacing is a type of electric metal arc surfacing and is performed by vibrating the electrode.

The vibration amplitude ranges from 0.75 to 1.0 times the diameter of the electrode wire. Electroslag surfacing.

A distinctive feature of this surfacing method is its high productivity, at which not only tens, but also hundreds of kilograms of deposited metal per hour can be achieved.

Surfacing is carried out with forced formation of metal in one pass. Electrodes are used in almost any cross-section: rods, plates, etc. The depth of penetration of the base metal can be adjusted within a wide range. Open arc surfacing.

For this purpose, flux-cored wire with internal protection is used, which allows expanding the scope of application of mechanized wear-resistant surfacing.

When surfacing with this wire, the use of flux or shielding gas is not required, therefore the method is simple and maneuverable and creates the possibility of restoring parts of complex shapes, deep internal surfaces, parts of small diameters, etc. Currently, there are various equipment designs, and a technology for strengthening parts has been developed wide range. Wire consumption is 1.15 - 1.35 kg

per 1

kg

of deposited metal.

The productivity of semi-automatic surfacing increases by 2 - 3 times compared to surfacing with stick electrodes. Plasma surfacing.

In plasma surfacing, the heat source is a high-temperature compressed arc produced in special burners. Plasma torches with a direct arc burning between a non-consumable tungsten electrode and the welded product are widely used. Sometimes combined type burners are used, in which two arcs burn simultaneously from one electrode - direct and indirect. The filler material in this surfacing method is wire, tape, powder, etc. Surfacing with the addition of fine-grained powder is primarily of practical interest. In this case, a combined type plasma torch is used. The powder is fed from the feeder to the burner using a transport gas and there it is blown into the arc. During its stay in the arc, most of the powder manages to melt, so that droplets of liquid filler material fall on the surface to be deposited.

Surfacing technology

Before surfacing, the height of the surfacing layer is set. Before surfacing, as well as before welding, the surface to be surfaced must be cleaned of dirt, rust, scale, oil and moisture. When applying the first layer of surfacing, they strive to overlap each previous bead by 25 - 30% of its width, while maintaining a constant height. If it is necessary to increase the height of the surfacing bead, surfacing of the next bead is carried out, having cleared the deposited layer of non-metallic inclusions and slag formed when applying the previous layer before surfacing. Depending on the grade of metal, surfacing can be carried out without heating the product or with preheating. The main requirements for the quality of surfacing are: reliable fusion of the base metal with the deposited metal; absence of defects in the deposited metal; identical properties of the deposited metal. Reliable fusion of the surfacing with the base metal is ensured by selecting the current strength, which for surfacing installations with a constant electrode feed speed corresponds to the selection of the wire or tape feed speed.

Self-test questions

1. For what purposes is surfacing used?

2. What surfacing methods do you know? Previous page

| table of contents | Next page |

Surfacing of metal-cutting tools and dies

Restoration of metal-cutting tools and dies is performed by arc surfacing in three ways: manual, automatic and semi-automatic.

The first option involves the use of electrodes. Metal-cutting tools and dies operate during cold and hot stamping, so they should be restored using the following grades of electrodes: OZI-3; OZI-5; OZI-6; TsS-1; CI-1M. The layer deposited with such materials has a high level of resistance to abrasion and crushing under heavy loads and high temperatures (up to 650-850°C). The product must be heated to 300-700°C before fusing. Fusing is carried out in 1-3 layers, the thickness is 2-6 mm.

We invite you to watch a video demonstration of the Zeller 769 electrode surfacing test.

Automatic and semi-automatic methods are carried out with alloyed wire using fluxes or pastes.

Surfacing of parts exposed to abrasion with impact loads and without impact loads

Products operating under conditions of intense surface wear and high shock loads must be overlaid with electrodes of the following brands:

Welding electrodes for surfacing OZN-400M

Advantages of OMG-N: they comply with state standards, deposition can be carried out with direct and alternating current of reverse polarity.

TsNIIN-4 is one of the most popular and popular brands.

Metal deposited with OZN-7M rods during multilayer deposition has increased resistance to cracking.

Advantages of OZN-400M: high productivity, deposited metal is characterized by increased hardness.

Advantages of OZN-300M: the deposited metal has increased stability of wear resistance and hardness; surfacing is performed with direct and alternating current of reverse polarity.

An example of such parts is elements of construction and earth-moving equipment.

For surfacing parts exposed to abrasion and without shock loads, the following grades of electrodes are used.

To obtain a deposited layer of special hardness, it is necessary to use surfacing electrodes T-590 and T-620. These brands are intended for repairing parts subject to intense abrasion. Thanks to a special coating, which includes ferrochrome, ferrotitanium, ferroboron, boron carbide and graphite, the hardness of the deposited metal can reach 62-64 HRC. Metal deposited with T-590 and T-620 materials is brittle and prone to cracking, and is therefore not intended to withstand significant shock loads. Fusing is carried out in 1-2 layers.

Repair of products made of various metals and alloys also has its own specific characteristics.

Surfacing of stainless steels

The most popular electrodes for surfacing corrosion-resistant steels are grades TsN-6L, TsN-12M-67. The core of such materials is a stainless high-alloy wire. The deposited metal has the following characteristic features: high corrosion resistance, resistance to scuffing. The second property allows these electrodes to be used for surfacing reinforcement products. The need for preheating (up to 300-600°C) and subsequent heat treatment depends on the brand of materials used.

The features of the welding process of stainless steels can be found in the article “Welding stainless steel”.

Surfacing of cast iron and its alloys

The most popular brands of electrodes for surfacing cast iron are:

Electrodes TsCh 4.

OZCH-2 are designed for surfacing ductile and gray cast iron.

MNCh-2 electrodes ensure the density and cleanliness of the deposited layer (after processing).

OZZHN-1 and OZZHN-2 are used for working with gray and high-strength cast iron.

TsCh-4 electrodes have good welding and technological characteristics: ease of ignition and stability of the arc, low spatter.

Some grades are universal; they can be used to weld various types of cast iron: malleable, gray, etc. Most are intended for certain types of alloys. A complete list of electrodes for welding cast iron can be found in the corresponding section.

Features of plasma metal surfacing

Strong, virtually unbreakable assemblies under any pressure force are produced using plasma surfacing. With the help of such processing, each of the products that have undergone the procedure acquires the necessary dielectric, thermal, physical and other properties. In other words, the products are hardened during the surfacing process. Metal cutting, as well as its processing, is carried out using a special cutter with a hot plasma flow.

Products made using plasma arc surfacing are distinguished by wear resistance, heat resistance, acid resistance, etc.

Compared to surfacing using an electrode, plasma surfacing has a number of advantages, but can only be used in production conditions. Installing a special installation and purchasing equipment to work with such units at home is at least an expensive pleasure. Therefore, think again whether there is a need to purchase a tool for rare use at home, or whether there is a place for using the good old electrode, which will turn out to be more profitable financially, but not a worse option.

Surfacing of copper and its alloys (bronze)

Products made from technically pure copper are deposited using Komsomolets-100 electrodes or filler rods, the composition of which is close to the composition of the base metal. It is recommended to use preheating to 300-500°C. If the copper temperature exceeds 500°C, then the deposited layer must be forged.

If it is necessary to surfacing bronzes, it is better to use OZB-2M electrodes. The deposited metal has high surface wear resistance.

Surfacing of copper and its alloys is carried out using direct current of reverse polarity exclusively in the lower spatial position.

The brands of electrodes intended for welding copper and its alloys can be found in the corresponding section.

Fluxes, powdered materials and cast rods

3.1 Fused fluxes

All fused fluxes developed for welding steels are also suitable for surfacing. Taking into account the specifics of surfacing - obtaining a minimum proportion of base metal in the deposited metal, special surfacing fluxes are usually pumice-like (Table 8).

Table 8. Fused fluxes for surfacing

| Stamps | Characteristic |

| AN-70 | Pumice-like low-silicon manganese-free flux for surfacing medium- and high-alloy steels has a low oxidizing ability, which causes a weak dependence of the composition of the deposited metal on the surfacing mode. AN-70 flux is “shorter” and more refractory than AN-20, so it can be used to fuse cylindrical surfaces of significantly smaller diameter than with AN-20 flux. Slag is easily separated from the surface at temperatures up to 800 °C |

| AN-28 | Pumice-like flux, low-silicon, manganese-free, intended for surfacing steel and cast iron strips |

3.2 Ceramic fluxes

Alloying of the deposited metal through ceramic fluxes is less effective than with flux-cored wire; the required quality of the deposited metal is achieved in an even smaller range of mode parameters. In addition, the content of metal components in it cannot exceed 25...30% due to arc shunting and disruption of arc discharge stability; however, in some cases this method may be more accessible to use (Table 9).

Table 9. Ceramic fluxes for surfacing

| Brand | Weld metal | Recommended wire | Operating conditions of welded parts | |

| Type | Hardness | |||

| FK-45/5Х10В5ФМ | 45Х10В5ФМ | HV 540 | Sv-20Х13 | Intensive wear at temperatures up to 600 °C (tools for hot metal forming) |

| ZhSN-5 | 20Х6МФ | HRC 36 HRC 42 HRC≥48 HRC 54 | Sv-08A Sv-08GA Sv-12GS Np-30HGSA | Intensive wear due to metal-to-metal friction, cyclic heat changes, high pressures (rolling rolls, roller conveyor rollers, brake pulleys) |

| ANK-18 | 30Х3Г1 | HV 400 HRC 50 HRC 50 | Sv-08 Sv-08A Np-30HGSA | Metal-to-metal friction (parts of road equipment, construction, agricultural and lifting machines) |

| ANK-19 | 60Х4ГС | HRC≥50 | Sv-08 A, Sv-08 | Abrasive wear (knives and road wheels of bulldozers, flat workpieces of bunkers) |

| ANK-40 | 25X1GS | HB 250 | Sv-08A, Sv-08 | Metal-on-metal friction |

Note. Fluxes FK-45/5Kh10V5VFM, ZhSN-5, ANK-40 are recommended for surfacing with direct current of reverse polarity, fluxes ANK-18, ANK-19 are recommended for surfacing with direct current of reverse polarity and alternating current.

Surfacing of aluminum and its alloys

OZA-1 electrodes.

The most effective restoration method is arc surfacing. Electrodes of the OZA, OZANA and UANA brands are intended for products and structures made of aluminum and its alloys.

Consumables OZA-1 ensures the production of metal with high corrosion resistance.

The special coating of OZANA-1 electrodes allows you to normalize the process and destroy the oxide coating formed on aluminum products during work.

To regulate the structural composition of the deposited metal, powder electrodes should be used. Electrodes of this type make it possible to create not only a deposited layer of equal strength to the base metal, but also a layer with significantly improved characteristics.

A complete list of electrodes for welding aluminum and its alloys is presented in the corresponding section.

Features of surfacing technology

The advantages of surfacing are that it allows you to obtain reliable adhesion of the metal to the base, as well as the necessary physical and technological parameters. The first is achieved through high-quality preparation of the product, and the second through the correct selection of materials for the work.

The essence of surfacing is that it is necessary to uniformly apply narrow strips of molten metal to the surface so that they join into a continuous thick layer, ranging in size from a tenth of a millimeter to ten millimeters.

Consumption of materials

To determine the cost of the finished product, it is important to correctly calculate the consumption of surfacing materials. Calculations are carried out in accordance with accepted standards for each specific type of work and materials. Also, knowing the exact quantity of necessary consumables can ensure process continuity and create reserves of materials.

Calculation of deposited metal during welding is one of the main indicators. There is a special formula to determine the value of this coefficient. The mass is calculated per 1 meter of weld. How to determine the mass of deposited metal during welding will be analyzed further:

G = F * y * L, where: F – cross-sectional area of the weld (in mm2) y – specific gravity of the metal (g/cm3) L – length of the weld is 1 meter.

Thanks to this formula, any performer will be able to calculate the mass of deposited metal during welding.

Calculation of electrodes for surfacing is also a significant quantitative parameter. The performer does not need to perform calculations to determine this value. Each brand of welding materials has its own indicator - electrode consumption during surfacing of 1 kg. metal varies from 1.4 to 1.8 kg.

to calculate the mass of deposited weld metal per linear meter. According to GOST, each form of weld made of carbon and low-alloy steels, performed by manual electric arc welding with a metal consumable electrode and welding in carbon dioxide, has an average value of this parameter.

Electric arc welding and surfacing

This is the most common restoration technology in industry and at home. It can be easily performed using conventional welding equipment. The work is performed with consumable coated electrodes and non-consumable ones with filler wire.

The quality of the final result is determined by the parameters of the electrodes. For repairs by welding, the cross-sectional area of the rods is selected depending on the size of the damage and the thickness of the metal. To create a layer with specified parameters, brands of electrodes with alloying additives are selected. They may be contained in the metal and coating of the rods.

Surfacing on parts made of low-carbon steels that have not been subjected to heat treatment is carried out using welding electrodes. The shape of products made of hardened alloy, high-carbon steel is restored using surfacing electrodes with additives or rods made of hard alloys. They also apply layers on the cutting edges of metal processing tools.

Important!

To prevent deformation, high-carbon alloy steel parts are preheated to 300⁰C.

After completion of work, a vacation is carried out to relieve internal stresses in the welds. For low carbon, low alloy steel, preheating is not required.

Surfacing electrodes

Manufacturers and sales companies offer a wide range of special electrodes for surfacing. The most popular surfacing materials are electrodes from the following manufacturers: “SpetsElektrod” (Moscow), “LEZ”, “SpetsElektrod” (Volgodonsk), “SZSM”, ESAB, Lincoln Electric. The wide range of consumables offered allows the contractor to choose the best option for electrodes to perform specific work. A complete list is presented in the section “Electrodes for surfacing surfaces of layers with special properties.”

Surfacing Services

Many companies operating in the metal processing industry offer related services. Companies provide surfacing services at a professional level, using specialized and modern equipment, and employees with extensive experience and knowledge. Craftsmen can process products of various sizes. Therefore, if the performer cannot carry out the fusing procedure independently, it is more advisable to turn to specialists. This will help significantly save money and time spent.